Professional Documents

Culture Documents

Belt Conveyor Project 03-07-2013

Uploaded by

Shashikala KolliparaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Belt Conveyor Project 03-07-2013

Uploaded by

Shashikala KolliparaCopyright:

Available Formats

CHAPTER-1 INTRODUCTION OF BELT CONVEYORS PREVENTION IS BETTER THAN CURE. It is more talked about than practiced.

It is economical, peaceful,prudent and safe to prevent an untoward happening and thus prevent loss than to bemoan the loss, trying to investigate the cause/s, the after-effect and invent cure: for accidents are caused and do not occur as a matter of course.Even with the advancement of modern technology, in different disciplines wherein various types of cures are available for various ills and shortcomings, Cure is only a cure and does not and cannot restore the original status and /or shape prior to the happening.There are side-effects which need greater caution and aftercare, after the cure.Thus ,the emphasis for preventionthan attempt a cure after the event. Loss may be in manpower, material and money. In an organization, loss due to breakdown has been worked out with precision.Whenever a breakdown occurs not only that equipment is not available till it is restored, but a substitute has to be arranged,if it is a continuous process, involving loss due to extra man-power, time and money in arranging the substitute or alternative arrangement. Then, we have consider, how we go about preventing a loss due to accident.It is by adapting Safety Measures and following Safety Principles for Safety is First. Safety is first and foremost and is always first and never be relegated to a second position.Safety is not only first and is essential in every walk of life and situation, be it in the Field of Factory,Office, Household including Kitchen and Bed-room, for lurks in every corner and every moment. Belt conveyors are perhaps the most common,economic and efficient means for continuous movement of materials between fixed points. These are in use in many industries and establishments for conveying a wide variety of materials ranging from small parcels to ore in bulk.Their size varies from a few meters in a warehouse to several hundred meters in a mine. Like any other transmission machinery, belt conveyors present risk of injury. Experience shows that conveyor accidents often involve fatal or very serious `injuries and severe damage to property. As conveyor systems are vital links in the production chain, their stoppage due to accidents or

breakdowns can lead to serious business interruption loss as evidenced in some of the fire incidents in power plants and elsewhere. In bulk material transportation systems, excessive spillage represents wastage of material and can present occupational safety and healthy pro

CHAPTER-2 Hazards in Belt Conveyor Systems Most accidents in Belt Conveyors occur when hands of persons working on the conveyors come into contact with the moving belt and the inadequately guarded nip points and pinch points near pulleys and idlers.Such accidents are usually severe,and sometimes fatal too.Mechanical failure of conveyor components due to deficiencies in design, operational and maintenance procedures also render the conveyor systems hazardous.Spillage of material, fires from friction, overheating,static charge and other electrical sources are the other important hazards encountered in belt conveyor system.

CHAPTER-3 DESIGN AND CONSTRUCTION For good performance, the Conveyor belt chosen for installation should have adequate tensile strength, wear resistance,frictional characteristics, flexibility and stretch.For special applications, the belt may require resistance to heat, oil, water, chemicals and static charge. Conveyor belts are generally constructed of a fabric core which must be strong enough to withstand and transmit the tension necessary to operate the belt.Use of multilayers or reinforcement with metal strands or mesh can add to the strength of the fabric core.The fabric core is then either covered or impregnated with appropriate flexible compound,natural or synthetic, and further strengthened as necessary with suitable wearing faces made again of natural or synthetic compounds.For example, a 6 ply nylon carcass with top and bottom rubber will suit bumpy and abrassive materials,whereas a 4-ply cotton carcass will be suitable for warehousing operations.Guidance on the most suitable type of belt for handling the required material is available from the manufacturers of conveyor belts and should be sought for.

The belt loading system should fill the belt with minimum spillage of excess material.The design criteria should take into account the quantum of spillage, the operating and maintenance procedures to clear the same and the associated injury hazards.In one of the newsprint mills, the authors came across an investigation into a fatal accident to a worker engaged for clearing the spilled bagasse pulp and shoveling it back on to the conveyor belt, which highlighted the design deficiency that resulted in substantial spillage of excess burden on the conveyor which simply could not match the loading rate. All parts of the conveying system should as far as possible meet the applicable national or international standards.During design and construction stage, it is necessary to adhere to the relevant provisions in the following statutes: 1.Factories Act, 1948 and the Factories Rules framed thereunder. 2.The Mines Act, 1952 3.The Indian Electricity Act, 1910. 4.The Dock Workers (Safety,Health & Welfare) Scheme, 1961. Further by choosing critical components of latest design, it is possible to reduce maintenance requirements of these parts. For example, self-aligning rollers reduce the problems of belt centering and spillage of materials.Permanently lubricated idlers, pressure oiling, or automatic gravity lubricators can eliminate the need for periodical lubrication and the possibility of injury to the personnel. SAFE ACCESS: Walkways on the sides of the conveyor facilitate inspection, repair and maintenance.Many conveyors run above ground level and should have gangway all along the length.The gangways should have chequered plate flooring to reduce risk of slipping and guarded by standard railing and toe boards.For access to the gangways, stairways are preferred to fixed ladders. If portable ladders are used they should be equipped with protection devices against falls. Such devices include anchoring arrangements to prevent lateral movement of ladder, antislip rubber shoes for stiles, etc. Plant personnel may have to cross the conveyors to reach work place on the otherside.Crossover bridges provided at short distances can reduce the temptation of employees to take a short cut from under the conveyor carriage or over the conveyor belt.Accidents involving persons falling off the crossover

bridges are also reported.To prevent such accidents, the platform and stairways of the crossover bridge should be non-slip type having hand rails and toe boards.A top rail at one metre height,an intermediate rail at 66 cm height and a toe board of 15 cm height from the safety requirements for stairways and work platforms or passageways at heights.In conveyor tunnels, adequate drainage should be maintained to drain out the rain water and underground water seeping through the tunnel walls. For safety of personnel working in conveyor enclosures especially at remote, elevated or underground enclosures, emergency exits should be provided and located conveniently to facilitate evacuation in the event of fire which generally spreads along the conveyor and also generates heat and smoke that obsecures the vision. CHAPTER-4 ELECTRICAL EQUIPMENT AND SAFETY DEVICES: The electrical equipment and wiring for the conveyor systems should conform to the statutory provisions and codes of practice.Whenever, bulk material is conveyed, the dusty atmosphere around warrants use of dust-tight electrical motors, switches and fittings.Fuses,relays, overload protection devices should be incorporated in the control systems.The overload device may be arranged to shutoff driving power may be considered for misalignment of belts also.By passing or sort circuiting of the above devices can create serious fire hazard.The need for periodic inspection of these devices for reliable operation is obvious. All starting and stopping switches should be positioned in a convenient location so that the operator can see as much of the conveyor as possible.These start-stop devices should be marked clearly and kept free of obstructions. Guards: All moving and power driven parts of the conveyor equipment should be guarded. This is a statutory requirement under Factories Act and the Rules. In general, guards are required for all accessible moving parts of conveyor system. These include the moving belt, motor-gear box couplings, tail and head pulleys and tension pulleys. The guards should be sturdy enough and should withstand the vibration. They may be of sheet metal or expanded metal, but as far as possible, the guards should

