Professional Documents

Culture Documents

Strain Gages Measure Force, Pressure & Flow

Uploaded by

Engr. AbdullahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strain Gages Measure Force, Pressure & Flow

Uploaded by

Engr. AbdullahCopyright:

Available Formats

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

SECTION 4 STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

Walt Kester STRAIN GAGES

The most popular electrical elements used in force measurements include the resistance strain gage, the semiconductor strain gage, and piezoelectric transducers. The strain gage measures force indirectly by measuring the deflection it produces in a calibrated carrier. Pressure can be converted into a force using an appropriate transducer, and strain gage techniques can then be used to measure pressure. Flow rates can be measured using differential pressure measurements which also make use of strain gage technology.

STRAIN GAGE BASED MEASUREMENTS

n Strain: n Force: n Pressure: n Flow: Strain Gage, PiezoElectric Transducers Load Cell Diaphragm to Force to Strain Gage Differential Pressure Techniques Figure 4.1 The resistance strain gage is a resistive element which changes in length, hence resistance, as the force applied to the base on which it is mounted causes stretching or compression. It is perhaps the most well known transducer for converting force into an electrical variable. Unbonded strain gages consist of a wire stretched between two points as shown in Figure 4.2. Force acting on the wire (area = A, length = L, resistivity = ) will cause the wire to elongate or shorten, which will cause the resistance to increase or decrease proportionally according to: R = L/A and R/R = GFL/L,

where GF = Gage factor (2.0 to 4.5 for metals, and more than 150 for semiconductors).

4.1

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS The dimensionless quantity L/L is a measure of the force applied to the wire and is expressed in microstrains (1 = 106 cm/cm) which is the same as parts-per-million (ppm). From this equation, note that larger gage factors result in proportionally larger resistance changes, hence, more sensitivity.

UNBONDED WIRE STRAIN GAGE

FORCE

R=

L A

STRAIN SENSING WIRE AREA = A LENGTH = L RESISTIVITY = RESISTANCE = R

R = GF L R L GF = GAGE FACTOR 2 TO 4.5 FOR METALS >150 FOR SEMICONDUCTORS

L L FORCE

= MICROSTRAINS ( )

1 = 1106 cm / cm = 1 ppm

Figure 4.2 Bonded strain gages consist of a thin wire or conducting film arranged in a coplanar pattern and cemented to a base or carrier. The gage is normally mounted so that as much as possible of the length of the conductor is aligned in the direction of the stress that is being measured. Lead wires are attached to the base and brought out for interconnection. Bonded devices are considerably more practical and are in much wider use than unbonded devices.

Perhaps the most popular version is the foil-type gage, produced by photo-etching techniques, and using similar metals to the wire types (alloys of copper-nickel (Constantan), nickel-chromium (Nichrome), nickel-iron, platinum-tungsten, etc. (see Figure 4.4). Gages having wire sensing elements present a small surface area to the specimen; this reduces leakage currents at high temperatures and permits higher isolation potentials between the sensing element and the specimen. Foil sensing elements, on the other hand, have a large ratio of surface area to cross-sectional area and are more stable under extremes of temperature and prolonged loading. The large surface area and thin cross section also permit the device to follow the specimen temperature and facilitate the dissipation of self-induced heat.

4.2

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

BONDED WIRE STRAIN GAGE

FORCE

n n n

SMALL SURFACE AREA LOW LEAKAGE HIGH ISOLATION

FORCE Figure 4.3

METAL FOIL STRAIN GAGE

FORCE

n n n n n

PHOTO ETCHING TECHNIQUE LARGE AREA STABLE OVER TEMPERATURE THIN CROSS SECTION GOOD HEAT DISSIPATION

FORCE Figure 4.4

4.3

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

Semiconductor strain gages make use of the piezoresistive effect in certain semiconductor materials such as silicon and germanium in order to obtain greater sensitivity and higher-level output. Semiconductor gages can be produced to have either positive or negative changes when strained. They can be made physically small while still maintaining a high nominal resistance. Semiconductor strain gage bridges may have 30 times the sensitivity of bridges employing metal films, but are temperature sensitive and difficult to compensate. Their change in resistance with strain is also nonlinear. They are not in as widespread use as the more stable metalfilm devices for precision work; however, where sensitivity is important and temperature variations are small, they may have some advantage. Instrumentation is similar to that for metal-film bridges but is less critical because of the higher signal levels and decreased transducer accuracy.

