Professional Documents

Culture Documents

Fabrication Procedure

Uploaded by

AndreMarcelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication Procedure

Uploaded by

AndreMarcelCopyright:

Available Formats

Number: MOP 002 Revision: 042110 Date: April 21, 2010 Page 1 of 3 QUALITY MANAGEMENT SYSTEM DOCUMENT

TITLE: Fabrication Procedure

1.0 PURPOSE

The Purpose of this procedure is to control the fabrication processes. This procedure provides for the communication of customer requirements to the shop, and inspection of product to the customer requirements.

2.0

APPLICABLE DOCUMENTS

FORM-015 Fabrication Traveler QAP-003 Control of Nonconforming Product Rejected Tag Customer Drawing

3.0

RESPONSIBILITIES

It is the responsibility of the shop supervisor to maintain this procedure. The Shop supervisor is responsible to assign and train inspectors. It is the responsibility of the welder to fabricate the part to the customer drawing and to follow this procedure and not move on to another step without inspection. The inspector must inspect the parts to the customer drawing.

4.0

4.1 4.2 4.3

PROCEDURE

The fabrication shop is given a Job Pack to fabricate a product. The Shop Lead man looks at the drawings, bills of material, and cut sheets to verify that there is adequate information to fabricate the part. The shop lead man gets the materials from the storage area and verifies that they are correct to the BOM and Cut sheet requirements and signs the fabrication traveler (FORM-015). The shop lead man gives the materials and job pack to a welder to fabricate the parts to the drawings. The welder completes the layout.

4.4

Approved By: _________________________________________________Date: ___________________ Controlled Copy, Do Not Duplicate

Number: MOP 002 Revision: 042110 Date: April 21, 2010 Page 2 of 3 QUALITY MANAGEMENT SYSTEM DOCUMENT 4.5 4.6 4.7 The shop supervisor or lead man inspects the layout of the part to the drawing and signs the fabrication traveler (FORM-015). The welder cuts the material to match the drawing. The welder or cuts or drills holes in the material to match the drawing. The welder fits up the parts as described on the drawing. If the welder does not understand the drawing, the welder is to ask the supervisor. If the drawing is still unclear, the QA Manager or Plant Manager is contacted to resolve the question with the customer in accordance with QAP-003. The shop supervisor or lead man inspects the fit-up of the part to the drawing and signs the fabrication traveler (FORM-015). The weld is completed by the welder. The shop supervisor or lead man inspects the weld of the part to the drawing and signs the fabrication traveler (FORM-015). If necessary steps 4.7 to 4.10 are repeated until the part is completed. When completed the part and job pack are moved to paint or to Final Inspection.

4.8 4.9 4.10 4.11 4.12

Approved By: _________________________________________________Date: ___________________ Controlled Copy, Do Not Duplicate

Number: MOP 002 Revision: 042110 Date: April 21, 2010 Page 3 of 3 QUALITY MANAGEMENT SYSTEM DOCUMENT

5.0

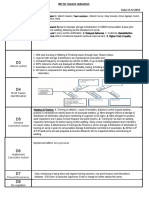

FLOWCHART

6.0

REVISION HISTORY

042110 Initial Trial Release.

Approved By: _________________________________________________Date: ___________________ Controlled Copy, Do Not Duplicate

You might also like

- Work Instruction For Bending Rev. 01.01.2013Document3 pagesWork Instruction For Bending Rev. 01.01.2013aymanmalah100% (1)

- Team Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitDocument1 pageTeam Mentor/ Leader Mr. Manish Gautam, Team Members:-Rakesh Kumar, Uday Gururani, Ankur Agarwal, Arvind, Antony, Sathish, RohitRakesh KumarNo ratings yet

- Welding Procedure and Safety ControlsDocument6 pagesWelding Procedure and Safety ControlsSIBINNo ratings yet

- Minera Chinalco Peru Project InstructionsDocument2 pagesMinera Chinalco Peru Project InstructionsLuisNo ratings yet

- Welding Consumable Receiving LogDocument11 pagesWelding Consumable Receiving LogKandula Raju100% (1)

- NDT Request (Template)Document4 pagesNDT Request (Template)Bethel NdifonNo ratings yet

- Weld Visual Report Rev.0Document1 pageWeld Visual Report Rev.0John TerryNo ratings yet

