Professional Documents

Culture Documents

b5 Rear Drive Shaft

Uploaded by

Tanee BoonmalertOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

b5 Rear Drive Shaft

Uploaded by

Tanee BoonmalertCopyright:

Available Formats

42-132

Rear drive shaft, servicing

Drive shafts, removing and installing

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required VAG 1383 A Engine/transmission jack Removing - Remove hex bolt for drive shaft.

- Remove heat shield for drive shaft -arrows-. - Unbolt drive shaft from drive flange.

42-133

- Remove hex key head bolt -1-. - Disconnect ABS vehicle speed sensor -2- out from wheel bearing housing. - Disconnect connector behind Three Way Catalytic Converter (TWC) and remove rear part of exhaust system.

- Place transmission jack e.g. VAG 1383 A under control arm. - Raise control arm slightly. - Drive drive shaft out of hub with a plastic head hammer if necessary. - Remove drive shaft. Installing Install in reverse order.

42-134

Tightening torques: Drive shaft to wheel hub Drive shaft to flanged shaft 5 Page 42-138 , item 2 Page 42-138 , item

Protective plate to rear final drive 23 Nm

42-135

Drive shaft with constant velocity joint, servicing

Special tools, workshop equipment, test and measuring appliances and aux. items required VW 401 Thrust plate VW 402 Thrust plate VW 408 A Press tool VW 411 Press tool VW 447 H Press plate VW 454 Press piece

42-136

Special tools, workshop equipment, test and measuring appliances and aux. items required VW 161 A Circlip pliers VAG 1331 Torque wrench VAG 1332 Torque wrench VAG 1682 Tension clamp T10065 Assembly device

42-137

Grease quantity and type Constant velocity joints are packed with grease G 000 603: Grease Outer joint diametermm 89 Inner joint 88 90 40 50 of total in:

Total amount Joint Boot [g] 90 [g] 40 [g] 50

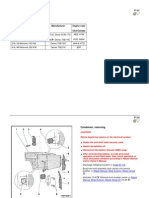

1 - Outer constant velocity joint Only replace complete Removing Fig. 1

Installing: drive onto shaft on to stop with plastic hammer

42-138

2 - Hex bolt Tightening torque: Changed to hex key head bolt Bolt M14: 115 Nm and turn 180 Bolt M16: 190 Nm and turn 180 further further

Vehicle must be standing on ground when tightening Replace each time after removing 3 - Protective boot Check for tears and chafing 4 - Hose clip Replace 5 - Multi-point socket head bolt M 8 x 48; 40 Nm 6 - Plate

42-139

7 - Protective boot for inner constant velocity joint Check for tears and chafing Drive off with drift Before installing on constant velocity joint, coat sealing surface with D-3 8 - Circlip Always replace Remove and install with VW 161 a 9 - Inner constant velocity joint Only replace complete Pressing off Pressing on 10 - Gasket Replacing. Pull off protective foil and stick onto joint. 11 - Circlip Fig. Fig. 2 3

42-140

12 - Drive shaft 13 - Circlip Not installed to all drive shafts Always replace Remove and install with VW 161 a 14 - Dished washer Outer diameter (concave side) contacts thrust washer 15 - Thrust washer 16 - Circlip Always replace Insert in shaft groove

42-141

Fig. 1

Pressing off outer constant velocity joint

- Clamp drive shaft in vice using vice clamps. - Remove clamp and slide back boot. - Drive constant velocity joint off drive shaft using drift -A-. Drive must be applied exactly on star of constant velocity joint. Driving joint on - Drive onto shaft with plastic hammer until securing ring engages. Fig. 2 Notes: First drive boot off with drift Pressing off inner constant velocity joint

42-142

Fig. 3

Pressing on inner constant velocity joint

- Press on joint up to stop. - Insert circlip. Note: Chamfer on inner diameter of ball hub (splines) must face the contact shoulder on the drive shaft.

You might also like

- Passat B5 - Rear Brake DiscDocument28 pagesPassat B5 - Rear Brake DiscBusu CypNo ratings yet

- VW Passat B5 42-1 Rear Axle, FFDocument19 pagesVW Passat B5 42-1 Rear Axle, FFJosé Luis Ormeño100% (1)

- b5 45-06Document15 pagesb5 45-06Tanee BoonmalertNo ratings yet

- VW Passat B5 87-132 AC Refrigerant SysDocument9 pagesVW Passat B5 87-132 AC Refrigerant SysJosé Luis Ormeño100% (1)

- Omegas Plus: Software ManualDocument40 pagesOmegas Plus: Software ManualВіктор ЛялькаNo ratings yet

- VW Passat B5 58-1 Rear DoorDocument26 pagesVW Passat B5 58-1 Rear DoorJosé Luis Ormeño100% (2)