be so designed as not to hamper maintenance, repair or cleaning jobs. For example, a guard should be positioned so that spillage falls outside the guard and can be easily cleared away without exposing the personnel to risk of injury. For tail and head pulleys and other vulnerable parts, guards should be interlocked with the drive mechanism such that it is not possible to have access to the mechanism unless the machine comes to a stop. One such method is to have doors that open after predetermined time delay after switching off the machine. The underside of an overhead conveyor section passing over an aisle or passageway should have sheet metal guard if there is a possibility of materials falling off the running belt. Such a guard can protect the passers from the sticky material that may fall off the return belt portion. Control & Disposal of Spillage: Material spilt from conveyor belts represents wastage and injury hazard.Bulk materials such as Urea & hygroscopic and render the neighbourhood of conveyor slippery.Spillage of combustable materials like wood chips and coal enhances the fire risk. Excessive spillage warrants deployment of manpower to put back the spilled material on the running conveyor belt to reduce the chance of materials falling off the belts. These can be conveniently erected at the conveyor loading points to retain in place the material that falls on the belt from the loading chutes. When properly fixed,they reduce spillage of materials substantially. For proper working, the skirt should be made of solid rubber. Use of discarded, old conveyor belts for the purpose should be avoided. Where metal skirts are used, they should either have sufficient clearance from the belt surface or be provided with rubber strips at the point of contact with the belt. In the absence of this precaution, the metal skirt may damage the conveyor belt. The spillage along the conveyor and the carry-over at the end of the conveyor, present problems of jamming of idlers and heating of conveyor belting. Where it is not possible to reduce such carry-over or to clear the same by shoveling it back onto the belt, arrangements should be made to sweep it into a terminal hopper. This is particularly

important at transfer towers or other elevated platforms which can accumulate substantial unwanted spillage with no easy way of removing it to ground level. Sweeping it into the surrounding air accentuates the dust nuisance. A hopper and a chute pipe to return the spillage from the elevated places either to the conveyor system or to a closed container at ground level would prove to be convenient and effective spillage disposal system. Brakes: Brake is expected to stop the conveyor in an emergency and should be capable of sustaining 25% excess of the peak load when applied. Back stop devices are provided on inclined conveyors to prevent the belt from running backwards when stopped on load. Ratchet and pawl and differential band brake are the two types of backstop devices normally provided on conveyors. These require regular inspection for proper working. Tensioning Devices: Tensioning devices are provided on conveyors for three reasons. To provide adequate belt tension, to prevent belt spillage and to compensate for stretch or shrinkage. For small conveyors (less than 50m), tension adjustment is done manually. The tail pulley and shaft should be properly guarded while adjusting the take-up manually when the belt is running. On large conveyors, automatic adjustment of belt tension is achieved by gravity counterweights or pneumatic/hydraulic tensioning arrangements. In the event of belt breakage the take up pulley and the counter-weight would drop down. To avoid possible injury to work men in the neighbourhood, it is necessary to guard the entire take up assembly by means of a wire mesh. Cleaning Devices: Belt cleaning devices are provided to reduce the accumulation of spillage along the length of the belt on return side and to keep the belt clean. These cleaning devices or scrapers as they are sometimes called, also reduce the wear and tear of the belt. Rotating brushes, scraper blades and water sprays are the three basic devices commonly used. Rotating brushes are used for removing damp

and sticky material from belts operating at high speed (1000 to 1500 rpm). For good results the scraper blade or the rotating brush should be placed behind the pulley at a point where the belt leaves the pulley. Water jet by itself is not considered effective. The jet can be used in conjunction with the rotating brush. Automatic self-aligning troughing and return rollers may be provided for belt centering. Outboard guide rollers fixed to the self-aligning frames cause the idlers to swing on contact with belt edge. These aligning rollers are effective in controlling spillage when provided on long conveyors. It is recommended that a distance of 40-50m be maintained between two self aligning frames. Fire Prevention and Protection: Belt fires often prove costly. They not only damage or destroy the belt, drive motors, speed reducers, electrical cables and structural parts but also cause loss of production till the conveyor system is brought back into operation after necessary repairs or replacement. In a power generation plant, a conveyor belt fire was responsible for nonavailability of electric power supply to consumers for several weeks. Further a fire in a running conveyor transporting materials like coal can be very dangerous because coal presents a potential fire hazard due to spontaneous ignition. The main sources of ignition in conveyor belts are friction between the belt and jammed idlers, belt slippage at the drive drum, materials carried by the belt(as in sinter plants), welding and cutting sparks and static charge accumulation on the belt. Conveyor belt fires and the associated losses can be controlled by providing fire resistant or non fire propagating belting, flame-proof motors in hazardous areas, provision of oil seals in speed reducers to avoid oil leakage, effective spillage, removal and disposal procedures, hot work permit system for welding or cutting work on, near or over the conveyor belts and frequent fire watch.Good operating and maintenance procedures obviously reduce the chance of outbreak of fire,especially due to friction. Static electricity collectors help to reduce fire and explosion hazards on belts that handle flammable dusty materials. Tinsel or needle point static collectors can be placed close to the pulleys and idlers which can be grounded through carbon or bronze brushes on the shaft. Bonding and grounding of drums and pulleys is also necessary.

The effective extinguishing medium for fires involving rubber belt is water in spray form. Automatic sprinklers or water spray protection along conveyor structure would prove useful especially if the conveyor belts are not fire resistant type. Small bore hose reels (1 ) or hydrants with landing valves at various levels may be provided to reach any part of the conveyor system. In pulverized coal conveyors it is advantageous to provide an automatic fire detection and alarm system coupled with a water spray arrangement along the conveyor and a water mist curtain at the head of conveyor where the material leaves the conveyor and enters into transfer towers. In enclosed coal conveyors, provision of carbon dioxide nozzles for manual or automatic operation may also be considered. It should be remembered that fire protection in belt conveyor installations is a specialist ,s job that requires careful consideration of the combustible nature of the material conveyed and of the belt material, the conveyor speed and the rate of application of the extinguishing medium for effective fire suppression. In the context of fire safety also, the utility of pull-cord to stop the movement of conveyor and consequently to reduce the speed of fire spread cannot be over emphased. Sometimes, conveyors may have to pass from one section to the other separated by a fire wall. It may be possible in certain situations to run conveyor through the roof over the fire wall. Otherwise, an automatically closing fire door has to be installed in the portion of the fire wall through which a conveyor may pass. A careful design of the controls is necessary to ensure that conveyor is stopped at a position where material on the conveyor will not block the fire door from closing. Alternatively, water spray protection for conveyor opening in fire walls may be provided.

Dust control Dust extraction devices should be installed where the dust of material being conveyed creates a fire hazard, toxic effects or a nuisance problem in the neighborhood, proper enclosures in conjunction with mechanical ventilation system at transfer points, bunker floors and near surge bins would reduce this

hazard. In some situations where the nature of material permits wetting, by water spray system could also effectively control the dust emission. Miscellaneous The equipment should be clearly visible, and hence permanent lighting should be provided bright enough and properly distributed in all the conveyor gantries, tunnels and pits. Operational Precautions Overload or interlocking devices should never be bypassed. Good housekeeping enhances safety and minimizes the risk of fire. All areas especially those surrounding the conveyor drives, walkways, safety devices and controls, should be kept free of spillage of materials being conveyed, unused equipment components and other obstacles. Dust deposits, oily rags, cardboard packagings, paper wrapping materials, cans and drums of lubricants should not be allowed to accumulate near conveyors in view of their fire hazard. All weeds, bushes or trees should be cleared from underneath and for at least 25 feet from both sides of conveyers supports. Oiling and lubrication should be done after stopping the conveyor unless there is an arrangement which does not require an oiler to come enclosed proximity to moving parts. Further no adjustment or repair should be made while conveyor is in motion. Operating personnel and cleaners should avoid even minor repairs on a running conveyor. Repair and maintenance preferably should be left to maintenance department. Riding on conveyors should be prohibited and this prohibition enforced strictly Effective supervision in necessary to ensure adherence to safe practices and to correct deviation before accidents occur. Conveyors should not be overloaded above the design parameters. Conveyors operators should wear protective helmet, safety shoes and close fitting clothes during operation. Innumerable accidents took place when loose clothing of workmen entangled with rotating or moving parts of the conveyor system and dragged the workmen into dangerous pitch points and interspaces between conveyor moving parts. Most of such accidents turn out to be fatal or serious. In a paper mill, a worker engaged in collecting the spilled bag asset from a conveyor,

