Professional Documents

Culture Documents

Ansys2Excite UsersGuide PDF

Uploaded by

deepali0305Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ansys2Excite UsersGuide PDF

Uploaded by

deepali0305Copyright:

Available Formats

Edition 01/2013

AVL List Gmbh 2013. All right reserved

Interfacing with ANSYS

Users Guide

AVL EXCITE POWER UNIT

VERSION 2013

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 i

AVL LIST GmbH

Hans-List-Platz 1, A-8020 Graz, Austria

http://www.avl.com

AST Local Support Contact: www.avl.com/ast-worldwide

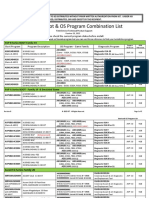

Revision Date Description Document No.

A 28-Jan-2005 ANSYS v8.1 EXCITE v6.1.2 Users Guide 06.0310.4772

B 07-Oct-2005 ANSYS EXCITE v6.1.2 Users Guide 06.0310.4779

C 09-Feb-2007 ANSYS EXCITE v7.0.1 Users Guide 06.0310.0701

D 31-May-2007 ANSYS EXCITE v7.0.2 Users Guide 06.0310.0702

E 20-Jul-2009 ANSYS EXCITE v2009.1 Users Guide 06.0310.2009

F 30-Mar-2010 ANSYS EXCITE v2010.0 Users Guide 06.0310.2010.0

G 19-Nov-2010 ANSYS EXCITE v2010 Users Guide 06.0310.2010

H 29-Jul-2011 ANSYS EXCITE v2011 Users Guide 06.0310.2011

I 25-Jan-2013 ANSYS EXCITE v2013 Users Guide 06.0310.2013

Copyright 2013, AVL List GmbH

All rights reserved. No part of this publication may be reproduced, transmitted, transcribed, stored

in a retrieval system, or translated into any language, or computer language, in any form or by any

means, electronic, mechanical, magnetic, optical, chemical, manual, or otherwise, without prior

written consent of AVL.

This document describes the ANSYS / AVL EXCITE Power Unit interface tool. It does not attempt

to discuss all of required theories to obtain successful solutions. It is your responsibility to

determine if you have sufficient knowledge and understanding to apply this software appropriately.

This software and document are distributed solely on an as is basis. The entire risk as to their

quality and performance is with you. Should either the software or this document prove defective,

you (and not AVL or its distributors) assume the entire cost of all necessary servicing, repair, or

correction. AVL and its distributors will not be liable for direct, indirect, incidental, or

consequential damages resulting from any defect in the software or this document, even if they

have been advised of the possibility of such damage.

The names of the software and hardware products used in this manual are mostly the respective

trademarks or registered trademarks of their companies.

ANSYS is a registered trademark of ANSYS Inc.

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 i

Table of Contents

1. Introduction ____________________________________________________________________ 1-1

1.1. Prerequisites _________________________________________________________________ 1-1

1.2. More Information _____________________________________________________________ 1-1

2. Overview _______________________________________________________________________ 2-1

3. Interface Procedure ____________________________________________________________ 3-1

3.1. Create EXCITE Power Unit Input Body Property File (*.exb) ______________________ 3-1

3.1.1. ANSYS Steps ______________________________________________________________ 3-2

3.1.2. EXCITE Power Unit Steps _________________________________________________ 3-19

3.2. Postprocessing with ANSYS ___________________________________________________ 3-22

3.2.1. Map EXCITE EHD/ENHD Pressure Results _________________________________ 3-22

3.2.2. Map EXCITE EPIL Pressure Results _______________________________________ 3-27

3.2.3. Create Transient Load Step Files ___________________________________________ 3-30

4. Tips & Tricks ___________________________________________________________________ 4-1

5. Troubleshooting ________________________________________________________________ 5-1

6. Appendix _______________________________________________________________________ 6-1

6.1. Static Reduction _______________________________________________________________ 6-1

6.2. Dynamic Reduction ____________________________________________________________ 6-1

6.2.1. Random Vibration Method __________________________________________________ 6-2

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

ii 25-J an-2013

List of Figures

Figure 3-1: Connecting a Structure to an Interface Point ................................................................ 3-4

Figure 3-2: Create Regular Mesh Window ........................................................................................ 3-5

Figure 3-3: Create Regular EHD Mesh Window ............................................................................... 3-6

Figure 3-4: Input parameter description ........................................................................................... 3-7

Figure 3-5: Irregular and Regular Mesh for Condensation .............................................................. 3-8

Figure 3-6: Listing of Correctly Created Contact .............................................................................. 3-9

Figure 3-7: Ansys Contact Manager .................................................................................................. 3-9

Figure 3-8: Create Regular EPIL Mesh Window............................................................................. 3-10

Figure 3-9: Create Regular EPIL Mesh Input Data ..................................................................... 3-11

Figure 3-10: Create Regular EPIL Mesh Input Data ................................................................... 3-11

Figure 3-11: Node Component PISTON_PRESS not created ..................................................... 3-12

Figure 3-12: Regular Piston Mesh ................................................................................................... 3-13

Figure 3-13: Top Piston and Epil Contacts ..................................................................................... 3-13

Figure 3-14: Create Input Files for AVL EXCITE Menu ............................................................ 3-16

Figure 3-15: FEM Preferences Window .......................................................................................... 3-19

Figure 3-16: Convert FE Data Window ........................................................................................... 3-20

Figure 3-17: EXCITE Power Unit Results Control Control Parameters Window ................... 3-21

Figure 3-18: EXCITE Power Unit Results Control Common Results Window........................ 3-22

Figure 3-19: Select FE Analysis Type Window ............................................................................... 3-23

Figure 3-20: Linear Static/Transient Stress Analysis Window ...................................................... 3-23

Figure 3-21: Linear Static/Transient Stress Analysis Boundaries Window ................................ 3-24

Figure 3-22: Map EXCITE EHD Pressure for Linear Static/Trans. Stress Analysis Window ...... 3-26

Figure 3-23: Linear Static/Transient Stress Analysis - Boundaries Window ................................ 3-28

Figure 3-24: Map EXCITE EPIL Pressure for Linear Static Stress Analysis Window ................. 3-29

Figure 3-25: Create Input for Stress Recovery from AVL Excite Results ...................................... 3-31

Figure 3-26: Solve Load Step Files Window .................................................................................... 3-31

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 1-1

1. INTRODUCTION

This document describes how to interact between ANSYS and EXCITE Power Unit. It is

recommended to use Ansys v12 and higher as there have been great improvements,

especially in Component Mode Synthesis substructuring.

The current version of Interface Ansys to Excite v2013 must be used with Ansys v12, when

using the CMS method for substructuring.

1.1. Prerequisites

It is advantageous if the user is already:

familiar with the concept of reduced structured model of engine parts

experienced in using ANSYS software

experienced in using EXCITE Power Unit software

1.2. More Information

The user may also refer to:

ANSYS Documentation, especially

Advanced Analysis Technique Guide - Chapter 9 - Substructuring

Advanced Analysis Techniques Guide - Chapter 11 Component Mode

Synthesis

Advanced Analysis Technique Guide - Chapter 12 - Rigid Body Dynamics and

the ANSYS-ADAMS Interface

Advanced Analysis Technique Guide - Chapter 14 - User-Programmable

Features and Nonstandard Uses

Structural Analysis Guide - Chapter 3 - Modal Analysis

Structural Analysis Guide - Chapter 5 - Transient Dynamic Analysis

Structural Analysis Guide - Chapter 6 - Spectrum Analysis

Multibody Analysis Guide

Contact Technology Guide

EXCITE Power Unit Documentation

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 2-1

2. OVERVIEW

The ANSYS to EXCITE Power Unit interface can be used to:

1. Create the EXCITE Power Unit input files from the whole or partial FE

models of engine parts.

2. Create the regular condensation mesh over the irregular FE model mesh

especially for bearing analysis (EHD2 joint) and piston liner analysis (EPIL

joint).

3. Map the EHD/ENHD/EPIL pressure results from the EXCITE Power Unit

simulation to FE model mesh.

4. Create the load step file(s) needed for calculation of stresses/stress history from

the EXCITE Power Unit simulation results

The current version of the interface supports all EXCITE Power Unit body types:

FLEXIBLE

RIGID

The current version of the interface creates the following EXCITE Power Unit input data

blocks depending on the body and solution type.

