Professional Documents

Culture Documents

ITP (Electrical)

Uploaded by

petroniko88Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ITP (Electrical)

Uploaded by

petroniko88Copyright:

Available Formats

The Petroleum Projects & Technical Consultations Co.

Q. PL. No. Page 1 of 6

PETROJET

Issue Revision :

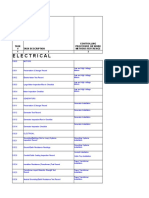

Date ITP Electrical NORTHERN PIPELINE COMPRESSION STATION

Prepared

Issued

Review

KPC Approved

The Petroleum Projects & Technical Consultations Co.

Q. PL. No. Page 2 of 6

PETROJET

Issue Revision :

Date ITP Electrical NORTHERN PIPELINE COMPRESSION STATION 1 METHOD STATEMENTS 1.1 Cable pulling 1.2 Splicer certification 1.3 Termination technician certification 1.4 Splice installation/termination 1.5 Cables tests 1.5.1 1.5.2 1.5.3 1.5.4 2 Continuity Insulation (Megger test) Earthing continuity High potential testing MATERIAL CERTIFICATES / TECHNICAL DATA 2.1 Cables 2.2 Splicer 2.3 Cable ladders, ladder covers, fixing bolts 2.4 Conduits 2.5 Sleeves 2.6 Glands 2.7 Sealing compound

QGX/20/00/EL/TS /NA/003 QGX/20/00/EL/TS /NA/003 QGX/20/00/EL/TS /NA/003 QGX/20/00/EL/TS /NA/003

QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051

QGX/20/00/EL/TS /NA/003 & vendors spec. QGX/20/00/EL/TS /NA/003 & vendors spec. QGX/20/00/EL/TS /NA/003 & vendors spec. QGX/20/00/EL/TS /NA/003 QGX/20/00/EL/TS /NA/003 & vendors spec. QGX/20/00/IN/TS/ NA/019

CONTROL OF INSPECTION, MEASURING & TEST EQUIPMENT

4 5

PERSONNEL QUALIFICATION INSTALLATION INSPECTION

The Petroleum Projects & Technical Consultations Co.

Q. PL. No. Page 3 of 6

PETROJET

Issue Revision :

Date ITP Electrical NORTHERN PIPELINE COMPRESSION STATION 5.1 Underground installation 5.1.1 5.1.2 5.1.3 5.1.4 5.1.5 Channel/trench as per CW installation (drawing & standard) Underground pipes, instrument cables crossing Sand bedding Cleanliness Duct bank completion

Applicable drawings

QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003

N/A

QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 QGX/20/00/EL/TS /NA/003 QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 QGX/20/00/EL/TS /NA/003 & vendors instructions

5.1.6 5.1.7 5.1.8 5.1.9 5.1.10 5.1.11 5.1.12 5.1.13

Cable type & size, as per schedule Cable protection device at conduit end Conduit coating Cable tagging Distance btw cables Cable marking Bending radius Cable extra length, near splicing box Splicing box installation Sleeve sealing

manufacturers instructions

QGX/20/00/EL/TS /NA/003 & vendors instructions QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 & applicable drawings

5.1.14

Sand backfilling

5.1.15

Warning device

5.1.16

Backfilling completion

5.1.17

Channel cover installation

The Petroleum Projects & Technical Consultations Co.

Q. PL. No. Page 4 of 6

PETROJET

Issue Revision :

Date ITP Electrical NORTHERN PIPELINE COMPRESSION STATION

5.1.18

Installation of cable routing markers

QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 & applicable drawings

5.2 Aboveground installation 5.2.1 Distance btw ladders, as per layout

5.2.2 5.2.3 5.2.4

Provision for future extension Bending radius (check elbow radius accordingly) Cable ladder supports, as per standard

5.2.5

Provision for cable ladder thermal expansion

5.2.6 5.2.7 5.2.8 5.2.8.a

Cable earthing, as per specifications & standards Cable installation, as per schedule Junction boxes installation (conform to area requirements) Cable connections in JB

Applicable drawings

QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 & applicable drawings QGX/20/00/EL/TS /NA/003 & applicable drawings

5.2.8.b

JB support

5.2.8.c 5.2.8.d

JB earthing JB number

Applicable drawings

QGX/20/00/EL/TS /NA/003 & applicable drawings

5.2.8.e

Cable glands as per spec. & of correct size

LOW VOLTAGE SWITCHGEAR & MOTOR CONTROL CENTER INSTALLATION 6.1 Installation & layout check 6.2 Equipment check (incl. drawer physical check) Applicable drawings Applicable drawings

The Petroleum Projects & Technical Consultations Co.

