Professional Documents

Culture Documents

In0126 GB PF 2008 05 B

Uploaded by

Cuong HoangOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

In0126 GB PF 2008 05 B

Uploaded by

Cuong HoangCopyright:

Available Formats

Solutions for pipe and fitting applications

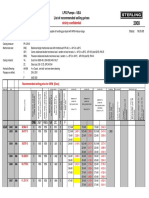

Grade Colour Designation MFR Tensile stress Tensile Charpy impact Charpy impact Typical applications

Grade Designation Type Colour MFR Density Tensile stress Tensile Corresponding Typical applications notched

(230°C / 2.16 kg) at yield modulus notched (+23°C)

(190°C / 5.0 kg) at yield modulus (-20°C)

g / 10 min Kg/m3 MPa MPa stripe grade g / 10 min MPa MPa kJ / m² kJ / m²

Polyethylene Polypropylene

Pressure Pipes Homopolymer

BorSafe™ HE3498-LS (orange) Industrial, pressure & non-pressure pipe systems,

Beta(ß)-PP™ BE60-7032 Grey PP-H 0.3 30 1300 50 5

BorSafe™ HE3496-LS (yellow) Drinking water, gas, sheets, profiles

BorSafe™ HE3490-LS PE100 HDPE Black 0.25 959 25 1100

BorSafe™ HE3495-LS (blue) sewage, industrial Industrial, non-pressure pipe systems,

BE50 Natural PP-H 0.3 36 1650 7 2

BorSafe™ HE3497-LS (brown) sheets, profiles

BorSafe™ HE3492-LS PE100 HDPE Orange 0.30 951 25 1100 Gas Industrial, non-pressure pipe systems,

BE50-7032 Grey PP-H 0.3 36 1650 7 2

sheets, profiles

BorSafe™ HE3494-LS PE100 HDPE Dark-blue 0.30 951 25 1100 Drinking water

HA104E Natural PP-H 0.8 35 1490 4.5 Soil & waste pipe systems

Injection moulded PE100

BorSafe™ HE3490-IM PE100 HDPE Black 0.55 959 25 1100 Block Copolymer

pressure fittings

PE100 for demanding Underground drainage & sewage, soil & waste,

BorSafe™ HE3490-LS-H PE100 HDPE Black 0.25 959 25 1100 BorECO™ BA222E Natural PP-HM** 0.3 32 1900 50 4

installation conditions solid wall systems

PE100 for demanding Underground drainage & sewage, soil & waste,

BorECO™ BA212E Natural PP-HM** 0.3 31 1700 50 5

BorSafe™ HE3494-LS-H PE100 HDPE Dark-blue 0.30 951 25 1100 installation conditions, solid & structured wall systems

drinking water Underground drainage & sewage,

BorECO™ BEC5015 Natural PP-B 0.3 30 1500 70 7

BorSafe™ HE3476-LS (yellow) structured wall.

Drinking water, gas, Underground drainage & sewage,

BorSafe™ HE3470-LS PE80 HDPE Black 0.30 956 22 1000 BorSafe™ HE3474-LS (blue) BA204E Natural PP-B 0.8 27 1100 20 4

sewage, industrial soil & waste systems

BorSafe™ HE3477-LS (brown)

Underground drainage & sewage,

Drinking water, gas, BEC5012 Natural PP-B 0.3 28 1300 70 5

BorSafe™ ME3446 (yellow) soil & waste systems

BorSafe™ ME3440 PE80 MDPE Black 0.85 951 19 800 sewage, industrial

BorSafe™ ME3445 (blue) BB412E Natural PP-B 1.3 28 1300 25 5 Cable conduit pipes

& PE80 pressure fittings

BorSafe™ ME3441 PE80 MDPE Yellow 0.80 944 19 800 Gas Injection moulding of compression fittings for

