Professional Documents

Culture Documents

Induction Motor

Uploaded by

ebasaytunoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Induction Motor

Uploaded by

ebasaytunoCopyright:

Available Formats

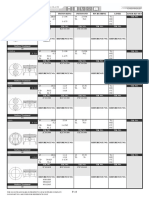

Induction Motor An induction or asynchronous motor is an AC electric motor in which the electric current in the rotor needed to produce

torque is induced by electromagnetic induction from the magnetic field of the stator winding. An induction motor therefore does not require mechanical commutation, separateexcitation or self-excitation for all or part of the energy transferred from stator to rotor, as in universal and DC motors. An induction motor's rotor can be either wound type or squirrel-cage type. Three-phase squirrel-cage induction motors are widely used in industrial drives because they are rugged, reliable and economical. Single-phase induction motors are used extensively for smaller loads, such as household appliances like fans. Although traditionally used in fixed-speed service, induction motors are increasingly being used with variable-frequency drives (VFDs) in variable-speed service. VFDs offer especially important energy savings opportunities for existing and prospective induction motors in variable-torque centrifugal fan, pump and compressor load applications. Squirrel cage induction motors are very widely used in both fixed-speed and VFD applications. n both induction and synchronous motors, the AC power supplied to the motor's stator creates a magnetic field that rotates in time with the AC oscillations. Whereas a synchronous motor's rotor turns at the same rate as the stator field, an induction motor's rotor rotates at a slower speed than the stator field. The induction motor stator's magnetic field is therefore changing or rotating relative to the rotor. This induces an opposing current in the induction motor's rotor, in effect the motor's secondary winding, when the latter [21] is short-circuited or closed through an external impedance. The rotating magnetic flux induces currents [22] in the windings of the rotor; in a manner similar to currents induced in a transformer's secondary winding(s). The currents in the rotor windings in turn create magnetic fields in the rotor that react against the stator field. Due to Lenz's Law, the direction of the magnetic field created will be such as to oppose the change in current through the rotor windings. The cause of induced current in the rotor windings is the rotating stator magnetic field, so to oppose the change in rotor-winding currents the rotor will start to rotate in the direction of the rotating stator magnetic field. The rotor accelerates until the magnitude of induced rotor current and torque balances the applied load. Since rotation at synchronous speed would result in no induced rotor current, an induction motor always operates slower than synchronous speed. The difference, or "slip," between actual and synchronous speed varies from about 0.5 to 5% for standard Design B torque curve induction motors. The induction machine's essential character is that it is created solely by induction instead of being separately excited as in synchronous or DC machines or being selfmagnetized as in permanent magnet motors. For rotor currents to be induced, the speed of the physical rotor must be lower than that of the stator's rotating magnetic field ( ); otherwise the magnetic field would not be moving relative to the rotor conductors and no currents would be induced. As the speed of the rotor drops below synchronous speed, the rotation rate of the magnetic field in the rotor increases, inducing more current in the windings and creating more torque. The ratio between the rotation rate of the magnetic field induced in the rotor and the rotation rate of the stator's rotating field is called slip. Under load, the speed drops and the slip increases enough to create sufficient torque to turn the load. For this reason, induction motors are sometimes [24] referred to as asynchronous motors. An induction motor can be used as an induction generator, or it can be unrolled to form the linear induction motor which can directly generate linear motion. There are five basic types of competing small induction motor: single-phase capacitor-start, capacitor-run, split-phase and shaded-pole types, and small polyphase induction motors.