Q. PL. No. Page 5 of 6

PETROJET

Issue Revision :

Date ITP Electrical NORTHERN PIPELINE COMPRESSION STATION 6.3 Insulating resistance check 6.4 Circuits operation check 7 HIGH & MEDIUM VOLTAGE SWITCHGEAR & PANELS 7.1 Installation & layout check 7.2 Equipment check 7.3 Insulating resistance check 7.4 Protection relay check 7.5 Wiring & circuits operation check 8 POWER TRANSFORMERS 8.1 Installation & layout check 8.2 Equipment check 8.3 Insulating resistance check 8.4 Dielectric strength test 8.5 Circuits operation check 9 ELECTRICAL MOTORS 9.1 Equipment check 9.2 Insulating resistance test 9.3 Spin test 9.4 No-load test 10 UPS & BATTERIES

QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051

Applicable drawings Applicable drawings

QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051

Applicable drawings Applicable drawings

QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051

Applicable drawings

QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & QGX/20/91/EL/TS /NA/042

10.1 Cable connections check 10.2 Transformer insulation measurement (UPS) 10.3 Battery arrangement check

Applicable drawings

QGX/20/00/EL/TS /NA/003, QGX/20/91/EL/TS /NA/042 & vendors instructions

10.4 Relay setting check

The Petroleum Projects & Technical Consultations Co.

Q. PL. No. Page 6 of 6

PETROJET

Issue Revision :

Date ITP Electrical NORTHERN PIPELINE COMPRESSION STATION

10.5 Frequency & voltage reading check

10.6 Remote alarm check

10.7 Operation test 11 LIGHTING SYSTEM

QGX/20/00/EL/TS /NA/003, QGX/20/91/EL/TS /NA/042 & vendors instructions QGX/20/00/EL/TS /NA/003, QGX/20/91/EL/TS /NA/042 & vendors instructions QGX/20/00/EL/TS /NA/003 & 051 QGX/20/91/EL/TS /NA/042

11.1 Equipment installation check 11.2 Insulation resistance test 11.3 Circuits operation check 11.4 Illumination level measurement 12 LIGHTENING SYSTEM

Applicable drawings

QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051 QGX/20/00/EL/TS /NA/003 & 051

12.1 Equipment installation check 12.2 Insulation resistance test 13 HEAT TRACING 13.1 Installation & layout check 13.2 Equipment installation check 13.3 Insulation resistance test 13.4 Circuits operation check

Applicable drawings

Applicable drawings Applicable drawings

QGX/20/00/EL/TS /NA/042 QGX/20/00/EL/TS /NA/042

S = "Contractor", E = "Client, C = COMPANY, A = Third Party H = Hold point - notification required, presence mandatory, W = Witness point - notification required, presence not mandatory, S = Surveillance R = Review = 100% inspection () = Spot checking Prepared By Issued By Reviewed By Print Name Date Print Name Date Print Name

Key

Dat

You might also like

- Handgun Shooting GuideDocument18 pagesHandgun Shooting GuideElijah Dave Buenaventura100% (1)

- 003-MS For Cable Joint and Termination PDFDocument19 pages003-MS For Cable Joint and Termination PDFKöksal Patan100% (1)

- MV Cable Pulling and Installation Method StatementDocument9 pagesMV Cable Pulling and Installation Method StatementMark Tristan Vallesteros100% (6)

- Electrical ITPDocument32 pagesElectrical ITPyoonchankim091194% (16)

- Electric ITP'sDocument23 pagesElectric ITP'sUtku Can Kılıç100% (3)

- Test Forms For SSDocument105 pagesTest Forms For SSRakesh Kumar75% (4)

- ITP For Bench Calibration of Instruments Rev.ADocument9 pagesITP For Bench Calibration of Instruments Rev.AGanga DaranNo ratings yet