BA160E-8229 Black PP-B 0.3 30 1300 50 5

BorSafe™ ME3444 PE80 MDPE Blue 0.80 947 19 800 Drinking water pressure pipes, irrigation

Random Copolymer

RA130E-8427*** Grey PP-R 0.3 25 900 20 2 Plumbing & heating, industrial

RA130E-1498*** White PP-R 0.3 25 900 20 2 Plumbing & heating

Beta-PPR™ RA7050 Steel-grey PP-RCT 0.3 25 900 40 2 Plumbing & heating

Grade Colour MFR Density PEX pipe standards Resin form Typical applications Beta-PPR™ RA7050-GN Green PP-RCT 0.3 25 900 40 2 Plumbing & heating

(190°C / 21.6 kg)

g / 10 min kg / m³ Filled Compound

BEC50T30 Natural Modified PP 0.6 28 3100 10 2.5 Profiles

Crosslinkable Polyethylene PEX for Pressure Pipes

Pipe Coating

Peroxide (PEX-a)

Borcoat™ BB108E-1199 White PP-B 0.9 25 1200 25 3 UV stabilised white top coat

BorPEX™ HE1878 Natural 3 955 EN ISO15875, DIN16892, ASTM F 876 Powder Plumbing & heating, gas, drinking water, industrial

Borcoat™ BB700E-7032 Grey Modified PP 1.6 25 1400 Thermal insulation material

BorPEX™ HE1878-E Natural 10 951 EN ISO15875, DIN16892, ASTM F 876 Powder Plumbing & heating, gas, drinking water, industrial

Borcoat™ GA700E-7032 Grey Syntactic PP 1.0 11 2000 Thermal insulation material

BorPEX™ HE2550 Natural 6 956 EN ISO15875, DIN16892, ASTM F 876 Powder Plumbing & heating, gas, drinking water, industrial

Borcoat™ EA165E Natural Modified PP 0.3 18 800 (±0°C) 75 65 Polymer for subsea field joints

BorPEX™ HE2591 Natural 10 944 EN ISO15875, DIN16892, ASTM F 876 Powder Plumbing & heating, gas, drinking water, industrial

Grafted adhesive for PP coating systems

Irradiation (PEX-c) Borcoat™ BB127E Natural Grafted PP 8 22 1100 15 8

up to 155°C

BorPEX™ HE2590 Natural 8.5 944 EN ISO15875, DIN16892, ASTM F 876 Pellets Plumbing & heating, gas, drinking water, industrial

BA202E Natural PP-B 0.3 28 1300 50 4 .5 Foam manufacture for thermal insulation

BorPEX™ HE2595 Black 7.5 955 EN ISO15875, DIN16892, ASTM F 876 Pellets Plumbing & heating, gas, drinking water, industrial

Borcoat™ BA213E Natural PP-B 0.3 31 1600 50 5 Thermal insulation material

BorPEX™ ME2592 Natural 10 936 DIN16894 Pellets Plumbing & heating, industrial Heavy weight coating for subsea

Borcoat™ MA115E Natural Modified PP 1.6 16

and special applications

Daploy™ WB130HMS Natural Modified PP 2.1 40 2000 3 1 Foam manufacture for thermal insulation

* Typical value: 190°C/5.0 kg

** PP-HM = new class of high modulus PP-B acc. to EN 1852-1

*** Other coloured compounds are available

Grade Colour MFR Density Resin form Typical applications

(190°C / 2.16 kg) Test Methods Grade Peel strength Peel strength

g / 10 min kg / m³

Designation for PE Borealis and Borouge have a broad product portfolio for various

adhesion @ 23°C adhesion @ 110°C

Polyethylene Designation for PEX pressure and non-pressure pipe applications.