- 17 Engine and Emission ControlDocument38 pages17 Engine and Emission ControlJoaoBorgesNo ratings yet

- PAL MaintenanceDocument4 pagesPAL MaintenanceLucas PrimaniNo ratings yet

- MR393CLIO5-Mechanisms and AccessoriesDocument184 pagesMR393CLIO5-Mechanisms and AccessoriesanghilaNo ratings yet

- G35 & 350Z Rev2 Clutch Bracket InstructionsDocument33 pagesG35 & 350Z Rev2 Clutch Bracket InstructionsChelsey VezinaNo ratings yet

- BMW E23 24 28 OdogearDocument9 pagesBMW E23 24 28 OdogearporkfaceNo ratings yet

- 11 31 001replacing Camshafts E90 320DDocument11 pages11 31 001replacing Camshafts E90 320DAdrian DoruNo ratings yet

- VW Passat b6 Brake Systems EngDocument93 pagesVW Passat b6 Brake Systems EngDanyBobNo ratings yet

- Timing Cover 190EDocument8 pagesTiming Cover 190ESergio Belmar CrisostoNo ratings yet

- Assembly Removal and Installation: G58 Manual TransmissionDocument9 pagesAssembly Removal and Installation: G58 Manual TransmissionPannie Ng100% (1)

- WAPU Overhaul BZBDocument8 pagesWAPU Overhaul BZBNedim ErkocevicNo ratings yet

- Kawasaki Z1000 - 2009 - Manual de Usuario ENGDocument165 pagesKawasaki Z1000 - 2009 - Manual de Usuario ENGParts JkawaNo ratings yet

- Technical Note 5008A KXX, and K4J or K4M or K9K Alternator Pulley: ReplacementDocument6 pagesTechnical Note 5008A KXX, and K4J or K4M or K9K Alternator Pulley: ReplacementShahrol Madun100% (1)

- Montare Distributie Audi A6 C7 2.0 TdiDocument12 pagesMontare Distributie Audi A6 C7 2.0 TdiEduard ŞtefanNo ratings yet

- Air Condition (AEH+AKL+AGN+AGU+APN+AQY+AGP+AQM+AGR+ALH)Document5 pagesAir Condition (AEH+AKL+AGN+AGU+APN+AQY+AGP+AQM+AGR+ALH)Melissa WillisNo ratings yet

- b6 70 PDFDocument81 pagesb6 70 PDFVlad ZahiuNo ratings yet

- Side Impact Sensor 8212 C Pillar Removal and InstallationDocument2 pagesSide Impact Sensor 8212 C Pillar Removal and InstallationMichael HernandezNo ratings yet

- Xantia - Function - Transponder Operated Anti-Theft DeviceDocument6 pagesXantia - Function - Transponder Operated Anti-Theft DeviceArturHeiseNo ratings yet

- VW Passat B5 21 (38) Charge Air SystemDocument47 pagesVW Passat B5 21 (38) Charge Air SystemJosé Luis OrmeñoNo ratings yet

- Volvo 740 AC - r12 R134a RetrofitDocument18 pagesVolvo 740 AC - r12 R134a RetrofitmazacotesNo ratings yet

- AC Pressure Chart R-134a Temperature Pressure ChartDocument3 pagesAC Pressure Chart R-134a Temperature Pressure ChartJoseph Tchagou PoumoNo ratings yet

- VW Passat b5 Maintenance EngDocument189 pagesVW Passat b5 Maintenance EngMarian NedelcuNo ratings yet

- 406Document5 pages406alkaline99No ratings yet

- Power Plant: LubricationDocument4 pagesPower Plant: LubricationCarmenGaNo ratings yet

- VW Golf 5 - Electro-Mechanical Steering Gear, Servicing (Generation II)Document49 pagesVW Golf 5 - Electro-Mechanical Steering Gear, Servicing (Generation II)NPNo ratings yet

- Ignition System, Servicing: 28-1, General Notes On Ignition System 28-1, Safety Precautions 28-1, Ignition, AssemblyDocument5 pagesIgnition System, Servicing: 28-1, General Notes On Ignition System 28-1, Safety Precautions 28-1, Ignition, AssemblyspikerowNo ratings yet

- Slide/tilt Sunroof: Volkswagen New BeetleDocument21 pagesSlide/tilt Sunroof: Volkswagen New BeetleHéctor Morales OrtegaNo ratings yet

- Front Suspension, ServicingDocument4 pagesFront Suspension, ServicingpabloNo ratings yet

- 700 06Document53 pages700 06Andrew HemNo ratings yet

- Caddy LHN 130, 140, 200, (Caddy) PDFDocument36 pagesCaddy LHN 130, 140, 200, (Caddy) PDFPE TruNo ratings yet

