Professional Documents

Culture Documents

6 Vaneflu

Uploaded by

Cretu DanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 Vaneflu

Uploaded by

Cretu DanCopyright:

Available Formats

6

Vane uture si clapeti de retinere / Buttery and Swing Check Valves

Vane uture si clapeti de retinere / Buttery and Swing Check Valves din fonta ductila / made of ductile cast iron

Vane uture si clapeti de retinere / Buttery and Swing Check Valves

Vane uture si clapeti de retinere / Buttery and Swing Check Valves din fonta ductila / made of ductile cast iron

Datorita optimizarii dimensiunii componentelor urmarite pentru standardele relevante, aceste vane au proprietati bune de inchidere, scurgere si evacuare. Diversele acoperiri cum ar cele cu vopsea din rasini epoxidice sau emailari ne permit sa raspundem multor cerinte ale clientilor nostri. In procesul de fabricatie este integrata testarea in conformitate cu DIN 3230/3. Due to optimized component dimensions under the observance of the relevant standards, these valves have very good shut-off, ow and damping properties. Various coatings such as epoxy resin powder or enamel enable us to respond to many customer requests. Testing in accordance with DIN 3230/3 is integrated in the course of manufacture.

Vane uture cu disc dublu excentric/ Buttery Valves

Vane uture cu disc dublu excentric / Buttery Valves with Doubly Eccentric Tilting Disk conf. DIN EN 558, GRI 14, lungime intre anse conf. DIN 200 la 1200, PN 10 si PN 16 / Soft-seated as per DIN EN 593, GR14 face-to-face length as per DIN EN 558, DN 200 to 1200, PN 10 and PN 16

Marcaj conformitate DIN-DVGW NV 6201AT2574. Vanele uture sunt confectionate cu dimensiuni de conectare ale anselor specicate de DIN EN 1092-2, PN 10/16 si cu lungimi intre anse GRF14. Cu ajutorul unei anse adaptoare proiectate conf. ISO 5211, sunt posibile combinatii cu orice varianta de actionare. Discul dublu excentric este echipat cu mansete legate interlaminar care au proprietati de alunecare foarte bune si astfel au o functionare deosebit de lina. Principalul dispozitiv de inchidere este inchis in ambele directii ale debitului printr-un inel garnitura cu prol elastic cu presiune reglabila. Axul de actionare este etansat cu o garnitura circulara cu prolul benzii asimetric si cu o a doua buza de etansare. Toate fetele sunt etansate suplimentar pentru a se asigura folosirea in locuri ingropate. Discul basculant este legat de axul de actionare prin intermediul unor conectori prolati. Axele de actionare au etansare axiala robusta, reglabila. Atunci cand sunt folosite pentru gaz si alte uide agresive, se asigura o etansare suplimentara in asa fel incat lagarul letat sa nu intre in contact cu respectivul uid.

1 Descriere

DIN-DVGW Conformity Mark NV-6201AT2574. KHK buttery valves are manufactured with ange connection dimensions specied by DIN EN 1092-2, PN 10/16, and in the GR14 face-to-face length. Due to an existing adapter ange designed with reference to ISO 5211, combinations with any actuator variants are possible. The doubly eccentric tilting disk is equipped with interlaminar-bonded sleeves that have very good sliding properties and is, therefore, particularly smooth-running. The main shut-off device is reliably sealed in both ow directions by an elastic prole packing ring with adjustable pressure. The actuating shaft is sealed by a lip seal with an unsymmetrical prole of the sealing lip and a second sealing edge. All faces are additionally sealed to ensure application for buried installation. The tilting disk is coupled with the shafts by form-t pinned connections. The shafts have a robust, adjustable axial lock. When used for gas and other aggressive media, an additional shaft seal is provided so that the bearing is not in contact with the medium.

