Professional Documents

Culture Documents

Metal Block

Uploaded by

Jitender YadavOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metal Block

Uploaded by

Jitender YadavCopyright:

Available Formats

Jitender Kumar 10001033

Experiment No - 12

First order dynamics (Metal block)

AIM: To determine the time constant of a first order system in metal block from its response to a step change in the input variable. APPARATUS: A brass cylindrical metal block. Oil bath with water heater. Digital Temperature indicators to indicate inlet and outlet temperature of cooling water with accuracy of 0.10C Stop watch. Cotton to wipeout oil from the thermometer. An air blower attached at the bottom of the glass tube

PROCEDURE: THEORY:Consider a metal block located in a flowing stream of fluid, whose temperature x varies with time. Our problem is to find out the variation in the metal block reading y with respect to time. The following assumption will be made to analyze this problem. All the resistance to heat transfer resides in the film surrounding the block The wall of a block doesnt expand or contract during transient response. The unsteady-state energy balance equation for this system can be written as Energy input - Energy output = Accumulation of energy. Fill the cylinder vessel with the desired quantity of selected liquid Start the agitator motor and adjust its speed (R.P.M) at desired value. Dip the given Metal block in the oil-bath and allow the temperature to rise around 1200C Take out the metal block from the oil bath and wipeout oil from its surface with cotton. Adjust the block at the top of the glass tube and start the air blower. Make sure the flow of air remains constant during the entire period. Note down the temperature as u start the temperature. Repeat above procedure for different speed of air blower.

[1]

Jitender Kumar 10001033

Experiment No - 12

When the block is subjected to some change in the surrounding temperature x(t) either the thermal energy will enter or leave the block and above equation can be written as ( ) 0 = / Where, [2]

A= Surface area of the block available for the heat transfer. [m2 ] Cp= Specific heat of stainless steel [Kcal/Kg*0C] m= Mass of block [Kg] t= Time [hr] h= Film heat transfer coefficient between surrounding fluid and block [Kcal/hr*m2*0C] Above equation is a first order different equation. Before solving this equation by means of Laplace transform, another variable deviation variable shall be introduced. The reason for this is that as long as the system is at its steady state, it is inconsequential to find indicated temperature as it is at its desired value. One is interested only when it deviates from its desired value. In the case of steady-state condition the things do not change with time and equation can be written as, ( ) 0 = 0 [3]

The subscripts is used to indicate that variable is at steady-state value. Equation 3 states that xs, ys in other words the thermometer reads true fluid temperature. Subtracting equation (3) from (2) gives [( ) ( )] 0 = ( )/ [4]

If we define the deviation variable to be difference between variables and its corresponding steady state value and denote it by in capital then we can write = ( ) = ( ) Substituting equation [5] in [4] and dividing both the sides by h*A gives = ( )/( ) (/) [6] [5]

Jitender Kumar 10001033

Experiment No - 12

Dimensions of

) = [] [/ ] [ 2 /] [1/2 ]= hr

It has a dimension of time alone. As soon as the thermometer is selected values of m, Cp becomes well defined. When the system of surrounding fluid is selected value of h also gets fixed. Thus for given metal block and given system m*Cp/h*A has a constant value and has a dimension of time. Thus this is known as time constant and denoted by . Thus equation [6]can be written as = / [7]

Taking Laplace transform of equation (7) and rearranging it as a ration of Y(S) and X(S) gives

() ()

1 ()+1

[8]

The expression on the right hand side of equation [8] is called transfer function of a system which the ratio of Laplace transform of response of a system(thermometer reading) to Laplace transform of input variable(surrounding fluid temperature) By reviewing steps leading to equation [8] it can be seen that the introduction of deviation variables prior to taking the Laplace transforms of the differential equation results in a transfer function that is free of initial condition because the initial values of X and Y are zero. In control system engineering, we are primarily concerned with the deviation of systems variables from their steady-state values. The use of deviation is natural as well as convenient. If a step change of magnitude A is introduced in forcing function (input variable) then it can be written as X(S) = A/S [9]

Substituting equation [9] in equation [8] and rearranging we get

(+1)

() =

[10]

Taking Laplace inverse of the above equation,

Jitender Kumar 10001033

Experiment No - 12

() = (1 / )

[11]

This is the response of the thermometer to step change in the input variable. From equation [11] it can be observed that after sufficiently long time contribution due to term e^-t/ will become zero and Y(t) will approach asymptotically. Several features of this response are: Value of Y(t) reaches 63.2% of its ultimate value after one time constant, After the elapsed time of 2, 3, 4 and 5 the percentage response is 86.5, 95, 98, and 99.2% respectively. From these facts one can consider that the response is essentially completed in 5 time constants. If response Y(t) is differentiated with respect to time we get,

()/ = (/ ) /

[12]

Equation [12] gives slope of response curve at any instant of time. Obviously the slope of response curve at time t=0 is given by (A/ ) Thus by making use of tangent to the response curve at t=0 as well as from 63.2% of the response the time constant of the system can be determined.