- Mitsubishi 4G9 Series EngineDocument171 pagesMitsubishi 4G9 Series EngineJessie Bechayda78% (9)

- Doosan Heavy Industries Vietnam cable tray installation documentsDocument4 pagesDoosan Heavy Industries Vietnam cable tray installation documentsGanga Daran100% (4)

- Instrument ITPDocument4 pagesInstrument ITPVictor Biacolo100% (2)

- 08.2 Method StatementDocument3 pages08.2 Method StatementelbaraniNo ratings yet

- Method Statement SwitchgearsDocument6 pagesMethod Statement Switchgearskamil100% (1)

- ElectricalDocument27 pagesElectricaleunica_dolojan100% (1)

- 5-ITP Control SystemDocument14 pages5-ITP Control Systemeraswasta67% (3)

- Inspection Test Plan For ElectricalDocument38 pagesInspection Test Plan For Electricalzampacaanas76% (29)

- Electrical Cable Tray Check SheetsDocument5 pagesElectrical Cable Tray Check SheetsAldeline SungahidNo ratings yet

- Electrical Work ProcedureDocument19 pagesElectrical Work ProcedureUmar Adamu100% (1)

- E201 - Elec Inspection Test Plan Template Rev 00 11.11Document15 pagesE201 - Elec Inspection Test Plan Template Rev 00 11.11Arbaaz KhanNo ratings yet

- Method Statement For MV Power Cables & Accessories InstallationDocument9 pagesMethod Statement For MV Power Cables & Accessories InstallationAdil HasanovNo ratings yet

- QA&QC Earthing SystemDocument6 pagesQA&QC Earthing SystemMuhammadZahirKhanNo ratings yet

- 3.itp ElectricalDocument28 pages3.itp ElectricalJoel Alcantara75% (4)

- ITP For Junction Box InstallationDocument4 pagesITP For Junction Box InstallationGanga Daran100% (1)

- Inspection and Test Plan (Itp) For ElectricalDocument38 pagesInspection and Test Plan (Itp) For ElectricalJames Pol JumarangNo ratings yet

- 00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkDocument12 pages00-GE-EQA-001 (Rev.a) Site Inspection and Test Plan For Electrical and I&C WorkAbdul Mohid SheikhNo ratings yet

- SL # 1-13 ACTIVITY AND CHARACTERISTICSDocument2 pagesSL # 1-13 ACTIVITY AND CHARACTERISTICSprasanta2011100% (4)

- VP-THI-QG59-130 Data Sheet For Main Motor (QG3&4) Rev.C2Document12 pagesVP-THI-QG59-130 Data Sheet For Main Motor (QG3&4) Rev.C2umeshNo ratings yet

- ITP For Batteries, Chargers and UPSDocument7 pagesITP For Batteries, Chargers and UPSUtku Can Kılıç100% (1)

- Cable Tray Installation ProcedureDocument9 pagesCable Tray Installation ProcedureMahmoud Tobala0% (1)

- LV Panel ChecklistDocument1 pageLV Panel ChecklistvaradharajanNo ratings yet

- GI Cable Tray & Trunking MethodDocument9 pagesGI Cable Tray & Trunking Methodrkss100% (1)

- Appendix 11, Electrical Inspection and Test PlanDocument1 pageAppendix 11, Electrical Inspection and Test PlanBraulio MartinezNo ratings yet

- Grounding Installation Inspection and Test Plan ITPDocument2 pagesGrounding Installation Inspection and Test Plan ITPtristan guarinoNo ratings yet

- OETC-74 - 400kV Tower Design Inputs To AL-BABTAINDocument146 pagesOETC-74 - 400kV Tower Design Inputs To AL-BABTAINMohamed Gad67% (3)

- 19L1370124F1 PDFDocument23 pages19L1370124F1 PDFRaul Soteras EstebanNo ratings yet

- Build a radiant battery charger using negative energyDocument9 pagesBuild a radiant battery charger using negative energysuso73100% (2)

- 049-Itp For Lighting and Small Power (Building) PDFDocument15 pages049-Itp For Lighting and Small Power (Building) PDFKöksal Patan100% (1)

- Electrical Junction Box ITPDocument1 pageElectrical Junction Box ITPkamilNo ratings yet

- QA&QC - Installation of Field InstrumentationDocument4 pagesQA&QC - Installation of Field InstrumentationMuhammadZahirKhan100% (1)

