Professional Documents

Culture Documents

Id 07945 - Power Wirewound Resistors

Uploaded by

SURJIT SINGHCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Id 07945 - Power Wirewound Resistors

Uploaded by

SURJIT SINGHCopyright:

Available Formats

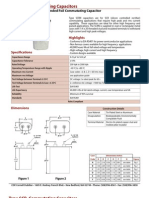

DESI GNED FOR HEAT SI NK M OUNTI NG

LOW OHM I C VALUES DOWN TO R005

SOLDER, CABLE, THREADED OR FAST-ON

TERM I NATI ONS

I NDUCTI VE OR LOW I NDUCTANCE

M ANUFACTURI NG APPROVED TO I SO 9001

Surf ace Temperat ure of resi st or rel at ed t o pow er di ssi pat i on. The resi st or

i s st andard heat si nk mount ed usi ng a propri et ary heat si nk compound.

The ARCOL HS st yl e i s a range of hi gh qual i t y, hi gh

st abi l i t y al umi ni um housed pow er w i rew ound resi st ors

desi gned f or di rect heat si nk at t achment . The resi st i ve

el ement i s w ound ont o hi gh t hermal conduct i vi t y

cerami c f ormers ground t o a cl ose t ol erance f i ni sh

ensuri ng maxi mum cont act f or rapi d heat t ransf er. Thi s

el ement i s encapsul at ed i n t he al umi ni um housi ng by a

t ransf er moul di ng process w hi ch ensures a good

humi di t y seal and a permanent compressi on f i t . The

encapsul ant i s a hi gh t emperat ure moul di ng compound

and t he speci al ARCOL moul d t ool desi gn ensures

accurat e concent ri ci t y of t he resi st i ve el ement i nsi de

t he housi ng gi vi ng a hi gh l evel of vol t age prot ect i on.

Our engi neers have 30 years experi ence i n t he desi gn

and manuf act ure of t hi s st yl e of resi st or and duri ng t hi s

peri od w e have produced many di f f erent HS t ypes t o

meet cust omers speci al requi rement s. If you need a

speci al desi gn f or your appl i cat i on, be i t hi gh vol t age,

short t erm overl oad, speci al mount i ng or t ermi nat i ons

t hen pl ease cont act us f or advi ce.

ALUM I NI UM HOUSED POWER WI REWOUND RESI STORS

HS300

HS250

HS200

HS150 HS50

HS75

HS25

HS15

HS10

HS100

0 20 50 75 100 150 200 250 300

POW ER D I SSI PA TI ON ( W A TTS)

200

100

5

S

U

R

F

A

C

E

T

E

M

P

E

R

A

T

U

R

E

R

I

S

E

(

C

)

HS

0 0 7 / 9 D A TA SH EET

S E R I E S

F E A T U R E S

T E M P E R A T U R E R I S E & P O W E R D I S S I P A T I O N O R D E R I N G S Y S T E M

LOW

I NDUCTI ON

WI NDI NG

C H A R A C T E R I S T I C S

Tolerance

Tolerance f or low values

Temperat ure Coef f icient s t ypical values

I nsulat ion resist ance (Dry)

Power dissipat ion @ high ambient t emperat ures

Ohmic values

Low induct ive (NHS)

NHS ohmic range

NHS working volt s

I nt ernal resist ance

Core

Element

End caps

Encapsulant

Housing

Terminals

St andard J ( 5%) and K ( 10%). Al so avai l abl e F ( 1%), G ( 2%) and H ( 3%).

Typi cal l y R05 5% R047 10%.

< 1K 100ppm St d. > 1K 25ppm St d. For l ow er TCRs pl ease cont act Arcol .

10,000 M mi ni mum.

Di ssi pat i on derat es l i nearl y t o zero at 200 C.

From R005 t o 100K dependi ng on wat t age st yl e.

Speci f y by addi ng N bef ore HS code e.g. NHS50.