Borcoat™ ME0420 200 40 For detailed information, please contact our local sales

IN0126/GB PF 2008 05 B

Steel Pipe Coating MFR (230°C / 2.16 kg)

MFR (190°C / 5.0 kg) representatives or visit us at www.borealisgroup.com / pipe

Borcoat™ ME0433 150 40

Borcoat™ HE3450 Black 2* 952 Pellets Bimodal HDPE top coat, up to 85°C MFR (190°C / 21.6 kg) and www.borouge.com

Borcoat™ BB127E >200 40

UV and thermal stabilised bimodal top coat for use with Density

Borcoat™ HE3453 Natural 2* 942 Pellets

colourable pipe coating systems other than black Tensile stress at yield

Tensile modulus

Borcoat™ ME0420 Natural 1.3 934 Pellets Grafted adhesive for HDPE systems Peel strength

Borcoat™ ME0433 Natural 5 934 Powder Grafted adhesive for HDPE systems Charpy impact, notched (+23°C)

Borecene™ RM7405 Black 6 940 Powder Rough coating and repairs Charpy impact, notched (-20°C)

Polypropylene pipe Polyethylene pipe

solutions solutions

Solutions for pipe and fitting applications

Solutions for

Pipe and fitting applications Borealis – a leading, innovative plastics provider

About Borealis Borealis has pioneered the development of stiff PP

Borealis is a leading provider of innovative, value grades for sewage and storm water pipes (BorECO™)

BorECO™ BorSafe™ creating plastics solutions. With more than 40 years of

experience in polyolefins and using our unique Borstar®

and “low sag” PE grades for large diameter PE pipes

(BorSafe™). In hot and cold water systems the widest

technology, we focus on the infrastructure, automotive range of PEX and PPR materials (including BorPEX™

Economical solutions with foresight Tailor made PE pressure pipe products

and advanced packaging markets across Europe, and the new Beta-PPR™) provide plastics solutions in

for non-pressure pipe systems from our proprietary bimodal process

the Middle East and Asia, through Borouge, our joint virtually all European plumbing and heating markets.

venture with the Abu Dhabi National Oil Company Steel pipe coating solutions are also addressed with

(ADNOC). Our production facilities, innovation centres the widest range of PE and PP materials and adhesives

and service centres work with customers in more (Borcoat™), which have been used in many of the

than 120 countries to provide materials that make world’s largest oil and gas pipeline projects. Through

an essential contribution to society and sustainable foresight and focus on customer needs, Borealis

development. We are committed to the principles of continues to provide innovative solutions for the pipe

Responsible Care® and to leading the way in 'Shaping and fittings industry that add real value throughout

the Future with Plastics'™. the value chain. We also know the high value that

our customers in the pipe and fittings industry place

on product consistency and processability. We pride

Borealis Pipe Systems ourselves on the performance of our products, and

Borealis is a leading global supplier of advanced through ongoing investment in upgrades and new

polyolefin plastics solutions for the pipe industry. plant programmes, we continue to set new records

Through more than 30 years of close dialogue with for output efficiency and product reliability. Borealis

customers and other stakeholders, we have developed believes that responsiveness is the foundation of

a broad and innovative product and service portfolio.

Beta-PPR™ BorPEX™

fruitful customer partnerships. We ensure this through

The applications cover water and gas distribution, highly skilled and experienced technical, marketing

waste and sewage disposal, chemical and industrial and product development people, located in Borealis

Unique high performance of next generation One stop shop for experience and projects, in-house plumbing and heating and oil & hubs across Europe: Central Europe, Scandinavia

polypropylene for pressure pipe systems innovation in cross-linked polyethylene gas exploration and transportation. Borealis believes and Finland. In addition we have a strong sales force

that customer-driven innovation is the only way to around Europe and close cooperation with our joint

achieve and sustain progress. In the pipe industry, venture Borouge in the Middle East and Asia.