Table 1: Overview of FE Input Data Blocks for EXCITE Power Unit

Block Name Description

DOFT table of degrees of freedom full FE model

EINF element information (type, group, nodes) full FE model

GEOM node list and coordinates full FE model

DOFP table of degrees of freedom partial FE model

EINP element information (type, group, nodes) partial FE model

GEOP node list and coordinates partial FE model

EIGV body eigenfrequencies

LCV load step load vector

BMASS body mass and inertia properties

KXX (reduced) stiffness matrix

MXX (reduced) mass matrix

DXX (reduced) damping matrix

KDIC element dictionary table

KELM bar element stiffness matrices

MFF lumped mass matrix of full (unreduced) model

X2OA transformation matrix linking omitted degrees of freedom to

analysis set of degrees of freedom (transposed) full FE model

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

2-2 25-J an-2013

X4OA transformation matrix linking omitted degrees of freedom to

analysis set of degrees of freedom (transposed) partial FE

model

PHA eigenvectors for each calculated eigenfrequencies

MGPS expanded nodal stress results for each calculated

eigenfrequencies

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-1

3. INTERFACE PROCEDURE

This chapter describes the ANSYS to EXCITE Power Unit interface procedure.

3.1. Create EXCITE Power Unit Input Body Property

File (*.exb)

To generate the body property file (*.exb) for an EXCITE Power Unit calculation, the

following steps (described in detail in sections 3.1.1 and 3.1.2.) have to be performed in

ANSYS:

1 Create the FE model of the EXCITE Power Unit body.

2 Define the MDOF's (Master Degrees Of Freedom) on nodes where the body should

be connected to other bodies via joints or where the external forces should be

applied. Especially for applying EHD/ENHD/EPIL joints if the model mesh is

irregular at the joint surfaces, then create the regular mesh for condensation.

3 Define the boundary conditions and load steps (optional).

4 Execute the EXCITE command with appropriate parameters for the current

body or open the AVL EXCITE Input interface window. Enter the necessary

parameters and select OK.

The EXCITE command will generate the following files, depending on the FE

model preparation and defined parameters :

<bodyname>.DOFT

<bodyname>.GEOM

<bodyname>.EINF

<bodyname>.DOFP

<bodyname>.GEOP

<bodyname>.EINP

<bodyname>.BMASS

<bodyname>.EIGV

<bodyname>.KDIC

<bodyname>.KELM

<bodyname>.OUT4

<bodyname>_MFF.OUT4

<bodyname>_DAMP.OUT4

<bodyname>_X2OA.OUT4

<bodyname>_X4OA.OUT4

<bodyname>_MEIG.OUT4

<bodyname>_MGPS.OUT

where <bodyname> is the defined EXCITE Power Unit body name

(Condensed Model name).

The next steps will be done in EXCITE Power Unit.

5 Create an appropriate folder in the fem/ subfolder of the EXCITE Power Unit

project path (FE Model Di r ect or y) and copy all generated files to this new

folder.

6 Start EXCITE Power Unit and select Options | FEM Preferences. Under FE-

Interface select ANSYS and define the used unit system in FE model.

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-2 25-J an-2013

7 Open Utilities Convert FE Data, select FE Solver ANSYS and appropriate

version. Select the FE Model Directory, define the name of the Condensed

Model, select 3D File (*.EINF file), if existing, and the Root Name of condensed

Files. Check other buttons that matches your model and simulation.

The utility will convert the input files to the new EXCITE body property file

(*.exb).

Optionally, the former geometry file *_GEOM.meg can be created, which can be

used either as 3D File representation or for the internal data recovery.

8 Select the body from the Elements list and define the properties. At FE Model

select at 3D Model either From Condensed Model or FE mesh and select file

<Condensed_Model>_GEOM.meg from the FE Model Directory folder. For

Condensed Model select the appropriate <Condensed_Model>.exb file.

9 Finish creating the EXCITE Power Unit model, set the simulation and results

parameters, and start the simulation.

10 To calculate the stress history, the steps described in section 3.2 should be

performed.

3.1.1. ANSYS Steps

Start the new ANSYS session.

3.1.1.1. Create FE Model

The first step is to create the model following the usual ANSYS procedure:

!----- start of model input file

/FILENAM, ! Jobname

/TITLE,....

/PREP7 ! Enter preprocessor

ET,1, ! define element type

MP,1 ! define material properties

R, ! define real constants

N,1,x,y,z ! define nodes

EN,1, ! define elements

D,1,UX ....... ! define boundary conditions (optionally)

..

.......

M,1,all . . . ! define master DOFs

.......

SAVE ! Save the model- (this database will be used later)

FINISH

! --------- end of model input file

This ANSYS database will be used later to create the EXCITE Power Unit input files and

to apply the EXCITE Simulation results on model for the Stress and/or Full Transient

Dynamic analysis.

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-3

Note: It is important in element and node creation to keep the node

and element numbering as low as possible (use ANSYS command

NUMCMP , node and NUMCMP , elem )

3.1.1.2. Modelling Interface (Master) Points

When building a model that will be used in an EXCITE Power Unit simulation, an

important consideration is how to represent interface points within the structure. An

interface point is a node that will have an applied joint or force in the EXCITE Power Unit

model. Note that in EXCITE Power Unit the forces can only be applied to interface points.

The user should consider the following when modelling the interface points:

Force (applied directly or via a joint) should be applied to the structure by

distributing it over an area rather than applying it at a single node.

If there is no node in the structure where you can apply the force or joint in

EXCITE Power Unit (for example, a pin centre), create a geometric location for

that point.

Use the following guidelines to determine the best way to model the interface points for

your structure:

Define all nodes where external forces and connections will be applied as interface

points. For introducing rotational degrees-of-freedom in models which consist of

solid elements, use constraint equations or a spider web of beam elements (as

shown in Figure 3-1). A good practice for modelling interface points is to reinforce

the area using beam elements or constraint equations. Using one of these

techniques will distribute the force over an area rather than applying it to a single

node, which would be unrealistic. If using a spider web of beam elements, use a

high stiffness and a small negligible mass for the beams. Otherwise, the stiffness

and mass of your model will be altered, which could result in eigenmodes and

frequencies that do not represent the original model.

You may use constraint equation commands such as CE and CERIG to attach the

interface node (for example, CERIG,MASTE,SLAVE,UXYZ, where MASTE is the

interface node). Avoid the RBE3 command since problems can occur with the

master degrees of freedom. If you use constraint equations, mesh the interface

point with a MASS21 element (use KEYOPT(3) = 0) that has small (negligible)

masses and inertias (1.E-12).

Do not define interface points that lie next to each other and are connected by

constraint equations or short beams. This type of connection would require too

many eigenmodes and result in a model that is not well conditioned.

Figure 3-1 shows three different ways of attaching an interface point to a structure. The

first two examples (a and b) demonstrate valid methods of attachment. The third example

(c) demonstrates a poor method of attachment that should not be used.

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-4 25-J an-2013

Figure 3-1: Connecting a Structure to an Interface Point

Each method depicted in Figure 3-1 is described as follows:

a) Constraint equations connect the interface point to the structure. This method is

recommended because:

Force is distributed over an area.

A MASS21 element is used to define the six degrees of freedom of the interface

point.

Moment loads are transmitted.

b) A spider web of beams connects the interface point to the structure. This method is

recommended (and preferred) because:

Force is distributed over an area.

A MASS21 element is not necessary (because the beams supply the six degrees of

freedom).

Moment loads are transmitted.

c) One beam is used to connect the interface point to the structure. This is not

recommended because:

The force is applied to the structure at a single node.

Solid elements do not have rotational degrees of freedom. Therefore, moments will

not be properly transmitted from the interface point to the structure (a spider web

scheme should be used).

3.1.1.3. Create Regular over Irregular FE model Mesh

Today, most of the FE meshes are created by free mesher generating an irregular

tetrahedral mesh. For bearing shell structures using (T)EHD2/EPIL/ENHD joints it is

necessary to have regular mesh for Master DOF definition.

Note: If you create your model which include bearings ( Crankshaft, Conrod or

Main Bearing Wall) from geometry (volumes, areas), please use the Ansys

feature for meshing the transition elements (pyramid) to create connection

between regular mesh on bearing shell and the irregular for the rest of the

structure. Such model is a clean Ansys model which runs fast and creates

results directly.