A single-phase induction motor requires separate starting circuitry to provide a rotating field to the motor. The normal running windings within such a single-phase motor can cause the rotor to turn in either direction, so the starting circuit determines the operating direction. In certain smaller single-phase motors, starting is done by means of a shaded pole with a copper wire turn around part of the pole. The current induced in this turn lags behind the supply current, creating a delayed magnetic field around the shaded part of the pole face. This imparts sufficient rotational field energy to start the motor. These motors are typically used in applications such as desk fans and record players, as the required starting torque is low, and the low efficiency is tolerable relative to the reduced cost of the motor and starting method compared to other AC motor designs. Larger single phase motors have a second stator winding fed with out-of-phase current; such currents may be created by feeding the winding through a capacitor or having it receive different values of inductance and resistance from the main winding. In capacitor-start designs, the second winding is disconnected once the motor is up to speed, usually either by a centrifugal switch acting on weights on the motor shaft or a thermistor which heats up and increases its resistance, reducing the current through the second winding to an insignificant level. The capacitor-rundesigns keep the second winding on when running, improving torque. Self-starting polyphase induction motors produce torque even at standstill. Available cage induction motor starting methods include direct-on-line starting, reduced-voltage reactor or auto-transformer starting, stardelta starting or, increasingly, new solid-state soft assemblies and, of course, VFDs. Polyphase motors have rotor bars shaped to give different speed-torque characteristics. The current distribution within the rotor bars varies depending on the frequency of the induced current. At standstill, the rotor current is the same frequency as the stator current, and tends to travel at the outermost parts of the cage rotor bars (by skin effect). The different bar shapes can give usefully different speed-torque characteristics as well as some control over the inrush current at startup. In wound rotor motors, rotor circuit connection through slip rings to external resistances allows change of speed-torque characteristics for acceleration control and speed control purposes.

You might also like

- LED Street LightsDocument2 pagesLED Street LightsebasaytunoNo ratings yet

- Plate TectonicsDocument7 pagesPlate TectonicsebasaytunoNo ratings yet

- Street Light DesignDocument1 pageStreet Light DesignebasaytunoNo ratings yet

- Series Resistor Capacitor CircuitDocument6 pagesSeries Resistor Capacitor CircuitebasaytunoNo ratings yet

- How Voltage, Current, and Resistance RelateDocument6 pagesHow Voltage, Current, and Resistance RelateebasaytunoNo ratings yet

- Capacitor Basic Theory of OperationDocument2 pagesCapacitor Basic Theory of OperationebasaytunoNo ratings yet

- Transformer Basic PrinciplesDocument4 pagesTransformer Basic PrinciplesebasaytunoNo ratings yet

- Capacitor QuirksDocument2 pagesCapacitor QuirksebasaytunoNo ratings yet

- TransformerDocument4 pagesTransformerebasaytunoNo ratings yet

- AC capacitor circuits explainedDocument5 pagesAC capacitor circuits explainedebasaytunoNo ratings yet

- AC Resistor CircuitsDocument2 pagesAC Resistor CircuitsebasaytunoNo ratings yet

- Resonant FiltersDocument12 pagesResonant FiltersebasaytunoNo ratings yet

- AC inductor circuits explainedDocument6 pagesAC inductor circuits explainedebasaytunoNo ratings yet

- Parallel Resistor Capacitor CircuitsDocument4 pagesParallel Resistor Capacitor CircuitsebasaytunoNo ratings yet

- Band Stop FilterDocument3 pagesBand Stop FilterebasaytunoNo ratings yet

- Band-Pass Filters: System Level Block Diagram of A Band-Pass FilterDocument3 pagesBand-Pass Filters: System Level Block Diagram of A Band-Pass FilterebasaytunoNo ratings yet

- High Pass 145Document7 pagesHigh Pass 145ebasaytunoNo ratings yet

- Troubleshooting and Repair of Consumer Electronics EquipmentDocument55 pagesTroubleshooting and Repair of Consumer Electronics Equipmentebasaytuno100% (2)

- Low Pass FilterDocument6 pagesLow Pass FilterebasaytunoNo ratings yet

- Fault Analysis in Transmission System Using MatlabDocument50 pagesFault Analysis in Transmission System Using MatlabSHIKHAR KHANDELWAL89% (46)

- Solar Car PDFDocument6 pagesSolar Car PDFSaif ShaikhNo ratings yet

- Filter Circuit Frequency ResponseDocument4 pagesFilter Circuit Frequency Responseebasaytuno100% (1)

- High Pass 145Document7 pagesHigh Pass 145ebasaytunoNo ratings yet

- High Pass FilterDocument4 pagesHigh Pass FilterebasaytunoNo ratings yet

- RLC Circuits EngphysDocument26 pagesRLC Circuits EngphysReddyvari VenugopalNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- C180 Kompressor Timing Chain ReplacementDocument14 pagesC180 Kompressor Timing Chain ReplacementPatricio Fernandez Barba0% (1)

- Mega Squirt ManualDocument190 pagesMega Squirt ManualMono Razvan50% (4)

- Toyota B EngineDocument26 pagesToyota B EngineTaimoor Ahmed100% (2)