1 Description

Vane uture cu disc dublu excentric / Buttery Valves

Vane uture cu disc dublu excentric / Buttery Valves with Doubly Eccentric Tilting Disk conf. DIN EN 558, GRI 14, lungime intre anse conf. DIN 200 la 1200, PN 10 si PN 16 / Soft-seated as per DIN EN 593, GR14 face-to-face length as per DIN EN 558, DN 200 to 1200, PN 10 and PN 16

2

DN 200 250 300 350 400 500 600 700 800 900 1000 1200

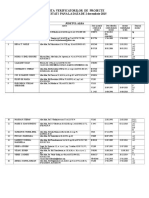

Modele, Dimensiuni si Parametri / Designs, Dimensions and Parameters

Greutate/ Weight (kg) 55 95 125 145 195 265 360 585 738 995 1285 2120

PN10

A 405 445 515 550 650 715 780 787 840 904 1090 1365 B 180 205 230 270 280 365 425 510 560 628 680 825 C 320 365 410 440 500 585 650 676 730 793 980 1225 D 340 400 455 505 565 670 780 895 1015 1115 1230 1455 E 40 63 63 63 80 100 100 125 125 125 160 200 F 170 190 240 240 280 300 300 329 325 325 360 450 h1 170 200 230 260 290 335 390 443 510 553 615 730 h2 155 170 180 180 180 290 290 300 300 300 470 560 h3 195 210 210 210 320 380 380 450 450 450 510 690 L 230 250 270 290 310 350 390 430 470 510 550 630 R 250 250 315 315 400 400 400 400 400 400 400 500 Lift/ Rotatii 12-13 12-13 13-14 13-14 30-32 30-32 30-32 53-55 53-55 53-55 53-55 108-110

PN16

DN 200 250 300 350 400 500 A 405 445 515 550 650 750 B 180 205 230 270 280 380 C 320 365 410 440 500 620 D 340 400 455 520 580 715 E 40 63 80 80 100 125 F 165 190 240 240 300 325 h1 170 200 230 260 290 360 h2 155 170 180 180 230 260 h3 195 210 210 210 320 350 L 230 250 270 290 310 350 R 250 250 315 315 400 400 Lift/ Rotatii 12-13 12-13 13-14 13-14 30-32 30-32 Greutate/ Weight (kg) 55 95 125 150 200 310

3 Modele / Designs

Tipul emailat / Enamelled Design Scaun etansare / Sealing seat: inel de etansare din cauciuc / rubber prole packing ring Corp vana / Valve body: EN-GJS-400-15/emailat intern, acoperit la exterior cu vopseluri din rasini epoxidice EN-GJS-400-15/internal enamelling, external epoxy resin powder coating / Disc batant / Tilting disk: EN-GJS-400-15/acoperit la exterior cu vopsea din rasini epoxidice/emailat la cererea clientului EN-GJS-400-15/epoxy resin powder-coated/enamelled upon customers request Spinglu piese montaj inox cu continut de crom min. 13% / Shafts/mounting parts: stainless steel containing a minimum chromium content of 13 % Prindere / Fasteners: inox cu continul de crom min. 175 (A2) stainless steel containing a minimum chromium content of 17 % (A2) Culoare / Colour: albastru / sky blue, RAL 5015

Tip inel de scaun corp vana / Valve Body Seat Ring Design

Scaun etansare / Sealing seat: Inel etansare din cauciuc scaun corp vana din inox cu continut de crom min 17% / rubber prole packing ring - valve body seat ring of stainless steel with a minimum chromium content of 17 % Corp vana / Valve body: EN-GJS-400-15/ interior si exterior acoperit cu vopsea din rasini epoxidice / internal and external epoxy resin powder coating Disc batant / Tilting disk: EN-GJS-400-15/ acoperit cu vopsea din rasini epoxidice / epoxy resin powder-coated Spinglu piese montaj inox cu continut de crom min. 13% / Shafts/mounting parts: stainless steel containing a minimum chromium content of 13 % Prindere / Fasteners: inox cu continut de crom min 17% (A2) / stainless steel containing a minimum chromium content of 17 % (A2) Culoare / Colour: albastru / sky blue, RAL 5015

Vane uture cu disc dublu excentric/ Buttery Valves

Vane uture cu disc dublu excentric / Buttery Valves with Doubly Eccentric Tilting Disk conf. DIN EN 558, GRI 14, lungime intre anse conf. DIN 200 la 1200, PN 10 si PN 16 / Soft-seated as per DIN EN 593, GR14 face-to-face length as per DIN EN 558, DN 200 to 1200, PN 10 and PN 16

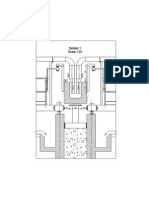

emailat intern / body, internally enamelled

disc basculant emailat la cerere / tilting disk enamelled upon request

surub xare / locking setscrew

surub strangere / fastening screw

inel presiune / pressure ring

garnitura elastomer / elastomer seal

Actionari / Actuators

- Dispozitiv autoblocare cu indicator mecanic de pozitie si roata de manevra. / Self-locking gear with mechanical position

indicator and handwheel.