For example see the verification example VM210.

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-5

The regular mesh is possible to create by two interface utilities, "create regular mesh"

which uses Ansys transition elements (recomended), and "create EHD mesh" which uses

Ansys 3-D contact elements.

a) Create regular mesh

If it is possible, create the regular bearing shell mesh by using interface procedure "create

regular mesh". Open the AVL-Menu "create regular mesh", fill up necesery data and press

the OK buton.

Enter data for the following (see Fig.3-4. for parameter explanation):

cpoint1 the coordinates of the center point of the edge of the EXCITE

Power Unit bearing/joint; this point must lie on the intersection

of the rotational axis and the plane through one side of the joint

radius joint/bearing radius

depth bearing depth/width

rotax direction of axis of rotation x|y|z (default value is z)

divr number of regular mesh division in radial direction (default

value is 40)

diva number of regular mesh division in axial direction (default value

is 5)

bsheld Bearing shell thickness

The new transition (pyramid) elements will be created with regular mesh on one side and

conected to the iregular mesh from the other side.

Figure 3-2: Create Regular Mesh Window

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-6 25-J an-2013

b) Create EHD mesh

The connection between two meshes will be made by 3-D Contact elements.

Note: Due to the very sensitive definition of contact elements, here are some

hints on how the contact pair should be defined:

the target elements should be defined over surface in contact of solid elements

the contact elements should be defined over regular mesh of shell/membrane

elements

the normal of target and contact elements should point to each other

the surface of contact elements must lie, and must be equal or smaller of target

surface (not a one node of contact elements must not be outside the target

surface)

All those hints are considered in the appropriate macro to create sufficient

contact pairs.

The first step is to create a node component TARGET from all nodes on external

bearing/joint surface which are in contact.

From the AVL EXCITE menu select Create EHD Mesh to open the following dialog:

Figure 3-3: Create Regular EHD Mesh Window

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-7

Figure 3-4: Input parameter description

Enter data for the following:

cpoint1 the coordinates of the center point of the edge of the EXCITE

Power Unit bearing/joint; this point must lie on the intersection

of the rotational axis and the plane through one side of the joint

radius joint/bearing radius

depth bearing depth/width

rotax direction of axis of rotation x|y|z (default value is z)

divr number of regular mesh division in radial direction (default

value is 40)

diva number of regular mesh division in axial direction (default value

is 5)

From defined values the ANSYS macro EHD_MESH.MAC will:

create the cylindrical working plane with origin in cpoint1, and working

axis wz oriented to rotax direction

check if the node component TARGET exists. If not, it will be created from

the selected nodes which lie on external surface at radius. Check carefully if

such created surface nodes are correct

create the TARGE170 elements over the faces of solid elements defined by

selected nodes (node component TARGET)

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-8 25-J an-2013

create the new (divr x diva) mesh of nodes (component CONTACT) in a plane

of bearing radius

create the thin membrane SHELL181 elements over the contact nodes

create the contact CONTA173 elements over the membrane elements

define the MDOFs in contact nodes

The result of this procedure is shown in the following figure.

Figure 3-5: Irregular and Regular Mesh for Condensation

Note: It is always recommended to check whether the contact pair is set up

correctly. From the command prompt enter Ansys command CNCHECK and

Ansys will perform checking of the contact pair. If the contact pair is set up

correctly, youll get the similar list to the following Ansys list window below:

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-9

Figure 3-6: Listing of Correctly Created Contact

Also, you can open the Ansys Contact Manager and check the created contact.

Figure 3-7: Ansys Contact Manager

Note: Although the created contact pair looks good and it is initially closed, it

should stay closed during the analysis. The best way to check this is to perform

simple free-free Block Lanczos modal analysis up to 100 modes without

expanding modes and use lumped mass approximation. The correct model is

given, when there is no single mode of the contact element.

Now the model is ready for condensation.

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-10 25-J an-2013

c) Create EPIL regular mesh

For the piston EPIL joint, the steps for creating regular mesh for condensation over

the irregular FE model mesh is similar to EHD joints.

The first step, if the piston pressure should be applied, is to create the node component

PISTON_PRESS from all nodes on piston top.

From the AVL EXCITE menu select Create EPIL Mesh to open the following dialog:

Figure 3-8: Create Regular EPIL Mesh Window

Enter data for the following:

cpoint1 coordinates of the reference point of the EPIL joint; this point

must lie on the intersection of the vertical piston axis and the

plane through the lower end of the piston

radius piston radius

p_hight total piston height; this value should be input when you want to

define master nodes for applying piston pressure; in that case

the node component TARGET_P should be created with all

nodes on the piston top surfaces

s_hight piston skirt height up to first ring

vertix direction of vertical axis (default value is z)

thrust direction of anti-thrust side (default value is x)

divr number of regular mesh division in angular direction (default

value is 16)

diva number of regular mesh division in axial direction (default value

is 10)

angle angle from anti-thrust side (default value is 45)

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-11

The following figures describe the input values:

Figure 3-9: Create Regular EPIL Mesh Input Data

Figure 3-10: Create Regular EPIL Mesh Input Data

From defined values the ANSYS macro EPIL_MESH.MAC will:

create the cylindrical working plane with origin in cpoint1, and working

axis wz oriented to rotax direction

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-12 25-J an-2013

check if the piston height is defined. If p_hight > 0 than search for the node

component PISTON_PRESS. If not defined, the note will be issued (Figure 3-

9) and the action will be stopped. Define the node component

PISTON_PRESS and start Create EPIL Mesh once again.

if the PISTON_PRESS is defined and p_hight > 0, than macro will create the

TARGE170 elements over the solid element faces defined by selected nodes,

create the new regular (16x4) mesh of nodes in cylindrical coordinate system

(component CONTACT) in a plane of piston top, create the membrane

SHELL181 elements over the contact nodes, create the contact CONTA173

elements and define the MDOFs in contact nodes ( Figure 3.10)

select the nodes in a plane of piston radius from +angle to angle, from wz=0

to S_hight, and create node component TARGETE

create the TARGE170 elements over the solid elements faces attached to node

component TARGETE

create the new (divr x diva) mesh of nodes (component CONTACT) in a plane

of piston radius

create the membrane SHELL181 elements over the contact nodes

create the contact CONTA173 elements in membrane nodes

define the MDOFs in contact nodes

The result of this procedure is shown in the following figures.

Figure 3-11: Node Component PISTON_PRESS not created

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-13

Figure 3-12: Regular Piston Mesh

Figure 3-13: Top Piston and Epil Contacts

Note: It is always recommended to check whether the contact pair is set up

correctly. From the command prompt enter Ansys command CNCHECK, Option,

RID1, RID2, RINC and Ansys will perform checking of the pair in contact.

Also, perform all other checks mentioned under 3.1.1.3. a).

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-14 25-J an-2013

3.1.1.4. Preparing FE Model for Partial Calculation

Not only for the full FE model, it is possible to perform the condensation on a part of the

Excite Body FE mesh, partial FE mesh.

The model should be prepared on the following way:

from the full FE model select the elements that make up the part you want to

analyze

create the Element Component from selected elements and name it u_set

save the Ansys database

The model is prepared for condensation, i.e. for the next step Start the Interface

Calculation.

Note: partial condensation will only be implemented if element

component u_set is defined in your Ansys FE model

3.1.1.5. Start the Interface Calculation

After the FE model has been created and Master DOFs applied to those degrees of freedom

which should be available in the EXCITE Power Unit model, the command EXCITE should

be executed from the command prompt or from EXCITE Power Unit Menu to obtain all the

input files for EXCITE Power Unit.

Command Mode

EXCITE, OUTNAME, NMODES, BODYTYP, DICT, DMAT, LOADV, ELCALC, USRNAME, MTXOUT, USECMS, NOLMM

Where:

OUTNAME EXCITE Power Unit default body name key that will be associated to

the output files

Generic 1 GearShaft1 10

Piston 2 GearWheel1 11

Conrod 3 Wheel1 12

Crankshaft 4 Chassis1 13

BalancerSh1 5 Exhaust1 14

BalancerSh2 6 MB-Wall 15

Engine 7 B-Pin 16

Powerunit1 8 P-Pin 17

Disc1 9 Shaft1 18

NMODES number of modes for dynamic reduction

BODYTYP the EXCITE Power Unit body type selection

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-15

o RIGID

o FLEXIBLE

DICT create bar element dictionary table and matrices, no/ yes

DMAT create reduced structural damping matrix, no/yes

LOADV create load cases vector, no/yes

ELCALC calculate element stresses (used for modal data recovery), no/yes

usrname user defined name that will be associated with the output files

(optional). It will overwrite predefined OUTNAME.