Di vi de st andard HS maxi mum val ue by 4.

Di vi de st andard HS maxi mum w orki ng vol t s by 1.414.

Avai l abl e on request .

Cerami c-st eat i t e or al umi na dependi ng on si ze.

Copper ni ckel al l oy or ni ckel chrome al l oy.

Ni ckel i ron or st ai nl ess st eel .

Hi gh t emperat ure moul di ng compound.

Anodi sed al umi ni um.

HS10 t o HS150: si l ver pl at ed st eel cored copper HS200 t o HS300: Brass, st ai nl ess st eel or copper cl ad st eel .

THREEMILESTONE INDUSTRIAL ESTATE, TRURO, CORNWALL, TR4 9LG, ENGLAND. Tel + 44 (0)1872 277431, Fax + 44 (0)1872 222002 ht t p://w w w.arcol .co.uk E-mai l sal es@arcol .co.uk

N

TOLERANCE

J

SERI ES

H S

WATTS (M AX)

HEAT SI NK

M OUNTED

2 5

NOM I M NAL

VALUE ()

2 R 2

TOLERANCE CODE F = 1% J = 5% K = 10%

ARCOL w i l l be pl eased t o advi se and t o provi de f urt her i nf ormat i on on

t he f ol l ow i ng subj ect s:

HS resi st ors f or pul se appl i cat i ons

Maxi mum overl oad

Induct ance val ues

Low ohmi c val ues

Speci al t ermi nat i ons

Al t ernat i ve al umi ni um housi ng desi gns and mount i ngs

Vol t age appl i cat i ons

I

I

I

I

I

I

I

Page 1 of 2

I

I

I

I

I

I

ALUM I NI UM HOUSED POWER WI REWOUND RESI STORS

HS

S E R I E S

E L E C T R I C A L S P E C I F I C A T I O N S

D I M E N S I O N S

ARCOL

TYPE

HS10

HS15

HS25

HS50

HS75

HS100

HS150

HS200

HS250

HS300

STYLE

M I L-R

18546

RE60

RE65

RE70

RE75

POWER RATI NG

ON STANDARD

HEAT SI NK

@ 25C

10

15

25

50

75

100

150

200

250

300

WATTS

@ 25C

WI THOUT

HEAT SI NK

5.5

8

12.5

20

45

50

55

50

60

75

RESI STANCE

RANGE

OHM S

R005-10K

R005-10K

R005-36K

R01-86K

R01-50K

R01-70K

R01-100K

R01-50K

R01-50K

R01-68K

LI M I TI NG

ELEM ENT

VOLTAGE

DC/ AC RM S

160

265

550

1250

1400

1900

2500

1900

2200

2500

APPROX

WEI GHT

GM S

4

7

14

32

85

115

175

475

600

700

TYPI CAL SURFACE

TEM PERATURE RI SE

C/ W STANDARD HEAT

SI NK M OUNTED

5.8

5.1

4.2

3.0

1.1

1.0

1.0

0.7

0.6

0.6

AREA CM

2

STANDARD HEAT SI NK

(ALUM I NI UM )

415

415

535

535

995

995

995

3750

4765

5780

THI CKNESS (M M )

1

1

1

1

3

3

3

3

3

3

ARCOL

TYPE

HS10

HS15

HS25

HS50

HS75

HS100

HS150

HS200

HS250

HS300

A M AX

16.5

21.0

28.0

29.7

47.5

47.5

47.5

72.5

72.5

72.5

DI M ENSI ONS (M M )