Disclaimer The information contained herein is to our knowledge accurate and reliable as compliance with performance indicators, conformity to samples or models, non-infringement or

of the date of publication. Borealis extends no warranties and makes no representations otherwise), nor is protection from any law or patent to be inferred. Insofar as products supplied

as to the accuracy or completeness of the information contained herein, and assumes no by Borealis or its subsidiary companies are used in conjunction with third party materials, it is

responsibility regarding the consequences of its use or for any printing errors. It is the customer’s the responsibility of the customer to obtain all necessary information relating to the third party

responsibility to inspect and test our products in order to satisfy himself as to the suitability of materials and ensure that Borealis’ products when used together with these materials are

the products for the customer’s particular purpose. The customer is also responsible for the suitable for the customer’s particular purpose. No liability can be accepted in respect of the

appropriate, safe and legal use, processing and handling of our products. Nothing herein shall use of Borealis’ products in conjunction with other materials. The information contained herein

constitute any warranty (express or implied, of merchantability, fitness for a particular purpose, relates exclusively to our products when not used in conjunction with any third party materials.

Borstar is a registered trademark of Borealis A / S.

BorECO, BorSafe, Beta-PPR, BorPEX, Borcoat, Shaping the Future with Plastics, Borecene, Beta(ß)-PP and Daploy are trademarks of Borealis A / S.

Borcoat™ PP Borcoat™ PE

© 2008 Borealis AG

Complete coating system solution Compatible, tested and proven systems

under extreme conditions with proven for multi-layer pipe coating

track records Borealis AG I IZD Tower I Wagramerstrasse 17-19 A-1220 Vienna I Austria

Tel +43 1 22 400 000 I Fax +43 1 22 400 333 I www.borealisgroup.com

You might also like

- Polypropylene 4820WZ: DescriptionDocument1 pagePolypropylene 4820WZ: DescriptionChivuAlexandruNo ratings yet

- Polypropylene 4720WZ: DescriptionDocument1 pagePolypropylene 4720WZ: DescriptionChivuAlexandruNo ratings yet

- Parker Technical Detail 3501E-N PDFDocument32 pagesParker Technical Detail 3501E-N PDFlaxmanNo ratings yet

- Iocl PP RaffiaDocument1 pageIocl PP RaffiaLaxman AhirNo ratings yet

- SPHBA - Motorsports Clean Break Couplings enDocument12 pagesSPHBA - Motorsports Clean Break Couplings enAlper SakalsizNo ratings yet

- PP 1-SERIES METHACRYLATE ADHESIVE TECH DATADocument3 pagesPP 1-SERIES METHACRYLATE ADHESIVE TECH DATAJoanna SąsaraNo ratings yet

- HPM Steel For MoldDocument15 pagesHPM Steel For MoldcadcamtaiNo ratings yet

- Spectrum SFBCDocument1 pageSpectrum SFBCAllen RichardNo ratings yet

- Logo Labels CatalogueDocument20 pagesLogo Labels CatalogueGareth PriceNo ratings yet

- Description: Polypropylene 8573Document1 pageDescription: Polypropylene 8573ChivuAlexandruNo ratings yet

- Pipe Design Basic MaterialDocument1 pagePipe Design Basic MaterialpandiangvNo ratings yet

- Polypropylene 4944CWZ: DescriptionDocument1 pagePolypropylene 4944CWZ: DescriptionChivuAlexandruNo ratings yet

- Series 450 - JOUCOMATIC Tie Rod Cylinders Type PESDocument2 pagesSeries 450 - JOUCOMATIC Tie Rod Cylinders Type PESIrham Lazuardi100% (1)

- Sterling Fluid Systems: LPG Pumps - UEA List of Recommended Selling PricesDocument3 pagesSterling Fluid Systems: LPG Pumps - UEA List of Recommended Selling Pricesrebelde1986No ratings yet

- Propor Hc-rev 3aDocument4 pagesPropor Hc-rev 3abuattugasmetlitNo ratings yet

- Fan Coil Connection Hoses Data SheetDocument2 pagesFan Coil Connection Hoses Data SheetROBERTO RAFAELNo ratings yet