lost his life when his dhotis got entangled with an idler and dragged him forward on to the moving conveyor belt. Conveyors should not be started without warning men who might be attending to repairs or lubrication of parts. The warning should preferably be an audible alarm given through public address system. In modern plants, closed circuit television system with screens grouped together in the control room gives the operator in the control room a view over the entire length and branches of the conveyor system. While loading the conveyors or removing materials workers sometimes stand on the supporting frames of conveyors. As the workers may slip and get caught in the conveyor belt, suitable platforms should be provided for the purpose. Inspection and Maintenance Precautions A standard preventive and scheduled maintenance programmed should be developed for all conveyor parts along with an inspection checklist. Initially, the maintenance schedule should be drawn up based on manufacturers recommendations and later modified based on experience on behavior of the equipment under the conditions of use. The observation during the inspections and the details of repair/maintenance work carried our should be recorded for reference and analysis. For example, the date of replacement of conveyor belt, the dare of jointing, the date of replacement of idlers, etc., would be useful, in review and modification of maintenance schedules based on experience. Such data would also help to indentify parts that suffer abnormal wear and tear or exhibit abnormal behavior and to investigate into the reasons for the same. Belt joints should be inspected frequently and the conditions of the joints should be recorded. In case of steel cord belts, the length of the joint should be measured and recorded every year. 2 to 3% increase in the length of the joint indicates imminent failure of the joint. Hence rejoining of the belt may be undertaken after detailed examination, if necessary. Motors when meggered once in every 6 months can provide a valuable early warning of failure. Hence periodic resting of motors may be incorporated in the inspection schedule. Motors require regular cleaning to remove accumulation of dust which restricts cooling and leads to dangerous overheating. Other parts of the conveyor system that need specific attention during maintenance are idlers which may wear flat by belt friction in the absence of free rotation and the gravity take up unit that may bottom-out with belt stretch or spillage

accumulation under it. Checking these parts as also the belt alignment periodically is important from the point of view of fire safety also. The inspection and maintenance schedules should also include periodic checking and cleaning of water spray nozzles and regular resting of the entire fire protection system. Attention should be paid to lubrication of conveyor part. It is important to use the appropriate grade of lubricant for heavy duty gear boxes and motors based on manufactures recommendations. Permanently lubricated idlers are of advantage in this context. Inventory management of critical parts like belts, pulleys, bearings, etc., assumes great significance in this context. Replacement of worn-out parts in time not only reduces the down time of conveyors but also the risk of accidents significantly. Often, safety is compromised by continued use of workout or broken down equipment because of no availability of suitable spare parts. Safe systems and procedures for maintenance are also important. How work permit system for welding or cutting work on or around belt conveyors, electrical work permit system for protection against electric shock and accidental starting of conveyor during the currency of the maintenance work, are some of the important elements of safe maintenance system. Before commencing any maintenance work on belt conveyor, ensure that all controls are switched off and locked out. Maintenance personnel should be aware of the fire hazard with the clanging fluids used in belt splicing and jointing work and fire prevention measures should be taken as required. The maximum tension rating for the belt recommended by the manufacturer should not be exceeded. Use of snub pulley under the drive pulley without increasing the tension of the belt. Training and Education It is common knowledge that causes 0f most accidents can be attributed to human error which in turn can be traced to lack of skills, knowledge and positive attitude to safety. Hence it is important that all those connected with conveyor operation are trained not only in safe operating procedures but in their attitude to work safety.

Every operator should understand the method of starting and stopping, hazards likely to arise in operation, the utility of guards and safety devices the need to report malfunction or non-functioning of any equipment and to avoid short cuts. They should be made aware of the nearest fire exits, communication facilities and the fire fighting techniques. Operator training in the backdrop of safe systems, procedures and environment is bound to enhance life of plant and equipment, reduce down time and of course improve the standard of safety.

CHAPTER-5 STATUTORY PROVISIONS SPECIFICALLY APPLICABLE TO CONVEYOR SYSTEMS Dock workers (Safety, Health & Welfare) Scheme, 1961. 1. Conveyors shall be of sound material, good construction and of sufficient strength to support safety the loads for which they are intended and shall be kept in good repair.

2. i) Conveying machinery shall be so constructed and installed as to avoid hazardous points between moving and stationery part or objects. ii) When a passageway is adjacent to an open conveyor, a clearance of at least 90cm (3 feet) shall be provided.

3. When dock workers have to cross over conveyors, regular crossing facilities affording safe passage and adequately lighted shall be provided. 4. Might pass beneath them, sheet or careen guards shall be provided to catch any material which might fall from the conveyors. 5. Power-driven conveyors shall be provided at loading and unloading stations, at drive and take-up ends, and at other convenient place, with devices for stopping the conveyor machinery in an emergency. 6. Adequate fencing shall be provided at transfer point. 7. Conveyors which carry loads up inclines shall be provided with mechanical devices that will prevent machinery from reversing and carrying the loads back towards the loading point in the event of the power being cut off.

8. Where two or more conveyors are operated together the controlling devices shall be so arranged that no conveyor can feed onto a stopped conveyor. 9. Where the tops of hoppers for feeding conveyors are less than 90 cm (3 feet) above the floors the openings shall be adequately guarded. 10.I) where conveyors extend to points not visible from the control stations, they shall be equipped with gongs, whistles of signal lights, to be used by the operators before starting the machinery so as to warm dock workers who might be in positions of danger. ii) Similar provisions shall be made where necessary to enable the dock workers to communicate with the operator. 11.Conveyors shall be provided with automatic and continuous lubrication systems, or with lubricating facilities so arranged that oiling and greasing can be performed without the oilers coming within dangerous proximity to moving parts. 12.Conveyors shall be thoroughly inspected once in every three months. 13.Dock workers shall not ride on conveyors. 14.Belt conveyors shall be provided with guards at the nips of belts and drums. 15.Intake openings of blowers or exhaust fans for pneumatic conveyors hall be protected with substantial metal screens or gratings. 16.Frames of gravity rollers and chutes shall be kept free of splinters, sharp edges and rough surfaces. 17.Gravity rollers and chutes shall not be used for the passage of dock workers. 18.Sideboards of chutes shall be of sufficient height to prevent cargo from falling off. *********

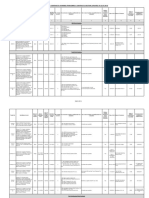

CHAPTER-6 LIST OF INDIAN STANDARDS BELT CONVEYORS

1. IS: 1891 - 1978 (Part 1) : Rubber Conveyors and Elevator belting General Purpose belting (Part 2) : Heat Resistant belting

(Part 3) : Oil Resistant belting (Part 4): Hygienic belting

2. IS: 3181 -1978 Fire Resistant Conveyor belting for under-ground use in Coal Mines. 3. IS: 4240 - 1984 Glossary of Conveyor terms and definitions. 4. IS:4776 -1977 (Part 1) Troughed belt Conveyors for surface installation. (Part 2) Troughed belt Conveyors for underground installation. 5. IS : 6687 -1972 Code of Practice for selection, storage, installation and maintenance of conveyor belting. 6. IS : 7155 -1974 Code of Practice for Conveyor Safety 7. IS : 7465 -1974 Portable and mobile and troughed belt Conveyors. 8. IS : 8531 -1986 Pulleys for Belt Conveyors 9. IS: 8597 -1977 Flat Belt Conveyors 10. IS: 8598 -1977 Idlers and Idlers sets for Belt Conveyors 11. IS: 9295 -1983 Steel Tubes for idlers for troughed Belt Conveyors. 12. IS: 9405 - 1980 ( Methods of kest of Conveyor Belt fasteners 13. IS: 11507 -1985 Synchronous best drive Pulleys. 14. IS: 11592 -1985 Code of Practice for selection and design of Belt Conveyors.