- Dispozitiv autoblocare cu indicator mecanic de pozitie. / Self-locking gear with mechanical position indicator and electric

actuator. La cerere: actionare pneumatica. / Upon request: Pneumatic actuator.

Pentru a usura utilizarea acestor vane uture pentru retelele de apa potabila, sunt folosite numai materiale corespunzatoare care respecta recomandarile Ministerului Federal al Sanatatii KTW si au acceptul corespunzator. Vaselinele de asamblare si unguentii de service trebuie de asemenea sa satisfaca aceste cerinte. / To facilitate the use of these buttery valves for drinking water applications, only such non-metallic materials are used which meet to KTW Recommendations of the Federal Ministry of Health and have a corresponding permit. Assembling grease and service lubricants must also meet these requirements. Nume / Name Corp vana, disc basculant, toate celelalte piese turnate / Valve body, tilting disk, all other castings Spingluri, garnituri de etansare axiala / Shafts, axial locking bush Garnituri de presiune, garnitura corpului vanei / Pressure ring, valve body seat ring Bucsile portante (letate) / Bearing bushes Suruburile de conectare, bolturile / Screw connections, pins Saibe / Washers Garnitura cu degajare, O-ring / Lip seal, O-ring Garniturile de etansare din elastomer / Elastomer packing rings Material EN-GJS-400-15 X20Cr13 X5CrNi18.10 Otel, material din compozit de teon / Steel/Teon composite material Inox ioxidabil austenitic A2 / A2 austenitic stainless steel Ionx A2 / A2 stainless steel EPDM/NBR , in funtie de mediu / depending upon medium EPDM/NBR, in funtie de mediu / depending upon medium Nr. Material / Material Number EN-JS-1030 1.4021 1.4301

4 Materiale/Protectie suprafata / Materials/Surface Protection

Vane uture cu disc dublu excentric/ Buttery Valves

Vane uture cu disc dublu excentric / Buttery Valves with Doubly Eccentric Tilting Disk conf. DIN EN 558, GRI 14, lungime intre anse conf. DIN 200 la 1200, PN 10 si PN 16 / Soft-seated as per DIN EN 593, GR14 face-to-face length as per DIN EN 558, DN 200 to 1200, PN 10 and PN 16

Aceste materiale sunt folosite pentru apa potabila. Alte tipuri de uide (ex. apa de mare, canalizari) vor avea prevzut un inel suplimentar de etansare pe spinglu (bucsa rezistenta la orice mediu). / The materials listed correspond to the water/ drinking water design. Others (e. g. sea water, sewage) with additional shaft sealing ring (medium-free bearing).

Vopsea din rasini epoxidice/ Epoxy resin powder

Protectie de suprafata / Surface Protection

Acoperire cu vopsea din rasini epoxidice reprezinta protectia de regim greu de lucru impotriva coroziunii, care permite utilizarea vanelor uture chiar si in conditii dicile. Acoperirea este facuta la uzina noastra, prin utilizarea vopsealor de acoperire sau acoperirii lichide. Aceasta tehnica permite realizarea straturilor groase de acoperire pe piese turnate cu o aderenta excelenta la materialul de baza. / This epoxy resin powder coating represents heavy-duty protection against corrosion which allows the use of the buttery valves even under difcult conditions. Coating is made at our internal plant using coating powders or liquid coating. This technique allows high thickness of coats with excellent adhesion to the basis material.

