Professional Documents

Culture Documents

Mathcad - Bolt Loading VDI M39 01

Uploaded by

Pete SwiftCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mathcad - Bolt Loading VDI M39 01

Uploaded by

Pete SwiftCopyright:

Available Formats

Bolt Loading VDI M39 01.

xmcd

Page 1 of 10

Bolt Loading VDI M39 01.xmcd

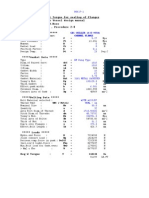

MARYLAND METRICS -- THREAD DATA CHART: Metric Thread -- Coarse Pitch

Nominal

Size

ISO M

Thread

Form

Type

Major

Diameter

mm

d=D

Pitch

mm

p

Root

Radius

mm

r

Pitch

Diameter

mm

d2=D2

Minor

Diameter

Male Thd.

d3

Minor

Diameter

Female Thd.

D1

Thread

Height

Male Thd.

h3

Thread

Height

Female Thd.

H1

Tap

Drill

Diameter

mm

20.00 M 20.00 2.50 0.361 18.376 16.933 17.294 1.534 1.353 17.50

copyright maryland met rics-- all right s reserved filnam:isomlee.xls ver t3a

Fastner size M20

Diameter at stress cross-section A.s (Minor dia of male thread)

D

S

16.933 mm :=

Shank diameter of bolt neck

D

T

16.933 mm :=

Effective diameter for friction at the contact of the head of the driven fastner

D

km

26 mm :=

Outside diameter of the consact area under the head of the driven fastner

D

W

30 mm :=

Assembly preload, bolt tensile load at tightning

F

M

:=

Allowable bolt preload, bolt tensile loat at shich the equivelent stress

considering tension and torsion is vR

p0.2

F

M.v

:=

Effective tensile stress cross-section of the bolt thread

A

S

245 mm

2

:=

Pitch of the bolt thread

P 2.5 mm :=

R

y

450 MPa :=

Actual proof stress of the bolt

Minimum 2% Proof stess fo bolt material ISO 898

R

p.0.2

450 MPa :=

Outside diameter of bolt at the smallest cross section

d

0

16.933 mm :=

Pitch diameter of the bolt thread

d

2

18.376 mm :=

Minor Diameter of bolt thread

d

3

16.933 mm :=

Page 2 of 10

Bolt Loading VDI M39 01.xmcd

Minimum cross section area of the bolt A

0

d

0

2

4

225.194 mm

2

= :=

Inside diameter of the contact area under the head of driven fastner d

h

:=

Half flank angle of blt thread

th

6

0.524 = :=

Coefficien of friction between bolt and nut thread

G

0.14 :=

Mimimum coefficien of friction between the bolt and nut thread

G.min

0.1 :=

Maximum coefficien of friction between the bolt and nut thread

G.max

0.14 :=

Coefficien of friction at the contact of the driven head

K

0.14 :=

Mimimum coefficien of friction at the contact of the driven head

K.min

0.14 :=

Maximum coefficien of friction at the contact of the driven head

K.max

0.14 :=

Degree of explotiaiton of bolt yield stress desired at max assembly condition 90% :=

Page 3 of 10

Bolt Loading VDI M39 01.xmcd

l

K

520 mm :=

Bolt clamp Length

Shank length

l

1

l

K

:=

Hole diameter

Joint coefficient

w 1 :=

Clamped parts hole diameter

d

h

22 mm :=

d

w

30 mm :=

D

A

110 mm :=

atan 0.6 ( ) 30.964 deg = :=

R

p.0.2.min

450 MPa :=

E

steel

200 GPa :=

E

conc

30 GPa :=

E

p

E

conc

:=

Maximum assembly preload

expected from tightening to specified

torque

F

M.Tab

A

S

R

p.0.2

1 3

4

1

d

3

d

2

+

P

d

2

G.min

cos

th

( )

+

|

\

|

|

(

(

(

(

2

+

86.112 kN = :=

Note this is not with in the VDI spec and should normally be taken from tables

A Minimum clamping force required F

A.max

45 kN :=

Page 4 of 10

Bolt Loading VDI M39 01.xmcd

R1 tightening factor in acordance with table 8

A

1.7 :=

Page 5 of 10

Bolt Loading VDI M39 01.xmcd

bolt diameter to clamping length

l

K

d

0

30.709 =

For friction coefficient class B

F

KRmin

50 kN :=

R2 Required minimum clamp load.

