Professional Documents

Culture Documents

IBM IndustryView For Semiconductor Standard (SiView)

Uploaded by

Immanuel HenneOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IBM IndustryView For Semiconductor Standard (SiView)

Uploaded by

Immanuel HenneCopyright:

Available Formats

IBM Global Business Services Solution Brief

Electronics/Manufacturing

IBM IndustryView for Semiconductor Standard (SiView)

Optimize production management of your global semiconductor manufacturing lines

Semiconductor companies face a growing set of challenges to manage opportunities, from identification through production. The global manufacturing ecosystem is increasingly complex. Volume growth coupled with downward pressure on margins and average selling prices (ASPs) are straining manufacturers ability to develop and manage their product portfolio. The inability to respond to sudden demand changes or production problems increases the overall manufacturing costs. It is also difficult to plan and schedule across complex manufacturing lines located worldwide. SiView Standard can transform your manufacturing execution systems (MESs) and processes by helping you get your semiconductor line up, running and stabilized early, and improving supply chain management through a unified system. Our solution can provide a competitive edge by implementing fully automated, single wafer control, and building a line to handle multiple lots in a carrier. SiView Standard can improve your strategic sourcing, collaboration and enterprise resource planning to support manufacturing processes. It integrates with your current enterprise systems to facilitate tighter supply chain and manufacturing linkages, so you can leverage economies of scale and respond quicker to market changes. The asset can also enable initial fab bring-up in record time.

Highlights:

Manages delivery schedule, costs, and quality in a unified system Merges quality and process information and integrates with equipment automation to realize the goal of on-demand fab Leverages a highly-reliable and high-availability server architecture that is globally integrated with a Specification Manager to support large-scale and multiple fabs

Managing delivery, times, costs, and quality in a unified system

When everything is connected using a single, integrated system, work can be performed effectively and efficiently. By tying manufacturing information to the supply chain, our asset can help improve productivity and return on investment, as well as reduce cycle time. And unifying process and quality data helps with lot tracking and quality improvement. Our team of experts provides services to help get your production line started early using these system integration tools and third-party vendor applications. All this leads to a more agile enterprise that can quickly ramp up and better respond to the semiconductor industrys continually changing landscape. By increasing visibility, we can help you adapt to and meet supply and demand conditions, thereby helping improve profitability, cut costs and support yield improvement.

IBM Global Business Services Solution Brief

Electronics/Manufacturing

Merging quality and process information and integrating with equipment automation

With our asset, you can globally integrate manufacturing processes throughout your value chain. By integrating and interconnecting these manufacturing lines, you can better understand process and operational needs and increase visibility into the sales pipeline, as well as recognize or anticipate trends. You can integrate this information and build a fully automated line, using automated operation scenarios that are based on industry standards, such as SEMI Equipment Communications Standard (SECS)/Generic Equipment Model (GEM). And you can monitor your fully automated line in real time. You can actively manage different operations, expertise and capabilities to open up your organizations and focus outwardly to connect more tightly with partners, suppliers and customers.

Copyright IBM Corporation 2013 IBM Global Services Route 100 Somers, NY 10589 U.S.A. Produced in the United States of America August 2013 All Rights Reserved IBM, the IBM logo and ibm.com are trademarks or registered trademarks of International Business Machines Corporation in the United States, other countries, or both. If these and other IBM trademarked terms are marked on their first occurrence in this information with a trademark symbol ( or ), these symbols indicate U.S. registered or common law trademarks owned by IBM at the time this information was published. Such trademarks may also be registered or common law trademarks in other countries. A current list of IBM trademarks is available on the Web at Copyright and trademark information at: ibm.com/legal/copytrade.shtml. Other product, company or service names may be trademarks or service marks of others. References in this publication to IBM products or services do not imply that IBM intends to make them available in all countries in which IBM operates.

Leveraging a highly-reliable and high-availability server architecture

The highly-reliable and high-availability server architecture mitigates and reduces the effect of any system problems on your production line. SiView Standard functions track production trial lots, manage multi-lots, and provide single wafer control, to support Quick Turn-Around Time (QTAT) operations. In addition, SiView Standard continually evolves and improves based on customer requirements and technology progression. It includes a system monitoring service for 24-hour operation. Your project team and the SiView development team cooperate to support and maintain the system, helping ensure that your system is available 24 hours a day, 7 days a week.