Email / Enamel

Emailarea asigura o protectie extrem de ecienta impotriva coroziunii datorita urmatoarelor proprietati / Enamelling provides extremely effective protection against corrosion which stands out for the following properties: - rezistenta la mediu extrem / extremely high resistance to the medium. - aderenta foarte buna la materialul de baza prin coacerea emailului / very good adhesion to the basis material by baking in the enamel. - cea mai buna protectie pe durata mare impotriva coroziunii exercitate, datorita rezistentelor mari de acoperiri de protectie cu email aplicata pe cavitati / best long-time protection against corrosion by utmost resistance of the enamel protective coat to tunnelling. - inalta stabilitate la temperatura / high temperature stability. Suprafata emailata neteda in corpul vanei garanteaza / The smooth enamel surface in the valve body guarantees: - forte scazute de actionare si utilizare indelungata a dispozitivului de inchidere / low actuating forces and long life of the main shut-off device. - pierderi hidraulice scazute / low hydraulic losses. - lipsa punctelor cu asperitati pentru depuneri si sedimente organice / no settling points for deposits and organic sedimentation.

Utiliarea acestor vane uture este destinata urmatoarelor domenii / The use of these buttery valves in intended in the following ranges: Presiune nominala / Nominal pressure: 10/16 (de la / from DN 600 in sus / on, 10 bar) Temperatura / Temperature: pana la / up to 70 C Medii / Media: apa, apa potabila, gaze / water, drinking water, gas Pentru medii acide/alcaline/corozive cu garnitura suplimentara pe spinglu. / For acid/alkaline/corrosive media with additional shaft seal.

Flansa conform / Flange as per DIN EN 1092-2 PN 10 PN 16 Proba de presiune cu apa in bari / Water Test Pressure in bar Corp vana / Valve Body 15 24 Dispozitiv de inchidere / Shut-Off Device 10 16 Suprapresiunea de lucru admisa in bari / Permissible Working Overpressure in bar 10 16

5 Date de proiectare si instalare / Project Planning and Installation Notes

Diametru nominal / Nominal Diameter DN 200-1200 DN 200-500

Vanele uture sunt folosite cu precadere in pozitia DESCHIS sau INCHIS. Folosirea lor ca vane de control este posibila intr-o mica masura. Presiunea diferentiala controlabila este de aprox. 1 la 3 bari, in functie de diametrul nominal. / Buttery valves are preferably used in ON/OFF service. The use as a control valve is possible to a limited extent. The controllable differential pressure is approx. 1 to 3 bar, depending upon the nominal diameter.

Vane uture cu disc dublu excentric/ Buttery Valves

Vane uture cu disc dublu excentric / Buttery Valves with Doubly Eccentric Tilting Disk conf. DIN EN 558, GRI 14, lungime intre anse conf. DIN 200 la 1200, PN 10 si PN 16 / Soft-seated as per DIN EN 593, GR14 face-to-face length as per DIN EN 558, DN 200 to 1200, PN 10 and PN 16

Testarea se face pe baza DIN EN 1074-1/2 si DIN EN 12266-1 utilizadu-se apa sau aer la nivelul permisibil de pierdere A; pentru vanele de gaz testarea se face conf. DIN 3230/5, in functie de cerintele clientului, in grupele de testare PG 1, PG 2, PG 3. / Testing is made on the basis of DIN EN 1074-1/2 and DIN EN 12266-1 using water or air at permissible leak rate A; for gas valves as per DIN 3230/5, depending upon the customers request, in test groups PG 1, PG 2, PG 3.

6 Testare si acceptare / Testing and Acceptance

7 Ordering Information / Informatii pentru comanada

- Descrierea unei vane uture cu diametru nominal de 400 mm, presiune nominala 10 bari, cu anse DIN EN 1092-2, de

lungime intre anse GR 14, cu inel de scaun din otel inoxidabil si actionare cu roata de manevra / Designation of a 400 mm nominal diameter buttery valve, 10 bar nominal pressure, with DIN EN 1092-2 anges, of GR14 face-to-face length, with stainless steel seat ring and gear with handwheel: Vana uture DN 400, PN 10, GR1, inel de scaun din otel inoxidabil conf. DIN EN 593, cu actionare manuala. / Buttery Valve DN 400, PN 10, GR14, stainless steel seat ring as per DIN EN 593, with manual actuator.