It should be put in single quotes.

MTXOUT create full mass matrix and/or recovery matrix

1 - create MFF only,

2 - create X2OA only,

3 - create both,

4 do not write out _X2OA.OUT4 file. For the later Excite Recovery

the Ansys binary file <bodyname_genCMS.tcms> will be used.

USECMS use Component Mode Synthesis (CMS), yes/no

(for more information see ANSYS online documentation Advanced

Guide). The calculation method for CMS is set to fixed.

Note: CMS does not yet support damping matrix reduction

NOLMM use lumped mass matrix approach, yes/no

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-16 25-J an-2013

GUI Mode

The EXCITE command can also be executed from the AVL EXCITE menu in GUI. Select

Start Excite button to open the following Create Input files for AVL EXCITE window.

Figure 3-14: Create Input Files for AVL EXCITE Menu

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-17

Select the EXCITE Body default name or type the user name in USRNAME field.

Select the body type and define the number of modes for dynamic reduction if needed (see

APPENDIX for more details about reduction).

If there are any beam elements in the model and body type (NOD6) requires element

dictionary table, activate DICT parameter.

This option will create element dictionary table (file named [OUTNAME].KDIC) and the

beam element stiffness matrices (file named [OUTNAME].KELM).

The DMAT key will activate the extraction of the reduced structure damping matrix, if the

damping parameters are included in the FE model, and will be written to the file

<bodyname>_DAMP.OUT4 in block DXX.

The LOADV option will activate the creation of the load case vector file

(<bodyname>.LCV) from previously created ANSYS load step files (<jobname>.s01 etc).

The ELCALC option will activate calculation of element stresses in expansion pass of

substructuring procedure. If MTXOUT is on, the following files will be created:

<bodyname>_MEIG.OUT4 containing the eigenvectors of the reduced structure and

<bodyname>_MGPS.OUT containing the stress tensors of the defined element set for each

eigenvector in MEIG

The MTXOUT option will activate creation of transformation matrix file

<bodyname>_X2OA.OUT4 (code > 2) and full mass matrix file <bodyname>_MFF.OUT4

(code = 1) for body type CON6. Code 4 will prevent ASCII output of file _X2OA.OUT4. In

that case for Excite Recovery the Ansys binary file <bodyname_genCMS.tcms> will be

used. This will save lot of interface run time, especially for large models (more than 1 mil

elements).

The USECMS option, if active, will perform Component Mode Synthesis (CMS) reduction,

otherwise, the Power Spectral Density (PSD) method will be used for reduction. For CMS

method the number of modes (NMODES) must be greater than zero. For more about PSD

and CMS methods see ANSYS documentation.

The NOLMM option specifies whether the lumped mass matrix formulation LUMPM will

be used (Yes/On default) or not (No/Off). The default value is appropriate for most

models. Only in special cases and with the full control of the user, the value No/Off can

be used.

Select OK to start the process.

ANSYS will perform all calculations and prepare the input files for the EXCITE Power

Unit simulation. The file format for the mass and stiffness matrices is the Nastran

OUTPUT4 file format. All files generated by ANSYS to EXCITE Power Unit Interface are

ASCII files and thus platform independent.

Note: The condensation for CON6 bodies with CMS method can be performed

only as a batch job due to the TCMS option. Please read the Ansys manual how to

perform the batch jobs for different platforms: Operation Guide Ch. 3. Running

the Ansys Program 3.4. Batch Mode.

The instruction for different platform follows.

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-18 25-J an-2013

3.1.1.6. Starting Batch Mode from the UNIX/Linux Command

Line

To start batch mode from the UNIX/Linux command line:

Foreground execution (ksh or sh shells):

ansys120 - b - p pr oduct var < i nput name > out put name 2>&1

Background execution (ksh or sh shells):

nohup ansys120 - b - p pr oduct var < i nput name > out put name 2>&1 &

The nohup command tells the system to ignore hang-up signals, enabling the ANSYS

program to continue executing if you log off from the system.

Foreground execution (csh shell):

ansys120 - b - p pr oduct var < i nput name > &out put name

Background execution (csh shell):

nohup ansys120 - b - p pr oduct var < i nput name > &out put name &

3.1.1.7. Starting Batch Mode from the Windows Command

Line

You can also start a batch job in Windows by issuing the ANSYS execution command

directly from the MS-DOS command prompt window or create the bat file with the

command string inside (all in one line). The format for the command depends on whether

you want ANSYS to run in the foreground or the background:

Foreground execution:

" <dr i ve>: \ Pr ogr amFi l es\ Ansys

I nc\ V120\ ANSYS\ bi n\ <pl at f or m>\ ansys120" - b - i i nput name - o

out put name

Background execution:

st ar t / mi n " <dr i ve>: \ Pr ogr amFi l es\ Ansys

I nc\ V120\ ANSYS\ bi n\ <pl at f or m>\ ansys120" - b - i i nput name - o

out put name

In upper commands the inputname is the name of input file with the following

instructions:

! ----------------------------- example of input file ---------------------

RESUME, Conrod,db ! read in Ansys database

! /INPUT, Fname, Ext ! or input model data from external file

! CDREAD, Option, Fname, ext ! or input model from archive file

!EXCITE,OUTNAME,NMODES,BODYTYP,DICT,DMAT,LOADV,ELCALC,USRNAME,MTXOUT,USECMS,NOLMM

EXCITE, 3, 20, 2, , , , , , 1, 1,

! --------------------------- end of file ---------------------------------

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-19

3.1.1.8. EXCITE Command Background - Excite Macro

The base of the EXCITE command is the macro called EXCITE.MAC, which can be found in

AVL-ANSYS installation folder ($AVLAST_HOME/EXCITE/<version>/fem/ansys).

You can copy the contest of that folder to any other folder for your convenient. But, the

EXCITE command will be recognized by the Ansys only if you define the ansys

environment variable ANSYS_MACROLIB to point to the folder where interface macros

are placed.

So, if you already have this environment variable defined, copy the interface macros to the

folder defined by your ANSYS_MACROLIB variable.

3.1.2. EXCITE Power Unit Steps

When the input files are created, the next step is to start the EXCITE Power Unit session.

3.1.2.1. Set FE-Interface Preferences

After opening EXCITE Power Unit, the first step is to define the FE-Interface Preferences.

Select Options | FEM Preferences to open the following window:

Figure 3-15: FEM Preferences Window

Under FE-Interface select ANSYS. Additionally select the global Axes of the FE-Model and

the correct unit system, which has been used for creating the FE model.

3.1.2.2. Convert FE Data

Before setting up the EXCITE model, the generated ANSYS interface files for each flexible

body have to be converted to the new EXCITE body property file (*.exb).

Therefore open Utilities Convert FE Data dialog and enter/select the following data:

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-20 25-J an-2013

Figure 3-16: Convert FE Data Window

select FE Solver ANSYS and appropriate version

select the FE Model Directory

select 3D Mesh File i.e. Ansys Element Info File (*.EINF file)

type the name of the EXB file (if it is blank, the EXB file will have the name of

the condensed body)

select the Root Name of DOFT/OUT4 Files from the ANSYS interface files

check in other buttons which are appropriate to the model

The utility will scan all available interface files and convert them to the new EXCITE body

property file (*.exb). Optionally, if a 3D File (*.EINF) has been defined, the former

geometry file *_GEOM.meg can be created, which can be used either as 3D File

representation or for the internal data recovery.

3.1.2.3. Create EXCITE Power Unit Model

Select the body from the Elements list and define the properties. At FE Model select at 3D

Model either From Condensed Model or FE mesh and select

<Condensed_Model>_GEOM.meg from the FE Model Directory folder.

For Condensed Model select the appropriate <Condensed_Model>.exb file.

3.1.2.4. Run Create Model and Simulation

Define the appropriate Control Parameters, Case and Model Parameters and run the

analysis.

