Professional Documents

Culture Documents

Asme Wps Demo

Uploaded by

Tomy GeorgeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Asme Wps Demo

Uploaded by

Tomy GeorgeCopyright:

Available Formats

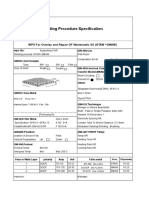

Welding Procedure Specification (WPS)

ASME Boiler and Pressure Vessel Code , Section IX Company Name: www.WPSAmerica.com Company Address: info@WPSAmerica.com, 1 (877) WPS-WELD

Welding Procedure Specification WPS No.: DEMO-WPS Supporting PQR No. (s): DEMO-PQR Revision No.: (0) Date: 12,12, 2005 Date: 11,12, 2005

Sheet 1 of 3

BASE METALS (QW-403)

P-No.: 4 Welded to P-No.: 4 OR Chem. Analysis and Mech. Prop. Welded to Chem. Analysis and Mech. Prop. Qualified Thickness Range mm (in) Qualified Diameter Range mm (in) N/A N/A Groove: 5 mm (3/16 in.) to 60 mm (2.36 in.) Groove: All Sizes Fillet: Unlimited Fillet: Unlimited Group No.: 1 Material Specification: SA-234 Type or Grade: WP11, Class 1 Group No.: 1 Material Specification: SA-335 Type or Grade: P11

Other information: This is a DEMO WPS from www.WPSAmerica.com

FIRST PROCESS

Welding Process (es): Type (s): Gas Tungsten Arc Welding (GTAW) Manual

SECOND PROCESS

Shielded Metal Arc Welding (SMAW) Manual

FILLER METALS (QW-404)

AWS Classification Electrode-Flux Class (SAW) SFA Specification Filler Metal F-No. Weld Metal Analysis A-No. Size of Filler Metals mm (in) Filler Metal Product Form Max. Weld Pass Thickness mm (in) Qualified Weld Metal Range: Groove mm (in) Qualified Weld Metal Range: Fillet mm (in) Weld Deposit Chemistry Flux Trade Name and Flux Type (SAW) Consumable Insert, Class and Size Other information: This is a DEMO WPS from www.WPSAmerica.com ER80S-G (see sheet 3) SFA 5.28 6 _ 2.0 mm (see sheet 3) Solid copper coated wire 1/8 in. 10 mm (3/8 in.) Unlimited _ N/A _ E8016-B2 (see sheet 3) SFA 5.5 4 3 3.25 mm (see sheet 3) Iron powder low hydrogen 3/16 in. 60 mm (2.36 in.) Unlimited _ N/A _

POSITIONS (QW-405)

Position (s) of Groove Welding Progression Position (s) of Fillet ALL Position Up ALL Position ALL Position Up ALL Position

PREHEAT (QW-406)

Preheat Temp. C (F) Interpass Temp. Max. C (F) Preheat Maintenance C (F) 150 C 280 C New Joint 150 C 280 C New Joint

GAS (QW-408)

Shielding Gas Type (Mixture) Flow Rate Flow Rate Flow Rate lt/min. (CFH) lt/min. (CFH) lt/min. (CFH) Trailing Gas Type (Mixture) Gas Backing (Mixture) 100% Ar 7 to 9 lt/min. N/A _ N/A _ N/A _ N/A _ N/A _

POSTWELD HEAT TREATMENT (QW-407)

Holding Temperature Range C (F): 680 C + or - 10 C Heating Rate C/hr (F/hr): 120 C/hr Cooling Rate C/hr (F/hr): 120 C/hr Holding Time Range: 1 hr/ in. (15 minutes Min.) Method: Furnace Method: Open Air

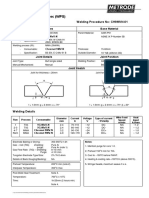

WPS No. DEMO-WPS ELECTRICAL CHARACTERISTICS (QW-409)

Following data may also shown on Table below in this sheet Current/ Polarity Amps (Range) Volts (Range) Wire Feed Speed (Range) mm/min (in/min) Travel Speed (Range) mm/min (in/min) Mode of Metal Transfer for GMAW (FCAW) Tungsten Electrode Size mm (in) Tungsten Type

Rev. (0)

Sheet 2 of 3

FIRST PROCESS

DCEN 90 to120 18 to 25 _ Manual control N/A 2.5 mm SFA 5.12 EWTh-2

SECOND PROCESS

DCEP 100 to 130 20 to 28 _ Manual control N/A _

TECHNIQUE (QW-410)

String or Weave Bead Multiple or Single Electrodes Multiple or Single Pass (per side) Orifice or Gas Cup Size Contact Tube to Work Distance mm (in) Initial and Interpass Cleaning Method of Back Gouging Oscillation Peening Other information: Clean each layer before start welding new passes/layers String Bead Single Multiple 5/8 in. Nozzle Size _ Brushing n/a _ Not Required String and Weave Bead Single Multiple _ _ Brushing and Grinding n/a _ Not Required

JOINTS (QW-402)

Joint Design: Groove Design Used Backing Type: Metal Backing Material (Refer to both backing and retainers.): Same as base metals Root Face RF: _ Groove Angle: _ Radius (J-U): _