- Descrierea unei vane uture cu diametru nominal de 300 mm, presiune nominala 16 bari, cu anse DIN EN 1092-2, de

lungime intre anse GR 14, emailata la interior si actionare electrica / Designation of a 300 mm nominal diameter buttery valve, 16 bar nominal pressure, with DIN EN 1092-2 anges, of GR14 face-to-face length, with inside enamelling, and with electric actuator: - Vana uture / Buttery Valve, DN 300, PN 16, GR14, emailata / enamelled , DIN EN 593, - cu actionare electrica si urmatoarele caracteristici specicate / with electric actuator and the following specied features: - cursa de manevra / travel actuation - forta de manevra / torque actuation - tip de curent / type of current - sistem de protectie / protective system - tip de curent / type of current - temperatura / heating - timp manevra pentru basculare 90 / moving time to tilt 90 etc. (Va rugam sa faceti referire la Documentatia de licitatie). / (Please refer to the Tender Text.)

Clapeti de retinere / Swing Check Valves

Clapeti de retinere / Soft-Seated Swing Check Valves GR14/15/48 lungimi intre anse conf. / face-to-face lengths as per DIN EN 558-1, DN 80 la / to DN 300, PN 10/PN 16

Clapetii de retinere cu dimensiuni de bransare a anselor conf. DIN 2501, PN 10/16, si GR14/GR15/GR48, lungimi intre anse sunt echipate cu clapeti concave cauciucate de jur-imprejur. Curbura si o bordura de etansare aata pe acoperirea cu cauciuc face ca, pe de o parte, diametrul nominal sa e in intregime liber in pozitia deschisa, si, pe de alta parte, sa se obtina o conditie buna de etansare in pozitia inchisa. / KHK soft-seated swing check valves with ange connection sizes as per DIN 2501, PN 10/16, and GR14/GR15/GR48 face-to-face lengths, are equipped with all-round rubber-coated, dished aps. The curvature and a sealing lip provided on the rubber coating ensure, on the one hand, that the entire nominal diameter is free in the open condition and that a very good sealing behaviour is obtained in the closed state, on the other hand. Pozitia de montare poate de la orizontal la vertical cu o directie ascendenta a debitului si axa clapetei orixontala. / The installation position may be from horizontal to vertical with a rising ow direction and a horizontal ap axis. Rezistente hidraulice deosebit de mici vor determina pierderi scazute de energie prin folosirea vanelor cu clapeta ca protectie controlata a pompei. / Particularly low ow resistances will result in low energy losses when the swing check valves are used as controlled pump protection. Alternativa de baza robusta livrata cu cateva componente poate extinsa prin urmatoarele optiuni / The robust basic variant furnished with few components can be extended by the following options: 1. Priza de drenare / Drain plug 2. Dispozitiv de refulare / Easing device 3. Instalatie senzor ( pozitia de mijjloc/DESCHIS/INCHIS) / Sensor installation (ON/OFF/middle position) 4. Resort de revenire pentru instalatii verticale / Return spring for vertical installation

1 Descriere / Description

Vana cu clapeti cu dispozitiv de refulare. / Swing check valve with easing device.

2 Dimensiuni / Dimensions

DN 80 100 125 150 200 200 250 250 300 300 PN 10/16 10/16 10/16 10/16 10 16 10 16 10 16 Lungime intre anse / Face-to-Face Length GR14 GR15 GR48 X X X X X X X X X X X X X X X X D 200 220 250 285 340 340 400 400 455 455 K 160 180 210 240 295 295 350 355 400 410 L GR14 GR15 180 280 190 300 350 400 400 GR48 260 300 350 400 500 500 600 600 700 700 b 19 19 19 19 20 20 22 22 24.5 24.5 n* x d 8 x 19 8 x 19 8 x 19 8 x 23 8 x 23 12 x 23 12 x 23 12 x 28 12 x 23 12 x 28 h1 100 110 145 145 192 192 231 231 271 271 GR14 16 16 h3 GR15 65 70 50 45 45 GR48 55 70 50 75 95 95 92 92 129 129 h4 110 120 212 212 270 270 367 367 392 392 B 152 172 246 246 341 341 440 440 520 520