COMPARISON BETWEEN METAL AND SEMICONDUCTOR STRAIN GAGES

PARAMETER METAL STRAIN GAGE 0.1 to 40,000 2.0 to 4.5 120, 350, 600, , 5000 0.1% to 0.2% SEMICONDUCTOR STRAIN GAGE 0.001 to 3000 50 to 200 1000 to 5000 1% to 2%

Measurement Range Gage Factor Resistance, Resistance Tolerance Size, mm

0.4 to 150 Standard: 3 to 6 Figure 4.5

1 to 5

Piezoelectric force transducers are employed where the forces to be measured are dynamic (i.e., continually changing over the period of interest - usually of the order of milliseconds). These devices utilize the effect that changes in charge are produced in certain materials when they are subjected to physical stress. In fact, piezoelectric transducers are displacement transducers with quite large charge outputs for very small displacements, but they are invariably used as force transducers on the assumption that in an elastic material, displacement is proportional to force. Piezoelectric devices produce substantial output voltage in instruments such as accelerometers for vibration studies. Output impedance is high, and charge amplifier configurations, with low input capacitance, are required for signal conditioning. Conditioning a piezoelectric sensor output is discussed in further detail in Section 5. 4.4

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

Strain gages can be used to measure force, as in Figure 4.6 where a cantilever beam is slightly deflected by the applied force. Four strain gages are used to measure the flex of the beam, two on the top side, and two on the bottom side. The gages are connected in an all-element bridge configuration. Recall from Section 2 that this configuration gives maximum sensitivity and is inherently linear. This configuration also offers first-order correction for temperature drift in the individual strain gages.

STRAIN GAGE BEAM FORCE SENSOR

VB RIGID BEAM FORCE R1 R1 R3

_ VO

R4

R2

R4

R2

R3

Figure 4.6

Strain gages are low-impedance devices; they require significant excitation power to obtain reasonable levels of output voltage. A typical strain-gage based load cell bridge will have (typically) a 350 impedance and is specified as having a sensitivity in terms of millivolts full scale per volt of excitation. The load cell is composed of four individual strain gages arranged as a bridge as shown in Figure 4.7. For a 10V bridge excitation voltage with a rating of 3mV/V, 30 millivolts of signal will be available at full scale loading. The output can be increased by increasing the drive to the bridge, but self-heating effects are a significant limitation to this approach: they can cause erroneous readings or even device destruction. Many load cells have "sense" connections to allow the signal conditioning electronics to compensate for DC drops in the wires. Some load cells have additional internal resistors which are selected for temperature compensation.

4.5

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

6-LEAD LOAD CELL

FORCE

+VB +SENSE +VOUT VOUT

SENSE VB

Figure 4.7

Pressures in liquids and gases are measured electrically by a variety of pressure transducers. A variety of mechanical converters (including diaphragms, capsules, bellows, manometer tubes, and Bourdon tubes) are used to measure pressure by measuring an associated length, distance, or displacement, and to measure pressure changes by the motion produced. The output of this mechanical interface is then applied to an electrical converter such as a strain gage or piezoelectric transducer. Unlike strain gages, piezoelectric pressure transducers are typically used for high-frequency pressure measurements (such as sonar applications or crystal microphones).

4.6

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

PRESSURE SENSORS

PRESSURE SOURCE

STRAIN GAGE

MECHANICAL OUTPUT PRESSURE SENSOR (DIAPHRAGM)

SIGNAL CONDITIONING ELECTRONICS

Figure 4.8

There are many ways of defining flow (mass flow, volume flow, laminar flow, turbulent flow). Usually the amount of a substance flowing (mass flow) is the most important, and if the fluid's density is constant, a volume flow measurement is a useful substitute that is generally easier to perform. One commonly used class of transducers, which measure flow rate indirectly, involves the measurement of pressure.

Flow can be derived by taking the differential pressure across two points in a flowing medium - one at a static point and one in the flow stream. Pitot tubes are one form of device used to perform this function. The flow rate is obtained by measuring the differential pressure with standard pressure transducers as shown in Figure 4.9. Differential pressure can also be used to measure flow rate using the venturi effect by placing a restriction in the flow as shown in Figure 4.10. Figure 4.11 shows a bending vane with an attached strain gage placed in the flow to measure flow rate.