B M AX

30.0

36.5

51.0

72.5

72.0

88.0

121.0

145.7

167.0

184.4

C M AX

8.8

11.0

14.6

14.8

24.1

24.1

24.1

41.8

41.8

41.8

D M AX

8.5

11.2

14.0

14.2

27.3

27.3

27.3

45.5

45.5

45.5

E M AX

15.9

19.9

27.3

49.1

48.7

65.2

97.7

89.7

108.7

127.7

F 0.3

11.3

14.3

18.3

39.7

29.0

35.0

58.0

70.0

89.0

104.0

G 0.3

12.4

15.9

19.8

21.4

37.0

37.0

37.0

57.2

57.2

59.0

H M AX

4.5

5.5

7.3

8.5

11.8

11.8

11.8

20.5

20.5

20.5

J M AX

2.4

2.8

4.7

5.2

10.4

15.4

20.4

10.4

10.4

12.4

K M AX

1.8

1.8

2.6

2.6

3.7

3.7

3.7

5.5

5.5

5.5

L 0.25*

2.4

2.4

3.2

3.2

4.4

4.4

4.4

5.1

5.1

6.6

M M AX

- - -

- - -

- - -

- - -

- - -

- - -

- - -

103.4

122.4

141.4

THREEMILESTONE INDUSTRIAL ESTATE, TRURO, CORNWALL, TR4 9LG, ENGLAND.

Tel + 44 (0)1872 277431 Fax + 44 (0)1872 222002

ht t p://w w w.arcol .co.uk E-mai l sal es@arcol .co.uk

Page 2 of 2

HS 200, 250, 300

6mm

A G

J

L

F

B

2.0

0.25

2.1 0.1

HS 10, 15,25, 50

D

H

K

C

HS 75, 100, 150

=

3.2

max.

3.0 0.1

*

=

Cent re hol e i n

each f l ange i s i n

150 Wat t s onl y

E

B

F

J

L

A G

= =

B

F

E E

M

J

L

A G

D

H

K

C

D

H

K

C

* 200 - 300 Wat t s i s 0.45

The informat ion cont ained herein does not form part of a cont ract and is subject t o change wit hout not ice. It is t he responsibilit y of t he cust omer t o ensure t hat t he component select ed from our range is suit able for t he int ended applicat ion.

If in doubt please ask us.

HEAT DI SSI PATI ON Whi l st t he use of propri et ary heat si nks w i t h

l ow er t hermal resi st ance i s accept abl e, uprat i ng i s not recommended.

For maxi mum heat t ransf er i t i s recommended t hat a heat si nk

compound be appl i ed bet w een t he resi st or base and heat si nk/chassi s

mount i ng surf ace. It i s essent i al t hat t he maxi mum hot spot

t emperat ure of 200C i s not exceeded and t heref ore t he resi st or must

be mount ed on a heat si nk of correct t hermal resi st ance f or t he pow er

bei ng di ssi pat ed.

M AXI M UM OVERLOAD Pl ease consul t t he f act ory f or assi st ance

concerni ng your part i cul ar overl oad appl i cat i on.

H E A T D I S S I P A T I O N A N D M A X I M U M O V E R L O A D

CERTIFICATENUMBERFM31218

VOLTAGE

PROOF

AC PEAK

1400

1400

3500

3500

6363

6363

6363

7070

7070

7070

VOLTAGE

PROOF

AC RM S

1000

1000

2500

2500

4500

4500

4500

5000

5000

5000

You might also like

- Hanson G209 (SW Valves)Document12 pagesHanson G209 (SW Valves)AKSHEYMEHTANo ratings yet

- Bohler Welding in Tool MakingDocument24 pagesBohler Welding in Tool MakingcfcshakerNo ratings yet

- Alumec English 020907Document7 pagesAlumec English 020907Javier OrzcoNo ratings yet

- Ea 934naDocument4 pagesEa 934nalacsmm982No ratings yet

- Vnyjxiyn: 3V2 Digit A/D Converters With Bandgap ReferenceDocument12 pagesVnyjxiyn: 3V2 Digit A/D Converters With Bandgap ReferenceminiecateNo ratings yet

- Guia de Usuario Omega Hx15Document12 pagesGuia de Usuario Omega Hx15microsoda8No ratings yet