Why IBM?

We have the global presence, experience, scale and capabilities to optimize your semiconductor manufacturing fab. We offer a unique combination of assets that can enable a rapid start-up of your line, integrating equipment and applications you need. We help manufacturing industries around the world become more productive, efficient and responsiveand tackle problems they once thought were unsolvablethrough systems, processes, services and infrastructures that are more instrumented, networked and intelligent.

Please Recycle

GBS03221-USEN-00

You might also like

- Configuration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingFrom EverandConfiguration Management for Senior Managers: Essential Product Configuration and Lifecycle Management for ManufacturingNo ratings yet

- IBM Global Integrated View (Planner)Document2 pagesIBM Global Integrated View (Planner)Immanuel HenneNo ratings yet

- Mes Pocket GuideDocument36 pagesMes Pocket Guidechandramohan muruganNo ratings yet

- SAP ME vs MII: Understanding the Differences Between SAP's Manufacturing Execution and Integration SolutionsDocument6 pagesSAP ME vs MII: Understanding the Differences Between SAP's Manufacturing Execution and Integration SolutionsFrancisco Abian GarciaNo ratings yet

- Ibm CompanyDocument20 pagesIbm CompanyAnirud KumarNo ratings yet

- SAP ME vs MII: Powerful Manufacturing SolutionsDocument6 pagesSAP ME vs MII: Powerful Manufacturing SolutionsFrancisco Abian GarciaNo ratings yet

- SAP Intro HenryDocument19 pagesSAP Intro HenryPiyush PandeyNo ratings yet

- Manufacturing Intelligence Provides The Right Mix For Dairy ProcessorDocument3 pagesManufacturing Intelligence Provides The Right Mix For Dairy ProcessorsayedmhNo ratings yet

- SAP Manufacturing IntegrationDocument20 pagesSAP Manufacturing IntegrationVassilis Papangelis100% (1)

- RS Consultancy IT automation energy monitoringDocument4 pagesRS Consultancy IT automation energy monitoringbabai_2007No ratings yet

- Sardar Automation Solutions Co, Ltd.Document16 pagesSardar Automation Solutions Co, Ltd.Sardar Perdawood100% (1)

- 1 Dist Industrial NADocument7 pages1 Dist Industrial NAspreeasNo ratings yet

- SAP Manufacturing ExecutionDocument14 pagesSAP Manufacturing Executionrizqi_83100% (2)

- VoltasDocument8 pagesVoltasVISHWAS GOWDA H VNo ratings yet

- ABB Cement Manufacturing Operations ManagementDocument4 pagesABB Cement Manufacturing Operations ManagementMadanKarkiNo ratings yet

- Manufacturing Transformation Through Digital IntegrationDocument5 pagesManufacturing Transformation Through Digital IntegrationliparyanNo ratings yet

- Sales & MArketingDocument6 pagesSales & MArketingAhamed NashathNo ratings yet

- SIMATIC IT Industry Libraries Hybrid For ProcessDocument21 pagesSIMATIC IT Industry Libraries Hybrid For ProcesskkpichaNo ratings yet

- NetSuite BrochureDocument16 pagesNetSuite Brochuredigvijay3900No ratings yet

- Netsuite Offers The Industry'S First and OnlyDocument21 pagesNetsuite Offers The Industry'S First and OnlytempshubhNo ratings yet

- Food & Beverage IndustryDocument8 pagesFood & Beverage IndustryMadhur AnandNo ratings yet

- Ampla at A GlanceDocument34 pagesAmpla at A GlanceBabar SaleemNo ratings yet

- Managementul Activelor SoftwareDocument51 pagesManagementul Activelor SoftwarerafaelorosNo ratings yet

- Proces wp001 - en P PDFDocument16 pagesProces wp001 - en P PDFReinaldo GomezNo ratings yet

- One Industry. One Erp. One Focus.: Erp Software Exclusively For Metal StampingDocument8 pagesOne Industry. One Erp. One Focus.: Erp Software Exclusively For Metal StampingTri H HarinantoNo ratings yet