The joint is symetrically clamped

F

Kerf

F

KRmin

:=

F

Kerf

5 10

4

N =

R3 Splitting the working load, elastic resilience and load introduction factor

S

l

K

A

S

E

steel

:=

S

1.061 10

5

mm

N

=

P

2

w d

h

tan

( )

ln

d

w

d

h

+

( )

D

A

d

h

( )

d

w

d

h

( )

D

A

d

h

+

( )

(

(

2

D

A

2

d

h

2

l

K

D

A

D

W

( )

w tan

( )

(

(

+

E

p

:=

P

3.697 10

6

mm

N

=

Load facto with the application under the bolt head

P

S

+

0.258 = :=

K

:=

f

Z

3.5 m := f

Z

3.5 10

6

m =

R4 Preload changes

See table 5.4/1 P64

F

Z

f

Z

2

P

S

+

489 N = := 2 no interfaces

R5 Determinine the minimum assembly preload

No temperature reqirements

F

Vth

0 N :=

F

M.min

F

Kerf

1

( )

F

A.max

+ F

Z

+ F

Vth

+ :=

F

M.min

84 kN =

Page 6 of 10

Bolt Loading VDI M39 01.xmcd

R6 Determine maximum assembly preload

F

M.max

A

F

M.min

:=

F

M.max

143 kN =

R7 Determine the assembly stress

red.Mzul

R

p.0.2.min

:=

red.Mzul

405 MPa =

F

Mzul

A

0

R

p.0.2.min

1 3

3

2

d

2

d

0

P

d

2

1.55

G.min

+

|

\

|

|

(

(

(

(

:=

F

Mzul

65 kN =

F

M.max

142.567 kN =

F

A.max

11.626 kN =

0.1 R

p.0.2.min

A

S

11.025 kN =

R8 Determine the working stress

F

A.max

11.626 kN =

F

S.max

F

Mzul

F

A.max

+ :=

F

S.max

76.632 kN =

Z.max

F

S.max

A

0

:=

Z.max

340.295 MPa =

max

M

g

W

p

:=

M

g

d ??????????

Page 7 of 10

Bolt Loading VDI M39 01.xmcd

F

S.max

76.632 kN =

F

M.max

142.567 kN =

F

M.min

83.863 kN =

F

A

G

S.max.x

F

S.max

S

0 mm

F

S.max

P

\

|

|

|

|

:=

G

M.max.x

F

M.max

S

0 mm

F

M.max

P

\

|

|

|

|

:=

G

M.min.x

F

M.min

S

0 mm

F

M.min

P

\

|

|

|

|

:=

G

S.max.y

0 kN

F

S.max

0 kN

|

\

|

|

|

|

:=

G

M.max.y

0 kN

F

M.max

0 kN

|

\

|

|

|

|

:=

G

M.min.y

0 kN

F

M.min

0 kN

|

\

|

|

|

|

:=

G

Z.x

F

M.min

F

Z

+

( )

S

0 mm

F

M.min

F

Z

+

( )

P

(

(

(

(

:=

G

Kerf.x

F

Kerf

( )

S

0 mm

F

Kerf

( )

P

(

(

(

(

:=

G

Z.y

0 kN

F

M.min

F

Z

( )

0 kN

(

(

(

(

:=

G

Kerf.y

0 kN

F

Kerf

( )

0 kN

(

(

(

(

:=

Page 8 of 10

Bolt Loading VDI M39 01.xmcd

2 1 0 1

50

100

150

G

S.max.y

kN

G

M.max.y

kN

G

M.min.y

kN

G

Z.y

kN

G

Kerf.y

kN

G

S.max.x

mm

G

M.max.x

mm

,

G

M.min.x

mm

,

G

Z.x

mm

,

G

Kerf.x

mm

,

Page 9 of 10

Bolt Loading VDI M39 01.xmcd

F

Kerf

Page 10 of 10

You might also like

- Mathcad - Bolt Loading VDI M39Document9 pagesMathcad - Bolt Loading VDI M39Pete SwiftNo ratings yet

- 2 ProracunDocument6 pages2 ProracunStjepan RadosavljevicNo ratings yet

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- Compressed air tank design and calculationsDocument6 pagesCompressed air tank design and calculationsDanijel DjordjicNo ratings yet

