Professional Documents

Culture Documents

Technical Data For Libra Metal Furring Runner PDF

Uploaded by

orc19Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data For Libra Metal Furring Runner PDF

Uploaded by

orc19Copyright:

Available Formats

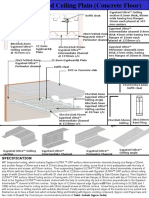

Metal Furring Runner

Concealed Metal Ceiling System For Direct Fix of Plasterboards.

FF10

FF30 FF20 FF40 180 AFB FF50

Libra Metal Furring is a concealed metal

system which is designed to create a ceiling that has a conventional plaster appearance where no joints are required.

Combining the Libra Metal Furring system with both tapered edge plasterboards and taped and filled joints allows a wide variety of decorations to be applied to the surface of the wall. For applications where hygiene is of prime importance, particularly in the medical field, surfaces can be left smooth. Items such as light fitting, access panels and ventilation units are easily accommodated within the ceiling system. Libra Metal Furring system consists of FF10 Furring Runner to which the plasterboard is

fixed, the face of which is knurled to assist drywall screw penetration, FF30 which is the Primary Channel to which the FF10 is fixed using the FF50 Wire Clip. FF20 which is the Perimeter Trim. The System is suspended using either FF40 Strap Hanger or 180 Hanger Angle where greater lateral stability is required and the AFB Angle Bracket can be used to fix the top of the suspension to the soffit.

Libra Metal Furring are manufactured using pre-galvanised mild steel to BS EN 10346 2009. Libra Metal Furring system has been Fire Resistance Tested in accordance with

BS 476: Part 23.

Metal Furring Runner

Concealed Metal Ceiling System For Direct Fix of Plasterboards.

Gypsum Board 900mm wide x 12.5mm thick.

Single Layer

Tapered edge board is fixed with bound edges at right angles to the Libra Systems furring runner section and adjoining edges are lightly butted. End joints must occur at the centre of a Libra Systems furring runner section. End joints should be staggered by half a board length leaving a 3mm gap between board ends. The boards are screw fixed to the Libra Systems furring runner section with 32mm drywall screws at 230mm centres and no closer than 25mm from bound edges. The end boards are screw fixed with 32mm drywall screws at 150mm maximum centres to the Libra Systems furring runner section and Libra Systems perimeter trim as far from ends as possible. The long edges of the board, whether bound or cut on site, are screwed to the Libra Systems perimeter trim only where it is joined by a Libra Systems furring runner section.

Where Libra Systems Primary Channels have to be joined, they should be overlapped back to back by 150mm minimum and fixed by two bolts and nuts. See Fig.1

Double Layer

When using two layers of board, the first layer of board is fixed exactly as a single layer boarding. The second layer, using tapered edge board, should be fixed with all joints staggered in relation to the first layer and screwed to the Libra Systems furring runner sections and Libra Systems perimeter trim using 38mm drywall screws.

Fig. 1

Joint and Screw Finishing

This should be carried out as recommended by the board manufacturer.

Details showing method of joining channel sections

Performance and Design Consideration Maximum Recommended Loads on Libra Systems Furring Runner System

Layout of Primary Channel with Furring Runner Sections set at 450mm centres. Suspension Centres. 1200mm 1200mm 1200mm Primary Channel Centres 600mm 900mm 1200mm 60Kg/m 40Kg/m 30Kg/m Maximum Load Including Board.

Where Libra Systems Furring Runner

sections have to be joined, the ends are nested together by 150mm minimum and crimped twice each side of overlapped sections using a crimping tool, or, alternatively, two Tek screws could be used on each side of the overlap. See Fig.2

Fig. 2

Detail showing method of joining furring runner sections.

Where light fittings and access panels are incorporated as part of the design requirements, it is important that the integrity of the ceiling is maintained when fire resistance and sound insulation are specified. Fixing to the system should always be made into the metal section and not directly into the plasterboard. Where heavy loads are installed, the primary grid layout should be adjusted in accordance with the above table. Where heavier loads than stated are being installed, these should be suspended independently from the structure.