OTHER CONVEYORS 15. IS: 5895 -1985 Steel Roller Conveyors 16.IS: 7423 - 1974 Dimensions for Apron Conveyors 17. IS: 8599 -1977 Recommendations for selection of Apron Conveyors 18. IS: 8646 - 1977 Scraper Conveyors 19.IS: 5563 - 1985 Screw Conveyors for Industrial use 20. IS: 5626 - 1970 Shackle type connecter units for high tensile steel chain for conveyors in mines 21. IS: 8723 -1978 Dimensions for Vibrating Conveyors and feeders with rectangular or trapezoidal trough 22. IS: 7439 -1974 Dimensions for Aeroslides 23. IS: 5972 -1970 Glossary of Pneumatic and Hydraulic Conveyor terms and definitions 24. IS: 8647 -1977 Design Criteria for Pneumatic Conveying systems 25.IS: 6834 -1973 Conveyor chains, Chain wheels and attachments. (Part) : Chains (Part 2) : Chain Wheels (Part 3): Attachments.

CHAPTER-7 PREVENTION OF ACCIDENTS DURING BELT CONVEYORS MAINTENANCE The development of any country depends on its industrial potential. Industrially, our country is making rapid progress. Materials handling activity in organisations is also picking up greater momentum and every industry is trying to have maximum output with faster and quicker methods. Amongst the materials handling equipment, the belt conveyor system has the advantage of simplicity in construction, high efficiency and low frictional loss resulting in low power requirement and economy in upkeep. The advantages of Belt Conveyor haulage have transformed what might be called Mechanical Curiosity to an indispensible component in the haulage system with a reputation for genuine usefulness in an ever widening field of application. Conveyor belts came into existence around 1868 when LYSTER, an English Engineer described to the

British Engineering Society his work on conveying bulk materials by endless belts made of two pulleys of rubber faced canvass. This mode of transport which was confined to a few thermal stations and cement plants is increasing in its use in ports, open cast and underground mines, steel plants and in various other fields. The Conveyors may be horizontal or inclined or a combination of both and can be arranged to convey material either up or down an incline. There are two main types of conveyors; (1) Flat type-generally used for bags, bottles, boxes and other packaged materials,widely used in production units although under certain conditions, loose materials in bulk such as soap may also be satisfactorily handled; (2) Trough type which enables the loading capacity to be increased by 60% without danger of spillage and is suitable for almost all bulk material in a dry, damp or semi-wet condition. The basic components of any Belt Conveyor are (1) Belt; (2) Carrying Idlers; (3) Return Idlers; (4) Head-end, Tail-end Snub Pulleys; (5) Drive mechanism. Cost wise, belting alone forms nearly 35 to 40% of the total cost and the other major share is the Conveyor rollers.Of the remaining components, the critical ones are parts of conveyor drive like Pulleys, Gear boxes, Couplings, electrical motors and other components and fixing arrangements. Visakhapatnam Port, one of the major Ports in India situated in East Coast,has first installed the Conveyor system in 1965 for exporting Iron Ore to Japan. Intially started with a loading rate of 2600 tonnes per hour its capacity increased to 3200 tonnes per hour. As the demand has further increased and the need to have a deep draft vessels along side the berth has been felt, the outer harbor came into existence in 1976, with a higher capacity loading of 8000 tonnes per hour. The whole system is divided in two parts as Receiving system and Shipping system. The Receiving system comprises of wagon tipplers and stackers connected by Conveyor system, for off-loading the ore from the wagons mechanically and to stockpile in stack yards with the help of stackers. All the Receiving system Conveyors are 1200mm wide steel cord conveyors and a few fabric belts. The shipping system comprises of Bucket wheel Reclaimers and a shiploader, connected by 1600mm wide steel cord conveyors. During shipment the ore is reclaimed with the help

of reclaimers and traverses a distance of about 5KM in different belts, finally off-loads into the ship. Totally about 20KM of belting is installed for the various operations. It is a herculean task to maintain this conveyor system which will be working round the clock all the 365 days of the year. Some conveyors are at an elevation of 10-20 metres. All the belts are interlocked and any weak link in the chain will bring the entire operation to a grinding halt causing appreciable loss. If the shipment is not done in time, heavy demurrages have to be paid and the prestige of the country is involved. To meet the export commitments effective maintenance of the conveyor system is to be carried out in an effective way. Inspite of several protective devices in-built in the system, accidents do take place while attending to the conveyors and have to be prevented both for the system and personnel working near-by. There should not be any compromise in safety aspect. Safety can; be analysed in terms of (1) System safety; (2) Personnel safety; Generally in a belt conveyor system a number of safety devices are provided, such as Emergency Switches, Pull Chord Switches, Overload Switches, Thermal fault, Belt tensions, Fluid Coupling hot, Sirens, etc. The purpose of provideing so many safety devices is to safeguard the system. As far as the safety of the personnel working near the conveyor system, is concerned, a number of provisions exist. These include cross-overs, guards on couplings and provision of meshing around the pulleys in drive houses, Ladders to reach elevated places for greasing the bearings, or for condition monitoring of bearings, easy accessibility for maintenance purposes or for changing the pulleys or idlers etc.Apart from these, personal protective equipments like boiler suits, helmets,goggles, gloves, aprons, safety belts, etc. also are provided to all the employees. Inspite of these precautions, accidents do occur on account of personal factors. These can be controlled through measures such as councelling and educating the personnel involved.

Let us consider the accidents that happen to the system and personnel during maintenance :1.Belt Jointing Conveyor belts fail prematurely due to a through cut,foreign material piercing the belt, impact of over-sized boulders, joint failure, or excessive wear of belt.When the belt fails while the loading is in progress,great effort has to be put in to restore the system quickly. People do commit mistakes in such circumstances, leading to accidents. Case Study:One of the joints of the lengthiest overhead conveyor No.6 has failed while the shipment was in progress. The belt passes through a lattice structure gallery.After the joint was positioned for making a fresh vulcanising joint, the staff were deployed. As it is a lattice structure wooden planks were arranged for people to move freely and safely to attend the work. The joint was prepared by the usual procedures of peeling, core separation, alignment matching etc.To have an uninterrupted work and also to attend quicker, the Incharge has asked the 3rd shift staff to continue in the 1st shift on O.T., even though the 1st shift staff were available. As soon as the 1st shift staff reported at site, the night batch wanted to go for tea break as they had to continue to work further.They went for tea and came back. One operator took some more time and came late. After coming, he saw the Asst.Engineer at spot checking the progress of work. This operator felt that he may be questioned for late coming, tried to go to his place in another way and kept his foot on a loose plank and fell down from that height of 10 metres. He had head injury and expired within 10 hours. The reasons for this accident were analysed. It was purely due to not following and adopting the basic safety principles.The contributing factors were as follows: (1) Anet should be provided under the gallery when vulcanising work is in progress. In this case, the net was there. (2) The staff should use the helmets when they are working at elevations, which precaution was not followed. (3) Continuing the work from especially night shift to 1st shift. All precautions should therefore be taken before attending to maintenance work.Several other types of accidents occur at the time of attending to belt repaires, such as cuts and lacerations to body while pealing of rubber due to the slippage of knife and in-eperience.