Joint Details/ Sketch:

Groove Details (or as per production drawing): Root Opening G: _

Table for recorded welding parameters; Refer to QW-409

Weld Layer(s) 1 2 3 to n Pass No. (s) 1 2 to 3 4 to n Process GTAW GTAW SMAW Filler Metal Classification ER80S-G ER80S-G E8016-B2 Filler Size Diameter mm (in) 2.0 mm 2.0 mm 3.25 mm Current Amps Range 90-120 90-120 100-130 Current Type & Polarity DCEN DCEN DCEP Wire Feed Speed Range mm/min (in/min) N/A N/A N/A Volts Range 18-25 18-25 20-28 Travel Speed Range mm/min (in/min) _ _ _ Fill and Cap Passes Max. Heat Input kJ/mm (kJ/in) Or Remarks Root Pass

Additional Notes: This is a DEMO-WPS prepared by online welding software of www.WPSAmerica.com Manufacturer or Contractors Welding Engineer:

Name: Jim Clark Signature: J.C. Title: Welding Engineer Date: 12, 12, 2005

Authorized by:

Name: John Smith Signature: J.S. Title: QA Manager Date: 12,12, 2005

WPS No. DEMO-WPS

Rev. (0)

Sheet 3 of 3

Heat Treatment (ASME Codes Guideline):

PREHEAT TABLE: ASME Section I: Preheating from Appendix A (A-100) (a) 250 F (120 C) for material which has either a specified minimum tensile strength in excess of 60,000 psi (410 MPa) or a thickness at the joint in excess of 1/2 in. (13 mm): (b) 50 F (10 C) for all other materials of P-No. 4 group.

POSTWELD HEAT TREATMENT TABLE: ASME Section I: Mandatory Requirements for PWHT of Table PW-39 Min. Holding Temperature: 1,200 F (650 C) Min. Holding Time for Weld Thickness (Nominal): Up to 2 in. (50 mm): 1 hr/in. (2 min/mm), 15 min Min. Over 2 in. (50 mm) to 5 in. (125 mm): 1 hr/in. (2 min/mm) Over 5 in. (125 mm): 5 hr plus 15 min for each additional inch over 5 in. (125 mm) Heating rate: The weldment shall be heated slowly to the holding temperature, Min. 100 F (55 C)/hr Cooling rate: Cool slowly in a still atmosphere to a temperature not exceeding 800 F (425 C) For Non-Mandatory conditions of PWHT, See Notes (1), (2) of Table PW-39

WPS Qualified Range (ASME IX Guideline):

Qualified Positions (Groove, Fillet): All Positions for Plate or Pipe. Unless specifically required otherwise by the welding variables (QW-250), a qualification in any position qualifies the procedure for all positions. The welding process and electrodes must be suitable for all positions permitted by the WPS (ASME Section IX, QW-203). (For impact test application, there are some restrictions for welding in vertical-uphill progression position; See ASME Section IX, QW-405.2) Qualified Thicknesses (Groove, Fillet): 3/16 in. (5 mm) Min., 2T Max. (Plate or Pipe) [For GMAW-Short Circuit Arc, when T is less than 1/2 in. (13 mm): 1.1T Max. ASME IX, QW-403.10] [For impact test application, except ESW process: Min. Qualified Thickness is either T or 5/8 in. (16 mm), whichever is less; This variable does not apply when a WPS is qualified with a PWHT above the upper transformation temperature or when an austenitic material is solution annealed after welding. ASME IX, QW-403.6] [For ferrous base metals other than P-No. 7, 8 and 45 (when test coupon receives a PWHT above the upper transformation temperature): 1.1T Max. ASME IX, QW-407.4] [For any weld pass greater than 1/2 in. (13 mm) thick: 1.1T Max. (Except GTAW process). ASME IX, QW-403.9] T: Thickness of Test Plate or Pipe Wall in PQR (ASME Section IX, Table QW-451.1) Qualified Diameters (Groove, Fillet): All Nominal Pipe (Tube) Sizes, within Qualified Thicknesses in PQR WPS Base Metal P-Numbers Allowed by PQR: Any metals of the same P-No. 4, plus combination between any metal from P-No. 4 to any metal from P-No. 3 or P-No. 1 (ASME Section IX, QW-424) Qualified WPS Filler Metal Allowed by PQR: Only Filler Metal categories with the same F-number and same A-number tested in PQR. Any electrode diameter sizes can be used in WPS, as it is not an essential variable for the most process and conditions. For Non-impacted test applications only, filler metal classification within an SFA specification, with the same F-number and the same A-number and the same minimum tensile strength and the same nominal chemical composition can be used in WPS. (ASME Section IX, QW-250)

You might also like

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- Welding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Document1 pageWelding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Lipika GayenNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- WPQ Template (Asme Ix) No LogoDocument4 pagesWPQ Template (Asme Ix) No LogorcpretoriusNo ratings yet

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- PQR WPQ Witness Report LatestDocument1 pagePQR WPQ Witness Report LatestSatish KeskarNo ratings yet