- Moment Connection - Flush End Plate-19.01.06Document48 pagesMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- Checking Intermediate Frame Member for Loads and CapacitiesDocument13 pagesChecking Intermediate Frame Member for Loads and Capacitiesanimesh91No ratings yet

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- C4.tension Member Compatibility ModeDocument45 pagesC4.tension Member Compatibility ModejojomarbunNo ratings yet

- Hoist DesignDocument15 pagesHoist DesignEzhil KumarNo ratings yet

- Column SpliceDocument6 pagesColumn SplicedudoodooNo ratings yet

- Master CalculationDocument9 pagesMaster CalculationRANA1575100% (2)

- Hoist Design Procedure For EOT CraneDocument14 pagesHoist Design Procedure For EOT CraneKeerthi KumarNo ratings yet

- ProblemsDocument22 pagesProblemsSuresh GoudNo ratings yet

- M2-CV-RC-D-005 (R1)Document22 pagesM2-CV-RC-D-005 (R1)ksshashidharNo ratings yet

- Stair DesignDocument6 pagesStair DesignBathrudeen IshakNo ratings yet

- Design of Composite Steel Girder BridgeDocument10 pagesDesign of Composite Steel Girder BridgesorowareNo ratings yet

- ZND332 - A-Base & Top Plate & Anchors-REV-E (Repaired)Document15 pagesZND332 - A-Base & Top Plate & Anchors-REV-E (Repaired)redflex9001889No ratings yet

- End Plate Design As Per-Ec3Document18 pagesEnd Plate Design As Per-Ec36j7100% (1)

- Workbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsDocument26 pagesWorkbook Workbook Workbook Workbook Workbook: Try Yourself QuestionsShubham mishraNo ratings yet

- Calculation of The Moment Resistance of Z - and C-Shaped Cold-Formed Sections According To Eurocode 3Document18 pagesCalculation of The Moment Resistance of Z - and C-Shaped Cold-Formed Sections According To Eurocode 3Liviu Ion100% (1)

- 1.5kW Gearbox Design for 1800 RPM Electric MotorDocument14 pages1.5kW Gearbox Design for 1800 RPM Electric MotorMuhammad ArslanNo ratings yet

- Base PlateDocument6 pagesBase PlatejasonjasonNo ratings yet

- Numericals On Design of GearsDocument59 pagesNumericals On Design of GearsNAVEEN H V MENo ratings yet

- RCCe11 Element DesignDocument9 pagesRCCe11 Element Designrelu59No ratings yet

- Flange Bolt LoadDocument3 pagesFlange Bolt LoadSAMER OSMANNo ratings yet

- Head Nozzle and Flange Calculation, DN100 (CF) Size NozzleDocument7 pagesHead Nozzle and Flange Calculation, DN100 (CF) Size Nozzleakın ersözNo ratings yet

- Design of Grade SlabDocument7 pagesDesign of Grade SlabMUTHUKKUMARAM100% (1)

- Flange CouplingDocument16 pagesFlange CouplingARUN VNo ratings yet

- Bracket - 4 DesignDocument1 pageBracket - 4 Designbjreddy100% (2)

- Connection Design ManualDocument34 pagesConnection Design ManualAlaa AssiNo ratings yet

- Boiler CalcDocument92 pagesBoiler CalcPrasanta Kumar BeheraNo ratings yet

- Design Calculation 4-PadeyesDocument4 pagesDesign Calculation 4-PadeyesMuhammad Yahdiman100% (3)

- Design of Beam Ledge Reinforcement as per ACI 318M95Document2 pagesDesign of Beam Ledge Reinforcement as per ACI 318M95auatipu100% (1)

- 321 Chapter 5 Splice DesignDocument91 pages321 Chapter 5 Splice DesignHemant Ramesh NarkarNo ratings yet

- CONNECTIONDESIGNMANUALDocument34 pagesCONNECTIONDESIGNMANUALanon_97209652No ratings yet

- Godrej & Boyce calculations for weld strength and size of RIL equipmentDocument10 pagesGodrej & Boyce calculations for weld strength and size of RIL equipmentSajal KulshresthaNo ratings yet

- Design of circular water tank reinforcementDocument20 pagesDesign of circular water tank reinforcementSourav Chandra83% (6)

- Machine Design 1: College of EngineeringDocument10 pagesMachine Design 1: College of EngineeringThink EngineeringNo ratings yet

- Baseplate Biaxial MZDocument26 pagesBaseplate Biaxial MZD SRINIVAS100% (1)