Smoking should be strictly prohibited. Uncured rubber, vulcanising cement and other chemicals will be used for vulcanising purpose which are highly inflammable. Electrical short circuits, bad earthing also create sparks and cause fires, and hence proper cables to be used and proper earthing should be provided for machines. 2.Gear Box Maintenance A constant watch on the gear boxes especially by maintenance crew, is arranged because it is a vital link between the motor and the conveyor.The oil is checked frequently and will be changed depending on its condition. Case Study The maintenance staff attended for changing oil to the Boom Conveyor Gear box of Stacker.They have taken clearance from all the concerned, informed to the operator not to start the conveyor till they give clearance and started their work. They drained the old oil and filled the Gear box with new oil. As their work was at an elevation of about 100 metres, the oil had to be lifted manually in stages, with the help of cans. A worker who was actually pouring the oil into the gear box positioned himself by keeping one leg on the Boom Conveyor pulley and the other leg on the gear box. When the work was in progress,the operator suddenly started the conveyor. One person who was standing near the conveyor jumped out, but the person who was standing on the conveyor had no chance to escape on any side. His leg was caught in between the idlers and belt and was cut off. The rest of the body fell down from that height resulting in instantaneous death. An exercise to find out causes of this fatal accident gives rise to the following questions and many other issues. (1) How did the operator start the conveyor knowing fully well that the maintenance staff are working and have not returned clearance? (2) Whether the maintenance staff have switched-off the Pull Chord Switch and emergency switch before attending to work. (3) Whether the Siren that is provided before the starting the conveyor below or not or whether both took place simultaneously. (4) Whether the Control Room Operator switched off the entire supply to the machine or not?

After studying all in detail, strict instructions were given to use all the safety devices and take preventive measures like switching off the switches etc,before attending to any work.

3.Maintenance on Idlers Idlers form an important item in conveyor system. Stucked-up idlers, damaged idlers and improper fixing cause damage to belts.When the ground clearance is less, the return idlers will get buried or jammed with heavy accumulation of slush, slurry, dribbles and fines especially in monsoon season. This jamming causes the belt to rub resulting in fast wear and also throws the belt out of alignment, some times causes damages by cutting the edges very badly and punctures, through-cuts, etc. Labour have to be engaged for clearing these accumulations for safe running. Sometimes the work may have to be attended while the belt is running if the accumulation is less. When it is more, the belt has to be stopped and proper precautions have to be taken by switching-off the switches and informing the concerned. Case Study The No.1 Conveyor runs through a tunnel 10 Metres deep and comes out. As the area is a marshy area, lot of seepage water accumulates and it is pumped out very frequently to prevent flooding. Dust and fines mix with this water and form a slurry that fills the whole area and causes obstruction for the running of conveyors. The operator has to see that there is no accumulation under the conveyors for safe running and whenever it is there, he arranges for clearing by the labour. One day after he reported for duty in the night shift, he found heavy accumulation. He stopped the conveyor, switched-off the PullChord and arranged for cleaning. After cleaning, he switched on the Pull Chord switch and gave clearance for running the belt. He stood on the Tail pulley frame to observe the belt for any damage or rubbing. After getting the clearance, the control room operator started the belt. The Operator who was standing on the frame slipped and fell on the belt and crushed between pulleys and died on the spot.

4.Pulley Maintenance Failure of pullies due to shaft shearing, failure of welding on the hub side, blow holes bearing failure or due to any other reason causes heavy damage to the costly belts. In one of the main conveyors a pulley had failed by shearing of a shaft on one side. By the time the operato realised this and stopped the conveyor, considerable damage had occurred. Nearly 1200 Metres length of belt was sheared-off into two pieces longitudinally. This belt was running at a speed of 210 metres/minute. Failure of any part of the pulley causes havoc. Conclusion: Even though the conveyor system helps us to do faster work, we must see that it should not cause havoc and play with our lives. Necessary training in using the various safety devices provided and following strictly without any hesitation or reservation as far as safety principles and procedures are concerned, will help in preventing the accidents to a great extent in and during the maintenance of conveyor system. The watch words are --- Never attempt to middle with any part when the belt is running. Never attempt to cross the belt when it is idle. Use always the safety equipments provided. Life is precious, once lost cannot get back. We demand for everything, but fail to use them. Until this concept changes, there is no salvation. So atleast change now and use the protective equipments supplied, follow the safety procedures and save your precious life and agony for your family.

CHAPTER -8 TYPICAL ACCIDENTS IN CONVEYOR SYSTEMS Unfenced Driving Drum The belt on a recently installed conveyor at a concrete works was found to be riding to one side and the operator made an adjustment. The following day he went up the catwalk to examine the top driving drum and pulley and, somehow, his right arm got caught between the belt and drum and was torn off. As a result of the accident the mans employers were prosecuted for failing to fence dangerous machinery. A director of the company said that the conveyor had been received from the manufacturers as a package plant complete with catwalk and ancillary equipment. He had assumed that all the necessary guards had been fitted when the plant was erected. The drum had since been guarded and in such a way them when the guard was opened, the electric supply to motor was automatically cut off. Unguarded Tail-End pulley A worker employed for cleaning of iron spillage at the dumper house of mechanical oven handling plant in a port, met with an accident. While working on this job he slipped and was caught in between the two rollers of the conveyor. He was taken to the hospital where he died afterwards. It was found that the two rollers and the belt at the tail end of the conveyor on which the workers were loading this spillage manually were neither guarded nor fenced off. The pull cord wire arrangement f sting the conveyor was found cut and was not viable at the point where the worker was doing the job. Lack of Supervision A lady worker was engaged on contract basis on the job of cleaning the coal spillages from the mechanical coal handing plant. The plant employed a chain pulley conveyor for transferring the coal discharged from ships to a thermal power station. While removing the spillage of coal with the help of shovels and broomsticks, the worker got entangled between the running belt and idlers of the conveyor. On hearing her cry, the belt was stopped by a worker in the vicinity with the help of pull cord arrangement. The lady was taken to the hospital where she succumbed to her injury. Lack of safety consciousness and knowledge about hazards on working with conveyor belts was the main reason for this accident.

Better guidance/instructions and adequate supervision might have prevented this accident. Inadequate Fire Protection A conveyor belt installed at a part for transferring sculpture from the wharf to the storage shed caught fire. As per the investigation, metal aids employed for collecting sculpture spillage might have generated the frictional heat leading to fire. Fire fighting system provided in to port was not functioning properly and hence the fire could not be controlled at its initial stage. Need for Scrapers In a coal washing plant, a worker was cleaning the tail end drum of a conveyor when he was frapped in between the belt and the drum resulting in fatal injuries. Investigation revealed that the tail-end drum and the belt were not guarded. In order to prevent danger, all head and tail pulley and belt in takes should be so guarded that access to them is impossible. Guards should extend at least 1 meter from the danger points. Necessity of Permit to work System Many accidents have occurred during maintenance work on or near conveyors when a permit-to-work system either has not been adopted or has not been drawn up with sufficient care. One such example id that of a fitter who was fatally injured when a bucket conveyor in which he was standing suddenly started and dragged him along beneath the metal frame work of the conveyor. This bucker conveyor was installed in the basement of a gas works and was used, in association with belt conveyor, to transport coke from the retort house to storage hoppers. The coke had been withdrawn from the retorts earlier in the afternoon and the yard men were working overtime in order to finish filling the storage hoppers ready for the next days deliveries. The shift foreman sent one of his men down into the basement to clear up spillage from the conveyors and then went into his office to write his report. When the man reached the basement he found that the conveyors had stopped and that a fitter was at work repairing a chute. The fitter was standing at one side of the bucket conveyor am leaning across it to reach the chute. Seeing the man, the fitter asked him to give him the spanner that fell down. The man searched in the coke spillage and eventually retrieved the spanner. The man then decided that he