You might also like

- Technical Specification For Interior Block A and LibraryDocument54 pagesTechnical Specification For Interior Block A and Librarymohammedjafar2508No ratings yet

- Suspended ceiling trims and accessories guideDocument28 pagesSuspended ceiling trims and accessories guideAna BatistaNo ratings yet

- BOQ-Acoustic Work at IIIDEM 31.01.2020Document10 pagesBOQ-Acoustic Work at IIIDEM 31.01.2020Kirti BaliNo ratings yet

- GI Plank - 200mm Micro PerforatedDocument1 pageGI Plank - 200mm Micro PerforatedPratik ThakkarNo ratings yet

- CORTEN STEEL EXTERIOR WALL SYSTEMDocument2 pagesCORTEN STEEL EXTERIOR WALL SYSTEMDen Bagoes ReditoNo ratings yet

- 8 - Ceilings Partitions Access FlooringDocument6 pages8 - Ceilings Partitions Access FlooringShawn LangleyNo ratings yet

- Abstract of cost for Prof. Cabin and False CeilingDocument9 pagesAbstract of cost for Prof. Cabin and False CeilingSHAILENDRANo ratings yet

- Urji ConstructionDocument9 pagesUrji ConstructiontofikkemalNo ratings yet

- DPWH Standard Specifications for Non-Structural Metal FramingDocument8 pagesDPWH Standard Specifications for Non-Structural Metal FramingleovorigNo ratings yet

- 71mm Thickness - Interior WallDocument1 page71mm Thickness - Interior WallPuneet SharmaNo ratings yet

- 3.6.3 Column and Beam Fire ProtectionDocument10 pages3.6.3 Column and Beam Fire Protectionodemircioglu2No ratings yet

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 pagesSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlNo ratings yet

- BOQ OF FURNISHING AND INTERIOR WORKSDocument16 pagesBOQ OF FURNISHING AND INTERIOR WORKSAbhishek SankerNo ratings yet

- DATA Fire Duct SystemsDocument8 pagesDATA Fire Duct SystemsRithwik T. HariNo ratings yet

- Modu Tek CatalogDocument184 pagesModu Tek Catalogiskierdo10No ratings yet

- TDS T 24 Grid Sus UpdatedDocument4 pagesTDS T 24 Grid Sus UpdatedSHEERAZ AHMAD (SHEERAZ A. BUTT)No ratings yet

- Fabrication Standard of Duct-AcDocument5 pagesFabrication Standard of Duct-AcVicky KumarNo ratings yet

- Boq PDFDocument21 pagesBoq PDFnohaNo ratings yet

- BOQ and Specs for Civil, Interior, Electrical and AC WorksDocument21 pagesBOQ and Specs for Civil, Interior, Electrical and AC WorksRadwan Noman100% (1)

- WB09 Floor Ceiling and Soffit Systems 10Document84 pagesWB09 Floor Ceiling and Soffit Systems 10Krish DoodnauthNo ratings yet

- Shingle Installation GuideDocument12 pagesShingle Installation GuideJefferson Mendieta100% (1)

- Method Statement For False Ceiling Works Gypsum Board, Beam Grid, Ceiling Tiles & BafflesDocument9 pagesMethod Statement For False Ceiling Works Gypsum Board, Beam Grid, Ceiling Tiles & BafflesAddis MekuriaNo ratings yet

- Rockwool BeamClad SystemsDocument4 pagesRockwool BeamClad SystemstwinpixtwinpixNo ratings yet

- Chain Link Fencing Guide: Specs, Installation & MoreDocument3 pagesChain Link Fencing Guide: Specs, Installation & MorevanmurthyNo ratings yet

- 02825barbed Wire FencingDocument5 pages02825barbed Wire FencingPatricia OrdoñezNo ratings yet

- Preliminary Estimate Iihr-Rkvy-Hybrid Vegetables Seed Production Project (Polyhouse)Document11 pagesPreliminary Estimate Iihr-Rkvy-Hybrid Vegetables Seed Production Project (Polyhouse)kajale_shrikant2325No ratings yet

- Beyma Line Array ProjectDocument22 pagesBeyma Line Array ProjectLeandro TolozaNo ratings yet

- Ceiling SpecDocument8 pagesCeiling Specagrima100% (3)

- Uni Span FormworkDocument30 pagesUni Span FormworkHans JonesNo ratings yet

- INTERIOR FURNISHING WORK OF NEW CIRCLE OFFICEDocument37 pagesINTERIOR FURNISHING WORK OF NEW CIRCLE OFFICESAI ASSOCIATENo ratings yet

- Chap 7 WiringDocument44 pagesChap 7 WiringrakshaNo ratings yet

- Ext WorksDocument5 pagesExt WorksahmadnazrulafiziNo ratings yet

- Instructions For Fixing EtalbondDocument9 pagesInstructions For Fixing EtalbondAlket DhamiNo ratings yet

- Stramit Bridging Detailing GuideDocument8 pagesStramit Bridging Detailing Guidenifty25No ratings yet

- Specification SmartFenceDocument3 pagesSpecification SmartFenceVimala PonnusamyNo ratings yet

- ProductsDocument3 pagesProductshab_gujaratNo ratings yet

- Hotels Electrical and Mechanical SpecificationsDocument32 pagesHotels Electrical and Mechanical SpecificationsArchanaShenoyNo ratings yet