- D3E804E4975-4-Cylinder Diesel Engine (1 6 L 4V TDI Common-Rail)Document15 pagesD3E804E4975-4-Cylinder Diesel Engine (1 6 L 4V TDI Common-Rail)jorgebautistagarciaNo ratings yet

- Engine PDFDocument8 pagesEngine PDFEsam PhlipeNo ratings yet

- SL1987-216 Service Condition of Cylinder LinersDocument2 pagesSL1987-216 Service Condition of Cylinder Linerssail2karthikNo ratings yet

- T50P Spec SheetDocument4 pagesT50P Spec SheetBen TanNo ratings yet

- (-) (-) (-) (-) (Honda New Items)Document5 pages(-) (-) (-) (-) (Honda New Items)Fredy HernanNo ratings yet

- RT-123 - A3 - Issue4 - Inspection and OverDocument7 pagesRT-123 - A3 - Issue4 - Inspection and OverGeorgios MariolisNo ratings yet

- Design Overview of The R350C Rotary Diesel Engine SeriesDocument9 pagesDesign Overview of The R350C Rotary Diesel Engine Series임학진No ratings yet

- 3UZ-FE Engine Control System ChartDocument3 pages3UZ-FE Engine Control System Chartbob loblawNo ratings yet

- 350/G 8 Cyl.: The O.E.M Trade Mark Is Property O.E.M Supplier Company O.E.M Part No. Are Used For Reference OnlyDocument10 pages350/G 8 Cyl.: The O.E.M Trade Mark Is Property O.E.M Supplier Company O.E.M Part No. Are Used For Reference OnlyЕвгений ДынникNo ratings yet

- 2t OilsDocument8 pages2t OilsPreshit DalviNo ratings yet

- 5 KVA Engien Alternator-Ashok LeylandDocument7 pages5 KVA Engien Alternator-Ashok LeylandmohdrashidNo ratings yet

- Tvs Motor Company: Parts CatalogueDocument56 pagesTvs Motor Company: Parts Cataloguetvsparavattani71% (7)

- Tds Filix MHPD-XDocument2 pagesTds Filix MHPD-XDaniel DaiaNo ratings yet

- EngineDocument14 pagesEngineChandraranga De SilvaNo ratings yet

- 1a3 Двигатель. Общая ИнформацияDocument15 pages1a3 Двигатель. Общая ИнформацияLuis Alberto BernalNo ratings yet

- 2gr-Fse WiringDocument23 pages2gr-Fse Wiringar.orang59No ratings yet

- Internal Combustion Engines: Friction and LubricationDocument35 pagesInternal Combustion Engines: Friction and LubricationB NinhNo ratings yet

- Lancer: Workshop Manual SupplementDocument109 pagesLancer: Workshop Manual Supplementjesus quevedoNo ratings yet

- Compressible Flow and Sr71Document61 pagesCompressible Flow and Sr71ram100% (2)

- Supported Vehicles - Lista Veicoli Supportati (03 - 01 - 2020) PDFDocument222 pagesSupported Vehicles - Lista Veicoli Supportati (03 - 01 - 2020) PDF謝宗佑No ratings yet

- 1d - Mde 2 - Cylinder HeadDocument16 pages1d - Mde 2 - Cylinder HeadArif DzkulfliNo ratings yet

- Ak TrainingDocument40 pagesAk TrainingBatuhanÇetinGüven100% (1)

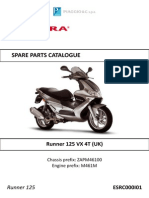

- Runner 125 VX 4T (UK)Document72 pagesRunner 125 VX 4T (UK)nf56uk0% (1)

- Vespa LXV 125 I.E. (EN)Document277 pagesVespa LXV 125 I.E. (EN)Manualles100% (1)

- The Ghyt Motor - Hefferlin ManuscriptDocument3 pagesThe Ghyt Motor - Hefferlin ManuscriptmaltyNo ratings yet

- Sistema de Combustible Con Inyector Bomba Pde y Edc s6 PDFDocument48 pagesSistema de Combustible Con Inyector Bomba Pde y Edc s6 PDFRuanWheeling100% (1)

- WP10 12 CNG Operation and Maintenance Manual and Service ManualDocument16 pagesWP10 12 CNG Operation and Maintenance Manual and Service Manualandres fabian100% (1)