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-21

3.1.2.5. Perform Result Evaluation

To calculate stress history later with ANSYS, some additional results parameters need to

be defined in Results Control.

First, all results need to be calculated on time base. Activate Time in Control Parameters

Output Results versus. This will create the results file (extension .GID) with the

channel Time in the first column, which is needed for the ANSYS Transient Dynamic

Analysis.

Figure 3-17: EXCITE Power Unit Results Control Control Parameters Window

Select Common Results Nodal Results and activate Relative for of All Connected

Nodes and of All Loaded Nodes. This will create the correct load for the ANSYS Transient

Dynamic Analysis later.

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-22 25-J an-2013

Figure 3-18: EXCITE Power Unit Results Control Common Results Window

Perform the task Create Results to get the appropriate GIDAS result files.

3.2. Postprocessing with ANSYS

After the simulation has finished and the results have been created and stored in the

Results folder, the ANSYS interface can be used to post-process the EXCITE Power Unit

results to:

map the pressure results from EXCITE Power Unit EHD/ENHD joint

map the pressure results from EXCITE Power Unit EPIL joint and pressure on

piston top

create the transient ANSYS load step files from EXCITE Power Unit

displacement results

3.2.1. Map EXCITE EHD/ENHD Pressure Results

a) EXCITE Power Unit Steps

The first step is to select the results from EXCITE Power Unit and create the input

files for ANSYS.

In the EXCITE Power Unit Main menu, select FE Analysis | Tasks | Add New Task

and select ANSYS for FE Solver. The following window will be opened.

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-23

Figure 3-19: Select FE Analysis Type Window

Select OK and the following window opens. Enter the necessary data.

Figure 3-20: Linear Static/Transient Stress Analysis Window

Define the results interval and increment.

Then select the Boundaries tab to access the fields shown in the following window.

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-24 25-J an-2013

Figure 3-21: Linear Static/Transient Stress Analysis Boundaries Window

For the Excite Joint, select Add and then select the appropriate joint.

Select OK to start the FE Task calculation and create the following files:

<joint_name>.acc file with selected time steps and acceleration for each time

step

<joint_name>.grid file with coordinates of EXCITE Power Unit EHD/ENHD

joint mesh

<joint_name>.press file with pressure data for each coordinate in grid file and for

each time step defined in acc file

Those files are located in folder <Case_Set.Case>/fea/.

For more information about FE Analysis Tasks refer to the EXCITE Power Unit Users

Guide.

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-25

Note: Theoretically, external forces and inertia forces are in

equilibrium. Due to numerical errors or due to mass discrepancies

between EXCITE and ANSYS, this is insufficient to prevent a rigid-

body motion of the FE-model. Hence, you must constrain the component

against rigid-body motion in order to do a static structural analysis. The

ANSYS offers the following options to achieve this:

for the first option, you must manually add constraints to the

ANSYS model that are compatible with the constraints used in the

EXCITE model (if possible), or use common engineering sense to

prevent rigid-body motion. This constrains must be defined in an

external file with name constrain.inp. Or, as a second option

add weak springs: The Ansys program adds weak springs

(COMBIN14 elements) to the corners of the bounding box of the

model. (For more information, see the WSPRINGS command

documentation). The weak springs prevent rigid-body motion

without influencing the stress results. (See Adding Weak Springs

for more information on how the program adds weak springs to the

model.)

b) ANSYS Steps

Open the new ANSYS session and read in the appropriate FE model (which was used

for condensation). Create the node component PSURF1 (and PSURF2 if there are two

joints) from nodes on bearing/joint surface. If the model need to be constrained, create

the external file named "constrain.inp" containing the Ansys "D" commands for each

constrained node and DOF, or use the Ansys command WSPRINGS to create

constrains by week springs.

Typical applications:

Single main bearing wall with one EHD2 joint

Connecting rod with one or two EHD2 joints

From the AVL EXCITE menu select Map EHD Results to open the following dialog.

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-26 25-J an-2013

Figure 3-22: Map EXCITE EHD Pressure for Linear Static/Trans. Stress Analysis

Window

Change, if necessary, and fill the empty fields with the appropriate files. An animation can

be performed if there is more than one time step in the acc or grid file. It is only for the

visualization and check of input data.

Select OK to start ANSYS macro EHD_MAP.MAC. For each time step defined in the acc

file, the macro will create ANSYS load step file <job_name>.s0x where x is the number of

load step, starting from the last created load step file.

To run load steps, use the ANSYS command LSSOLVE or press Solve

Lin.StaticEHD/EPIL Stress button from EXCITE Power Unit Menu.

The calculated results might be reviewed in the ANSYS Post-processor:

for one load step in POST1

for the time period in POST26

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-27

3.2.2. Map EXCITE EPIL Pressure Results

a) EXCITE Power Unit Steps

The first step is to select the results from EXCITE Power Unit and create the input

files for ANSYS.

In the EXCITE Power Unit menu, select FE Analysis | Tasks | Add New Task and

select ANSYS for FE Solver. Select OK and the Linear Static/Transient Stress

Analysis window opens (7).

It is essential to apply all acting loads on the piston model:

Gas force at piston top and top land

EHD pressure force at piston skirt

Joint reaction force at piston boss bearings

Acceleration Load

Therefore select the Boundaries tab and

1. Select Forces/Displacements at Nodes and add the Excite body nodes of the

piston boss bearings to apply the joint reaction forces.

2. Add EHD Pressure Load is selected. Add the EPIL joint to apply the EHD contact

forces at piston skirt.

3. Select Add Acceleration Load and Get from Excite Global Results to apply the

acceleration load.

4. Select Add Cylinder Pressure Load, define the Node Set/Nodes where the gas

force was acting and the Bore Diameter to recalculate and generate the

corresponding gas pressure.

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-28 25-J an-2013

Figure 3-23: Linear Static/Transient Stress Analysis - Boundaries Window

Select OK to start the FE Task calculation and create the following files:

<body_name>.acc file with selected time steps and acceleration for each

time step

<joint_name>.grid file with coordinates of EXCITE Power Unit EPIL

joint mesh

<joint_name>.press file with pressure data for each coordinate in grid file

and for each time step defined in acc file

<joint_name>_GAS.press file with top cylinder pressure data for each time step

defined in acc file

Those files are located in folder <Case_Set.Case>/fea/.

For more information about EXCITE Power Unit FE Tasks refer to the EXCITE Power

Unit Users Guide.

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-29

Note: Theoretically, external forces and inertia forces are in

equilibrium. Due to numerical errors or due to mass discrepancies

between EXCITE and ANSYS, this is insufficient to prevent a rigid-

body motion of the FE-model. Hence, you must constrain the component

against rigid-body motion in order to do a static structural analysis. The

ANSYS offers the following options to achieve this:

for the first option, you must manually add constraints to the

ANSYS model that are compatible with the constraints used in the

EXCITE model (if possible), or use common engineering sense to

prevent rigid-body motion. This constrains must be defined in an

external file with name constrain.inp. Or, as a second option

add weak springs: The Ansys program adds weak springs

(COMBIN14 elements) to the corners of the bounding box of the

model. (For more information, see the WSPRINGS command

documentation). The weak springs prevent rigid-body motion

without influencing the stress results. (See Adding Weak Springs

for more information on how the program adds weak springs to the

model.)

b) ANSYS Steps

Open the new ANSYS session and read in the appropriate FE model (which was used

for condensation) and add weak springs or create the file with constrains.

Create the node component PSURF1 for nodes on piston skirt, and PSURF2 for piston

nodes on top if the cylinder pressure is defined.

From the AVL EXCITE menu select Map EPIL Results to open the following dialog:

Figure 3-24: Map EXCITE EPIL Pressure for Linear Static Stress Analysis Window

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-30 25-J an-2013

Fill the empty fields with appropriate files. An animation can be performed if there is more

than one time step in the acc or grid file. It is only for the visualization and check of input

data.

Select OK.

This will start ANSYS macro EPIL_MAP.MAC. For each time step defined in acc file, the

macro will create ANSYS load step file <job_name>.s0x where x is the number of the load

step, starting from the last created load step file.

To run load step, use the ANSYS command LSSOLVE, or press Solve

Lin.StaticEHD/EPIL Stress button from AVL EXCITE menu.