- SNP - Network PlanningDocument17 pagesSNP - Network PlanningDebasis NandaNo ratings yet

- SAP Warehouse Management YTYDocument6 pagesSAP Warehouse Management YTYmarcopolllo8880% (1)

- Smarter Software For A Smarter Planet: Fueled by Expertise. Built For Change. Ready For WorkDocument8 pagesSmarter Software For A Smarter Planet: Fueled by Expertise. Built For Change. Ready For WorkjoindocNo ratings yet

- Current Status of ERP SystemsDocument8 pagesCurrent Status of ERP SystemsMax TanNo ratings yet

- Sim Chapter 9Document29 pagesSim Chapter 9nenidsNo ratings yet

- Certification Material PDFDocument224 pagesCertification Material PDFGaddam NeerajNo ratings yet

- The Web and Automation: What Is The Internet Model?Document2 pagesThe Web and Automation: What Is The Internet Model?Patricio CajasNo ratings yet

- Totally Integrated AutomationDocument8 pagesTotally Integrated AutomationShamim Ahsan ParvezNo ratings yet

- Plant-To-Business (P2B) Interroperability Using The Isa-95 StandardDocument4 pagesPlant-To-Business (P2B) Interroperability Using The Isa-95 Standardsaatank1No ratings yet

- Netsuite: AdvantagesDocument2 pagesNetsuite: AdvantagesJoeNo ratings yet

- ImVision Broc HRDocument8 pagesImVision Broc HRjesusjglNo ratings yet

- 10 Technology Best PracticesDocument8 pages10 Technology Best Practicesदीपक सैनीNo ratings yet

- Solution in Detail Manufacturing ETO and Project ManufacturingDocument28 pagesSolution in Detail Manufacturing ETO and Project ManufacturingBijaya MahanandaNo ratings yet

- Automating Your Business with NGOSS FrameworksDocument2 pagesAutomating Your Business with NGOSS FrameworksAyoDeji AyeniNo ratings yet

- Gartner-Microsoft Joint Newsletter - Implementing Your Next-Generation Integration PlatformDocument31 pagesGartner-Microsoft Joint Newsletter - Implementing Your Next-Generation Integration Platformaaaqqq326No ratings yet

- ISA 95 CodelcoDocument43 pagesISA 95 CodelcojackobondNo ratings yet

- Auto Component BrochureDocument4 pagesAuto Component BrochureMadhu SundharNo ratings yet

- US Supply ChainDocument4 pagesUS Supply ChainJana YoungNo ratings yet

- Brandl - Business To Manufacturing CollaborationDocument11 pagesBrandl - Business To Manufacturing CollaborationHeriberto Salvador Salort BizamaNo ratings yet

- Netsuite Brochure PDFDocument21 pagesNetsuite Brochure PDFscarscar123No ratings yet

- ADDM New Customer PresentationDocument17 pagesADDM New Customer PresentationkkuppachiNo ratings yet

- Agility Platform WebDocument2 pagesAgility Platform WebvishnuprakashNo ratings yet

- ABB DSS MAKES FASTER BETTER DECISIONSDocument2 pagesABB DSS MAKES FASTER BETTER DECISIONSWilson JolombaNo ratings yet

- Unit 15 Uses of Computers in Production and Operations: StructureDocument18 pagesUnit 15 Uses of Computers in Production and Operations: StructureAnil KumarNo ratings yet

- Acsis SAP AII OER Config Accel ProgramDocument2 pagesAcsis SAP AII OER Config Accel ProgramAndric BelNo ratings yet

- ABB in The Pharmaceutical Industry PDFDocument8 pagesABB in The Pharmaceutical Industry PDFjagl77No ratings yet

- Session15 EA1 ES&SCM FULLDocument57 pagesSession15 EA1 ES&SCM FULLSreyas SudarsanNo ratings yet

- Buyers Guide MESDocument22 pagesBuyers Guide MESscribdjh100% (2)

- Case Study: Built Integration Competency Center (ICC) For Leading Swedish Oil ManufacturerDocument4 pagesCase Study: Built Integration Competency Center (ICC) For Leading Swedish Oil ManufacturerindyanexpressNo ratings yet