4.7

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

PITOT TUBE USED TO MEASURE FLOW RATE

FLOW PITOT TUBE

P1

P2 MECHANICAL OUTPUT STRAIN GAGES

DIFFERENTIAL PRESSURE TRANSDUCER

CONDITIONING ELECTRONICS

Figure 4.9

MEASURING FLOW RATE USING THE VENTURI EFFECT

FLOW RESTRICTION

P1

P2 DIFFERENTIAL PRESSURE TRANSDUCER MECHANICAL OUTPUT STRAIN GAGES

CONDITIONING ELECTRONICS

Figure 4.10

4.8

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

BENDING VANE WITH STRAIN GAGE USED TO MEASURE FLOW RATE

FLOW BENDING VANE WITH STRAIN GAGE

"R" CONDITIONING ELECTRONICS

Figure 4.11

BRIDGE SIGNAL CONDITIONING CIRCUITS

An example of an all-element varying bridge circuit is a fatigue monitoring strain sensing circuit as shown in Figure 4.12. The full bridge is an integrated unit that can be attached to the surface on which the strain or flex is to be measured. In order to facilitate remote sensing, current excitation is used. The OP177 servos the bridge current to 10mA around a reference voltage of 1.235V. The strain gauge produces an output of 10.25mV/1000. The signal is amplified by the AD620 instrumentation amplifier which is configured for a gain of 100. Full-scale strain voltage may be set by adjusting the 100 gain potentiometer such that, for a strain of 3500, the output reads 3.500V; and for a strain of +5000, the output registers a +5.000V. The measurement may then be digitized with an ADC which has a 10V fullscale input range. The 0.1F capacitor across the AD620 input pins serves as an EMI/RFI filter in conjunction with the bridge resistance of 1k. The corner frequency of the filter is approximately 1.6kHz.

4.9

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

PRECISION STRAIN GAGE SENSOR AMPLIFIER

+15V 7 1 10mA 0.1F 1k 1k 3 + 15V 4 5 100 1.7k 8.2k 1k 1k +15V STRAIN SENSOR: Columbia Research Labs 2682 Range: 3500 to +5000 Output: 10.25mV/1000 +1.235V 30.1k 124 7 + 3 6 OP177 2 27.4k +15V +1.235V 4 15V 2 AD620 8 100 499 6 VOUT 3.500V = 3500 +5.000V = +5000 +15V

2N2907A

AD589

Figure 4.12

Another example is a load cell amplifier circuit shown in Figure 4.13. A typical load cell has a bridge resistance of 350. A 10.000V bridge excitation is derived from an AD588 precision voltage reference with an OP177 and 2N2219A used as a buffer. The 2N2219A is within the OP177 feedback loop and supplies the necessary bridge drive current (28.57mA). To ensure this linearity is preserved, an instrumentation amplifier is used. This design has a minimum number of critical resistors and amplifiers, making the entire implementation accurate, stable, and cost effective. The only requirement is that the 475 resistor and the 100 potentiometer have low temperature coefficients so that the amplifier gain does not drift over temperature.

4.10

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

PRECISION LOAD CELL AMPLIFIER

+15V +15V 1k +10.000V 350 350 4 15V 2 6 7 +10.000V + 3 1 3 AD588 9 4 +15 7 1 8 350 350 3 AD620 + 4 15V 350 LOAD CELL 100mV FS 5 6 VOUT 0 TO +10.000V FS 6 8 10 +15V 2 15V 16 13 12 11

2N2219A

OP177 2

475 100

Figure 4.13 As has been previously shown, a precision load cell is usually configured as a 350 bridge. Figure 4.14 shows a precision load-cell amplifier that is powered from a single supply. The excitation voltage to the bridge must be precise and stable, otherwise it introduces an error in the measurement. In this circuit, a precision REF195 5V reference is used as the bridge drive. The REF195 reference can supply more than 30mA to a load, so it can drive the 350 bridge without the need of a buffer. The dual OP213 is configured as a two op amp in-amp with a gain of 100. The resistor network sets the gain according to the formula: G =1+ 10 k 20 k + = 100 . 1k 196 + 28.7

For optimum common-mode rejection, the resistor ratios must be precise. High tolerance resistors (0.5% or better) should be used. For a zero volt bridge output signal, the amplifier will swing to within 2.5mV of 0V. This is the minimum output limit of the OP213. Therefore, if an offset adjustment is required, the adjustment should start from a positive voltage at VREF and adjust VREF downward until the output (VOUT) stops changing. This is the point where the amplifier limits the swing. Because of the single supply design, the amplifier cannot sense signals which have negative polarity. If linearity at zero volts input is required, or if negative polarity signals must be processed, the VREF connection can be connected to a voltage which is mid-supply (2.5V) rather than ground. Note that when VREF is not at ground, the output must be referenced to VREF.

