Professional Documents

Culture Documents

Arc Flash Mitigation PDF

Uploaded by

Alexander WijesooriyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arc Flash Mitigation PDF

Uploaded by

Alexander WijesooriyaCopyright:

Available Formats

Arc flash mitigation

Designing out unsafe systems

Mott MacDonald analyses and models equipment to identify and advise design changes to protect against arc flash incidents. Arc flash incidents can cause death, permanent injury, financial and legal consequences.

Model and analyse systems to preempt and diagnose problems within new and existing facilities Provide clear and concise findings and recommendations including personal protective equipment requirements

Advise on optimised protection settings and protective relay replacement where applicable Help employers and employees achieve a safer working environment, protect equipment and improve efficiency at the same time

www.power.mottmac.com

What is arc flash?

Arcing faults can occur if the energy available at electrical equipment is sufficient to maintain a conductive path through the air or insulation from live parts to grounded parts or between two live parts of different phases. Arcing faults produce ultraviolet light radiation causing damage to skin, eyes, hearing and igniting some types of clothing that are within the approach boundaries.

Our track record

Our experienced electrical power engineering staff have a proven track record of carrying out arc studies. We have undertaken arc flash assessment, review, design evaluation and implementation and made recommendations for such clients as: AMEC Group BRF Calpine Gemma Power Systems Genzyme Noble Environmental Power Northeast Utilities RasGas ScottishPower Technip

Our services include:

Data collection System modelling and coordination studies System operating modes Arc flash design assessments Risk assessment and mitigation Safety warning labels in compliance with NEC

What Mott MacDonald can offer

Improvements to protection system co-ordination, such as relay selectivity, should be realised to reduce incident energy levels available and arc flash boundary distances at a given work location while improving reliability. We use the latest tools SKM Power Tools, ETAP and EDSA to analyse the incident energy level available from which mitigating alternatives are investigated and proper personal protective equipment (PPE) levels recommended. The latest safety standards suggest that arc flash studies are advisable where a fault analysis or protection relay co-ordination study has not been performed in recent years. We believe that many facilities require an engineered approach to identify electrical hazards. A team of highly experienced power systems engineers at MottMacDonald is ready to provide this analysis to protect your interests and personnel.

Contact us Europe/Asia Dr Keith McLeay t +44 141 222 4617 e keith.mcleay@mottmac.com Africa Robert Wallis t +27 11 886 6573 e wallisr@merz.co.za USA Keith Svensen t +1 781 915 0048 e keith.svensen@mottmacinc.com Middle East Paul Looker t +971 506 626 568 e paul.looker@mottmac.com

National standards

At Mott MacDonald we have a full understanding of the national standards and owner responsibilities. NFPA 70E Standard for Electrical Safety in the Workplace provides a standard that covers the aspects of electrical safety-related work practices and maintenance of the electrical systems. The Occupational Safety&Health Administration (OSHA) also considers NFPA 70E the recognised industry practice as based on IEEE 1584 IEEE Guide for Performing ArcFlash Hazard Calculations methods. In the UK, the Health and Safety at Work Act, Electricity at Work Regulations and PPE at Work Regulations require employers to assess the workplace, determine the hazards present and supply employees with the necessary PPE.

Mott MacDonald is a global management, engineering and development consultancy with a strong engineering base. With annual revenue of 1billion, we combine the skills of over 14,000staff with a strong presence in 140countries.

JK/05/10

www.mottmac.com

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Tan Delta FAQDocument6 pagesTan Delta FAQDev SwainNo ratings yet

- Section12 0307Document8 pagesSection12 0307narcisomoroNo ratings yet

- HVPD Pcic Middle East 2016 Abu-20Document9 pagesHVPD Pcic Middle East 2016 Abu-20Alexander WijesooriyaNo ratings yet

- About Partial DischargeDocument3 pagesAbout Partial DischargeAlexander WijesooriyaNo ratings yet

- CSI ExistingInstallation 260573.171Document7 pagesCSI ExistingInstallation 260573.171Vinod MuruganNo ratings yet