- DIN 28091-2 GasketDocument20 pagesDIN 28091-2 Gasketengfaridmalk100% (1)

- Laying PVC pipes and manholes for underground drainageDocument1 pageLaying PVC pipes and manholes for underground drainagevinoj chandranNo ratings yet

- Doniflon 2010: Properties Appropriate Industries & ApplicationsDocument2 pagesDoniflon 2010: Properties Appropriate Industries & Applicationsflasher_for_nokiaNo ratings yet

- Tuboscope Coatings Spec SheetDocument2 pagesTuboscope Coatings Spec SheetEduard Gadzhiev67% (3)

- PTE800 v0119Document2 pagesPTE800 v0119krishnenduNo ratings yet

- Make Your Life Better With: BuwonDocument19 pagesMake Your Life Better With: BuwonhuynhthingocthuNo ratings yet

- Chemical Compatibility GuideDocument15 pagesChemical Compatibility GuidewaltliewNo ratings yet

- MSKPN-HP SeriesDocument1 pageMSKPN-HP SeriesHANIF AKBARNo ratings yet

- Castrol Product Training: It'S More Than Just Oil. It'S Liquid EngineeringDocument106 pagesCastrol Product Training: It'S More Than Just Oil. It'S Liquid EngineeringFerry Marketing SekafuNo ratings yet

- Catalog: Heating Systems Domestic Water Supply Systems Sewer SystemsDocument23 pagesCatalog: Heating Systems Domestic Water Supply Systems Sewer SystemsIndranil SarkarNo ratings yet

- TM Series 3" & 4" A1: Water Meters Commercial Grade MetersDocument1 pageTM Series 3" & 4" A1: Water Meters Commercial Grade Metersjonathan Reano MendozaNo ratings yet

- Brazing, Soldering, Torches & GasesDocument11 pagesBrazing, Soldering, Torches & GasesMusic NetNo ratings yet

- Heraform®: Acetal CopolymerDocument3 pagesHeraform®: Acetal CopolymerDiegoTierradentroNo ratings yet

- BrederoShaw PDS 3LPPDocument2 pagesBrederoShaw PDS 3LPPdipankarbasakNo ratings yet

- Valve Cross SectionDocument1 pageValve Cross SectionJaya PrakashNo ratings yet

- Petg TDS1Document1 pagePetg TDS1CosminNo ratings yet

- Carte PrecontraintTX30 GBDocument2 pagesCarte PrecontraintTX30 GBManjunath ShettyNo ratings yet

- Paint system for above ground pipe field weldsDocument2 pagesPaint system for above ground pipe field weldsSam JoseNo ratings yet

- HDPE Jacketed Pre-Insulated Piping System FeaturesDocument2 pagesHDPE Jacketed Pre-Insulated Piping System FeaturesVivek ShuklaNo ratings yet

- Double ball automatic air valvesDocument2 pagesDouble ball automatic air valvesMohamed RaafatNo ratings yet

- Phe M3Document2 pagesPhe M3Vishnu Vardhan . CNo ratings yet

- Lukor HXF 4810 H High Density Polyethylene Film PropertiesDocument1 pageLukor HXF 4810 H High Density Polyethylene Film Propertiesjoseito741258No ratings yet

- F.6 Alfagomma CatalogueDocument5 pagesF.6 Alfagomma CatalogueStanislaus NurcahyoNo ratings yet

- Plastic Mold Steels High Quality: HI-PM SeriesDocument6 pagesPlastic Mold Steels High Quality: HI-PM SeriestaknevNo ratings yet

- 4Th Main RoadDocument1 page4Th Main RoadMani CadNo ratings yet

- BPL Englisch 2019Document32 pagesBPL Englisch 2019cloantafNo ratings yet

- EFRHDocument5 pagesEFRHJamin SmtpngNo ratings yet

- TRELLEBORG FLUID HANDLING SOLUTIONSDocument8 pagesTRELLEBORG FLUID HANDLING SOLUTIONSAtmoterra AtmoterraNo ratings yet