4.11

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

SINGLE SUPPLY LOAD CELL AMPLIFIER

196 +VS 2 REF195 1F 4 350 350 3 2 (VREF) 10k 1k 28.7 1k 10k

+5.000V 8 1 6 1/2 OP213 5 + 7 VOUT

1/2 OP213 + 4

G = 100

350

350

Figure 4.14

The AD7730 24-bit sigma-delta ADC is ideal for direct conditioning of bridge outputs and requires no interface circuitry. The simplified connection diagram is shown in Figure 4.15. The entire circuit operates on a single +5V supply which also serves as the bridge excitation voltage. Note that the measurement is ratiometric because the sensed bridge excitation voltage is also used as the ADC reference. Variations in the +5V supply do not affect the accuracy of the measurement.

The AD7730 has an internal programmable gain amplifier which allows a fullscale bridge output of 10mV to be digitized to 16-bit accuracy. The AD7730 has self and system calibration features which allow offset and gain errors to be minimized with periodic recalibrations. A "chop" mode option minimizes the offset voltage and drift and operates similarly to a chopper-stabilized amplifier. The effective input voltage noise RTI is approximately 40nV rms, or 264nV peak-to-peak. This corresponds to a resolution of 13 ppm, or approximately 16.5-bits . Gain linearity is also approximately 16-bits. Further discussion of this type of ADC can be found in Section 8.

4.12

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

LOAD CELL APPLICATION USING THE AD7730 ADC

+FORCE RLEAD 6-LEAD LOAD CELL +SENSE +5V AVDD + VREF + AIN AIN VREF +5V/+3V DVDD

VO

AD7730 ADC 24 BITS

SENSE

FORCE

RLEAD

GND

Figure 4.15

PERFORMANCE OF AD7730 LOAD CELL ADC

n Assume: u Fullscale Bridge Output of 10mV, +5V Excitation u "Chop Mode" Activated u System Calibration Performed: Zero and Fullscale n Performance: u Noise RTI: 40nV rms, 264nV p-p u Noise-Free Resolution: 80,000 Counts (16.5 bits) u Gain Nonlinearity: 18ppm u Gain Accuracy: < 1V u Offset Voltage: <1V u Offset Drift: 0.5 V/C u Gain Drift: 2ppm/C u Note: Gain and Offset Drift Removable with System Recalibration Figure 4.16

4.13

STRAIN, FORCE, PRESSURE, AND FLOW MEASUREMENTS

REFERENCES

1. 2. 3. 4. 5. 6. 7. Ramon Pallas-Areny and John G. Webster, Sensors and Signal Conditioning, John Wiley, New York, 1991. Dan Sheingold, Editor, Transducer Interfacing Handbook, Analog Devices, Inc., 1980. Walt Kester, Editor, 1992 Amplifier Applications Guide, Section 2, 3, Analog Devices, Inc., 1992. Walt Kester, Editor, System Applications Guide, Section 1, 6, Analog Devices, Inc., 1993. Harry L. Trietley, Transducers in Mechanical and Electronic Design, Marcel Dekker, Inc., 1986. Jacob Fraden, Handbook of Modern Sensors, Second Edition, Springer-Verlag, New York, NY, 1996. The Pressure, Strain, and Force Handbook, Vol. 29, Omega Engineering, One Omega Drive, P.O. Box 4047, Stamford CT, 06907-0047, 1995. (http://www.omega.com) The Flow and Level Handbook, Vol. 29, Omega Engineering, One Omega Drive, P.O. Box 4047, Stamford CT, 06907-0047, 1995. (http://www.omega.com) Ernest O. Doebelin, Measurement Systems Applications and Design, Fourth Edition, McGraw-Hill, 1990. AD7730 Data Sheet, Analog Devices, http://www.analog.com.

8.

9. 10.