- Sawamlah SS, 3 Weeks Schedule Update Till 21.01.2014Document17 pagesSawamlah SS, 3 Weeks Schedule Update Till 21.01.2014William E. NuevoNo ratings yet

- Quality Control Procedure Installation of Switchgears, Motor Control Centers and Bus Ducts (Guideline)Document9 pagesQuality Control Procedure Installation of Switchgears, Motor Control Centers and Bus Ducts (Guideline)Muralimohan PandianNo ratings yet

- 4.itp For Instrumentation & ControlDocument10 pages4.itp For Instrumentation & ControlJoel Alcantara75% (4)

- Rev.0 - ITP For Cable Pulling & Termination & JointingDocument3 pagesRev.0 - ITP For Cable Pulling & Termination & JointingUtku Can Kılıç100% (1)

- Instrumentation Inspection and Quality Control InterviewDocument3 pagesInstrumentation Inspection and Quality Control InterviewzhangyiliNo ratings yet

- Electrical ITPDocument4 pagesElectrical ITPVictor Biacolo100% (1)

- Electrical Work ProcedureDocument18 pagesElectrical Work ProcedureWilliam Berrospi Garcia100% (3)

- Apredizaje Aceleración Nissan X-TrailDocument5 pagesApredizaje Aceleración Nissan X-TrailHERNAN DARIO ZAPATA BUSTAMANTENo ratings yet

- MS For Lighting & Small Power InstallationDocument17 pagesMS For Lighting & Small Power InstallationGanga Daran0% (1)

- Electrical ITPDocument26 pagesElectrical ITPNorman Morales100% (2)

- ITP (Instrumentation)Document9 pagesITP (Instrumentation)Yaser A. Al-Bustanji100% (1)

- Project: Samsun CCPP: Title: ITP of SwitchgearsDocument4 pagesProject: Samsun CCPP: Title: ITP of SwitchgearsUtku Can Kılıç100% (1)

- Piping SpecDocument355 pagesPiping Speclcaron44100% (1)

- Inspection and Test Plan for Cable Pulling, Termination, Jointing and Conduit WorksDocument2 pagesInspection and Test Plan for Cable Pulling, Termination, Jointing and Conduit WorksUtku Can Kılıç75% (4)

- Ms For Installation & Testing of Ups - BatteriesDocument9 pagesMs For Installation & Testing of Ups - Batterieskamal8610No ratings yet

- Electrical Conduit Installation ITPDocument3 pagesElectrical Conduit Installation ITPGanga Daran100% (1)

- Quality Plan For Electrical WorkDocument16 pagesQuality Plan For Electrical WorknercyNo ratings yet

- ITP For MCC - HV - LV-switchgear Boards-PaneDocument2 pagesITP For MCC - HV - LV-switchgear Boards-Panerodel100% (1)

- Lighting & Small Power ITPDocument5 pagesLighting & Small Power ITPGanga Daran100% (1)

- Lightning Protection ITPDocument3 pagesLightning Protection ITPUtku Can KılıçNo ratings yet

- 038-Pro Welding Consumable Control Procedure PDFDocument20 pages038-Pro Welding Consumable Control Procedure PDFKöksal Patan100% (7)

- Cable Tray InstallationDocument6 pagesCable Tray InstallationsbpathiNo ratings yet

- UPS and Battery ChecklistDocument2 pagesUPS and Battery ChecklistkamilNo ratings yet

- Procedure Installation of Grounding & Lightning System - LABUAN BAJO PDFDocument9 pagesProcedure Installation of Grounding & Lightning System - LABUAN BAJO PDFWika Djoko ONo ratings yet

- Qatar Petroleum Construction Co. Ltd Inspection & Test PlanDocument1 pageQatar Petroleum Construction Co. Ltd Inspection & Test PlanmeeNo ratings yet

- 10083a 9 V1J Ezs0 00020Document24 pages10083a 9 V1J Ezs0 00020Mena KamelNo ratings yet

- Technical Specifications - EnglishDocument126 pagesTechnical Specifications - EnglishAmitendu PatnaikNo ratings yet

- QAP For ACSR Conductor PDFDocument10 pagesQAP For ACSR Conductor PDFprithvirajd20100% (1)