must get nearer to the job, so he climbed into one of the buckets and the man handed up the tool-kit to the fitter, who put it in the bottom of the bucket. Meanwhile the yard foreman had noticed that the conveyors had stopped although the storage hoppers were not yet completely filled, so he met the up the staircase to the control-point for the conveyors. On the way he met the shift charge hand (who was responsible for the immediate control of to conveyors) and asked him why the conveyor were not running. The charge hand said that he had switched off because the thought that the yard men had finished using the conveyors for the day. The yard foreman then continued on his way and switched on the conveyors. The fitter was still working from the bucket conveyor and, at the time when the yard foreman set the conveyors in motion, he was crouching down to select another tool from those lying in the bottom of the bucket, He sensed what was happening by the slight jerk given by the conveyor as it started to move. He tried to jump clear, but lost his balance and fell. The other man quickly pressed the emergency stop but it took about 30 seconds for the conveyor to come to rest. In the time the fitter had been dragged along beneath the conveyor and had received multiple injuries as he was crushed against fixed parts of the plant. No one except the man who had gone to clear up the spillage was aware that the fitter was socking on the conveyor. The fitter himself had not taken any action to isolate the plant, but even if he had done so there would have been no guarantee that it would not be re-started as was indeed done by the yard foreman. The bucket conveyor should, of course, have been securely guarded so as the prevent access to all trapping points, but the fitter would have found it necessary to remove at least some of the guards in order to work on the chute. In such circumstances the only reliable way in which he could have been protected was by the operation of an effective permit -to- work system that ensures disconnection of power supply, locking the circuit breaker or the switch, display of action notice on the switch about the men at work and issue of a written permit to maintenance men which has to be necessarily surrendered before the power can be switched on. Failure to Follow Instructions A bagging operator was operating the automate bag filling machine, which feeds 50 lbs bags of polyethylene onto a conveyor belt, when he saw that a bag at the end of the conveyor was lying angled across the idler rollers at the end of the angled position, in doing so his left foot was trapped and drawn between the conveyor belt and the idler rollers.

The injured said that he had pushed the stop button by is operating seat before getting on to the conveyor belt, but he thought it probable that he had not pushed it hard enough. Asked if he had been warned and instructed not to climb onto a moving conveyor, he said that he had been warned. The committee noted that a safety poster 18 x 26 was posted at eye level 12 away from the bagging operating control position, warning persons not to go on conveyor belts. The push button was operated by the committee to see if the belt would continue moving after the stop button had been pushed; the movement of the belt after the button had been pushed was 2. Evidently, the cause was failure to follow instructions. This accident has been brought to the attention of all personnel emphasizing the danger of walking on a moving conveyor. They were reminded that severe disciplinary action may be taken against any person disregarding a safety rule. As an engineering remedy, the idler roller closest to the conveyor belt was fitted so that the axle of the roller rests in open ended angled slots. The existing jointed conveyor belt was also replaced with an endless belt. It was also decided that in addition to the stop button to stop the conveyor, the opening to the belt from the operators control position should be guarded by a swing arm connected to a micro switch. Unsafe Posture at Unguarded pulley Conveyors were started prior to resuming normal plant operation and were carrying reclaimed produce during cleanup. Several minutes after the conveyors were started up, the return belt alarm sounded, indicating a conveyor belt was not moving due to slipping of the drive pulley under the belt. The employee, who was on the floor above, rushed downstairs in an efforts to get the return belt moving quickly to prevent the product spilling onto the floor. He mounted the steel frame, placed one foot on the drive pulley bearing housing and pressed down on the belt with the other floor. His floor slipped from the housing into the cramped area between the wing-type drive pulley and the frame, and his ankle was struck by the rotating pulley. Slipping at the drive point occurred because the product dust, when moist, is extremely slippery and because the drive pulley was placed at the lower end of the belt when originally installed due to lack of space at the head of the belt. Also, protective guards had to been provided which would have made it impossible for the employee to get into this unsafe position. (Investigation revealed that he had seen others do the same thing without incident).

The employee disregarded safe work procedures which called for (1) spreading some product dust on the underside of the belt to increase friction, and /or (2) stopping the belt and having it tightened. As a preventive measure, the plant undertook an engineering study to determine to possibility of changing the drive to the head of the belt. A job safety. Analysis was also made of this operation, after which the correct procedures were reviewed with all concerned personnel. Guards were installed on all exposed pulleys. Employees were instructed to stop the conveyor drive when slipping occurs and to notify their supervisor, immediately, so that the belt may be tightened properly.

Need for Lockout and Tagging Product accumulation was being removed from a centrifuge conveyor. While the injured employee was cleaning the drive pulley, the conveyor suddenly began moving and his arm was frown in between the pulley and the belt resulting in fractures of the right radius, ulna and humorous. The injured employee did not observe recognized good practice which requires lock-out and tagging of the main switch before starting work on power-driven equipment. Even though he had been talking with the injured employee just a few minute before the accident, the centrifuge operator did not understand that cleaning work was in progress and that it would continue. The injury occurred when he reset the relays, which had been tripped, and started the unit in order to unload one of the centrifuges. Safety rules and practices must receive the full support of all employees, and strict adherence must be required by supervision. Employees hold is instructed on proper lock-out and tagging procedures, which should also be reviewed. When men are working together, it is essential that there be complete understanding by each person as to both the work being done and that which is planned. This subject could be discussed at plat safety meetings. Accident during Alignment Correction Operator noticed the conveyor belt was running to one side tail pulley, and he attempted to align the belt by throwing fine material between the bottom of the belt and the top of the belt idler. After throwing the fine material, has leaned over the belt to check he alignment; he attempted to support his bodys weight with his right hand, and his hand slipped and was caught between the belt and an idler. A

second man heard him call and pulled the emergency stop cable located alongside of the belt. He suffered a fractured finger and abrasions on the back of the hand. The Employee performed an unsafe act and placed himself in a vulnerable position. All employees should have been instructed not to throw fines on belts in order to align them. An emergency stop cable should be installed along side of the tail pulley, and a guard be placed at this location to prevent anyone from getting close to the roll. Improper Design of Guard An operator sustained a partial amputation of his finger when it was caught in a conveyor belt drive. The injured had noticed the product conveyor belt from No.1 cooler was not moving. He reported it to his foreman, who obtained the services of two electricians to determine if a fuse had burned out. The electricians found the fuse to be O.K. and in checking the switch from found a load to be on the line. One of the electricians and the production shift foreman then checked out visually the motor for the belt drive on the conveyor. By the use of a flashlight, the two men could tell the motor, approximately eight feet off the floor, was running but belt was slipping in the motor belt sheave. The shift foreman explained to the operator that the motor was running but the belt was slipping and he used a flashlight to point this out. While the operator was obtaining a ladder for a closer look, the shift foreman hen into the bag room a few feet away to review his production requirements and see if he could at until maintenance arrived at 8.00 a.m. to get the unit repaired. The operator placed the ladder and climbed up near the west side of the motor and reached his right hand behind the metal belt guard to determine if the belt was moving. At the precise moment he touched the belt, the operator said the belt apparently began moving and pulled his right hand toward the motor pulley. His right middle finger was caught between the belt and the pulley, amputating approximately two-thirds of the distal phalanx. Trapped by pulley and belt A rubber conveyor belt used for handling foundry sand was cellar beneath the foundry floor. It was used to elevate sand from the cellar floor and to deposit it in a hopper; the head pulley of the conveyor being 9ft.above the cellar floor. Access to the head pulley was obtained through a trapdoor in the ground floor. When a foundry worker noticed some sand sticking to the face of the head pulley he opened the trapdoor and stepped down onto part of the frame of the conveyor and