- Bus DuctDocument7 pagesBus DuctAlexander WijesooriyaNo ratings yet

- Introduction To Vibration, Introduction To Vibration FLUKEDocument3 pagesIntroduction To Vibration, Introduction To Vibration FLUKEwilliamb285No ratings yet

- What Is Partial Discharge Testing - Vertiv InsightsDocument5 pagesWhat Is Partial Discharge Testing - Vertiv InsightsAlexander WijesooriyaNo ratings yet

- About Partial DischargeDocument3 pagesAbout Partial DischargeAlexander WijesooriyaNo ratings yet

- DC AnalysisDocument10 pagesDC AnalysisAlexander WijesooriyaNo ratings yet

- Vibration AnalysisDocument12 pagesVibration AnalysistheealokNo ratings yet

- Electrical Safety Program - Arc FlashDocument16 pagesElectrical Safety Program - Arc FlashAlexander WijesooriyaNo ratings yet

- Fundamentals of Vibration Measurement and Analysis ExplainedDocument13 pagesFundamentals of Vibration Measurement and Analysis ExplainedJaime BerryNo ratings yet

- Hyundai U-ACB NewDocument108 pagesHyundai U-ACB NewAlexander Wijesooriya100% (3)

- 1-Bill Cantor Steve McCluer - DC Arc FlashDocument10 pages1-Bill Cantor Steve McCluer - DC Arc FlashMarco Miranda RodríguezNo ratings yet

- Arc Flash Hazard Analysis and Mitigation PaperDocument20 pagesArc Flash Hazard Analysis and Mitigation PapergjanitoNo ratings yet

- Photoelectrochemical System StudiesDocument17 pagesPhotoelectrochemical System StudiesAlexander WijesooriyaNo ratings yet

- 26-3400 Arc Flash PDFDocument7 pages26-3400 Arc Flash PDFAlexander WijesooriyaNo ratings yet

- Synchronous Motor Control PDFDocument20 pagesSynchronous Motor Control PDFPradeep_VashistNo ratings yet

- PV - Diesel System Concept March 08Document23 pagesPV - Diesel System Concept March 08Alexander WijesooriyaNo ratings yet

- Medium Voltage Capacitor Bank SpecificationsDocument4 pagesMedium Voltage Capacitor Bank SpecificationsAlexander WijesooriyaNo ratings yet

- Manual For MV Power CapacitorsDocument13 pagesManual For MV Power CapacitorsAlexander WijesooriyaNo ratings yet

- PSO Based Optimal PV Placement For Maximizing PenetrationDocument5 pagesPSO Based Optimal PV Placement For Maximizing PenetrationAlexander WijesooriyaNo ratings yet

- Types of MotorsDocument12 pagesTypes of MotorsMatin Inamdar100% (1)

- Install Guide Ferrups-EatonDocument76 pagesInstall Guide Ferrups-EatonaguwibowoNo ratings yet

- Eaton 9170plus BCMDocument32 pagesEaton 9170plus BCMAlexander WijesooriyaNo ratings yet

- BR15303035EN FERRUPS 60Hz 0514Document2 pagesBR15303035EN FERRUPS 60Hz 0514Alexander WijesooriyaNo ratings yet

- 7PG21 Solkor RF Technical Manual Chapter 3 Applications GuideDocument15 pages7PG21 Solkor RF Technical Manual Chapter 3 Applications GuideAlexander WijesooriyaNo ratings yet

- Eaton FERRUPS User GuideDocument128 pagesEaton FERRUPS User GuideGordon WilkinsNo ratings yet

- PC 041Document8 pagesPC 041Alexander WijesooriyaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Method-Statement-CMC TowerDocument5 pagesMethod-Statement-CMC TowerEkram AliNo ratings yet

- EOS Basic Clerical Works Level IDocument56 pagesEOS Basic Clerical Works Level Iዋለልኝ አድማሱ ተገኘNo ratings yet

- Clean Before You Leave The Scene 2. Inspect and DisassembleDocument1 pageClean Before You Leave The Scene 2. Inspect and DisassembleJhon AyalaNo ratings yet

- Hydronic L-Ii: Technical Description, Installation, Operating and Maintenance InstructionsDocument44 pagesHydronic L-Ii: Technical Description, Installation, Operating and Maintenance InstructionsVasile DimofteNo ratings yet