4.14

You might also like

- Newnes Radio and Electronics Engineer's Pocket Book: Revised by the Editorial Staff of Electronics Today InternationalFrom EverandNewnes Radio and Electronics Engineer's Pocket Book: Revised by the Editorial Staff of Electronics Today InternationalNo ratings yet

- 5 Design and Implementation of Test of Audiometric Based On MicrocontrollerDocument12 pages5 Design and Implementation of Test of Audiometric Based On MicrocontrollerجعفرالشموسيNo ratings yet

- IoT BooksDocument5 pagesIoT Bookslatha_rajendran1No ratings yet

- NV 2002-07 Understanding and Using Norton Op-Amp ICs Parts 1-2Document9 pagesNV 2002-07 Understanding and Using Norton Op-Amp ICs Parts 1-2Dylan KomichekNo ratings yet

- Ship Shaft EarthingDocument12 pagesShip Shaft EarthingEdi LeeNo ratings yet

- Introduction To Sensors: Edited From: Sookram SobhanDocument52 pagesIntroduction To Sensors: Edited From: Sookram SobhanJongin KimNo ratings yet

- Eecs100 Eecs43 Lab7-StrainGaugeDocument5 pagesEecs100 Eecs43 Lab7-StrainGaugegilmeanualexmihai100% (1)

- Capacitor Decode PageDocument4 pagesCapacitor Decode PageManitNo ratings yet

- Measure Signals with a CRODocument3 pagesMeasure Signals with a CROImran Shaukat100% (1)

- Virtual WireDocument13 pagesVirtual WirePedro Nuno Sabugueiro OliveiraNo ratings yet

- Centroid Acorn CNC12 Probe Setup GuideDocument26 pagesCentroid Acorn CNC12 Probe Setup Guidexavitury95No ratings yet

- Analog MultiplexerDocument13 pagesAnalog MultiplexerSanjoy PandaNo ratings yet

- TestComplete Cookbook Sample ChapterDocument30 pagesTestComplete Cookbook Sample ChapterPackt PublishingNo ratings yet

- External Current Limiting CircuitDocument3 pagesExternal Current Limiting CircuitmikcomiNo ratings yet

- ESR Tester 096kDocument41 pagesESR Tester 096kFabrício AngieneNo ratings yet

- Oscilloscope Guide - How Oscilloscopes Work - BK PrecisionDocument7 pagesOscilloscope Guide - How Oscilloscopes Work - BK PrecisionmedhyalNo ratings yet

- Basic Mechatronics Slides PDFDocument60 pagesBasic Mechatronics Slides PDFdladidaNo ratings yet

- PS3381 1C2Document185 pagesPS3381 1C2Anonymous pCDWPnaNo ratings yet

- Nodal Method of Circuit AnalysisDocument2 pagesNodal Method of Circuit Analysismail2sgarg_841221144No ratings yet

- High Performance Portable BenchSupply, DIYDocument9 pagesHigh Performance Portable BenchSupply, DIYBryan Fantasía FuryNo ratings yet

- Labview Binary Conversion and Logic DesignDocument21 pagesLabview Binary Conversion and Logic DesignVarunSunilNo ratings yet

- Create a Spring-Pendulum System Simulation in LabVIEWDocument18 pagesCreate a Spring-Pendulum System Simulation in LabVIEWladevitaNo ratings yet

- Fx890pz1z1gr EngDocument126 pagesFx890pz1z1gr EngppinedabNo ratings yet

- Introduction to LABVIEW and Virtual Instruments for ECG Signal ProcessingDocument3 pagesIntroduction to LABVIEW and Virtual Instruments for ECG Signal ProcessingMohammad RizkiNo ratings yet

- 1 Electrical - and - Electronics - Measurment. McGraw Hill, 2013-413-651Document239 pages1 Electrical - and - Electronics - Measurment. McGraw Hill, 2013-413-651Andrea Acuña100% (1)

- Freeplay Energy Aid Products BrochureDocument28 pagesFreeplay Energy Aid Products BrochureFreeplay EnergyNo ratings yet

- 2 Field Effect Transistors (FETs)Document39 pages2 Field Effect Transistors (FETs)July ReyesNo ratings yet

- Schmitt Trigger PDFDocument16 pagesSchmitt Trigger PDFΝίκος Καλούσης100% (2)