- Hot Applied Coal Tar Coatings Protect PipesDocument13 pagesHot Applied Coal Tar Coatings Protect PipesgrtunaNo ratings yet

- Hot Applied Coal Tar Coatings Protect PipesDocument155 pagesHot Applied Coal Tar Coatings Protect PipesmattarchiNo ratings yet

- manDM6700 PDFDocument64 pagesmanDM6700 PDFMiguel Angel Cara Rios100% (1)

- GE Lighting Systems Decashield Lighting System Brochure 12-74Document4 pagesGE Lighting Systems Decashield Lighting System Brochure 12-74Alan MastersNo ratings yet

- Arcol HS Series (Resistencias de Potencia)Document2 pagesArcol HS Series (Resistencias de Potencia)meroka2000No ratings yet

- Catalogo Fuentes MWDocument100 pagesCatalogo Fuentes MWCharles TineoNo ratings yet

- Ea 9396Document4 pagesEa 9396lacsmm982No ratings yet

- Effect of Welding and Post-Weld Heat Treatment on Ducol W30 SteelDocument21 pagesEffect of Welding and Post-Weld Heat Treatment on Ducol W30 Steelshanker100% (1)

- Mean Well 2013 Taiwan Excellence AwardsDocument100 pagesMean Well 2013 Taiwan Excellence AwardsaldemirernestoNo ratings yet

- DP SWITCHES HIGH STATIC PRESSURE ADJUSTABLE SET POINTDocument6 pagesDP SWITCHES HIGH STATIC PRESSURE ADJUSTABLE SET POINTNavneet SinghNo ratings yet

- Chip Monolithic Ceramic Capacitors GuideDocument186 pagesChip Monolithic Ceramic Capacitors GuideRanaJafaryNo ratings yet

- PVC 300DataSheetDocument3 pagesPVC 300DataSheetarnella_hNo ratings yet

- Features Description: SBVS002Document12 pagesFeatures Description: SBVS002fuckoffscribd42No ratings yet

- Chemical Resistance GuideDocument36 pagesChemical Resistance GuideHeiner PalaciosNo ratings yet

- Vishay Aluminum Capacitors GuideDocument7 pagesVishay Aluminum Capacitors GuideMuhammad Ardi AnggaraNo ratings yet

- Specifications: Type SCRN Film-Paper/Extended Foil Commutating CapacitorDocument4 pagesSpecifications: Type SCRN Film-Paper/Extended Foil Commutating CapacitorCheranjeevi ChiruNo ratings yet

- 1135 FDocument7 pages1135 FTimmyJuriNo ratings yet

- Holophane Outdoor Substation Series Brochure 8-79Document2 pagesHolophane Outdoor Substation Series Brochure 8-79Alan MastersNo ratings yet

- Valves CatalogueDocument30 pagesValves CatalogueRuth Sarai YañezNo ratings yet

- His08S0420 8-Ch An Alog in Pu T Dat Alogger: - OverviewDocument1 pageHis08S0420 8-Ch An Alog in Pu T Dat Alogger: - OverviewPrudhvi RajkrishnaNo ratings yet

- Distibutor Tubes: Important Safety InformationDocument2 pagesDistibutor Tubes: Important Safety InformationEsteban Vanegas AlvarezNo ratings yet

- HTR India - Products - Current Sense Resistors - Current Sense Open Frame Resistors - OA (English)Document4 pagesHTR India - Products - Current Sense Resistors - Current Sense Open Frame Resistors - OA (English)crplzNo ratings yet

- Booster Pumps Multistage Vertical 60HzDocument28 pagesBooster Pumps Multistage Vertical 60Hzrhusseinpos4765No ratings yet

- S-8B1 8B1TDocument6 pagesS-8B1 8B1TbryandownNo ratings yet

- Energy Wire Technical Data SheetDocument5 pagesEnergy Wire Technical Data SheetMJ.ANILKUMARNo ratings yet