- TNF Ceiling C46 Components and InstallationDocument8 pagesTNF Ceiling C46 Components and InstallationcmkohNo ratings yet

- Anechoic ChambersDocument28 pagesAnechoic ChambersvtechelectricNo ratings yet

- Civil & Interior Works Boq - NXP SL - No Description Unit QTY A Civil Work 1.0 Block Work 100Mm THKDocument8 pagesCivil & Interior Works Boq - NXP SL - No Description Unit QTY A Civil Work 1.0 Block Work 100Mm THKShreya BhattacharyaNo ratings yet

- Ultra Silent Handling Storage and Installation ManualDocument7 pagesUltra Silent Handling Storage and Installation ManualyaseraleweNo ratings yet

- Specification of Toilet BlockDocument2 pagesSpecification of Toilet BlockKuldeep ChakerwartiNo ratings yet

- FLOORING - Installation ManualDocument28 pagesFLOORING - Installation ManualAlex GeronaNo ratings yet

- 1401201307-Furnishing - Madangir BoqDocument26 pages1401201307-Furnishing - Madangir BoqdawitgggNo ratings yet

- S Rapid Clamp BRDocument8 pagesS Rapid Clamp BRSteven NaungNo ratings yet

- Hopergy Roof Mounting System Installation Manual V2.2Document24 pagesHopergy Roof Mounting System Installation Manual V2.2Jason HallNo ratings yet

- Enquiry - Cable Tray - APL TowerDocument4 pagesEnquiry - Cable Tray - APL Towerrkpatel40No ratings yet

- Canales UNISTRUTDocument44 pagesCanales UNISTRUTMarkNo ratings yet

- TechnicalDatasheetDexune Mineral Fibre - 2 12082015 0410Document1 pageTechnicalDatasheetDexune Mineral Fibre - 2 12082015 0410Avan SinghNo ratings yet

- Bid PDFDocument4 pagesBid PDFAr Shubham KumarNo ratings yet

- Minimum Spacing of Main Bars?Document4 pagesMinimum Spacing of Main Bars?Ellijha FetalveroNo ratings yet

- Topspan 22 40Document6 pagesTopspan 22 40bradrimmNo ratings yet

- IsolcomerDocument8 pagesIsolcomerToth HelgaNo ratings yet

- Epoxy Bonded Reinforcement To Concrete Decks and BeamsDocument2 pagesEpoxy Bonded Reinforcement To Concrete Decks and BeamsFrancisco Javier Martinez BurgoNo ratings yet

- Fire Door Certification Scheme DetailsDocument2 pagesFire Door Certification Scheme DetailsTAHER AMMARNo ratings yet

- N Stress Floor SlabDocument4 pagesN Stress Floor SlabBen Sim NitroNo ratings yet

- Mtethod of ConstructionDocument8 pagesMtethod of ConstructionSteven ReyesNo ratings yet

- HWD0194Document2 pagesHWD0194Ever Nina LauraNo ratings yet

- Division 3 Specs WrittingDocument16 pagesDivision 3 Specs WrittingJaymar Palomares OrilloNo ratings yet

- Stair - Plan & PerspectiveDocument1 pageStair - Plan & Perspectiveorc19No ratings yet

- Basicspec ElevatorDocument2 pagesBasicspec Elevatororc19No ratings yet

- Architecture ReviewsDocument22 pagesArchitecture Reviewsorc19No ratings yet

- Professional Education UnitsDocument1 pageProfessional Education UnitsNelvin Rivera NoolNo ratings yet

- HD Woodson High School - CPMDocument17 pagesHD Woodson High School - CPMorc19No ratings yet

- Tropical Humid ArchitectureDocument16 pagesTropical Humid ArchitectureJayson Hernandez100% (1)

- Excel Tutorial: Learn Formatting, Charts, and MoreDocument12 pagesExcel Tutorial: Learn Formatting, Charts, and Moremjay15No ratings yet

- Code On Sanitation - PhilippinesDocument23 pagesCode On Sanitation - PhilippinesNicoel100% (2)

- Tropical Architecture - 1 PDFDocument22 pagesTropical Architecture - 1 PDForc19100% (1)

- Metal Ceiling Installation PDFDocument7 pagesMetal Ceiling Installation PDForc19No ratings yet

- PD957Document29 pagesPD957YelNo ratings yet

- Tropical Architecture PDFDocument1 pageTropical Architecture PDForc19No ratings yet

- 1987 ConstitutionDocument49 pages1987 ConstitutionAerwin AbesamisNo ratings yet

- Good Building Handbook PhilippinesDocument85 pagesGood Building Handbook Philippines61cmNo ratings yet