- Piping Fabrication Installation QCP On SiteDocument1 pagePiping Fabrication Installation QCP On SiteTarun PatelNo ratings yet

- ITP For Mild Steel Pipe WorksDocument4 pagesITP For Mild Steel Pipe WorksKumar AbhishekNo ratings yet

- Sop Hydraulic Punch and ShearDocument1 pageSop Hydraulic Punch and ShearBorislav VulićNo ratings yet

- Projects Assessments For Welding ProcessDocument8 pagesProjects Assessments For Welding ProcessKamarul NizamNo ratings yet

- 01fitting in FabricationDocument11 pages01fitting in Fabricationv.bhamidi100% (1)

- GRP Inspection Report SummaryDocument2 pagesGRP Inspection Report SummaryJoseph Perez100% (1)

- Daily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDocument1 pageDaily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDeniz AydinNo ratings yet

- Inspection and Test Plan for Piping Fabrication and InstallationDocument16 pagesInspection and Test Plan for Piping Fabrication and InstallationEyoh EffiongNo ratings yet

- Process Validation 1Document1 pageProcess Validation 1tayyabNo ratings yet

- Check List For Welding MachinesDocument1 pageCheck List For Welding MachinesSaravanan JambunathanNo ratings yet

- Powder Coating Procedure Guide for Oven Temperature Control, Degreasing, and Part PreparationDocument1 pagePowder Coating Procedure Guide for Oven Temperature Control, Degreasing, and Part Preparationnastyn-1No ratings yet

- Welding Control ProcedureDocument9 pagesWelding Control ProcedureRomi Abdul RahmanNo ratings yet

- Welding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Document2 pagesWelding Quality Control Plan (WQCP) Requirements in Accordance With "Welding Quality Control"Go MocNo ratings yet

- Welding Repair Procedure for PT. Juhdi Sakti EngineeringDocument4 pagesWelding Repair Procedure for PT. Juhdi Sakti EngineeringRiky SumantriNo ratings yet

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNo ratings yet

- Works Instructions For Cutting MachineDocument2 pagesWorks Instructions For Cutting Machineyadu kumar singhNo ratings yet

- Incoming Material Inspection Report: Date of ReceiptDocument1 pageIncoming Material Inspection Report: Date of ReceiptRaj MNo ratings yet

- SOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesDocument3 pagesSOP (Standard Operating Procedure) "WELDING PROCESS": Shoes Hand Glows GogglesMagesh Waran100% (1)

- Welding Control ProcedureDocument4 pagesWelding Control Procedurevenkatesh100% (2)

- 8 JSA Holyday TestDocument3 pages8 JSA Holyday TestYosua SitumorangNo ratings yet

- Welding InspectionDocument7 pagesWelding Inspectionzahid_497100% (1)

- NTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportDocument2 pagesNTPC Ge Power Services PVT LTD: Liquid Penetrant Examination ReportBalkishan DyavanapellyNo ratings yet

- Welder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersDocument1 pageWelder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersGopalakrishnan GovindarajNo ratings yet

- Welding ChecklistDocument1 pageWelding ChecklistMichael Miotk0% (1)

- Control of Welding ConsumableDocument6 pagesControl of Welding ConsumableRaja Rathinam100% (1)

- MNT - QC - BP - 001 Blasting & Painting ReportDocument1 pageMNT - QC - BP - 001 Blasting & Painting Reportsivagnanam sNo ratings yet

- Welder TrainingDocument13 pagesWelder Trainingויליאם סן מרמיגיוסNo ratings yet

- Work Method Statement FOR HSS PQTDocument6 pagesWork Method Statement FOR HSS PQTenels77No ratings yet

- Fit Up Report: Project Name Project No. Tank No. Report No. DateDocument1 pageFit Up Report: Project Name Project No. Tank No. Report No. DatekarthikumarnpNo ratings yet

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- Procedure For Installation of Steel Stair StructureDocument6 pagesProcedure For Installation of Steel Stair StructureImamah AliNo ratings yet

- QIR 121 Bolts Torque ReportDocument1 pageQIR 121 Bolts Torque ReportSamer BayatiNo ratings yet

- Inspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadDocument1 pageInspection Date: Period: Brand and Type of Tools & Equipments: Valid Until: Color Code Capacity: Inventory No.: Result (Hasil) Remark Good BadilyasNo ratings yet

- Flange Installation ProceduresDocument3 pagesFlange Installation Proceduresgplese0100% (1)