- Design CalculationsDocument52 pagesDesign Calculationsrodolfo barbosaNo ratings yet

- Discussion & Correction Factors: Ampacity TablesDocument2 pagesDiscussion & Correction Factors: Ampacity TablesalbertoNo ratings yet

- Osram HCI Halos Metal Halide Lamps Catalog 1975Document4 pagesOsram HCI Halos Metal Halide Lamps Catalog 1975Alan MastersNo ratings yet

- Custom 465 Stainless SteelDocument20 pagesCustom 465 Stainless SteelGrafton Montgomery100% (1)

- 2vre 4400TGDocument2 pages2vre 4400TGkolombo1776No ratings yet

- Technical Data: Relative Humidity SensorDocument4 pagesTechnical Data: Relative Humidity Sensorandresromero80No ratings yet

- Mafna Fca Upgrade Ahu 052316 01ls - SubmittalDocument13 pagesMafna Fca Upgrade Ahu 052316 01ls - SubmittalTej Vir SinghNo ratings yet

- 10D9Document9 pages10D9piyushpandeyNo ratings yet

- Kem A4002 EevDocument16 pagesKem A4002 EevAndrzej GomulaNo ratings yet

- Dse9150 9130 9155 9255 Data SheetDocument2 pagesDse9150 9130 9155 9255 Data SheetMohamed Salah Allam100% (1)

- Raypa Autoklav AES AEDocument9 pagesRaypa Autoklav AES AELuis MedranoNo ratings yet

- Motor Re WindingDocument11 pagesMotor Re WindingAbhishek Singh Chauhan100% (4)

- Ibrape M 110Document26 pagesIbrape M 110thothothothoNo ratings yet

- Technical - Specs - Tai Lieu Ve Han TIGDocument12 pagesTechnical - Specs - Tai Lieu Ve Han TIGthanhdung20061085No ratings yet

- Type: SL-770: Keyword: Enhanced StartDocument1 pageType: SL-770: Keyword: Enhanced StartchuckreyesNo ratings yet

- Manual Rele 24vDocument2 pagesManual Rele 24vCpernia EnriqueNo ratings yet

- 0859 Solid State Relays Data SheetDocument23 pages0859 Solid State Relays Data SheetglennandlynneNo ratings yet

- APV Hybrid - Welded Heat ExchangerDocument8 pagesAPV Hybrid - Welded Heat Exchangerkingathur26681No ratings yet

- GE Lighting Systems Commercial Lighting Designers Guide 1973Document12 pagesGE Lighting Systems Commercial Lighting Designers Guide 1973Alan MastersNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Total Energy: International Series in Heating, Ventilation and RefrigerationFrom EverandTotal Energy: International Series in Heating, Ventilation and RefrigerationNo ratings yet

- The Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingFrom EverandThe Art of Welding: Practical Information and Useful Exercises for Oxyacetylene and Electric Arc WeldingNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 110 Semiconductor Projects for the Home ConstructorFrom Everand110 Semiconductor Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsFrom EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsRating: 5 out of 5 stars5/5 (1)

- # Ponumber Podt Ven - Code Vend - Name PRD - CodeDocument3 pages# Ponumber Podt Ven - Code Vend - Name PRD - CodeSURJIT SINGHNo ratings yet

- God ChangesDocument1 pageGod ChangesShannon100% (2)

- MotivationDocument4 pagesMotivationSURJIT SINGHNo ratings yet

- Fo No. Code No. Description Qty. Reason Rts NoDocument1 pageFo No. Code No. Description Qty. Reason Rts NoSURJIT SINGHNo ratings yet

- And We Say We Work HardDocument13 pagesAnd We Say We Work HardSURJIT SINGHNo ratings yet

- Italian, Swiss, German Industrial Vacuum CleanersDocument2 pagesItalian, Swiss, German Industrial Vacuum CleanersSURJIT SINGHNo ratings yet