The calculated results might be reviewed in the ANSYS Post-processor:

for one load step in POST1

for the time period in POST26

3.2.3. Create Transient Load Step Files

Start the new ANSYS session, change the job name (working directory, title etc.) and

Resume from ANSYS database for the appropriate Excite body.

Start the interface calculation by executing the command EXCITE_R (from the ANSYS

Solution level) in Command Prompt or from AVL EXCITE menu/Excite Recovery:

Command Mode

EXCITE_R, BODYNAM1, EXTEND, EXRESDIR, STEPTIMS

where:

BODYNAM1 the name of the EXCITE body result file without extension (as

there are many body result files in a form

bodyname-masternode-DOF-rel.[EXTEND]

user needs to define only one of them)

EXTEND EXCITE body results file extension (GID)

EXRESDIR the path to the EXCITE body results folder (it may be relative or

absolute path)

STEPTIMS step increment for reading the EXCITE results

GUI Mode

The EXCITE_R command can be executed from the AVL EXCITE menu. Select Excite

Recovery to open the following dialog:

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 3-31

Figure 3-25: Create Input for Stress Recovery from AVL Excite Results

Select one of the EXCITE body result files by Browsing the folder containing the result

GIDAS files. The file name is limited up to 32 characters, the file extension is limited up to

8 characters, and the folder path is limited up to 248 characters (ANSYS limits).

Enter the Time Step Increment for reading the EXCITE body results. Default value 1

means that every time step from the EXCITE result file will be read (value 2 means every

second time step will be read). This value defines how many ANSYS Load Step files will be

created. The EXCITE simulation might have several thousands of time steps, and for Time

Step Increment=1 the same number of ANSYS Load Step files will be created. The user

should define the desired number of time steps. Mostly it is sufficient to generate 240 360

time steps (each 2

nd

or 3

rd

deg CA).

Select OK to start creating ANSYS Load Step files.

ANSYS will create all Load Step files and place them in the current working folder.

The names of the files will be: <j ob_name>. s01, <j ob_name>. s02, <j ob_name>. s03,

etc.

With the ANSYS command LSSOLVE (Solution Solve From LS Files), select which

time steps will be used in the calculation.

Figure 3-26: Solve Load Step Files Window

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

3-32 25-J an-2013

Note: Depending on the number of DOFs in the model (the number of

equations to be solved) and the number of load steps, the ANSYS output

files might be very large (hundreds GB). It is recommended with ANSYS

Run-Time Stats to investigate how much disk space is needed and how

long the calculation will take.

The calculated results might be reviewed in the ANSYS Post-processor:

for one load step in POST1

for the time period in POST26

The base of this command is the macro called EXCITE_R.MAC, which can be found in

AVL-ANSYS Installation folder (see the Installation Guide for details).

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 4-1

4. TIPS & TRICKS

It is always good, before starting the condensation, to check the FE model. Perform

the CMS substructure analysis on created model

________________

/solu

antyp,substructure

seopt,subelem,2,0,,resolve

cmsopt,fix, 20, ,, , ,

lumpm,on

eqslv,sparse

solve

fini

___________________________________

To connect the master nodes to the surrounding structure use the high stiffness

BEAM4 elements with orientation defined by angles, not with the third node (read

the Chapter 5.4. Master Degrees of Freedom in a Substructured Multibody

Simulation in Multi Body Analysis Guide, search also for spider technique). Here

follows one of the possible 'spider' method:

MN = xx ! define master node

!

ET,x,BEAM4 ! define baeam element

R,x,..... ! use high stiffness

MP,DENS,x,... ! ues low mass density

!

NSEL,S ....... ! Select nodes to be connected to the Master node

NSEL,A,,,MN ! add the master node to the selection

! Generate spider web of beams

TYPE,x

REAL,x

MAT,x

!

*GET,nmin,node,,num,min

*GET,nnum,node,,count

*SET,jj,0

*DO,jj,1,nnum-2

E,MN,nmin

NSEL,u,,,nmin

*GET,nmin,node,,num,min

*ENDDO

!

ALLS

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

4-2 25-J an-2013

Always put a MASS21 element with the very low masses and inertia masses to the

master node (as a stand alone node, or as a part of elements with 3 DOF's per

node). For real constant always use all values: MASSX, MASSY, MASSZ, IXX, IYY,

IZZ, e.g. R,1,1.e-12,1.e-12,1.e-12,1.e-12,1.e-12,1.e-12

If there are several parts connected into the one body (crankshaft with pully and fly

wheel) use the same mesh on the both sides and merge the nodes, or use the Ansys

contact and target elements (170, 173, 174 or 175) with keyopt(2)=2, keyopt(4)=1

(force distributed) or 2 (rigid surface) and keyopt(12)=5 or 6. If you are using rigid

connection (CERIG or CE) it is always good to put dummy mass elements into the

master and slave nodes. Here is one way how to do it:

_____________________________________________

/PREP7

NSEL,S,CE,,1,maxCEnumber ! select nodes with constrains

ESLN,S ! select elements attached to selected nodes

ESEL,U,TYPE,,solid_min,solid_max ! unselect solid elements

NSLE,U ! unselect nodes attached to the mass elements

ESEL,NONE ! unselect all elements

!

cm,nomass,node ! create component with nodes

!

! create mass element properties

et,max+1,mass21

mp,ex,max+1,210000

mp,nuxy,max+1,.3

mp,dens,max+1,1e-12

r,max+1,1e-12,1e-12,1e-12,1e-12,1e-12,1e-12

type,max+1

mat,max+1

real,max+1

NCOUNT = ndinqr(0,13) ! find the number of selected nodes

NEXTNODE = 0

! add mass elements

*do,i,1,NCOUNT

*get,NEXTNODE,node,NEXTNODE,nxth

e,NEXTNODE

*enddo

____________________________________________________

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 4-3

Current limitation (due to Ansys limitation)

Command HBMAT must be used for output of the reduced mass and stiffness

matrices because of accuracy (dumping the mass and stiffness matrices from the

SUB file doesn't give the satisfied accuracy). For using this command in Ansys 11.0

modules Mechanical, it's necessary to install Ansys 11. Service Pack1.

When dumping a .FULL file, the rows and columns corresponding to specified

constraints (e.g., D commands) are eliminated from the system of equations and

therefore are not written to the .MATRIX file. Also, rows and columns

corresponding to eliminated (slave) degrees of freedom from coupling and/or

constraint equations (e.g., CE, CP commands) are also eliminated from the system

of equations and are not written to the .MATRIX file. The DOFs that are

eliminated from any coupling and/or constraint equations are determined

internally by the solution code and may not match what you specified via the

CE/CP (or similar) commands.

CMS does not yet support damping matrix reduction. ANSYS sets the matrix

generation key to 2 automatically (SEOPT,SEMATR).

For the versions prior to v14, Ansys doesn't allow to define array or table

parameter greater than 2**28 because of unadjusted pointers. This gives an error

even on 64-bit architecture

_____________________________

**** ERROR *** CP = 212.450 TIME= 18:13:56

Array or table parameter _EARRAY is too large for 32 bit address. The setting of

parameter is not possible. .

_________________

According to that, in current interface the maximum element number might be

10,324,440. If you have higher elements numeration, renumber or compress the

element numbers (NUMCMP,ELEM)

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 5-1

5. TROUBLESHOOTING

If you have any problem using the ANSYS to EXCITE Power Unit Interface, contact the

technical support to assist you at excite_support@avl.com.

Please specify the following:

ANSYS version

ANSYS to Excite Interface version (can be find on top of EXCITE.MAC)

EXCITE Power Unit version (can be found under Menu Help | About)

hardware platform

body type

short description of the problem

if possible, attach

ANSYS model database (db, cdb) or model input file

ANSYS ERR file

ANSYS log file

ANSYS out file (if exists)

dbexc.parm (interface file might be huge)

the list or screenshot of the folder where interface was running

any other information that might help in detecting the problem

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 6-1

6. APPENDIX

This chapter describes the theoretical background of ANSYS Reduction.

6.1. Static Reduction

In order to obtain reduced mass and stiffness matrices as well as the corresponding tables

of degrees of freedom and geometry the ANSYS substructure analysis features is used:

A substructure containing the whole FE model of the body is generated. Those degrees of

freedom which should be available in the EXCITE Power Unit simulation are defined as

the master degrees of freedom. Optionally, boundary conditions (constraints) can be set for

the substructure.