- Capacitor Start Induction Motor - Its Phasor Diagram Characteristic & Applications - Circuit GlobeDocument9 pagesCapacitor Start Induction Motor - Its Phasor Diagram Characteristic & Applications - Circuit Globejeet kumarNo ratings yet

- ResistorDocument12 pagesResistorShantanu ChouguleNo ratings yet

- PIC Microcontroller Architecture and ApplicationsDocument8 pagesPIC Microcontroller Architecture and ApplicationsAli Baig100% (1)

- MyDAQ Lab Manual 2011Document25 pagesMyDAQ Lab Manual 2011ilet09No ratings yet

- PLCHAPTER07Document70 pagesPLCHAPTER07Bayu Ardiansyah100% (1)

- Cylinder Lubrication Developments and Lubricants Drain AnalysisDocument14 pagesCylinder Lubrication Developments and Lubricants Drain AnalysisAnto KattikkaranNo ratings yet

- Programmable ControllersDocument35 pagesProgrammable ControllersvasudevananishNo ratings yet

- Monitor & Control Greenhouse EnvironmentDocument2 pagesMonitor & Control Greenhouse EnvironmentTushara Chand100% (1)

- Atmega 328 PDocument344 pagesAtmega 328 PAlexandre100% (1)

- Sinusoids and PhasorsDocument65 pagesSinusoids and Phasorskamranzeb057No ratings yet

- Transistor BasicsDocument5 pagesTransistor BasicsMahesh KumbharNo ratings yet

- Lecture Notes For Analog ElectronicsDocument54 pagesLecture Notes For Analog Electronicsmom028No ratings yet

- Acd PDFDocument4 pagesAcd PDFkhyatichavdaNo ratings yet

- RadioShack ElectronicsDataBookDocument116 pagesRadioShack ElectronicsDataBookRobert Pérez Martinez100% (2)

- EE DiagramsDocument35 pagesEE DiagramsRai JeanNo ratings yet

- ElectronicsDocument218 pagesElectronicsmohan100% (1)

- Portable Operation FT-818 Go KitDocument54 pagesPortable Operation FT-818 Go Kit_0379victor_No ratings yet

- Solid State RelayDocument4 pagesSolid State RelayemacineNo ratings yet

- Basic Motor Formulas and Calculations: Rules of Thumb (Approximation)Document10 pagesBasic Motor Formulas and Calculations: Rules of Thumb (Approximation)Angga Prasetya KusumanataNo ratings yet

- Esr LCR r2d2Document6 pagesEsr LCR r2d2Toñi Lopez Vilches100% (1)

- DC Voltage RegulatorsDocument18 pagesDC Voltage RegulatorsAaisha TahirNo ratings yet

- BASIC OPERATING PRINCIPLES AND PILOT PROTOTYPE DEVELOPMENTDocument8 pagesBASIC OPERATING PRINCIPLES AND PILOT PROTOTYPE DEVELOPMENTtheodorakis017781No ratings yet

- Handbook of Ac Servo SystemsDocument41 pagesHandbook of Ac Servo SystemsJoas Alvarez PizarroNo ratings yet

- UPS Power 10 KVA, 20kva, 30 Kva, 40kva Redundant UPS - Uninterruptible Power SupplyDocument4 pagesUPS Power 10 KVA, 20kva, 30 Kva, 40kva Redundant UPS - Uninterruptible Power SupplyGamatronicNo ratings yet

- Transformer Less Power Supply CalculationDocument4 pagesTransformer Less Power Supply Calculationtuckla1No ratings yet

- Unit II Overview of Sensors, Transducers and Their Characteristics SpecificationsDocument29 pagesUnit II Overview of Sensors, Transducers and Their Characteristics SpecificationsPrema ElizabethNo ratings yet

- Electronic Pressure SensorsDocument5 pagesElectronic Pressure Sensorsmcbmcb159No ratings yet

- Strain Measurement and Analysis On The Load in Universal Testing MachineDocument7 pagesStrain Measurement and Analysis On The Load in Universal Testing MachineInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Electrical Strain Gauge and Wheatstone BridgesDocument14 pagesElectrical Strain Gauge and Wheatstone BridgesChetan B ArkasaliNo ratings yet

- Pressure TransducerDocument12 pagesPressure TransducerAsif BhatiNo ratings yet

- PRESENTATION ON STRAIN GAUGE MEASUREMENTDocument18 pagesPRESENTATION ON STRAIN GAUGE MEASUREMENTaslamhossainNo ratings yet