- Composite Beam Simply Supported DesignDocument21 pagesComposite Beam Simply Supported DesignTharanga Pradeep100% (1)

- Bolt Torq. (Moss+Farr)Document9 pagesBolt Torq. (Moss+Farr)Bahtiar Anak LaNang100% (1)

- Design of Wall Footing Project #Document3 pagesDesign of Wall Footing Project #Raghad F Al-Zu'biNo ratings yet

- Connessione A Taglio EC3 IngleseDocument15 pagesConnessione A Taglio EC3 Inglesemihai_serban13No ratings yet

- Design of I C Engine Connecting RodDocument6 pagesDesign of I C Engine Connecting RodBinoy K BNo ratings yet

- F-0201 Special Blind Calculation (N9)Document2 pagesF-0201 Special Blind Calculation (N9)rustamriyadiNo ratings yet

- Gusset Plate Design for Cleveland Clinic Abu DhabiDocument4 pagesGusset Plate Design for Cleveland Clinic Abu Dhabikalpanaadhi75% (4)

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Modification Thickness of A FlangeDocument3 pagesModification Thickness of A FlangePeter PerezNo ratings yet

- Mathcad - 539900-050-130 Padeye Pulling Skid 9.5 TDocument7 pagesMathcad - 539900-050-130 Padeye Pulling Skid 9.5 TPablo Diego Didoné100% (1)

- A1. SGH CanopyDocument41 pagesA1. SGH CanopyMoustafaNo ratings yet

- Design A Beams by EurocodeDocument32 pagesDesign A Beams by EurocodelibanpiresNo ratings yet

- ENGI 8673 Subsea Pipeline Engineering Lecture 17 ExampleDocument3 pagesENGI 8673 Subsea Pipeline Engineering Lecture 17 ExampleThyago de LellysNo ratings yet

- Purlin Cleat 220908Document24 pagesPurlin Cleat 220908kalpanaadhi100% (2)

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Herts Contact StressDocument4 pagesHerts Contact StressPete SwiftNo ratings yet

- FLENDERDocument79 pagesFLENDERekin100% (4)

- Bapp A4 Stru Bro 2011Document24 pagesBapp A4 Stru Bro 2011Pete SwiftNo ratings yet

- Bridge Design Eurocodes Worked Examples Annex OnlyDocument150 pagesBridge Design Eurocodes Worked Examples Annex OnlyAhmed AjelNo ratings yet

- Bapp Threaded Studs1Document3 pagesBapp Threaded Studs1Pete SwiftNo ratings yet

- Workshop SafetyDocument18 pagesWorkshop SafetyPete SwiftNo ratings yet

- Macalloy 500Document4 pagesMacalloy 500jc100adNo ratings yet

- Bridges by Doug KnightDocument18 pagesBridges by Doug KnightPete SwiftNo ratings yet

- Deco Heavy Duty Adjustable Anchors Sales SheetsDocument2 pagesDeco Heavy Duty Adjustable Anchors Sales SheetsPete SwiftNo ratings yet

- Flow Analysis Around A RotatinDocument11 pagesFlow Analysis Around A RotatinPete SwiftNo ratings yet

- Bridon Crane Rope CatalogueDocument80 pagesBridon Crane Rope CataloguePete Swift100% (1)

- Deco Heavy Duty Adjustable Anchors Sales SheetsDocument2 pagesDeco Heavy Duty Adjustable Anchors Sales SheetsPete SwiftNo ratings yet

- Bentonite Support Fluids in Civil Engineering - FPSDocument31 pagesBentonite Support Fluids in Civil Engineering - FPSMirza Ibrahim Thamrin100% (1)

- Marine Fender CatalogDocument38 pagesMarine Fender CatalogPete SwiftNo ratings yet

- EM 1110-2-2703 Lock Gates and Operating EquipmentDocument287 pagesEM 1110-2-2703 Lock Gates and Operating EquipmentPete Swift100% (1)

- E-STATEMENT Emirates Bank International/eStatements/E-STATEMENT 0215827741601 06 APR 2023 1601 MRETL 06-04-2023 PDFDocument12 pagesE-STATEMENT Emirates Bank International/eStatements/E-STATEMENT 0215827741601 06 APR 2023 1601 MRETL 06-04-2023 PDFShanish JobNo ratings yet