- PQR 01 PDFDocument2 pagesPQR 01 PDFVijay BhaleraoNo ratings yet

- OC-1-1-FCAW-1 Rev 0 PDFDocument4 pagesOC-1-1-FCAW-1 Rev 0 PDFDario100% (1)

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- PWHT ReportsDocument1 pagePWHT ReportsKarthikNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- WOPQ Form English1Document2 pagesWOPQ Form English1oaperuchenaNo ratings yet

- July weld repair rate reportDocument2 pagesJuly weld repair rate reportSalahuddin FarooquiNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- NPCIL Tube Fitting SpecificationsDocument22 pagesNPCIL Tube Fitting Specificationssumant.c.singh1694100% (1)

- PAHARPUR COOLING TOWERS MAGNETIC PARTICLE TEST REPORTDocument1 pagePAHARPUR COOLING TOWERS MAGNETIC PARTICLE TEST REPORTGoutam Kumar DebNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Ferrite Content ReportDocument2 pagesFerrite Content ReportJawad MunirNo ratings yet

- Hydro test report for 750mm dismantling jointDocument2 pagesHydro test report for 750mm dismantling jointAnonymous a8oga83No ratings yet

- Hardness Pro Form1Document2 pagesHardness Pro Form1gst ajah100% (1)

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 pagesQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonNo ratings yet

- OCS Engineering & Construction Visual Inspection ReportDocument1 pageOCS Engineering & Construction Visual Inspection ReportvinothNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- Inspection Report - ValvesDocument2 pagesInspection Report - ValvesJaspal KaurNo ratings yet

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- 03 WPS CS 1Document3 pages03 WPS CS 1mohammadNo ratings yet

- Dimensional Check-Form 3TDocument3 pagesDimensional Check-Form 3Tlempeng durianNo ratings yet

- WFP 2-01 ASME B31 Piping Welding ProcedureDocument8 pagesWFP 2-01 ASME B31 Piping Welding Procedureleodavid87No ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- 13CR MARTENSITIC STAINLESS STEEL PQR WPS REVIEWDocument1 page13CR MARTENSITIC STAINLESS STEEL PQR WPS REVIEWenels77No ratings yet

- BPV IX-16-3 QW-283 - ButteringDocument1 pageBPV IX-16-3 QW-283 - ButteringyutweldingNo ratings yet

- Sample WPS 1Document13 pagesSample WPS 1waqas pirachaNo ratings yet

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 pagesUtoc Preliminary Wps Shell Project 270807 PDFErick HoganNo ratings yet

- Gtaw 106Document2 pagesGtaw 106ganeshkumarg_1No ratings yet

- Zzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsDocument1 pageZzze) I (ZFRP: QW-163 Acceptance Criteria - Bend Tests QW-163 Acceptance Criteria - Bend TestsSARSAN NDTNo ratings yet

- NDT Report - Dovetail WheelsDocument4 pagesNDT Report - Dovetail WheelsOm Ar TanNo ratings yet

- Hardness Test Report: Test Details Machine DetailsDocument1 pageHardness Test Report: Test Details Machine DetailsESHWAR CHARYNo ratings yet

- Itp Electrical SwitchgearDocument4 pagesItp Electrical SwitchgearpertmasterNo ratings yet

- Sample Forms WPS PQRDocument22 pagesSample Forms WPS PQRGMNo ratings yet

- QF Qa 30 Visual Dimension Final Inspection ReportDocument8 pagesQF Qa 30 Visual Dimension Final Inspection ReportVikas Mani TripathiNo ratings yet

- Helium Leak Testing DubaiDocument32 pagesHelium Leak Testing DubaiAbhijitNo ratings yet

- Pretest Piping Punch List (Empty)Document1 pagePretest Piping Punch List (Empty)Jorge GarciaNo ratings yet

- Certificate of Origin Form F For China-Chile FTADocument2 pagesCertificate of Origin Form F For China-Chile FTAinspectormetNo ratings yet

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- STS QAC SOP 006 Repair Procedure For Stainless SteelDocument5 pagesSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriNo ratings yet

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- Welding Procedure Specifications for P91 Butt WeldsDocument6 pagesWelding Procedure Specifications for P91 Butt WeldssrinivasanNo ratings yet

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNo ratings yet

- ASME Boiler and Pressure Vessel Code Welding Procedure SpecificationDocument3 pagesASME Boiler and Pressure Vessel Code Welding Procedure SpecificationArupendranarayan ThakurNo ratings yet

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariablesAnonymous rYZyQQot55No ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- WPS TITLEDocument2 pagesWPS TITLERichard Periyanayagam86% (14)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksFrom EverandArizona, Utah & New Mexico: A Guide to the State & National ParksRating: 4 out of 5 stars4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoFrom EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoRating: 5 out of 5 stars5/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptFrom EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptRating: 5 out of 5 stars5/5 (1)

- The Bahamas a Taste of the Islands ExcerptFrom EverandThe Bahamas a Taste of the Islands ExcerptRating: 4 out of 5 stars4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksFrom EverandNew York & New Jersey: A Guide to the State & National ParksNo ratings yet

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensFrom EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo ratings yet