Clapeti de retinere / Swing Check Valves

Clapeti de retinere / Soft-Seated Swing Check Valves GR14/15/48 lungimi intre anse conf. / face-to-face lengths as per DIN EN 558-1, DN 80 la / to DN 300, PN 10/PN 16

3 Modele / Designs

Modelul emailat / Enamelled Design Garnitura scaun / Sealing seat: Corp vana / Valve body: Clapeta / Flap: Capac / Cover: Garnitura capac / Cover seal: Inchideri / Fasteners: Colour: Epoxy Resin Powder Design Garnitura scaun / Sealing seat: Corb vana / Valve body: Clapeta / Flap: Capac / Cover: Garnitura capac / Cover seal: Prinderi / Fasteners: Culoare / Colour:

bordura de cauciuc - emailat / rubber lip - enamel EN-GJS-400-15/ emailat la interior, acoperit la exterior cu vopsea din rasini epoxidice / EN-GJS-400-15/internal enamelling, external epoxy resin powder coating EN-GJS-400-15/ cauciucata de jur-imprejur / all-round rubber coating EN-GJS-400-15/ emailat la interior, acoperit la exterior cu vopsea din rasini epoxidice / internal enamelling, external epoxy resin powder coating prol de cauciuc / rubber prole Inox A2 / A2 stainless steel sky blue, RAL 5015 ordura de cauciuc acoperire cu vopsea din rasini epoxideice / Rubber lip epoxy resin powder coating EN-GJS-400-15/ emailat la interior, acoperit la exterior cu vopsea din rasini epoxidice / internal and external epoxy resin powder coating EN-GJS-400-15/ cauciucata de jur-imprejur / all-round rubber coating emailat interior si exterior acoperit cu vopsea din rasini epoxidice EN-GJS-400-15 EN-GJS-400-15 internal and external epoxy resin powder coating prol cauciuc / rubber prole inox A2 / A2 stainless steel albastru / sky blue, RAL 5015

Pentru a usura utilizarea acestor clapeti in aplicatii pentru apa potabila, sunt folosite numai acele materiale ne-metalice care respecta recomandarile Ministerului Federal al Sanatatii KTW si au acceptul corespunzator. / To facilitate the use of these swing check valves for drinking water applications, only such non-metallic materials are used which meet to KTW Recommendations of the Federal Ministry of Health and have a corresponding permit. Nume / Name Corp vana, clapete, capac / Valve body, aps, cover Prinderi / Fasteners Cauciucare clapeta, garnitura / Flap rubber coating, seal Material EN-GJS-400-15 inox A2 / A2 stainless steel NBR KTW Permis pentru apa/gaz / Permit for water/gas Nr. Material / Material Number EN-JS-1030

4 Materiale/protectie suprafata / Materials/Surface Protection

Cauciucare EPDM la cerere / EPDM rubber coating upon request.

Protectie de suprafata / Surface Protection

Vopsele din rasini epoxidice / Epoxy resin powder Aceasta acoperire cu vopsea din rasini epoxidice reprezinta protectia de regim greu de lucru impotriva coroziunii, care permite utilizarea vanelor uture chiar si in conditii dicile. Acoperirea este facuta la uzina noastra, prin utilizarea vopsealor de acoperire sau acoperirii lichide. Aceasta tehnica permite realizarea straturilor groase de acoperire pe piese turnate cu o aderenta excelenta la materialul de baza. / This epoxy resin powder coating represents heavy-duty protection against corrosion which allows the use of the buttery valves even under difcult conditions. Coating is made at our internal plant using coating powders or liquid coating. This technique allows high thickness of coats with excellent adhesion to the basis material. Culoare / Colour: albastru / sky blue Email / Enamel Emailarea asigura o protectie extrem de ecienta impotriva coroziunii datorita urmatoarelor proprietati / Enamelling provides extremely effective protection against corrosion which stands out for the following properties: - rezistenta extrem de ridicata la orice mediu / extremely high resistance to the medium. - aderenta foarte buna la materialul de baza / very good adhesion to the basis material by baking in the enamel.