- RAI Technical LTDDocument11 pagesRAI Technical LTDadNo ratings yet

- Climatronic 4-C From November 2002 PDFDocument1,356 pagesClimatronic 4-C From November 2002 PDFAluma MotorNo ratings yet

- VW AG4 (097 / 01N) : Ganzeboom Transmission Parts & Torque ConvertersDocument2 pagesVW AG4 (097 / 01N) : Ganzeboom Transmission Parts & Torque ConvertersMustafa KoperNo ratings yet

- VW Golf 5 steering torque specsDocument2 pagesVW Golf 5 steering torque specsNPNo ratings yet

- BYD-ED400 User Manual (English) 2010-05-04Document25 pagesBYD-ED400 User Manual (English) 2010-05-04Jacobo Antonio Camacho ZarateNo ratings yet

- Workshop Manual: Sales Division Technical Network LeadershipDocument64 pagesWorkshop Manual: Sales Division Technical Network LeadershipCarlos J. Gómez TortajadaNo ratings yet

- VW Passat b5 Door Lock Mechanism RepairDocument8 pagesVW Passat b5 Door Lock Mechanism RepairJosé Luis Ormeño67% (3)

- K9K 732 Manual 1 of 2Document9 pagesK9K 732 Manual 1 of 2Jose Luis MedinaNo ratings yet

- Work Instructions: Seite 1 Von 19 60385420deDocument19 pagesWork Instructions: Seite 1 Von 19 60385420depankituna5487No ratings yet

- Cylinder Head - Installation (Cylinder Head Assembly) - Fiat 500Document8 pagesCylinder Head - Installation (Cylinder Head Assembly) - Fiat 500Fran SanchezNo ratings yet

- 4TWX4036 Service FactsDocument4 pages4TWX4036 Service FactsAlejandro OrdoñezNo ratings yet

- Common Vaillant Boiler Error CodesDocument6 pagesCommon Vaillant Boiler Error CodesAdnan DuricNo ratings yet

- CJZC Engine Crankshaft GroupDocument28 pagesCJZC Engine Crankshaft GroupDaniel100% (1)

- Audi R8 Spyder - Fuel Cap 2Document4 pagesAudi R8 Spyder - Fuel Cap 2ohshafiNo ratings yet

- Ar09.10 P 1050akDocument3 pagesAr09.10 P 1050akAleksandar TubinNo ratings yet

- Running Gear SystemDocument35 pagesRunning Gear SystemMohammed Bin Jafarullah100% (2)

- Service: Wheel and Tire GuideDocument113 pagesService: Wheel and Tire GuidealexNo ratings yet

- 1996 Jetta TDI Wiring LONG4Document1 page1996 Jetta TDI Wiring LONG4Carlos CuadraNo ratings yet

- Mountfield Westwood: Westwood Garden Tractors 1987 Parts CatalogueDocument13 pagesMountfield Westwood: Westwood Garden Tractors 1987 Parts CatalogueWinfried SibbertNo ratings yet

- Cylinder Head Removing and InstallingDocument9 pagesCylinder Head Removing and Installingblackj3ckNo ratings yet

- PD InjectorDocument5 pagesPD InjectorTomas NoneeNo ratings yet

- Aaz 1z Ahu DisassemblDocument40 pagesAaz 1z Ahu DisassemblSergi Hernandez CasagoldaNo ratings yet

- Phaeton Front SuspensionDocument84 pagesPhaeton Front SuspensionnathanstittNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- SsangYong RODIUS Owner's Manual PDFDocument297 pagesSsangYong RODIUS Owner's Manual PDFTanee BoonmalertNo ratings yet

- (Guitar Method) J.S. Bach For Electric GuitarDocument38 pages(Guitar Method) J.S. Bach For Electric GuitarAnonymous qLJd1kf4No ratings yet

- Ultra40 PDFDocument1 pageUltra40 PDFTanee BoonmalertNo ratings yet

- b5 Ac Refrigerant Syst ServDocument29 pagesb5 Ac Refrigerant Syst ServTanee BoonmalertNo ratings yet

- b5 Ac Refrigerant Syst ServDocument29 pagesb5 Ac Refrigerant Syst ServTanee BoonmalertNo ratings yet

- Laptuta Castle in The SkyDocument3 pagesLaptuta Castle in The SkyTanee Boonmalert100% (1)

- VW Passat 1997-2004 Airbag, Seat, Transmission & Brake InspectionDocument118 pagesVW Passat 1997-2004 Airbag, Seat, Transmission & Brake Inspectionianaalina0% (1)

- VW Climatronic Codes Service EngDocument24 pagesVW Climatronic Codes Service Engmegatron_vf50% (2)

- Passat GLS Wagon FeaturesDocument0 pagesPassat GLS Wagon FeaturesTanee BoonmalertNo ratings yet