- Simatic It Mes and BeyondDocument10 pagesSimatic It Mes and BeyondLeand_limaNo ratings yet

- Integration Strategies in A SaaS Environment - XML LogoDocument41 pagesIntegration Strategies in A SaaS Environment - XML LogokarunaduNo ratings yet

- MES Buyers GuideDocument22 pagesMES Buyers GuidetuvaohNo ratings yet

- Automation Point Product BriefDocument4 pagesAutomation Point Product BriefRaajaRaja CholanNo ratings yet

- Extending Business Intelligence With DashboardsDocument12 pagesExtending Business Intelligence With DashboardsImmanuel HenneNo ratings yet

- IBM Semiconductor Success White PaperDocument12 pagesIBM Semiconductor Success White PaperImmanuel HenneNo ratings yet

- The New Software-Defined Supply Chain, 2013Document18 pagesThe New Software-Defined Supply Chain, 2013Immanuel HenneNo ratings yet

- IBM Worklight V6.0Document4 pagesIBM Worklight V6.0Immanuel HenneNo ratings yet

- Get To Know The IBM SPSS Product Portfolio PDFDocument12 pagesGet To Know The IBM SPSS Product Portfolio PDFImmanuel HenneNo ratings yet

- 2012 Ibm Cognos Tm1Document8 pages2012 Ibm Cognos Tm1Immanuel HenneNo ratings yet

- IBM Worklight v6.0 - Technical White Paper, 2013Document12 pagesIBM Worklight v6.0 - Technical White Paper, 2013Immanuel HenneNo ratings yet

- Magic Quadrant For Mobile Application Development PlatformsDocument34 pagesMagic Quadrant For Mobile Application Development PlatformsImmanuel HenneNo ratings yet

- Service Virtualization - The Economics of Software TestingDocument8 pagesService Virtualization - The Economics of Software TestingImmanuel HenneNo ratings yet

- Ibm Rational DoorsDocument4 pagesIbm Rational DoorsImmanuel HenneNo ratings yet

- IBM Tririga Workplace Mangement - Saving CostDocument8 pagesIBM Tririga Workplace Mangement - Saving CostImmanuel HenneNo ratings yet

- Solve Your Toughest Planning and Scheduling ProblemsDocument18 pagesSolve Your Toughest Planning and Scheduling ProblemsImmanuel HenneNo ratings yet

- Buyer's Checklist: How To Find A Solution That Delivers Fast ROIDocument6 pagesBuyer's Checklist: How To Find A Solution That Delivers Fast ROIImmanuel HenneNo ratings yet

- Anti-Malware and Data Protection For Network SecurityDocument2 pagesAnti-Malware and Data Protection For Network SecurityImmanuel HenneNo ratings yet

- Selecting A Managed Security Services ProviderDocument12 pagesSelecting A Managed Security Services ProviderImmanuel HenneNo ratings yet

- Manage Identities and Access For Continuous Compliance and Reduced RiskDocument8 pagesManage Identities and Access For Continuous Compliance and Reduced RiskImmanuel HenneNo ratings yet

- IBM TRIRIGA - The Power of True Integration in Workplace Management SolutionsDocument8 pagesIBM TRIRIGA - The Power of True Integration in Workplace Management SolutionsImmanuel HenneNo ratings yet

- Ibm Rational DoorsDocument4 pagesIbm Rational DoorsImmanuel HenneNo ratings yet

- IBM and Siemens PLM SoftwareDocument8 pagesIBM and Siemens PLM SoftwareImmanuel HenneNo ratings yet

- The Blackwell Guide To Business Ethics PDFDocument349 pagesThe Blackwell Guide To Business Ethics PDFJeremy Neufeld75% (4)

- Marketing Management PPT AllsessionsDocument577 pagesMarketing Management PPT AllsessionsArfa FatimaNo ratings yet

- Research ProposalDocument34 pagesResearch ProposalSimon Muteke100% (1)

- Starbucks Success Built on Ethics and QualityDocument19 pagesStarbucks Success Built on Ethics and QualityReuben EscarlanNo ratings yet