The reduced mass and stiffness matrices with the dimension [nMDOF*nMDOF] are

written to the filename.OUT4 file. The theoretical explanation is given below.

The substructure analysis uses the technique of matrix reduction to reduce the system

matrices to a smaller set of DOFs.

Consider the basic form of the static equations:

| | { } { } F u = (1)

{ } F includes nodal and pressure effects. The equations may be partitioned in two groups,

the master (retained) DOFs, here denoted by the subscript "m", and the slave (removed)

DOFs, here denoted by the subscript "s".

)

`

=

)

`

s

m

s

m

ss sm

ms mm

F

F

u

u

K K

K K

(2)

or expanding:

| | { } | | { } { }

m s ms m mm

F u u = + (3)

| | { } | | { } { }

s s ss m sm

F u u = + (4)

The master DOFs should include all DOFs of all nodes on surfaces that connect to other

parts of the structure and all nodes where external forces will be applied.

6.2. Dynamic Reduction

The dynamic behavior of the structure is obtained using the ANSYS Spectral Analysis

features.

First, the constrained Modal Analysis (constrains are defined on nodes having the MDOF's)

is performed and the modes are expanded, and then the participation factors of the Random

Vibration (PSD) Analysis are calculated (for more information on Spectral Analysis refer to

ANSYS Structural Analysis Guide, Chpt. 6). Those participation factors are then used for

transformation of the stiffness and mass matrices obtained from the static reduction.

The theoretical explanation follows.

Interfacing with ANSYS Users Guide EXCITE Power Unit v2013

6-2 25-J an-2013

6.2.1. Random Vibration Method

For partially correlated nodal and base excitations, the complete equations of motions are

segregated into the free and the restrained (support) DOF as:

)

`

=

)

`

+

)

`

+

)

`

0

F

U

U

K K

K K

U

U

C C

C C

U

U

M M

M M

r

f

rr rf

fr ff

r

f

rr rf

fr ff

r

f

rr rf

fr ff

(5)

where { }

f

U are the free DOF and { }

r

U are the restrained DOF (excited by random

loading). { } F is the nodal force excitation activated by a value of force. The value of force

can be other than unity, allowing for scaling of the participation factors.

The free displacements can be decomposed into pseudo-static and dynamic parts as:

{ } { } { }

d s f

u u u + = (6)

The pseudo-static displacements may be obtained from equation (5) by excluding the first

two terms on the left-hand side of the equation and by replacing { }

f

u by { }

s

u :

{ } | | | |{ } | |{ }

r r fr ff s

u u u = =

1

(7)

in which | | | | | |

fr ff

=

1

. Physically, the elements along the

th

i column of | | are the

pseudo-static displacements due to a unit displacement of the support DOFs excited by the

th

i base PSD. These displacements are written as load step 2 on the .rst file. Substituting

equations (7) and (6) into (5) and assuming light damping yields:

| |{ } | |{ } | |{ } { } | || | | | ( ){ }

r fr ff a ff a ff d ff

F u C + + +

~

(8)

The second term on the right-hand side of the above equation represents the equivalent

forces due to support excitations.

Using the mode superposition analysis

( ) { } | | ( ) { } t y t u

d

= (9)

the above equations are decoupled yielding:

,

2

2

j j j j j j j

G y y y = + + ( ) n ..., , , j 2 1 = (10)

where: n = number of mode shapes chosen for evaluation (input quantity

NMODE)

j

y = generalized displacements

j

and

j

= natural circular frequencies and modal damping ratios

The modal loads

j

G are defined by:

{ } { }

j r

T

j j

G + = (11)

EXCITE Power Unit v2013 Interfacing with ANSYS Users Guide

25-J an-2013 6-3

The modal participation factors corresponding to support excitation are given by:

{ } | || | | | ( ) { }

j

T

fr ff j

+ = (12)

and for nodal excitation:

{ } { } F

T

j j

= (13)

You might also like

- Abaqus-Excite Workflow in Automotive Powertrain AnalysisDocument12 pagesAbaqus-Excite Workflow in Automotive Powertrain AnalysisDmitry GrenishenNo ratings yet

- 006 EUC 007 Magna SteyrDocument10 pages006 EUC 007 Magna SteyrEduardo ValdiviesoNo ratings yet

- WBv12.1 Emag Tutorial3 Busbars PDFDocument58 pagesWBv12.1 Emag Tutorial3 Busbars PDFAraz SNo ratings yet

- Ansys Forte Tutorials 2022 R1Document292 pagesAnsys Forte Tutorials 2022 R1MiguelSchuchterNo ratings yet

- ANSYS Mechanical Users GuideDocument1,824 pagesANSYS Mechanical Users GuideHadrian RochaNo ratings yet

- Cyclic Symmetry TopicsDocument73 pagesCyclic Symmetry TopicsMoisés MachadoNo ratings yet

- 01 EXCITE Release NotesDocument92 pages01 EXCITE Release NoteshenevilNo ratings yet

- ANSYS Motion 2019 R3 EHD Bearing TutorialDocument13 pagesANSYS Motion 2019 R3 EHD Bearing TutorialbadaboyNo ratings yet

- Mechanical APDL Material Reference - AnsysDocument168 pagesMechanical APDL Material Reference - AnsysDiego VegaNo ratings yet

- ANSYS TUTORIAL FOR TORQUE ANALYSIS OF SHAFT WITH TWO DISKSDocument13 pagesANSYS TUTORIAL FOR TORQUE ANALYSIS OF SHAFT WITH TWO DISKSPugazhenthi ThananjayanNo ratings yet

- 2023 Abaqus For Engineers Fe Safe Research Gate PreviewDocument105 pages2023 Abaqus For Engineers Fe Safe Research Gate PreviewSaid EL FakkoussiNo ratings yet

- ANSYS Mechanical APDL Modeling and Meshing GuideDocument244 pagesANSYS Mechanical APDL Modeling and Meshing GuidejozNo ratings yet

- Using Remote Display Technologies With ANSYS Workbench ProductsDocument326 pagesUsing Remote Display Technologies With ANSYS Workbench ProductsjemanuelvNo ratings yet

- Tutorials CFX Mesh PDFDocument256 pagesTutorials CFX Mesh PDFLebada NeagraNo ratings yet

- Calculating and Displaying Fatigue ResultsDocument42 pagesCalculating and Displaying Fatigue ResultsBekirHanNo ratings yet

- Fatigue Life Prediction of Lower Suspension Arm Using Strain-Life ApproachDocument15 pagesFatigue Life Prediction of Lower Suspension Arm Using Strain-Life Approachabraham silva hernandezNo ratings yet

- ANSYS, Inc. Licensing GuideDocument124 pagesANSYS, Inc. Licensing GuideMa HdiNo ratings yet

- SC2015 enDocument148 pagesSC2015 enunmeshNo ratings yet

- ANSYS Fluent V2F Turbulence Model ManualDocument100 pagesANSYS Fluent V2F Turbulence Model ManualjemanuelvNo ratings yet

- ANSYS ACT API Reference Guide PDFDocument2,470 pagesANSYS ACT API Reference Guide PDFJuan David BurgosNo ratings yet

- Ans Elem PDFDocument1,478 pagesAns Elem PDFAwahida WidiNo ratings yet

- Simulation of Biaxial Wheel Test and Fatigue Life Estimation ConsideringDocument9 pagesSimulation of Biaxial Wheel Test and Fatigue Life Estimation Consideringesmaeel ghafari100% (1)

- 7 Christian Gaier Multi Axial Fatigue Analysis With The Fe Post Processor Femfat Utmis 2010Document50 pages7 Christian Gaier Multi Axial Fatigue Analysis With The Fe Post Processor Femfat Utmis 2010ashish38799100% (2)

- CFD Tutorial - Rigid Body Modeling - EdrDocument16 pagesCFD Tutorial - Rigid Body Modeling - EdrRajeuv GovindanNo ratings yet

- ANSYS ACT API Reference Guide PDFDocument1,964 pagesANSYS ACT API Reference Guide PDFLuis Humberto Martinez PalmethNo ratings yet

- Le Van Sy PHD Thesis PDFDocument205 pagesLe Van Sy PHD Thesis PDFNhan LeNo ratings yet