endeavourer to scrape the sand off the pulley surface while the conveyor was running. His arm was caught between the belt and pulley but fortunately his injuries were not severe. Following the accident close fitting guards similar to that already fid to the tail pulley, were provided at the head pulley. The need for effective guarding extends dangerous parts which are accessible during normal working and should be provided where any work, however unusual, has to be done. In another case a workmans arm was severely bruised when he was caught in the intake of a pulley and conveyor belt while attempting to clear away sand. The conveyor was being used to convey sand across a foundry floor. At the time of the accident the man was standing on a pile of sand with his arm in a gap in the side frame of the conveyor to clear sand from the vicinity of the belt tensioning device. When the sand on which he was standing moved, he stumbled and his hand went into the nip between the conveyor belt and tail pulley. The guarding which was provided was not completely effective although in this case the man obtained access to the dangerous nip by putting his arm through a fairly small opening in the machine support frame. This could be a case where partial enclosure had, to some extent, hidden the dangerous nip. Cleaning should not have been carried out in either of these cases with the machinery in motion. Insecure position + Inadequate Guarding As accident occurred on a coke belt conveyor of the trough type which was used for conveying coke from a hopper to a stock yard. At the retime of the accident the plant had only been operating for a short time and there had been numerous teething troubles one of which had been the failure of coke to flow freely through the hopper opening onto the conveyor. As a result a man had to be stationed permanently above the hopper opening to free blockages with an iron bar. To do this he sat on an angle support adjacent to the hopper opening and while in this position his foot went into the nip between an idler roller and the conveyor belt. At this point slipping plates were provided alongside the belt and these prevented the belt from lifting. The operators foot was jammed between the idler roller and the spillage plate. Fortunately the belt slipped on the driving drum although the drive did pick up intermittently, driving the mans foot further into the nip. He was in this position for about an hour before his shouts for help were finally heard and the conveyor stopped. He was very lucky to escape with only a severely brushed foot.

Absence of Nip Guards A similar accident happened in a chemical works in a section of the plant involved in the production of synthetic magnesia. In this case the belt conveyor was used to carry magnesium hydroxide paste from a filter plant to a hopper feeding a drying kiln. The conveyor was inclined to the hopper from ground level to a height of about 45 if. A walkway alongside the belt gave access for cleaning and greasing. During its progress up the conveyor and due to its semi liquid nature, the paste tended to seep over the edge of the belt and to build up on the idler rollers and on the sides of the head pulley and these deposits were removed by workers using hand tools. The accident happened when a worker was attempting to scrape the paste deposit from the head pulley with the conveyor in motion. The scraper slipped and his hand was taken into the nip between and the head pulley. He was trapped in this position with the belt abrading his arm, for more than 10 minutes. It was found necessary to cut the belt and release the drum from its bearing block in order to free him. He suffered severe friction burns on his arm and chest. Again only one stop button was provided for the conveyor and this was not in a very convenient position. Quite obviously nip guards should have been fitted to the dangerous in running nip between the head pulley and the belt. Conveyor belt Fire in a steel plant A major fire broke out recently in the coal conveyor system of the thermal power project pf a steel plant. The conveyor belt at the bunker level caught fire and was damaged beyond repair. No one was injured. Though investigation is yet to be completed and the actual events that led to the incident are to be determined, the damage was believed to be substantial owing to high cost of the belt, about 100 meters of which were destroyed in the fire. In another fire incident in the coal landing conveyor belt that occurred an year back in the same plant, nearly 900 meters of the conveyor belt the electrical motors were burnt, resulting in a loss that was estimated to run into crosses of rupees. The fire safety of the conveyor systems in the plant need to be assessed for finding the deficiencies and the feasible remedial measures. Overheated Clinker Shuts Down cement plant Clinker at a cement mill was transferred from two kilns to storage by a complicated system of belt conveyors in un spkrinklered corrugated asbestos and corrugated iron enclosures. Clinker leaving the kilns at about 2100oF was cooled

to 150oF 200oF. Thermocouples in the cooler recorded clinker temperatures and adjustments were made to the operation of the kiln to maintain proper temperatures. A fixed water-spray system at the cooler was available. Hot clinker ignited one of the rubber conveyor belts, and the flames spread to five other belts. Six conveyor belts were consumed. Conveyor machinery, enclosure, scales, an elevated bridge, and electrical equipment were heavily damaged. Full production was not resumed until 2 week later. Improper Design of Conveyor Capacity contributed to Fatality In a paper mill, a worker engaged in removing the spillage of burgesses along a belt conveyor section met with a fatal accident. His job was to remove the spilled material by a shovel and to put it back on the running conveyor. During the progress of such work the shovel got entangled between the idler and the conveyor belt, and he tipped forward onto the belt. This occurred at the tail end section of the belt that feeds onto a discharge chute leading to lower elevation. The worker was carried by the belt section and thrown into the chute through which he rolled won. In the process, his head struck against some fixed part and died. Investigations revealed scope for guarding at the tail end section of the belt and also for redesigning the belt width so as to minimize the chances of spillage of the material. CHAPTER-9 DESIGNING ELECTRICALS FOR SAFETY IN CONVEYORS

Designing Electricals in Conveyor technology is always showing up new problems in connection with safety. Techniques are changing almost every day, new techniques replacing the old ones. Yet it is almost surprising to find that the principles involved are just the same, although, the processes or products are quite different.

Protective Devices The following are a few electrical devices, to be provided in the belt conveyor systems:

1.

Selection of mode of operation by the selector switch as a programmer setter.

2. De-interlock switch. 3. Starting the conveyor by sequence switches. 4. Simultaneous stopping of the conveyors. 5. Rope operated emergency switches to stop the conveyor from any place. 6. Limit switches to prevent excessive sway of the belt. 7. Indication lamp to indicate the running of the conveyor. 8. Indication lamp flashing to locate the conveyor that was stopped by emergency. 9. Siren to hoot in advance to the starting of the conveyor system. 10.Annunciation panel to indicate the fault that caused stoppage. 11.Over speed relays, wherever necessary. 12.Electronic weighing arrangement. 13.Metal detectors. 14.Magnetic separators. 15.Electronic timers. 16. Single Phase prevention relays 17.Magnetic pick-up. 18.Instruments like voltmeter ammeter, etc., 19.Kilo-watt hour mater. 20.Programmer logic control. 21.Public address system 22.Wireless transmitting and receiving sets 23.Intercom 24.Good lighting

The Electrical/Electronic Controllers in control apparatus may be classified as Automatic or Non-automatic according to the application and construction. Automatic Equipments of Devices These devices consist of the following: 1. Air break contactors employed for switching on and off of electric motors as well as other power equipments. 2. Devices like relays that respond to changing of electrical values in a circuit and acting upon the second or control circuits of other apparatus to obtain automatic performance. 3. Devices like limit switches by means of which the operator can actuate the control circuit or other devices like contactors, relays, etc. in order to start and stop the control operations or to change a control programmer. Usually these devices are mechanically handled with the operating machine and act upon control circuits in a sequence depending upon the position, the machines go through in their operations. 4. Devices like regulators that serve for maintaining or changing the operating valves of control electrical installations. Again apparatus may be low-voltage or high-voltage depending upon the working voltage of the circuit in which it is employed.

Non-automatic Apparatus or Devices These will consist of the following: 1. Knife switches, change over switches, rotary switches, etc., with perform manual on/off switching and change over operations in low voltage power circuits. 2. Low-voltage fuses specially designed of the protection of power circuit and electrical installations from large short circuit and overload currents. 3. The resistors, rheostats and controllers designed to control currents and voltage in electrical machines and circuits.

Common protective Arrangements The following protections are commonly employed for an electrical drive.

1. HRC fuses for short circuit protection. 2. Relays for overload protection Fuses H.R.C. Fuses are normally provided for short circuit protection. When the motor is of smaller size it is usual to employ re-wearable type fuses. This will have the advantage of renewing the fuse wire whenever it melts. But there is a tendency for these fuses to get aged and consequently deteriorate unevenly when subjected to repeat over currents that invariably occur during the starting of A.C Induction Motors. This may result in single phasing conditions. In case one of the three fuses blows the motor will still be working drawing higher current in the two sound lines.

Cartridge Type Fuses These are popular known as H.R.C.Fuses, i.e. high rupturing capacity fuses. As in the previous case the fuse elements will not suffer from any material l deterioration. The characteristics of these fuses are as below: H.R.C Fuse link consists of a metallic fuse element surrounded by an arcextinguing fixture in the from of a granular non-conducting material. The element and filler are totally enclosed in a strong and robust insulating container which has flame proof and heat resistant properties.