- FRP Piping SpecificationDocument4 pagesFRP Piping SpecificationPetrNo ratings yet

- Fusion Welding System: Wavin PPRDocument2 pagesFusion Welding System: Wavin PPRvinayak abhaleNo ratings yet

- Seriesgp 2000Document1 pageSeriesgp 2000JJMEDINA REUNIONESNo ratings yet

- Tool Steel MMDocument3 pagesTool Steel MMBhushan UNo ratings yet

- Polypropylene Sheet Extrusion Data SheetDocument1 pagePolypropylene Sheet Extrusion Data SheetChivuAlexandruNo ratings yet

- Low melting polypropylene for medical filmsDocument1 pageLow melting polypropylene for medical filmsChivuAlexandruNo ratings yet

- Sasol HNR100Document2 pagesSasol HNR100brandon abella gutierrezNo ratings yet

- SUBMERSUBAL PUMP SeriesDocument1 pageSUBMERSUBAL PUMP SeriesYehude Guillen RomeroNo ratings yet

- Peters ELPEGUARD SL1301Document9 pagesPeters ELPEGUARD SL1301Faqrie AziziNo ratings yet

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- 37 Chinese Art Wide ScreenDocument37 pages37 Chinese Art Wide ScreenCuong HoangNo ratings yet

- Cuo NG: Signatu Re Not Verified!Document13 pagesCuo NG: Signatu Re Not Verified!Cuong Hoang100% (1)

- High Density Polyethylene Pipe SystemsDocument10 pagesHigh Density Polyethylene Pipe SystemsCuong Hoang100% (1)

- uPVC PipesDocument23 pagesuPVC PipesCuong Hoang50% (2)

- Quy Luat Tu NhienDocument23 pagesQuy Luat Tu NhienCuong HoangNo ratings yet

- ROWELD Catalogue 2008 DraftDocument68 pagesROWELD Catalogue 2008 DraftCuong HoangNo ratings yet

- Resistance To Chemical - Phan Ung Voi Cac Loai HoaDocument5 pagesResistance To Chemical - Phan Ung Voi Cac Loai HoaCuong Hoang100% (1)

- Resistance To Chemical - Phan Ung Voi Cac Loai HoaDocument5 pagesResistance To Chemical - Phan Ung Voi Cac Loai HoaCuong Hoang100% (1)

- Cuo NG: Signatu Re Not Verified!Document40 pagesCuo NG: Signatu Re Not Verified!Cuong HoangNo ratings yet

- Installation - Huong Dan Lap Dat Ong PPRDocument6 pagesInstallation - Huong Dan Lap Dat Ong PPRCuong HoangNo ratings yet

- Calendar Aubade 2009Document13 pagesCalendar Aubade 2009Cuong Hoang75% (4)

- Bang Gia PVC BMDocument1 pageBang Gia PVC BMCuong Hoang100% (1)

- PPR Catalogue ResizeDocument16 pagesPPR Catalogue ResizeCuong Hoang100% (1)

- (Physics) 2010 TSSM Unit 4 ExamDocument37 pages(Physics) 2010 TSSM Unit 4 ExamakashNo ratings yet

- Finals-Fluid Mech PrintDocument5 pagesFinals-Fluid Mech PrintJune CostalesNo ratings yet

- Drilling Chokes BrochureDocument12 pagesDrilling Chokes BrochureAshok SureshNo ratings yet

- Climate Change Information KitDocument66 pagesClimate Change Information Kitnephila100% (2)

- Void Former SD Filcor Cordek RampDocument1 pageVoid Former SD Filcor Cordek RampShamaNo ratings yet

- Application of Taguchi Method to Optimize Electro-Cyclone Separator ParametersDocument30 pagesApplication of Taguchi Method to Optimize Electro-Cyclone Separator ParametersAniruddha DasNo ratings yet

