Professional Documents

Culture Documents

B100 PDF

Uploaded by

user2336Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B100 PDF

Uploaded by

user2336Copyright:

Available Formats

32 BUILD June/July 2007

BUILD RIGHT

INSULATING SLAB-ON-

GROUND FLOORS

Current methods for adding insulation to slab-on-ground floors have some

disadvantages. However, recent BRANZ research has developed more effective

methods.

By Ian Cox-Smith, BRANZ Thermal Testing Scientist

C

urrent practice for adding insulation

to slab-on-ground foors usually

involves either putting the insulation

under the perimeter of the slab,

or putting it on the outside vertical face of

the foundation wall, including the area of

foundation exposed above ground level.

While the frst technique is relatively easy

to implement, its effectiveness is limited by

the fact that without a thermal break between

the slab and foundation, heat from the interior

environment can readily fow along the slab

and through the foundations to the exterior.

The second technique is more diffcult to

implement, and even though there are some

proprietary solutions that use expanded

polystyrene formwork they are reliant on

fnding an effective means to protect the

insulation. The technique is particularly

diffcult to use when the wall system is a

standard 90 mm timber frame.

When is insulation required?

Addition of insulation is usually required for

small foor slabs (<80 m

2

) and where there

are heating elements embedded into the

slab. Insulation is also recommended when

the local water table is less than 1 m below

ground level.

Apart from very large foor slabs achieving

SNZ/PAS 4244: 2003 Insulation of

lightweight-framed and solid-timber houses,

recommended better practice (R1.9 m

2

C/W)

requires the addition of insulation to a slab-

on-ground foor.

New, improved methods

Figure 1 illustrates a more effective

insulation method that uses timber to

Figure 1: Floor slab insulation single storey.

90 mm

direct-fxed cladding

framing (insulation

omitted for clarity)

bottom plate on dpc

H3.2 140 x 45 mm

timber insert

120 mm

reinforced concrete

foor slab

polystyrene

insulation

dpm on sand

blinding and

hardfll

165 mm

200 mm

155 mm

90 mm

H3.2 140 x 45 mm

timber insert

reinforced concrete

foor slab

polystyrene

insulation

dpm on sand

blinding and

hardfll

Figure 2: Floor slab insulation double storey.

cladding

framing (insulation

omitted for clarity)

20 mm cavity

battens

bottom plate on dpc

reinforcing through

hole drilled in

timber insert

BUILD June/July 2007 33

provide a thermal break between the

slab and its foundation. In this case, the

construction is single storey. For double

storey construction, the foor slab is required

to be tied to the foundation (see Figure

2). In both cases it may be necessary to

cast the bottom plate fxing in place to

avoid spalling of the concrete faces when

attempting to install the fxing later.

Some heat will still be able to bypass

the insulation in the area between the

thermal break and bottom plate. A further

improvement in the thermal performance of

the slab can be achieved by using 140 mm

deep wall studs to eliminate this gap (see

Figure 3).

Figure 4 shows an insulation solution

for a slab-on-ground foor where the wall

is brick veneer. Since the bricks provide

some additional thermal resistance, as well

as protection for the insulation, additional

insulation under the perimeter of the slab

may not be necessary. It is important to apply

a wedge of mortar to the top edge of the

insulation and to align it with the weep holes

to ensure proper drainage of the cavity.

A Building Research Levy funded study

developed this new method (see pages 103

105 for a report on the research project).

165 mm

120 mm

140 mm

H3.2 140 x 45 mm

timber insert

reinforced concrete

foor slab

polystyrene

insulation

dpm on sand

blinding and

hardfll

bottom plate on dpc

direct-fxed cladding

140 x 45 framing

(insulation omitted

for clarity)

Figure 3: Floor slab insulation single storey with 140 mm studs. Figure 4: Floor slab insulation single or double storey with masonry veneer cladding.

240 mm

90 mm

reinforced concrete

foor slab

polystyrene

insulation

dpm on sand

blinding and

hardfll

bottom plate on dpc

framing (insulation

omitted for clarity)

masonry veneer

cladding

wall underlay

weep holes

wedge of mortar

sloped to exterior

50 mm

setdown

50 mm

polystyrene

insulation

16 mm (10 mm

plaster coat & 6 mm

capillary break)

You might also like

- Enef Peter Roots Thermal Bridges Powerpoint 15-09 1 PDFDocument68 pagesEnef Peter Roots Thermal Bridges Powerpoint 15-09 1 PDFuser2336No ratings yet

- Draftsight TrainingDocument278 pagesDraftsight Traininguser2336100% (1)

- How to Properly Insulate a SlabDocument22 pagesHow to Properly Insulate a Slabuser2336No ratings yet