- Chair BillDocument1 pageChair BillSURJIT SINGHNo ratings yet

- Angle Grinder Safety ProceduresDocument1 pageAngle Grinder Safety ProceduresSURJIT SINGHNo ratings yet

- Safe Work Procedure (Drill Press)Document2 pagesSafe Work Procedure (Drill Press)SURJIT SINGH100% (1)

- Self-Discovery Reflection QuestionsDocument1 pageSelf-Discovery Reflection QuestionsSURJIT SINGHNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Work Instruction TemplateDocument7 pagesWork Instruction TemplateSURJIT SINGHNo ratings yet

- Manpower Status and Productivity Insights for Month of --Month-- 2009Document32 pagesManpower Status and Productivity Insights for Month of --Month-- 2009SURJIT SINGHNo ratings yet

- Effective Time Management Important Vs UrgentDocument23 pagesEffective Time Management Important Vs Urgentmunisa1961No ratings yet

- WHS EP Housekeeping4Document1 pageWHS EP Housekeeping4SURJIT SINGHNo ratings yet

- View PDFDocument1 pageView PDFSURJIT SINGHNo ratings yet

- WHS EP Eyeprotection3Document1 pageWHS EP Eyeprotection3SURJIT SINGHNo ratings yet

- Training Calendar: Topic Int./ ExtDocument2 pagesTraining Calendar: Topic Int./ ExtSURJIT SINGHNo ratings yet

- ESD Work Instruction WI-OPS-005Document17 pagesESD Work Instruction WI-OPS-005Niv Narkiss75% (4)

- HeijunkaDocument18 pagesHeijunkamamanbudiNo ratings yet

- SPECAA22421Document4 pagesSPECAA22421SURJIT SINGHNo ratings yet

- SPECAA22421Document4 pagesSPECAA22421SURJIT SINGHNo ratings yet

- SPECAA22421Document4 pagesSPECAA22421SURJIT SINGHNo ratings yet

- New Microsoft Word DocumentDocument9 pagesNew Microsoft Word DocumentSURJIT SINGHNo ratings yet

- Hind Rectifiers LTD.: Semiconductor DivisionDocument3 pagesHind Rectifiers LTD.: Semiconductor DivisionSURJIT SINGHNo ratings yet

- FORCED AIR COOLED ALTERNATOR MOUNTED RECTIFIER TEST REPORTDocument5 pagesFORCED AIR COOLED ALTERNATOR MOUNTED RECTIFIER TEST REPORTSURJIT SINGHNo ratings yet

- Epoxy ResinDocument7 pagesEpoxy ResinAtiq JamNo ratings yet

- From The 6Ms To The 6QsDocument8 pagesFrom The 6Ms To The 6QsSURJIT SINGHNo ratings yet

- All About Diesel LocoDocument293 pagesAll About Diesel LocoDeepak Chauhan100% (9)

- Monthly Safety Report SampleDocument2 pagesMonthly Safety Report SampleSURJIT SINGH82% (33)

- Filters in GeneralDocument3 pagesFilters in GeneralJoseGarciaRuizNo ratings yet

- Calibration Procedure Crowcon Xgard Gas Detectors - 5720273 - 01Document16 pagesCalibration Procedure Crowcon Xgard Gas Detectors - 5720273 - 01Daniel Rolando Gutierrez FuentesNo ratings yet

- Reformasi Birokrasi Di AustraliaDocument54 pagesReformasi Birokrasi Di Australiazaky ahmadNo ratings yet

- English 9 - Q2 - M5Document16 pagesEnglish 9 - Q2 - M5myraNo ratings yet

- TMJC - H2 - 2021 - Prelim P2Document9 pagesTMJC - H2 - 2021 - Prelim P2猪猪侠No ratings yet

- 2016 Book IrrigationAndDrainageEngineeriDocument747 pages2016 Book IrrigationAndDrainageEngineeriJesús Garre Ruiz100% (2)