- Oyster Perpetual Day-Date Oyster Perpetual Gmt-Master IiDocument6 pagesOyster Perpetual Day-Date Oyster Perpetual Gmt-Master IiTanee BoonmalertNo ratings yet

- 400+ TOP ELECTRICAL Engineering Interview Questions & Answers PDFDocument1 page400+ TOP ELECTRICAL Engineering Interview Questions & Answers PDFZedo ZedoNo ratings yet

- Raised Floor SystemDocument17 pagesRaised Floor SystemZehra JabeenNo ratings yet

- 03 ATV610 Installation Manual en EAV64381 03Document67 pages03 ATV610 Installation Manual en EAV64381 03Freddy Suhartono50% (4)

- EDDYFI LYFT Specifications Sheet 01Document4 pagesEDDYFI LYFT Specifications Sheet 01Josue RuizNo ratings yet

- CIXI GESHINI ELECTRIC APPLIANCE CO.,LTD Contact and Product SpecsDocument1 pageCIXI GESHINI ELECTRIC APPLIANCE CO.,LTD Contact and Product SpecsToni GNo ratings yet

- Safety inspection checklist for bar cutting and bending machineDocument14 pagesSafety inspection checklist for bar cutting and bending machinepartha50% (2)

- GST NO-33AABPC9011G1ZE Quotation 235 MaterialsDocument1 pageGST NO-33AABPC9011G1ZE Quotation 235 MaterialsSaravana MNo ratings yet

- Machinists Screw JackDocument3 pagesMachinists Screw Jackmauri_ros100% (1)

- Ip Control Valve Calibration FormDocument1 pageIp Control Valve Calibration FormKester Ndabai0% (1)

- CP 12-2 Checklist - Loading and UnloadingDocument2 pagesCP 12-2 Checklist - Loading and UnloadingDanish ShaikhNo ratings yet

- Precision Pliers 490-Bi... : Heavy Duty Side CutterDocument1 pagePrecision Pliers 490-Bi... : Heavy Duty Side CutterAkmalNo ratings yet

- Service Manual: TA-DX8Document14 pagesService Manual: TA-DX8Eliel ToledoNo ratings yet

- Intel and Core I7 (Nehalem) Dynamic Power ManagementDocument11 pagesIntel and Core I7 (Nehalem) Dynamic Power ManagementRiza D. MarcoNo ratings yet

- ElectropeneumaticsDocument164 pagesElectropeneumaticstharindu100% (1)

- Sumex Drill BrochureDocument2 pagesSumex Drill Brochurealexandresjr7No ratings yet

- Excellon 136lspecsDocument13 pagesExcellon 136lspecsAntonio BermudezNo ratings yet

- AEEB. AEVB Series Standard Efficiency (IE1) Low Voltage: Rotates The WorldDocument12 pagesAEEB. AEVB Series Standard Efficiency (IE1) Low Voltage: Rotates The WorldKHA120096 StudentNo ratings yet

- Alarmlist-0510-11 2Document132 pagesAlarmlist-0510-11 2Valeriy DomashenkoNo ratings yet

- 100X DatasheetDocument2 pages100X Datasheetbiswasdipankar05No ratings yet

- Custom VK 8000 With HVSP Op Man 70-9048 Rev ADocument77 pagesCustom VK 8000 With HVSP Op Man 70-9048 Rev AyaungNo ratings yet

- H8C DatasheetDocument5 pagesH8C DatasheetJavier Quiroga de la RozaNo ratings yet

- BobcatDocument3 pagesBobcatJorge CabreraNo ratings yet

- Illuminated Emergency Balloon SignalDocument4 pagesIlluminated Emergency Balloon Signaldavid19775891No ratings yet

- Bearings Seals Greases Chapter 53 Page 762Document13 pagesBearings Seals Greases Chapter 53 Page 762AbdurhamanNo ratings yet

- 03 Ts 51Document4 pages03 Ts 51giovanni ampueroNo ratings yet

- 40XMH'11 40XW'11: (67TL) (67TK)Document50 pages40XMH'11 40XW'11: (67TL) (67TK)Carlos NetoNo ratings yet

- Ocean Yc Ycb Ycb-Sc Catalogue 2012.04.24 PDocument12 pagesOcean Yc Ycb Ycb-Sc Catalogue 2012.04.24 Ppramithbuddhikaisi100% (1)

- SONY LCD TV Bravia KLV-S26A10Document80 pagesSONY LCD TV Bravia KLV-S26A10Ricardo Chaman ChavezNo ratings yet

- Fire Detection: General CatalogueDocument128 pagesFire Detection: General CatalogueNam Hoai LeNo ratings yet

- Dja2500 - 4000 Service Manual PDFDocument38 pagesDja2500 - 4000 Service Manual PDFVedmitra Sharma100% (2)