- Ticona Molded Plastic Gear DesignDocument6 pagesTicona Molded Plastic Gear DesignpolumathesNo ratings yet

- D473 - Sedimetnos Por ExtracciónDocument6 pagesD473 - Sedimetnos Por ExtracciónCarito LopezNo ratings yet

- Foundation Ch.61Document45 pagesFoundation Ch.61nelsonsainzNo ratings yet

- PET Resistance To H2O2Document2 pagesPET Resistance To H2O2JoanBensonNo ratings yet

- Dr. Fixit Modern Tile Adhesive: DescriptionDocument3 pagesDr. Fixit Modern Tile Adhesive: DescriptionkiranNo ratings yet

- Msds NaoclDocument6 pagesMsds NaoclJuan ChristopherNo ratings yet

- J. Chem. SOC.(A), 1971: Single-crystal Raman and Far-infrared Spectra of Tetrakis(thiourea)-nickel(ii) DichlorideDocument3 pagesJ. Chem. SOC.(A), 1971: Single-crystal Raman and Far-infrared Spectra of Tetrakis(thiourea)-nickel(ii) DichlorideFernandaIbarraVázquezNo ratings yet

- Physics of Aqueous Phase Evolution in Plutonic EnvironmentsDocument11 pagesPhysics of Aqueous Phase Evolution in Plutonic Environmentsjunior.geologia100% (1)

- Novaliches High School: 2. Dots in LEDS Represent A. Valence Electrons. B. Protons. C. Neutrons. D. ElectronsDocument4 pagesNovaliches High School: 2. Dots in LEDS Represent A. Valence Electrons. B. Protons. C. Neutrons. D. ElectronsExtremelydarknessNo ratings yet

- Oxford Quantum Theory Lecture NotesDocument92 pagesOxford Quantum Theory Lecture Notest ElderNo ratings yet

- Calculations and units in analytical chemistryDocument17 pagesCalculations and units in analytical chemistryangelaNo ratings yet

- Mil DTF 5541fDocument12 pagesMil DTF 5541fMarcos PerezNo ratings yet

- Types of Concrete Joints in Building StructuresDocument2 pagesTypes of Concrete Joints in Building StructuresMuhafeez GoolabNo ratings yet

- Furnaces and BoilersDocument23 pagesFurnaces and BoilersPraveen VaratharajanNo ratings yet

- Products For QPCR and QRT-PCRDocument32 pagesProducts For QPCR and QRT-PCRcostajac18882No ratings yet

- 20) Complexometric TitrationDocument47 pages20) Complexometric TitrationCzarina Angelli AnastacioNo ratings yet

- Design of Compression MembersDocument22 pagesDesign of Compression MembersChee Fong MakeNo ratings yet

- HW Hydraulics (setII) Ch3Document4 pagesHW Hydraulics (setII) Ch3Zairah Francisco100% (1)

- Earth Pressure Calculation Web PDFDocument273 pagesEarth Pressure Calculation Web PDFKumaranNo ratings yet

- Gmaw STTDocument4 pagesGmaw STTAnonymous 0rt9KWmNNo ratings yet

- Specific HeatDocument2 pagesSpecific HeatVanessa Christonette SistosoNo ratings yet

- Ion ExchangeDocument25 pagesIon ExchangeArie Ikhwan SaputraNo ratings yet

- ATP Synthesis and Oxidative Phosphorylation ExplainedDocument5 pagesATP Synthesis and Oxidative Phosphorylation Explainedkman0722No ratings yet

- (Semiconductors and Semimetals 56) Robert Hull and John C. Bean (Eds.) - Germanium Silicon - Physics and Materials-Elsevier, Academic Press (1998)Document459 pages(Semiconductors and Semimetals 56) Robert Hull and John C. Bean (Eds.) - Germanium Silicon - Physics and Materials-Elsevier, Academic Press (1998)Domenico BarillariNo ratings yet