- Using Remote Display Technologies With ANSYS Workbench ProductsDocument10 pagesUsing Remote Display Technologies With ANSYS Workbench ProductsprashanthNo ratings yet

- Fluid Dynamics Verification Manual PDFDocument194 pagesFluid Dynamics Verification Manual PDFNui Computercenter Swu OnkNo ratings yet

- ANSYS Mechanicalfasdfasfs APDL Thermal Analysis GuideDocument100 pagesANSYS Mechanicalfasdfasfs APDL Thermal Analysis GuideAnonymous QJ7OUeju0% (1)

- Configuring High Performance Computing GuideDocument34 pagesConfiguring High Performance Computing GuideSuri Kens MichuaNo ratings yet

- Introduction To Workbench and CFX WorkflowDocument44 pagesIntroduction To Workbench and CFX WorkflowRaoni AmbrosioNo ratings yet

- ANSYS ACT Developers Guide PDFDocument506 pagesANSYS ACT Developers Guide PDFojbulmerNo ratings yet

- QuantumX-System MANUALDocument218 pagesQuantumX-System MANUALclaudiotech76No ratings yet

- AnsysDocument18 pagesAnsysmechanical engineering100% (12)

- ANSYS AutodynDocument22 pagesANSYS AutodynAhmed Dyal100% (1)

- APDL HelpDocument220 pagesAPDL HelpFaisal Naveed SiddiquiNo ratings yet

- Workbench Users Guide 15Document294 pagesWorkbench Users Guide 15ppyim2012No ratings yet

- Customize ANSYS with User Programmable FeaturesDocument5 pagesCustomize ANSYS with User Programmable FeaturesshirbhatenjNo ratings yet

- Arduino Ventilation ControlDocument40 pagesArduino Ventilation ControlPraveen KumarNo ratings yet

- ExavatorDocument38 pagesExavatorAnwar SafariNo ratings yet

- SimMechanics Getting Started 2014bDocument40 pagesSimMechanics Getting Started 2014bengrasheedNo ratings yet

- Torque Arm Shape OptimizationDocument8 pagesTorque Arm Shape OptimizationJay MalaneyNo ratings yet

- ANSYS Mechanical APDL Fluids Analysis Guide PDFDocument46 pagesANSYS Mechanical APDL Fluids Analysis Guide PDFda_pinon100% (1)

- Ansys Fensap-Ice Tools ReferenceDocument40 pagesAnsys Fensap-Ice Tools ReferenceΈνκινουαν Κόγκ ΑδάμουNo ratings yet

- Shezad Thesis PDFDocument111 pagesShezad Thesis PDFShezad NilamdeenNo ratings yet

- ANSYS CFD-Post User's GuideDocument372 pagesANSYS CFD-Post User's GuideAdrian DavidNo ratings yet

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationFrom EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationNo ratings yet

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationFrom EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationNo ratings yet

- Guide to Load Analysis for Durability in Vehicle EngineeringFrom EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonRating: 4 out of 5 stars4/5 (1)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- Turbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsFrom EverandTurbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsNo ratings yet

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Engineering Design via Surrogate Modelling: A Practical GuideFrom EverandEngineering Design via Surrogate Modelling: A Practical GuideRating: 5 out of 5 stars5/5 (1)

- Autonica Manual FeDocument40 pagesAutonica Manual FeManuel PedroNo ratings yet

- 3bhs112321 Zab E51 o Acs1000ad ParametrosDocument380 pages3bhs112321 Zab E51 o Acs1000ad ParametrosEnrique TorrezNo ratings yet

- Model Lvdt-8: Acces I/O Products Inc 10623 Roselle Street, San Diego, CA 92121 TEL (858) 550-9559 FAX (858) 550-7322Document28 pagesModel Lvdt-8: Acces I/O Products Inc 10623 Roselle Street, San Diego, CA 92121 TEL (858) 550-9559 FAX (858) 550-7322DJ MAXNo ratings yet

- Tem PlugDocument1 pageTem Plugdeepali0305No ratings yet

- A Multi Axial Fatigue Analysis Method ForDocument13 pagesA Multi Axial Fatigue Analysis Method ForShivanand ArwatNo ratings yet

- To Calculate Critical Heat Flux: 1) 1 Heat FluxDocument2 pagesTo Calculate Critical Heat Flux: 1) 1 Heat Fluxdeepali0305No ratings yet

- Constitutional Provisions For Scheduled Castes Tribes Backward ClassesDocument3 pagesConstitutional Provisions For Scheduled Castes Tribes Backward Classesdeepali0305No ratings yet

- HR vs FR: Key DifferencesDocument2 pagesHR vs FR: Key Differencesdeepali0305No ratings yet

- Lab 5 6 7Document6 pagesLab 5 6 7deepali0305No ratings yet

- Integration Formulas: 1. Common IntegralsDocument5 pagesIntegration Formulas: 1. Common IntegralssiegherrNo ratings yet

- Mass FlowDocument1 pageMass Flowdeepali0305No ratings yet

- Combustion Process With Def.Document11 pagesCombustion Process With Def.Suresh VaddeNo ratings yet

- CFD Studies of Combustion in Diesel EngineDocument4 pagesCFD Studies of Combustion in Diesel Enginedeepali0305100% (1)

- Mass FlowDocument1 pageMass Flowdeepali0305No ratings yet

- MIT18 03SCF11 s21 4text PDFDocument3 pagesMIT18 03SCF11 s21 4text PDFdeepali0305No ratings yet

- Refrigeration and Air Conditioning 2nd Ed. - W. Stoecker, J. Jones WWDocument440 pagesRefrigeration and Air Conditioning 2nd Ed. - W. Stoecker, J. Jones WWSBW100% (25)

- Vol - 6 - 6 - 695 - 708 - EHSAN AHMEDDocument14 pagesVol - 6 - 6 - 695 - 708 - EHSAN AHMEDdeepali0305No ratings yet

- Refrigeration Cycle Efficiency and ComponentsDocument8 pagesRefrigeration Cycle Efficiency and ComponentsJames TheeNo ratings yet

- Strength Assessment: - According To Amount Highest StressDocument3 pagesStrength Assessment: - According To Amount Highest Stressdeepali0305No ratings yet

- Test #2: Math 4355 - Spring 2012Document4 pagesTest #2: Math 4355 - Spring 2012deepali0305No ratings yet

- (Ayatollahi e Mohammadi) - Thermo-Mechanical Fatigue Life Assessment of A Diesel Engine PistonDocument11 pages(Ayatollahi e Mohammadi) - Thermo-Mechanical Fatigue Life Assessment of A Diesel Engine PistonNeimar Soares SilvaNo ratings yet

- Euler Eq. PDFDocument2 pagesEuler Eq. PDFdeepali0305No ratings yet

- Shaft analysis calculation of load capacity according to DIN 743Document8 pagesShaft analysis calculation of load capacity according to DIN 743droessaert_stijnNo ratings yet

- Fatigue On Engine PistonDocument13 pagesFatigue On Engine PistonSatheesh Sekar100% (1)

- Assessment of Fatique Life According To FKM-Code Within HyperWorks PDFDocument19 pagesAssessment of Fatique Life According To FKM-Code Within HyperWorks PDFdeepali0305No ratings yet

- Autofena 3D: Assessment of Static Strength and Fatigue Life According To Fkm-Guideline Within HyperworksDocument25 pagesAutofena 3D: Assessment of Static Strength and Fatigue Life According To Fkm-Guideline Within Hyperworksdeepali0305No ratings yet

- Individual TaxpayersDocument3 pagesIndividual TaxpayersJoy Orena100% (2)

- Kinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide CatalystsDocument9 pagesKinetics of Acetone Hydrogenation For Synthesis of Isopropyl Alcohol Over Cu-Al Mixed Oxide Catalysts李国俊No ratings yet

- Energy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefDocument8 pagesEnergy Efficiency Existing Ship Index (Eexi) : Regulatory DebriefSalomonlcNo ratings yet

- Module 1 (Social Innovation)Document7 pagesModule 1 (Social Innovation)Marinette Medrano50% (2)

- Xu10j4 PDFDocument80 pagesXu10j4 PDFPaulo Luiz França100% (1)

- Indian companies involved in trade dispute caseDocument15 pagesIndian companies involved in trade dispute caseakshay daymaNo ratings yet