Application The H.R.C Fuses are usually employed in series with the ACBs of capacities inadequate to deal with an increased short circuit kilo volt amperes. This will prevent any damage to the ACBs the replacement of which will be costly and time consuming. The H.R.C.Fuses also protect the3 motors from any abnormal short circuit conditions. Irrespective of the supply system (whether neutral is earthed or not) it is necessary to fix one fuse in each of the three supply lines. Overload protection The employment of the following devices is found common in practice.

Solenoid Overload Relay This is usually dash pot type. The mode of operation is that each supply line current energies a solenoid causing on iron plunger to lift. This lifting again pushes a common bar to trip the ACB by cutting off supply to its coil, whenever a sustained over current flows. In order to prevent plunger action and tripping due to any momentary over currents like those while starting an induction motor a damping arrangement is provided by filling each dash pot with oil. There is also a setting to adjust the time delay. Thermal Overload Relay Commonly the actuating element in such a relay is a Bi-metal strip. The thermo static element is made by welding together, throughout their entire length, strips of two metals having widely different coefficients of expansion. When a straight strip of this bi-metal is fast ended to a fixed base at one end and it is subjected to a change in temperature, the differential expansion causes the free and to move and actuate a relay. It can be used to operate either to open or close a normally- closed to normally open contact. In some makes the motor current flows direct to the element and in others through a heater coil located close to the bi-metal strip. Load setting adjustments ate provided with a compensating device to allow for variations in the expansion of the metals due to ambient temperature. The time taken for the bi-metal strip to expand sufficiently to operate the tripping mechanism gives the necessary retarding action.

Positive Back-up protection In spite of the conventional overload protection as discussed above there is every possibility for a failure of an electric motor due to sustained overload in its windings not sensed by the above protections. The type of fault is usually in the form of earth fault or short circuit. So, it is better to provide a positive back-up protection to sense and indicate any abnormal over-current dentition first and if not attended to in time trip the power supply to the motor. The latest trend is to imbed devices called thermostats at a few critical locations. The thermostat will sense a pre-set temperature and give indication before the temperature develops to a level that would be dangerous to the insulation. Thermostats are semi-conductors of ceramic material made by sintering mixtures of metallic oxides such as cobalt, manganese, nickel, copper and uranium. These are available in forms of beads, discs, washers and rods.

Each stator phase winding will be embedded with two sets of such sensors. Each set with three thermostats one on each phase will be connected in series. One set will be used to give an alarm indicating an excess temperature of 120 oC in the windings. In the case of motors that have Class B insulation, the permissible maximum temperature rise to the windings is 130 oC, the temperature goes beyond this limit it will be injurious to the windings of the motor. Hence, quick and suitable action will have to be taken to prevent the cause continuing. Before taking any remedial action if the temperature in the winding shoots-up over 130oc, the second set will trip the motor from its power supply, thereby ensuring an efficient positive back-up protection. The two sets of the thermostats for two different response temperatures will have different color Cades and hence will help in connecting them in series. Combined Thermal Overload and Single phase preventer The relay embodies three bi-metal strips carrying the line currents and an auxiliary switch for connection in the tripping circuit of the main control equipment. The thermal strips project between the hinged insulated brats which are normally held together by a spring. The heating of the thermal strips by the passage of current causes them to bend upwards, so raising the thermal strips by the passage of current causes them to bend upwards, so raising the upper bar. The lower one follows, as it is held to the upper one by a spring. After a predetermined movement of the bimetal strips, a projection from the lower bar strikes a step, which prevents it following the upper bar any further. The step which limits the movement of the lower bar does not carry any current, but is made of bi-metallic strip with the same characteristic as the strips which do, so that changes of temperature other than those die to the passage of current affect both in the same way. This makes the relay independent of ambient temperature. A continued up ward movement of the thermal strips will raise the upper bar unit as separated from the new stationary lower bar sufficiently for the mechanical trip to be released and so opening the circuit of a no-volt coil situated on the main control equipment. Sing-phase prevent or If one supply line is open-circuited, its thermal strip will cool and down, while the other two will continue to bend up. This will separate the bars and trip the auxiliary which, thus opening the circuit of a release coil situated elsewhere. In general, thermal overload devices are especially suitable for the smaller h.p.motor. It is preferable that they be protected by distribution fuses to open the circuit, in the event of short-circuit conditions, i.e. the current reaching 5 to 6 times

the full load current of the motor, to avoid any permanent change in the characteristic of the bimetal by prolonged heavy current. No-volt Release The purpose of fitting no-volt release devices is to automatically disconnect the motor from the supply in the event of a general failure of power supply, and to ensure that the commented apparatus cannot be re-started or be damaged when the supply is resumed. No-volt releases are usually of the magnetic type, with an iron plunger excited by a coil connected across two of the supply lines. When the coil is energized the plunger is drawn upwards to engage some mechanisms or electrical contracts, so making the starting gear operative. The coil continues to hold when the voltage is about 20% less than normal at ordinary working frequency, but releases if the voltage falls about 50% less than normal.

Contactor as No-Load Release The energizing coil of a contactor is often employed as a component part of a starter or circuit breaker. As this coil is excited across two of the three supply lines, and controlled by START and STOP push-buttons, or other equivalent, the coil ceases to hold on and disconnects the motor from the supply when the voltage fails. Upon the resumption of supply, the connected motor should not be able to function until the RE-SET button or device, been operated. Description of Electrical Devices in Brief A selection switch provided at the drive of a conveyor or at control desk in a control room would enable it to be starte3d manually or in sequence, and stopped. In positions of the switch, the conveyor could be started manually be present 3 of the switch, the conveyor could be started only when the succeeding conveyor in the direction of flow is started and reaches 80-90% of the rated speed. By turning the switch to 2 position the conveyor could be stopped. So long as this switch is in this position, it will not be possible to start it under any condition. DE-Interlock switch To facilitate test running the conveyor independently, provision is made by employing a key-switch which should be normally available with supervisory personnel and should be operated only under his authority. During production, the conveyor should not be run in the de_interloked condition.

Sequence Switch The starting of the conveyor in sequence is made possible by the employment of a sequence switch. This switch prevents the possibility of choking of the rail end of the conveyor. Father this switch will stop the conveyor from the point of feeding along with the loading excavator. Simultaneously, stopping of all the preceding conveyors including the leading the loading excavator will be made possible by suitable provision in the system. This will prevent any possible over dumping of a tail end of a conveyor .i.e. the transfer point. Pull Cord Switch for Emergency Stopping During an emergency, it would be possible to stop the conveyor from any place by pulling a rope stretched along both the sides of the conveyor, by using a pull cord tripping switch. One end of the rope will be anchored to a lever operated switch at the end or at any convenient location. Once the conveyor is stopped by operating the switch, the attendant will have to look into the cause and reset the switch, start the conveyor again. Without manually resetting, it will not be possible to start the conveyor. The person who actuated the emergency switch should announce the cause. The conveyor should not be allowed to work without these switches in circuit under any circumstances.

Contactor as No-Load Release The energizing coil of a contactor is often employed as a component part of a starter or circuit breaker. As this coil is excited across two of the three supply lines, and controlled by START and STOP push-buttons, or other equivalent, the coil ceases to hold on and disconnects the motor from the supply when the voltage fails. Upon the resumption of supply, the connected motor should not be able to function until the RE-SET button or device, been operated. Description of Electrical Devices in Brief A selection switch provided at the drive of a conveyor or at control desk in a control room would enable it to be starte3d manually or in sequence, and stopped. In positions of the switch, the conveyor could be started manually be present 3 of the switch, the conveyor could be started only when the succeeding conveyor in the direction of flow is started and reaches 80-90% of the rated speed. By turning