- Guide To Preparing Tax Research MemosDocument2 pagesGuide To Preparing Tax Research MemoscglaskoNo ratings yet

- MFS 7104 Quantitative TechniquesDocument2 pagesMFS 7104 Quantitative TechniquesDavid KNo ratings yet

- Watertown City Manager's Status and Information Report Sept. 6, 2019Document8 pagesWatertown City Manager's Status and Information Report Sept. 6, 2019NewzjunkyNo ratings yet

- Pulungmasle High School: Boy Scouts of The Philippines - Pulungmasle High School Chapter Work Plan For S.Y 2018-2019Document3 pagesPulungmasle High School: Boy Scouts of The Philippines - Pulungmasle High School Chapter Work Plan For S.Y 2018-2019Rd DavidNo ratings yet

- Radiation Safety Officers Handbook A PDFDocument100 pagesRadiation Safety Officers Handbook A PDFAlejandro Zubiate100% (1)

- Mass Transfer in Industrial ApplicationsDocument1 pageMass Transfer in Industrial ApplicationsMPD19I001 VITHISHA MNo ratings yet

- Detailed Scheduling Planning Board Technical HelpDocument6 pagesDetailed Scheduling Planning Board Technical Helpmanojnarain100% (1)

- أسئلة شاملة 1Document25 pagesأسئلة شاملة 1ibraheemalabsi99No ratings yet

- Module 4 NotesDocument20 pagesModule 4 NotesvijaykumaryadavNo ratings yet

- Tugas (UTS) ASPK - Andro Tri Julianda (95017019)Document4 pagesTugas (UTS) ASPK - Andro Tri Julianda (95017019)محمد عزيرNo ratings yet

- DLTSoul DrinkersDocument7 pagesDLTSoul DrinkersIgnacio Burón García100% (1)

- Mobil Dynagear Series Performance ProfileDocument2 pagesMobil Dynagear Series Performance ProfileXavier DiazNo ratings yet

- Adolescent InterviewDocument9 pagesAdolescent Interviewapi-532448305No ratings yet

- Brent Academy of Northern Cebu, Inc: Talisay, Daanbantayan, Cebu First Periodical TestDocument2 pagesBrent Academy of Northern Cebu, Inc: Talisay, Daanbantayan, Cebu First Periodical TestKristine RosarioNo ratings yet

- C6713 Lab ManualDocument51 pagesC6713 Lab Manualsmganorkar100% (1)

- Call For IPSF-EMRO Regional Working Group Subcommittees 2018-19Document4 pagesCall For IPSF-EMRO Regional Working Group Subcommittees 2018-19IPSF EMRONo ratings yet

- TW Ycm01265958803Document62 pagesTW Ycm0126595880313239563No ratings yet

- A Thesis 123Document77 pagesA Thesis 123Meli SafiraNo ratings yet

- GA 33 KV VCB HT Panel - Siddharth Nagar Project. UPDocument17 pagesGA 33 KV VCB HT Panel - Siddharth Nagar Project. UPaayushNo ratings yet

- Residual Stresses of Plate With Holes by ANSYS Analysis - Hani Aziz AmeenDocument14 pagesResidual Stresses of Plate With Holes by ANSYS Analysis - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- ISSAQ: An Integrated Sensing Systems For Real-Time Indoor Air Quality MonitoringDocument15 pagesISSAQ: An Integrated Sensing Systems For Real-Time Indoor Air Quality MonitoringKemHuyềnNo ratings yet

- Hyponymy and Hypernymy: Jump To Navigationjump To SearchDocument8 pagesHyponymy and Hypernymy: Jump To Navigationjump To SearchSteven HamNo ratings yet

- Rip Bushing PDFDocument38 pagesRip Bushing PDFTravis Wood100% (1)

- Apu White SmokeDocument3 pagesApu White SmokeGoutam SahaNo ratings yet