- 2.FIT-UP & 3. Welding ReportDocument2 pages2.FIT-UP & 3. Welding Reportkhurshid alam Khan100% (1)

- Work Instructions - FabricationDocument3 pagesWork Instructions - Fabricationvivek suresh0% (1)

- Safe Use of Lifting Machines and Lifting TackleDocument59 pagesSafe Use of Lifting Machines and Lifting TackleJakesNo ratings yet

- Tasks and Responsibilities of RWCDocument1 pageTasks and Responsibilities of RWCKDT100% (1)

- Welding duties checklistDocument1 pageWelding duties checklistMuhammed ThanzeelNo ratings yet

- Valid SOP: Standard Operating ProceduresDocument10 pagesValid SOP: Standard Operating ProceduresShahid Raza100% (2)

- Checklist For Fabrication & Erection of Structural Steel WorkDocument1 pageChecklist For Fabrication & Erection of Structural Steel Workbetelehem hailuNo ratings yet

- SOP - 03C Rev 1 Weld Shop PDFDocument9 pagesSOP - 03C Rev 1 Weld Shop PDFGohilakrishnan Thiagarajan100% (1)

- Method Statement For Blasting and PaintingDocument11 pagesMethod Statement For Blasting and PaintingAbdullah Abdullah100% (2)

- Weld Repair ProcedureDocument15 pagesWeld Repair Proceduremohd as shahiddin jafriNo ratings yet

- Welding Inspector Job and ResponsilbilitiesDocument5 pagesWelding Inspector Job and ResponsilbilitiesFelix GomintongNo ratings yet

- Manufacturing Quality Plan (MQP)Document2 pagesManufacturing Quality Plan (MQP)Ranjit Singh100% (3)

- Q.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteDocument5 pagesQ.c-me-UQ-09 (Weld Identification and Weld Traceability Procedure) Re WriteAws Mohamed100% (1)

- Procedure For Heat Treatment Dated 29-09-06Document8 pagesProcedure For Heat Treatment Dated 29-09-06ravi00098100% (1)

- 03-01 Material TraceabilityDocument1 page03-01 Material TraceabilityAngel AngeleyeNo ratings yet

- Pickling Work InstructionDocument1 pagePickling Work InstructionmanesarkarNo ratings yet

- Fabrication Procedure FlowDocument3 pagesFabrication Procedure FlowtrikjohNo ratings yet

- MOP-002 Fabrication ProcedureDocument3 pagesMOP-002 Fabrication ProcedureAjay G GopalNo ratings yet

- Fabrication Quality Control 2-20-08Document4 pagesFabrication Quality Control 2-20-08Vinoth KumarNo ratings yet

- Installation Instructions - Lites - PDFDocument1 pageInstallation Instructions - Lites - PDFAndreMarcelNo ratings yet

- PDFDocument4 pagesPDFAndreMarcel100% (1)

- Installation Instructions - VLV Louvers PDFDocument1 pageInstallation Instructions - VLV Louvers PDFAndreMarcelNo ratings yet

- Installation Instructions - VLV Louvers PDFDocument1 pageInstallation Instructions - VLV Louvers PDFAndreMarcelNo ratings yet

- Installation Instructions - Lites - PDFDocument1 pageInstallation Instructions - Lites - PDFAndreMarcelNo ratings yet

- MaxfieldCompanyBrocSMDocument20 pagesMaxfieldCompanyBrocSMAndreMarcelNo ratings yet

- Bridge Crane Datasheet: Manufacturer Installation Serial NoDocument2 pagesBridge Crane Datasheet: Manufacturer Installation Serial NoAndreMarcelNo ratings yet

- Factors Affecting Pipe Spool FabricationDocument7 pagesFactors Affecting Pipe Spool FabricationtkarasonNo ratings yet

- Lean Production Power PointDocument34 pagesLean Production Power PointAndreMarcelNo ratings yet

- Basics of Welding Certifications, Test Positions & ProcessesDocument3 pagesBasics of Welding Certifications, Test Positions & ProcessesSivaratnam NavatharanNo ratings yet

- Procedure Vessel Class IIDocument10 pagesProcedure Vessel Class IIAndreMarcelNo ratings yet

- Pressure Piping Alternative Test Methods Procedure RequirementsDocument13 pagesPressure Piping Alternative Test Methods Procedure RequirementsSoner KulteNo ratings yet