- BR-6228nS - NC User ManualDocument147 pagesBR-6228nS - NC User Manualmac52187No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- KFC Solano - Strucl - 041217 PDFDocument31 pagesKFC Solano - Strucl - 041217 PDFFroilan EspinosaNo ratings yet

- Design of Circular FootingDocument9 pagesDesign of Circular FootingLe Vu AnNo ratings yet

- Ir. Davy SukamtaDocument25 pagesIr. Davy SukamtarezaNo ratings yet

- Comparitive Design Study BS8110 Vs EC2Document127 pagesComparitive Design Study BS8110 Vs EC2DaGoose81100% (1)

- Rebound Hammer - Marikina BridgeDocument2 pagesRebound Hammer - Marikina BridgeJohn Rheynor MayoNo ratings yet

- Flexural Strength of Concrete Beam Specimen: Laboratory Experiment NoDocument7 pagesFlexural Strength of Concrete Beam Specimen: Laboratory Experiment NokeishasantiagoNo ratings yet

- Lot - 1 Weekly Progress ReportDocument14 pagesLot - 1 Weekly Progress ReportMesfin DerbewNo ratings yet

- Beam - GBDocument1 pageBeam - GBJake CortezNo ratings yet

- Cobicif-Reportdescription Eng PDFDocument700 pagesCobicif-Reportdescription Eng PDFĐạt Nguyễn TuấnNo ratings yet

- Reinforced Concrete Continuous Beam Analysis and Design (ACI 318-14) PDFDocument44 pagesReinforced Concrete Continuous Beam Analysis and Design (ACI 318-14) PDFsteveNo ratings yet

- Software Application - 21CV582Document32 pagesSoftware Application - 21CV582Surendra PNo ratings yet

- Lecture - Malaysia Roads and Bridges Rev1Document45 pagesLecture - Malaysia Roads and Bridges Rev1Ashaari Cha-eNo ratings yet

- UNITY INFRA PROJECTS LTD. DAILY PROGRESS REPORTDocument37 pagesUNITY INFRA PROJECTS LTD. DAILY PROGRESS REPORTZakirRazaNo ratings yet

- Internship Report On 120 Mens Hostel ConstructionDocument47 pagesInternship Report On 120 Mens Hostel ConstructionApollyon A100% (3)

- Reinforcing BarsDocument3 pagesReinforcing BarsSabre D. ButitoNo ratings yet

- Project Construction Management: Data SheetDocument8 pagesProject Construction Management: Data SheetyfcbrandonNo ratings yet

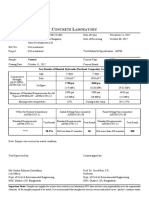

- Oncrete Aboratory: Test Results of Blended Hydraulic (Portland Composite) CementDocument2 pagesOncrete Aboratory: Test Results of Blended Hydraulic (Portland Composite) CementNadira PervinNo ratings yet

- Computation of Symmetrical Free Standing StaircasesDocument6 pagesComputation of Symmetrical Free Standing Staircaseswalaywan100% (1)

- Flier - Refresher Course On Prestressed Concrete DesignDocument3 pagesFlier - Refresher Course On Prestressed Concrete DesignMano HarNo ratings yet

- CV Sajid B.E. CivilDocument4 pagesCV Sajid B.E. CivilSajid Ali AbbasiNo ratings yet

- 2005 EWS T300 Glulam Connection Details APADocument20 pages2005 EWS T300 Glulam Connection Details APAVinícius Da Cunha FerreiraNo ratings yet

- Steel Beams With Web OpeningsDocument17 pagesSteel Beams With Web OpeningspestfariaNo ratings yet

- Prestress Concrete ไฟล์รวม PDFDocument430 pagesPrestress Concrete ไฟล์รวม PDFNA Sleeper0% (1)

- Prefab Building Elements For Affordable Housing.Document41 pagesPrefab Building Elements For Affordable Housing.shrikant100% (7)

- Estimate For Construction of 2 Rooms Civil Work: Below Finish Floor LevelDocument13 pagesEstimate For Construction of 2 Rooms Civil Work: Below Finish Floor LevelShashikant GaurNo ratings yet

- 100'x30' 4U4S (Taunggyi)Document18 pages100'x30' 4U4S (Taunggyi)R Kar HeinNo ratings yet

- TN-326 Average Pre CompressionDocument3 pagesTN-326 Average Pre CompressionPartha Pratim RoyNo ratings yet

- Cameron Middle East Skid Structural Calculation ReportDocument33 pagesCameron Middle East Skid Structural Calculation Reportsridhar100% (1)

- Columns and Shear Walls Means Vertical Elements Form Work We Cane Remove After24 Hours But Slab Form Work Depend On Span Same Like ThisDocument16 pagesColumns and Shear Walls Means Vertical Elements Form Work We Cane Remove After24 Hours But Slab Form Work Depend On Span Same Like ThisImam ShakilNo ratings yet