Clapeti de retinere / Swing Check Valves

Clapeti de retinere / Soft-Seated Swing Check Valves GR14/15/48 lungimi intre anse conf. / face-to-face lengths as per DIN EN 558-1, DN 80 la / to DN 300, PN 10/PN 16

- cea mai buna protectie pe durata mare impotriva coroziunii exercitate, datorita rezistentelor mari ale acoperirii de protectie cu email aplicata pe cavitati / best long-time protection against corrosion by utmost resistance of the enamel protective coat to tunnelling. - inalta stabilitate la temperatura / high temperature stability. Suprafata emailata neteda in corpul vanei garanteaza / The smooth enamel surface in the valve body guarantees: - forte scazute de actionare si utilizare indelungata a dispozitivului de inchidere / low actuating forces and long life of the main shut-off device. - pierderi hidraulice scazute / low hydraulic losses. - lipsa punctelor cu asperitati pentru depuneri si sedimente organice / no settling points for deposits and organic sedimentation.

Clapetii de retinere sunt destinate retelelor pe apa potabila si canalizare. Este posibila si utilizarea lor pentru gaze intr-o masura limitata. Diametrele nominale DN 80 si DN 100 sunt oferite la lungimi intre anse GR14, GR15 si GR48, iar diametrele nominale DN 150 si DN 200 sunt disponibile la lungimi intre anse GR15 si GR48 conf. DIN EN 558-1. Uilizarea clapetilor este posibila pana la temperatura de 400 C pentru acoperire vopseluri epoxidice si pana la 700 C pentru acoperiri cu email. Suprapresiunea permisa de lucru corespunde presiunii nominale. Pentru pozitii verticale de instalare la diferente mari de presiune va rugam sa ne contactati. Senzorii inductivi usureaza indicarea pozitiei clapetei (DESCHIS/INCHIS si pozitii intermediare pentru DN de la 100 in sus) Instalarea unui dispozitiv de refulare este de asemenea posibila. / These soft-seated swing check valves are provided for drinking water and sewage applications. For gas, their use is possible to a limited extent. Nominal diameters DN 80 and DN 100 are offered at GR14, GR15 and GR48 face-to-face lengths, while the DN 150 and DN 200 nominal diameters are available at GR15 and GR48 face-to-face lengths as per DIN EN 558-1. The use of these swing check valves is possible up to a temperature of 40 C for epoxy resin powder, and below 70 C for enamel. The permissible working overpressure corresponds to the nominal pressure. For vertical installation position and high pressure difference, please consult us. Inductive sensors facilitate ap position indication (ON/OFF and intermediate positions from DN 100 onward). The installation of an easing device is also possible.

5 Date de proiectare i instalare / Project Planning and Installation Notes

Testarea este efectuata in conformitate cu DIN EN 1074-1/2 si DIN EN la nivel de pierderi A, cu apa sau aer / Testing is performed in accordance with DIN EN 1074-1/2 and DIN EN 12266-1 at leak rate A, using water or air. DN 80 100 125 150 200 200 250 250 300 300 PN 10/16 10/16 10/16 10/16 10 16 10 16 10 16 Presiununea de testare in bari / Test Pressure in bar p min p max 1.7 24 1.5 24 0.5 24 0.5 24 0.5 15 0.5 24 0.5 15 0.5 24 0.5 15 0.5 24

6 Testare si acceptare / Testing and Acceptance

Descrierea unei clapeti de retinere, diametru nominal 100 mm, presiune nominala 10 bari, lungime intre anse GR 14, pentru apa cu temperatura pana la 40 C / Designation of a soft-seated swing check valve, 100 mm nominal diameter, 10 bar nominal pressure, GR14 face-to-face length, for water up to 40 C: Clapeti de retinere / swing Check Valve, DN 100, PN 10, GR14. (Va rugam sa faceti referire la Documentatia de licitatie). / (Please refer to the Tender Text).