- Ay3 0Document4 pagesAy3 0AndreMarcelNo ratings yet

- Oil N Gas EPC PracticeDocument4 pagesOil N Gas EPC PracticeiwansalmaNo ratings yet

- LSIS - Molded Case Circuit Breaker (MCCB) - CatalogDocument140 pagesLSIS - Molded Case Circuit Breaker (MCCB) - CatalogNguyen LuongNo ratings yet

- Maintain Safe Systems with Maintenance Free EarthingDocument12 pagesMaintain Safe Systems with Maintenance Free EarthingRavi Shankar ChakravortyNo ratings yet

- Refrigeration Cycles and Systems: A Review: ArticleDocument18 pagesRefrigeration Cycles and Systems: A Review: ArticleSuneel KallaNo ratings yet

- Ligaya NG Buhay EnsembleDocument2 pagesLigaya NG Buhay EnsembleFrinzess VelascoNo ratings yet

- Petrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1135 A/BDocument11 pagesPetrobras FPSO Carioca MV30: Inspection and Test Plan (Pump & Package) For PBA-1135 A/BAliasgar100% (1)

- CIECO PPC1000R Installation Manual V3.3Document61 pagesCIECO PPC1000R Installation Manual V3.3TomNo ratings yet

- Bip 0072-2014 PDFDocument94 pagesBip 0072-2014 PDFgrNo ratings yet

- He Likes TravelingDocument7 pagesHe Likes Travelingmesser3No ratings yet

- Conscious Competence Learning ModelDocument2 pagesConscious Competence Learning ModelMaanveer SinghNo ratings yet

- Understanding Future Tenses with "Be Going To" and "WillDocument11 pagesUnderstanding Future Tenses with "Be Going To" and "WillYasmín CastilloNo ratings yet

- Powercell PDX Brochure enDocument8 pagesPowercell PDX Brochure enFate Laskhar VhinrankNo ratings yet

- Xinge Zhang LinkedinDocument3 pagesXinge Zhang Linkedinapi-289180707No ratings yet

- How to Write Effective Business and Technical ReportsDocument10 pagesHow to Write Effective Business and Technical ReportsDemverNo ratings yet

- Caracterización Y Zonificación Edáfica Y Climática de La Región de Coquimbo, ChileDocument23 pagesCaracterización Y Zonificación Edáfica Y Climática de La Región de Coquimbo, ChileSantos DamasNo ratings yet

- LTSpiceModelTutorial 2Document2 pagesLTSpiceModelTutorial 2Hermawan Rahmat HidayatNo ratings yet

- Electrolysis Cell Student ActivityDocument3 pagesElectrolysis Cell Student ActivityPersonnumberunoo0% (2)

- "Solid Waste Management": Visvesvaraya Technological UniversityDocument24 pages"Solid Waste Management": Visvesvaraya Technological UniversityManu MonaNo ratings yet

- Timeouts PT8.5xDocument21 pagesTimeouts PT8.5xJack WangNo ratings yet

- Nuclear Medicine Inc.'s Iodine Value Chain AnalysisDocument6 pagesNuclear Medicine Inc.'s Iodine Value Chain AnalysisPrashant NagpureNo ratings yet

- Automatic Temperature Controlled FanDocument27 pagesAutomatic Temperature Controlled Fankannan100% (2)

- Gpover Ip FormatDocument61 pagesGpover Ip FormatGaurav SethiNo ratings yet

- MobisudDocument2 pagesMobisudNguyen Duy KhangNo ratings yet

- Rilem TC 162-TDF PDFDocument17 pagesRilem TC 162-TDF PDFAref AbadelNo ratings yet

- Bop Test Info PDFDocument18 pagesBop Test Info PDFjairaso2950No ratings yet

- 012 08808aDocument19 pages012 08808asrNo ratings yet

- Ie0if32023001028 Rev01Document92 pagesIe0if32023001028 Rev01fernando choqueNo ratings yet

- Pasundan United FC - Anggaran Dasar Dan Rumah Tangga Pasundan United FCDocument1,231 pagesPasundan United FC - Anggaran Dasar Dan Rumah Tangga Pasundan United FCdondo lambaNo ratings yet

- Emision StandardsDocument4 pagesEmision StandardsAshish RoongtaNo ratings yet

- Ca Va de SoiDocument15 pagesCa Va de SoiManideep SrirangamNo ratings yet