- College of Home Economics, Azimpur, Dhaka-1205.: Seat Plan, Group:-ScienceDocument3 pagesCollege of Home Economics, Azimpur, Dhaka-1205.: Seat Plan, Group:-Sciencesormy_lopaNo ratings yet

- Real Estate Development Business PlanDocument5 pagesReal Estate Development Business PlanA. FranciscoNo ratings yet

- R 449 PDFDocument24 pagesR 449 PDFKhaleel KhanNo ratings yet

- An Introduction To Software DevelopmentDocument19 pagesAn Introduction To Software Developmentsanjeewani wimalarathneNo ratings yet

- DCIT 21 & ITECH 50 (John Zedrick Iglesia)Document3 pagesDCIT 21 & ITECH 50 (John Zedrick Iglesia)Zed Deguzman100% (1)

- 9th Science Term 3 Model Question Paper English MediumDocument3 pages9th Science Term 3 Model Question Paper English MediumStalin JesudossNo ratings yet

- ExcaliburDocument113 pagesExcaliburYuvarajaa SomasundaramNo ratings yet

- A LITTLE CHEMISTRY Chapter 2-1 and 2-2Document5 pagesA LITTLE CHEMISTRY Chapter 2-1 and 2-2Lexi MasseyNo ratings yet

- 01 035 07 1844Document2 pages01 035 07 1844noptunoNo ratings yet

- CHAPTER 7development StrategiesDocument29 pagesCHAPTER 7development StrategiesOngHongTeckNo ratings yet

- Teaching Arts in ElementaryDocument21 pagesTeaching Arts in ElementaryJackaii Waniwan IINo ratings yet

- Model HA-310A: Citizens BandDocument9 pagesModel HA-310A: Citizens BandluisNo ratings yet

- Archana PriyadarshiniDocument7 pagesArchana PriyadarshiniJagriti KumariNo ratings yet

- Training Manual W Appendix 3-20-14 RsDocument193 pagesTraining Manual W Appendix 3-20-14 RsZakir Ullah100% (5)

- The Contemporary Contrabass. by Bertram TuretzkyDocument5 pagesThe Contemporary Contrabass. by Bertram TuretzkydoublepazzNo ratings yet

- Cheatsheet HomebrewDocument1 pageCheatsheet HomebrewfredmnNo ratings yet

- Eye Floaters Cure - Natural Treatment For Eye FloatersDocument34 pagesEye Floaters Cure - Natural Treatment For Eye FloatersVilluri Venkata Kannaapparao50% (2)

- 2022 Australian Grand Prix - Race Director's Event NotesDocument5 pages2022 Australian Grand Prix - Race Director's Event NotesEduard De Ribot SanchezNo ratings yet

- SeminarDocument30 pagesSeminarRahul prajapatiNo ratings yet

- The Retired Adventurer - Six Cultures of PlayDocument14 pagesThe Retired Adventurer - Six Cultures of Playfernando_jesus_58No ratings yet

- 20 Đề Thi Thử Tiếng Anh Có Đáp Án Chi Tiết - LovebookDocument462 pages20 Đề Thi Thử Tiếng Anh Có Đáp Án Chi Tiết - LovebookPhương UyênNo ratings yet

- Mammals of South America, Vol. 2 PDFDocument1,363 pagesMammals of South America, Vol. 2 PDFJose Jaime Henao OsorioNo ratings yet

- CLASS PROPHECY 2018-2019: Edmarie C. AmbrosDocument2 pagesCLASS PROPHECY 2018-2019: Edmarie C. AmbrosMarilou SolisNo ratings yet

- Deflected Profile of A BeamDocument2 pagesDeflected Profile of A BeamPasindu MalithNo ratings yet

- Write EssayDocument141 pagesWrite Essayamsyous100% (1)

- Past Progressive WorksheetDocument3 pagesPast Progressive WorksheetSantiago VargasNo ratings yet

- HandwritingDocument25 pagesHandwritingajeshtnNo ratings yet

- Crema Coffee Garage - Understanding Caffeine Content of Popular Brewing Methods Within The Australian Coffee Consumer MarketDocument33 pagesCrema Coffee Garage - Understanding Caffeine Content of Popular Brewing Methods Within The Australian Coffee Consumer MarketTDLemonNhNo ratings yet

- Bracing Connections To Rectangular Hss Columns: N. Kosteski and J.A. PackerDocument10 pagesBracing Connections To Rectangular Hss Columns: N. Kosteski and J.A. PackerJordy VertizNo ratings yet