- Strain Gauge ProjectDocument18 pagesStrain Gauge ProjectAnkit GargNo ratings yet

- HPL HowTo PDFDocument9 pagesHPL HowTo PDFAndrew FongNo ratings yet

- TORQUE Administrators Guide PDFDocument238 pagesTORQUE Administrators Guide PDFEngr. AbdullahNo ratings yet

- 106 BDocument11 pages106 BEngr. AbdullahNo ratings yet

- 106 BDocument11 pages106 BEngr. AbdullahNo ratings yet

- Roll Torque UsersguideDocument13 pagesRoll Torque UsersguideEngr. AbdullahNo ratings yet

- Sys Design Course ContentsDocument4 pagesSys Design Course ContentsEngr. AbdullahNo ratings yet

- A10541191S19Document5 pagesA10541191S19Engr. AbdullahNo ratings yet

- Thesis3 Low Cost Monitoring System For Solar SystemDocument125 pagesThesis3 Low Cost Monitoring System For Solar SystemEngr. AbdullahNo ratings yet

- Thesis3 Low Cost Monitoring System For Solar SystemDocument125 pagesThesis3 Low Cost Monitoring System For Solar SystemEngr. AbdullahNo ratings yet

- Fault DiagnisisDocument8 pagesFault DiagnisisEngr. AbdullahNo ratings yet

- SyllabusDocument2 pagesSyllabusEngr. AbdullahNo ratings yet

- Experiences Setting Up A Rocks Based Linux Cluster: Tomas Lind en Helsinki Institute of Physics CMS Programme 08.12.2003Document29 pagesExperiences Setting Up A Rocks Based Linux Cluster: Tomas Lind en Helsinki Institute of Physics CMS Programme 08.12.2003Engr. AbdullahNo ratings yet

- A10541191S19Document5 pagesA10541191S19Engr. AbdullahNo ratings yet

- SyllabusDocument2 pagesSyllabusEngr. AbdullahNo ratings yet

- Ref - 2 Dorin Bica PDFDocument7 pagesRef - 2 Dorin Bica PDFEngr. AbdullahNo ratings yet

- Ref - 1 IEEE Committee Report PDFDocument12 pagesRef - 1 IEEE Committee Report PDFEngr. AbdullahNo ratings yet

- Cyber Essentials Requirements PDFDocument17 pagesCyber Essentials Requirements PDFEngr. AbdullahNo ratings yet

- L Ccompxe 2011 Sp1.11.339 Release Notes en USDocument39 pagesL Ccompxe 2011 Sp1.11.339 Release Notes en USEngr. AbdullahNo ratings yet

- Verification of BernoulliDocument2 pagesVerification of BernoulliEngr. AbdullahNo ratings yet

- RCI QuestionDocument4 pagesRCI QuestionEngr. AbdullahNo ratings yet

- Quickspecs: Microsoft Windows Server 2012 R2 Microsoft Windows Server 2012 R2Document18 pagesQuickspecs: Microsoft Windows Server 2012 R2 Microsoft Windows Server 2012 R2Engr. AbdullahNo ratings yet

- StanfordHPCConf Rocks PresoDocument59 pagesStanfordHPCConf Rocks PresoEngr. AbdullahNo ratings yet

- Cyber Essentials Requirements PDFDocument17 pagesCyber Essentials Requirements PDFEngr. AbdullahNo ratings yet

- Friction Factor ExperimentDocument3 pagesFriction Factor ExperimentEngr. AbdullahNo ratings yet

- DPHX Report G5Document13 pagesDPHX Report G5Engr. AbdullahNo ratings yet

- Friction Factor CalDocument13 pagesFriction Factor CalEngr. AbdullahNo ratings yet

- Friction Factor ExperimentDocument3 pagesFriction Factor ExperimentEngr. AbdullahNo ratings yet

- Computing Fourier Series and Power Spectrum With MATLAB: TEX PaperDocument15 pagesComputing Fourier Series and Power Spectrum With MATLAB: TEX PaperekhadhanaNo ratings yet

- FF Lab ReportDocument3 pagesFF Lab ReportEngr. AbdullahNo ratings yet

- Defined and Described: Figure 2. Transformer-Coupled SSR Figure 1. Hybrid SSRDocument5 pagesDefined and Described: Figure 2. Transformer-Coupled SSR Figure 1. Hybrid SSRpidmap2No ratings yet