- Solatube Solar Prism Natural LightingDocument9 pagesSolatube Solar Prism Natural LightingnkagNo ratings yet

- Bid - Sage, 767 3rd Avenue, 31st & 33rd Floor, New York, NYDocument2 pagesBid - Sage, 767 3rd Avenue, 31st & 33rd Floor, New York, NYcristianldg2000No ratings yet

- Single and twin jet power supply circuit diagramsDocument1 pageSingle and twin jet power supply circuit diagramsBondanNo ratings yet

- Ac and DC Machines Objectives Type QuestionsDocument6 pagesAc and DC Machines Objectives Type QuestionsJohn Norie BaydalNo ratings yet

- Fast Splice Kit III: Type No.: HF FSK3Document2 pagesFast Splice Kit III: Type No.: HF FSK3odethNo ratings yet

- OP 800SD 800SD-2 OP530-V01 D FinalDocument2 pagesOP 800SD 800SD-2 OP530-V01 D FinalPasindu PriyankaraNo ratings yet

- Light - AnswersDocument3 pagesLight - AnswersSanyam 1 BNo ratings yet

- Daewoo Matiz 2000-2013 Airbags 1-6 PDFDocument6 pagesDaewoo Matiz 2000-2013 Airbags 1-6 PDFsheoNo ratings yet

- VS120, VS220, VS420, VS425, VS440, VS463 - Installation ContactorsDocument2 pagesVS120, VS220, VS420, VS425, VS440, VS463 - Installation ContactorsDaniloNo ratings yet

- RCC folded plate slab detailsDocument1 pageRCC folded plate slab detailsVinita KumariNo ratings yet

- GMI-27B - Vacuum Tubes - Russian Electronics Company PDFDocument1 pageGMI-27B - Vacuum Tubes - Russian Electronics Company PDFRaghu VutukuruNo ratings yet

- 4000kva PDFDocument1 page4000kva PDFsofiene otayNo ratings yet

- DT250:360:400 Ignition GuideDocument3 pagesDT250:360:400 Ignition Guidemarcusrex0% (1)

- Stock 25 de Marzo 2022Document25 pagesStock 25 de Marzo 2022fernandoNo ratings yet

- Inkel PA-2000 - 4000 - VE0402Document10 pagesInkel PA-2000 - 4000 - VE0402migfraya100% (1)

- Simple Transistorized Ignition Retrofit Circuit DiagramDocument2 pagesSimple Transistorized Ignition Retrofit Circuit DiagramgordomanotasNo ratings yet

- Electrical Formulas: General InformationDocument1 pageElectrical Formulas: General InformationalbertoNo ratings yet

- Power Supply System Bza 130 02/2 - 48 V DC, With Central Unit Installation TestDocument22 pagesPower Supply System Bza 130 02/2 - 48 V DC, With Central Unit Installation TestcmapatziNo ratings yet

- Vacuum Circuit Breaker or VCB and Vacuum InterrupterDocument2 pagesVacuum Circuit Breaker or VCB and Vacuum InterrupterHakim Abu BakarNo ratings yet

- Concrete Record As Per New Drawing Sr/No Description of Work No L (FT) W (FT) H (FT) Qty (CFT) Qty (Cum) A Basement 1 UgwtDocument24 pagesConcrete Record As Per New Drawing Sr/No Description of Work No L (FT) W (FT) H (FT) Qty (CFT) Qty (Cum) A Basement 1 UgwtSheikh Muneeb Ul HaqNo ratings yet

- Installation Instructions: Model Number TDF-3A-120V TDF-10A-120V TDF-20A-120V TDF-3A-240V TDF-10A-240V TDF-20A-240VDocument2 pagesInstallation Instructions: Model Number TDF-3A-120V TDF-10A-120V TDF-20A-120V TDF-3A-240V TDF-10A-240V TDF-20A-240Vhgdung12No ratings yet

- White Paper Understanding Ignition SystemsDocument2 pagesWhite Paper Understanding Ignition SystemsMatthew RosenNo ratings yet

- BETA Protecting: Miniature Circuit BreakersDocument1 pageBETA Protecting: Miniature Circuit BreakersWalter CataldoNo ratings yet

- Modular DIN Rail Products GuideDocument60 pagesModular DIN Rail Products Guidedaniel.cabasa2577No ratings yet