- Management Discussion & Analysis highlights key developments in Indian economy, housing finance industry and company's progressDocument136 pagesManagement Discussion & Analysis highlights key developments in Indian economy, housing finance industry and company's progressVritika JainNo ratings yet

- Evaly PR Plan by PDFDocument20 pagesEvaly PR Plan by PDFAl-Rafi Ahmed100% (1)

- Overview of Digital MarketingDocument4 pagesOverview of Digital MarketingSUJIT SONAWANENo ratings yet

- Ulaganath Madan-FinalDocument9 pagesUlaganath Madan-Finalapi-3719687100% (4)

- Assignment 1.1Document2 pagesAssignment 1.1Heina LyllanNo ratings yet

- Tutorial 2-5 Submitted BY:SULAV GIRI (40765)Document6 pagesTutorial 2-5 Submitted BY:SULAV GIRI (40765)Smarika ShresthaNo ratings yet

- Student Assignment Answer ALIDocument9 pagesStudent Assignment Answer ALIasadullahqureshi2No ratings yet

- Chapter 1 problem 3 exercisesDocument18 pagesChapter 1 problem 3 exercisesAlarich CatayocNo ratings yet

- Transforming HR with Technology ExpertiseDocument2 pagesTransforming HR with Technology ExpertiseAdventurous FreakNo ratings yet

- ADTimes 2021 Perfetti Van MelleDocument9 pagesADTimes 2021 Perfetti Van MelleDIBYAJYOTI BISWALNo ratings yet

- 2.1 Chapter 2 - The Fundamental Concepts of AuditDocument21 pages2.1 Chapter 2 - The Fundamental Concepts of AuditĐức Qúach TrọngNo ratings yet

- Sports TourismDocument14 pagesSports TourismJaipurnetNo ratings yet

- Public Procurement Reform in Developing Countries - The Uganda Experience PDFDocument19 pagesPublic Procurement Reform in Developing Countries - The Uganda Experience PDFByaruhanga EmmanuelNo ratings yet

- ACLC College Tacloban Marketing PrinciplesDocument70 pagesACLC College Tacloban Marketing PrinciplesSherwin HidalgoNo ratings yet

- Group Presentation Guides: Real Company Analysis Improvement InitiativesDocument9 pagesGroup Presentation Guides: Real Company Analysis Improvement InitiativesVy LêNo ratings yet

- Activity Based CostingDocument13 pagesActivity Based CostingSudeep D'SouzaNo ratings yet

- Running Account BillDocument4 pagesRunning Account BillModa GyatiNo ratings yet

- Cloud Operations PlaybookDocument127 pagesCloud Operations PlaybookSantosh Kumar100% (1)

- 8th Mode of FinancingDocument30 pages8th Mode of FinancingYaseen IqbalNo ratings yet

- Basic Banking Tools and VocabularyDocument1 pageBasic Banking Tools and Vocabularyperrine11No ratings yet

- Digital Marketing PresentationDocument16 pagesDigital Marketing PresentationAreeb NarkarNo ratings yet

- S4HANA Sales Certification QuestionsDocument3 pagesS4HANA Sales Certification QuestionsSiddharth Sinha100% (2)

- Mergers and Acquisitions of Masan and Singha as a Tool for GrowthDocument6 pagesMergers and Acquisitions of Masan and Singha as a Tool for GrowthNguyễn Trần HoàngNo ratings yet

- Ensuring Global Insurance Compliance with Local LawsDocument9 pagesEnsuring Global Insurance Compliance with Local LawsDjordje NedeljkovicNo ratings yet

- Insurance Basics: Characteristics, Risks, and BenefitsDocument10 pagesInsurance Basics: Characteristics, Risks, and Benefitsmark sanadNo ratings yet

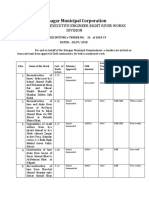

- Srinagar Municipal Corporation: Office of The Executive Engineer Right River Works DivisionDocument7 pagesSrinagar Municipal Corporation: Office of The Executive Engineer Right River Works DivisionBeigh Umair ZahoorNo ratings yet