7 Informatii pentru comanda / Ordering Information

You might also like

- Cerere Emitere Aviz Principiu APA CANAL IfDocument1 pageCerere Emitere Aviz Principiu APA CANAL IfCretu DanNo ratings yet

- Rev 01 Memoriu SanitareDocument46 pagesRev 01 Memoriu SanitareCretu DanNo ratings yet

- Strategia SCUP2007 2013Document31 pagesStrategia SCUP2007 2013Cretu DanNo ratings yet

- GHIDUL SOLICITANTULUI Pentru SubMasura 7.2 Septembrie 2015Document36 pagesGHIDUL SOLICITANTULUI Pentru SubMasura 7.2 Septembrie 2015Dann TudorNo ratings yet

- 02 Plan Sistematizare Pe Verticala - PTDocument1 page02 Plan Sistematizare Pe Verticala - PTCretu DanNo ratings yet

- SKMBT 22314101408390Document1 pageSKMBT 22314101408390Cretu DanNo ratings yet

- NP 007 - 1997 - Proiectare Structuri in Cadre Din B. ADocument84 pagesNP 007 - 1997 - Proiectare Structuri in Cadre Din B. ACretu DanNo ratings yet

- Ghidul Proiectantului 2012 PDFDocument100 pagesGhidul Proiectantului 2012 PDFCretu DanNo ratings yet

- Verificatori de ProiecteDocument207 pagesVerificatori de ProiecteGabriel LadaruNo ratings yet

- Parshall P5Document1 pageParshall P5Cretu DanNo ratings yet

- 02 Plan Sistematizare Pe Verticala - PTDocument1 page02 Plan Sistematizare Pe Verticala - PTCretu DanNo ratings yet

- 3.2. Clasor de Nisip - Fisa TehnicaDocument2 pages3.2. Clasor de Nisip - Fisa TehnicaCretu DanNo ratings yet

- AHSH L2 Sisteme Gravit ComplexeDocument3 pagesAHSH L2 Sisteme Gravit ComplexeCretu DanNo ratings yet

- Decantoare SecundareDocument1 pageDecantoare SecundareCretu DanNo ratings yet

- Decantoare SecundareDocument1 pageDecantoare SecundareCretu DanNo ratings yet

- Advance Design UserGuide 2011Document300 pagesAdvance Design UserGuide 2011Cretu DanNo ratings yet

- Advance Concrete UserGuide 2011Document110 pagesAdvance Concrete UserGuide 2011Cretu DanNo ratings yet

- Manual Graitec Advenced SteelDocument164 pagesManual Graitec Advenced SteelScurtu Nicu100% (1)

- Advance Concrete UserGuide 2011Document110 pagesAdvance Concrete UserGuide 2011Cretu DanNo ratings yet

- Automatizarea Bazinului de AerareDocument5 pagesAutomatizarea Bazinului de AerarevalipanduruNo ratings yet

- Detaliu Conectare Retea Exist.Document1 pageDetaliu Conectare Retea Exist.Cretu DanNo ratings yet

- Detaliu Conectare Retea Exist.Document1 pageDetaliu Conectare Retea Exist.Cretu DanNo ratings yet

- Ghid Retele de Distributie A Apei - S CalosDocument467 pagesGhid Retele de Distributie A Apei - S Caloscucpegard100% (4)

- Detaliu Conectare Retea Exist.Document1 pageDetaliu Conectare Retea Exist.Cretu DanNo ratings yet

- Referat Etica Si Deontologie JudiciaraDocument13 pagesReferat Etica Si Deontologie JudiciaraCretu Dan100% (1)

- PROIECT - Risc La InundatiiDocument37 pagesPROIECT - Risc La InundatiiCretu DanNo ratings yet

- I-22-99 Normativ Pentru Proiectarea Si Executarea Conductelor de Aductiune Si A Retelelor de Aliment Are Cu Apa Si Canalizare Ale LocalitatilorDocument30 pagesI-22-99 Normativ Pentru Proiectarea Si Executarea Conductelor de Aductiune Si A Retelelor de Aliment Are Cu Apa Si Canalizare Ale LocalitatilorAdela Toma100% (1)

- Geometrie DescriptivaDocument204 pagesGeometrie Descriptivacozocozo100% (1)

- Cap 2 CimenturiDocument11 pagesCap 2 CimenturiCîrstea MădălinaNo ratings yet

- Gratare Metalice ZincateDocument2 pagesGratare Metalice ZincateCretu DanNo ratings yet