- Alpha Olefin C14-C16-C18P Blend-English (US)Document14 pagesAlpha Olefin C14-C16-C18P Blend-English (US)lyesNo ratings yet

- Information Sheet 4.1-1Document3 pagesInformation Sheet 4.1-1Novelyn RabinoNo ratings yet

- Alumunium Chlorohydrate MSDSDocument4 pagesAlumunium Chlorohydrate MSDShinur awaNo ratings yet

- Safety Precautions for KEYENCE GL-T11R Safety RelayDocument8 pagesSafety Precautions for KEYENCE GL-T11R Safety Relayjuan carlosNo ratings yet

- Electrocuted HelperDocument2 pagesElectrocuted Helperjacc009No ratings yet

- WSNZ 1751 Local Exhaust Ventilation QG v15 0 FA LRDocument14 pagesWSNZ 1751 Local Exhaust Ventilation QG v15 0 FA LREshams ShamsNo ratings yet

- 023 Procedure Equipment MaintenanceDocument6 pages023 Procedure Equipment MaintenanceHSE CERI100% (1)

- Audit Checklist TemplateDocument18 pagesAudit Checklist TemplateDesi AgustiniNo ratings yet

- SHE-procedure and Workbook AUG2018Document48 pagesSHE-procedure and Workbook AUG2018Dennis C. BalinasNo ratings yet

- Grade 11 Disaster Readiness and Risk ReductionDocument5 pagesGrade 11 Disaster Readiness and Risk ReductionKJ MarquezNo ratings yet

- C 561Document2 pagesC 561Asep TheaNo ratings yet

- PSG21-2020 Guidelines For Competent Persons Involved in Witnessing of Pressure Tests - Pressure Testing GuidanceDocument14 pagesPSG21-2020 Guidelines For Competent Persons Involved in Witnessing of Pressure Tests - Pressure Testing GuidanceLiu YangtzeNo ratings yet

- Synerquest Management Consultancy Services IncDocument2 pagesSynerquest Management Consultancy Services IncRobin RubinaNo ratings yet

- TAE40116 WHS Policies and Procedures V4.0Document8 pagesTAE40116 WHS Policies and Procedures V4.0Monal PansalNo ratings yet

- Guard Rail CP-BP Tebal 4,5 MM (Tipe B)Document1 pageGuard Rail CP-BP Tebal 4,5 MM (Tipe B)rani wulansariNo ratings yet

- Physical security system essentialsDocument5 pagesPhysical security system essentialsLindo Gondales Jr.No ratings yet

- Fire Evacuation PlanDocument4 pagesFire Evacuation PlanMiguel AlexandreNo ratings yet

- Guidance on Risk Management in Mental HealthDocument54 pagesGuidance on Risk Management in Mental Healthjazz8181No ratings yet

- Man PDFDocument36 pagesMan PDFSang RòmNo ratings yet

- S HD22RP PDFDocument4 pagesS HD22RP PDFAbigail ChabekNo ratings yet

- AL QOOZ CONTRACTING HAZARD ASSESSMENTDocument7 pagesAL QOOZ CONTRACTING HAZARD ASSESSMENTشاز إياسNo ratings yet

- What Factors Affect The Building Code Title 24Document2 pagesWhat Factors Affect The Building Code Title 24trish_schwenk9556No ratings yet

- JHA Civil WorksDocument2 pagesJHA Civil Worksethelchudi100% (11)

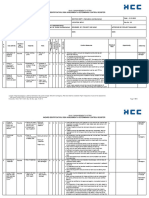

- HIRA - Stressing Platform at Pylon and Working-Hcc F 001 15 001-r9Document4 pagesHIRA - Stressing Platform at Pylon and Working-Hcc F 001 15 001-r9Pinaki BhattacharjeeNo ratings yet

- Engineer / Supervisor: Skills RequiredDocument2 pagesEngineer / Supervisor: Skills RequiredAbid HussainNo ratings yet

- Final FSSR FILE-food Grade Act-2010 PDFDocument676 pagesFinal FSSR FILE-food Grade Act-2010 PDFImran Niaz KhanNo ratings yet