- 83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsDocument12 pages83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsmaulikgadaraNo ratings yet

- IEEE STD C37.30.1 Estandar de Requisitos para Interruptores de Aire de AV AC para Nivelesmayores A 1000VDocument104 pagesIEEE STD C37.30.1 Estandar de Requisitos para Interruptores de Aire de AV AC para Nivelesmayores A 1000Valex100% (4)

- Engine & Transmission ToolsDocument45 pagesEngine & Transmission Toolsabduallah muhammad100% (1)

- CompoundingDocument5 pagesCompoundingMajester RigsNo ratings yet

- JUS StandardsDocument28 pagesJUS StandardsgarejkaNo ratings yet

- TV Compatibility with Verbatim HDDsDocument2 pagesTV Compatibility with Verbatim HDDsmirciulicacatyNo ratings yet

- Carimin Acacia Stability-Onhire Loading JerunDocument6 pagesCarimin Acacia Stability-Onhire Loading Jerunh2sbnj86b4No ratings yet

- Pull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLineDocument7 pagesPull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLinecnuneza4No ratings yet

- Valvula Selectora Trans.Document4 pagesValvula Selectora Trans.enriqueNo ratings yet

- New Schedule For Sunset Limited Benefits Passengers and Improves Financial PerformanceDocument3 pagesNew Schedule For Sunset Limited Benefits Passengers and Improves Financial Performanceapi-26433240No ratings yet

- A03_Grader_IRCD_InstructionsDocument2 pagesA03_Grader_IRCD_InstructionsClausulaLover24No ratings yet

- A Report On Workability of Fresh Concrete by Slump TestDocument5 pagesA Report On Workability of Fresh Concrete by Slump TestRishabhJain100% (1)

- ITILDocument16 pagesITILelenviegas82No ratings yet

- Exploratory Boring Spacing & DepthDocument24 pagesExploratory Boring Spacing & Depth18106 Mahmudur RahmanNo ratings yet

- 2 CAD Connecting Rod ForgingDocument56 pages2 CAD Connecting Rod ForgingIsrar EqubalNo ratings yet

- Operation Manual: Daikin Room Air ConditionerDocument92 pagesOperation Manual: Daikin Room Air ConditionerbenNo ratings yet

- 13 - Principles of Flight - QuestionsDocument80 pages13 - Principles of Flight - QuestionsEdgar Muñoz Fernández50% (4)

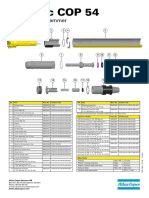

- 9853 1239 01 - COP 54 Service Poster - LOWDocument1 page9853 1239 01 - COP 54 Service Poster - LOWValourdos LukasNo ratings yet

- FH400 73158464 Pca-6.140Document431 pagesFH400 73158464 Pca-6.140IgorGorduz100% (1)

- Reinforced ConcreteDocument13 pagesReinforced ConcreteRenukadevi Rpt17% (18)

- Antena Eh para 10 MetrosDocument3 pagesAntena Eh para 10 Metros10sd156No ratings yet

- Sample Purchase Specification For ClariflocculatorDocument1 pageSample Purchase Specification For Clariflocculatorcontactdevansh1174No ratings yet

- Civil Engineering Reference BooksDocument2 pagesCivil Engineering Reference Booksdevbrat boseNo ratings yet

- Motores SumergiblesDocument68 pagesMotores SumergiblescyberespiaNo ratings yet

- Huawei EHuawei - Erelay - Solution - OverviewRelay Solution OverviewDocument31 pagesHuawei EHuawei - Erelay - Solution - OverviewRelay Solution Overviewtariq8283% (6)

- Interaction & Bank EffectDocument6 pagesInteraction & Bank EffectAkash KandwalNo ratings yet

- Communication System (LC-ECE204G) LAB ManualDocument54 pagesCommunication System (LC-ECE204G) LAB ManualBindia HandaNo ratings yet

- Microcontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiDocument4 pagesMicrocontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiTarun SinghNo ratings yet

- CED 426 Quiz # 2 SolutionsDocument26 pagesCED 426 Quiz # 2 SolutionsMary Joanne AninonNo ratings yet