- HPT30103 Research Methodology Group 3Document26 pagesHPT30103 Research Methodology Group 3Rizq ZaidiNo ratings yet

- Marketing Strategies of Olper's.....Document15 pagesMarketing Strategies of Olper's.....don_zed_420100% (6)

- Advanced Engineering Mathematics by Erwin Kreyszig - Advanced Engineering Mathematics For Everyone!!!! PDFDocument3 pagesAdvanced Engineering Mathematics by Erwin Kreyszig - Advanced Engineering Mathematics For Everyone!!!! PDFRose Hunter0% (3)

- Projectiles/Projectile Simulator/Projectile Simulator InteractiveDocument4 pagesProjectiles/Projectile Simulator/Projectile Simulator InteractiveEldienGarciaBucol100% (1)

- Republic of The Philippines (PCGG) vs. COCOFED, Et Al., G.R. No. 147062-64, December 14, 2001Document13 pagesRepublic of The Philippines (PCGG) vs. COCOFED, Et Al., G.R. No. 147062-64, December 14, 2001Lou Ann AncaoNo ratings yet

- Fertilizer Academy Courses Catalogue 2022Document83 pagesFertilizer Academy Courses Catalogue 2022Lokesh RavichandranNo ratings yet

- Spring 2023 - CS201 - 1Document3 pagesSpring 2023 - CS201 - 1Nadeem NayamatNo ratings yet

- Resume - Gratten WardDocument1 pageResume - Gratten WardgrattenwardNo ratings yet

- HOC PO - 04 2019VTP-CeragonEquipos OROCOM - F. 1068203Document2 pagesHOC PO - 04 2019VTP-CeragonEquipos OROCOM - F. 1068203Lucero Anyacu SelarayanNo ratings yet

- HRM HeinzDocument14 pagesHRM HeinzAkshay TyagiNo ratings yet

- FYA IntroductionDocument15 pagesFYA IntroductionAmin ARNo ratings yet

- Machine Vision and Robot Process Capabilities ExplainedDocument58 pagesMachine Vision and Robot Process Capabilities ExplainedBelay ShibruNo ratings yet

- CH 12Document44 pagesCH 12kevin echiverriNo ratings yet

- Mid Term 2 Fall 2014Document1 pageMid Term 2 Fall 2014Mahmoud Ahmed TawfikNo ratings yet

- Change Management Process AssessmentDocument5 pagesChange Management Process AssessmentKamrul Islam SakibNo ratings yet

- S G L.L.P.: Attorneys For Defendant Arizona Secretary of State Katie HobbsDocument25 pagesS G L.L.P.: Attorneys For Defendant Arizona Secretary of State Katie Hobbspaul weichNo ratings yet

- Quantitative Research by Dr. Myla M. Arcinas SDRC WebinarDocument56 pagesQuantitative Research by Dr. Myla M. Arcinas SDRC WebinarFerry FrondaNo ratings yet

- Complete Report IzliyaDocument49 pagesComplete Report IzliyaMuizzuddin RosliNo ratings yet

- PDF Ciara Herndon Resume December 2020Document3 pagesPDF Ciara Herndon Resume December 2020api-484247819No ratings yet

- Assertion: Jmeter TutorialDocument7 pagesAssertion: Jmeter TutorialInteract peopleNo ratings yet

- Engine Tune-Up: Section 7Document13 pagesEngine Tune-Up: Section 7Francis VincentNo ratings yet

- ECG-Foam CalculationDocument22 pagesECG-Foam CalculationzshehadehNo ratings yet

- Face Recognition Using Cloud ComputingDocument22 pagesFace Recognition Using Cloud ComputingrmidhunajyothiNo ratings yet

- McWane ULFM Hydrants & ValvesDocument4 pagesMcWane ULFM Hydrants & ValvesAhmed RamzyNo ratings yet

- P N M T: PNMT (Java Version) Operation ManualDocument85 pagesP N M T: PNMT (Java Version) Operation ManualRaja solaimalaiNo ratings yet

- SALN 2013 FormDocument2 pagesSALN 2013 FormCpdo Bago100% (1)

- Vibration Reduction in A Variable Displacement Engine Using Pendulum AbsorbersDocument6 pagesVibration Reduction in A Variable Displacement Engine Using Pendulum Absorbersdeepak_gupta_pritiNo ratings yet

- Indian Contract Act 1872 SummaryDocument66 pagesIndian Contract Act 1872 Summaryyuvraaj sharmaNo ratings yet

- Cisco IOS Configuration Fundamentals and Network Management Configuration Guide, Release 12.3Document3 pagesCisco IOS Configuration Fundamentals and Network Management Configuration Guide, Release 12.3christopherfaustNo ratings yet