Jitender Kumar 10001033

Experiment No - 12

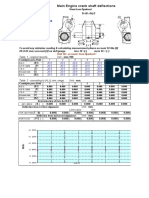

Observation Table

For low flow rate of air blower

time (s) 0 22.41 39.25 65.27 91.81 118.97 145.91 177.58 207.31 249.59 311.55 360 424.4 483.46 583.61 620.46 736.59 838.44 1004.47 1269.52 1535 Temperature (0C) 95 93 90 87 84 81 78 75 71 67 64 60 57 54 50 47 44 41 38 36.3 97.2 683.444 617.512 585.010 566.723 553.062 538.015 537.105 526.431 514.857 532.693 539.652 538.266 543.067 581.535 526.741 552.965 553.647 578.100 626.855 686.933 20.09 8.50 2.79 0.42 2.82 5.47 5.63 7.50 9.54 6.40 5.18 5.42 4.58 2.18 7.45 2.84 2.72 1.58 10.14 20.70 (sec) error in Tpred (0C) 97.2 94.567 92.655 89.81 87.04 84.335 81.777 78.92 76.379 72.987 68.45 65.23 61.354 58.165 53.459 51.926 47.694 44.631 40.676 36.329 33.597 error in Temperature 0 0.46 0.37 0.21 0.05 0.40 0.96 1.18 1.84 2.80 2.16 1.92 2.26 2.04 1.00 3.85 1.48 1.43 0.79 4.40 7.45

Average time constant 1 = 569.13 sec

Jitender Kumar 10001033

Experiment No - 12

For high flow rate of air blower

time (s) 0 31 49.41 68 90 113 137 169 201 239 283 332 394 475 591 819 997

Temperature (0C) 83 80 77 74 71 68 65 62 59 56 53 50 47 44 41 38 37.1

(sec)

error in

Tpred. (0C) 83

error in T

542.352 419.500 372.967 358.117 347.241 337.884 343.164 341.961 344.804 348.982 351.523 358.634 370.823 392.932 457.093 525.533

39.66 8.02 3.96 7.78 10.58 12.99 11.63 11.94 11.21 10.14 9.48 7.65 4.51 1.18 17.70 35.33

78.857 76.549 74.326 71.83 69.367 66.948 63.946 61.182 58.182 55.056 51.967 48.578 44.892 40.789 35.554 33.144

1.43 0.59 0.44 1.17 2.01 3.00 3.14 3.70 3.90 3.88 3.93 3.36 2.03 0.52 6.44 10.66

Average time constant 2 = 388.34 sec.

Jitender Kumar 10001033

Experiment No - 12

Graphs-

Temperature vs Time (low blower rate)

100 90

Temperatire (0C)

80 70 60 50 40 30 0 200 400 600 800 Time (sec) Observed Predicted 1000 1200 1400 1600

Temperaure vs Time (high blower rate)

90 80

Temperature (0C)

70 60 50 40 30 0 100 200 300 400 500 Time (sec) Observed Predicted 600 700 800 900 1000

Jitender Kumar 10001033

Experiment No - 12

Results and Conclusion:The average time constants for metal block system are: For low speed of air blower = 569.13 Seconds. For high speed of air blower = 388.34 Seconds. As result clearly portrays that if we increase the speed of air blower the heat transfer rate will increase because we are increasing the velocity of fluid i.e. air and we know that heat transfer coefficient depends on the velocity (heat transfer coefficient depends on Reynolds number and Reynolds number depends on velocity) so if h increases heat transfer rate will increase it will take less time to reach in steady state so time constant will decrease. The difference between thermometer experiment and in this experiment is that this experiment done in forced convection and the thermometer has been done in natural convection so we have observed that time constant for forced convection is less as compare to the natural convection, reason is same velocity of fluid increases.

You might also like

- Approved Annual Programme 2014Document1 pageApproved Annual Programme 2014Kiran KumarNo ratings yet

- NLC GATE 2014 recruitment for GET postsDocument5 pagesNLC GATE 2014 recruitment for GET postsSagar BodkheNo ratings yet

- Advt 1-2013-R-IDocument10 pagesAdvt 1-2013-R-IJitender YadavNo ratings yet

- ThermometerDocument4 pagesThermometerJitender YadavNo ratings yet

- SBHS1Document7 pagesSBHS1Jitender YadavNo ratings yet

- Notification SAIL Management Trainee PostsDocument9 pagesNotification SAIL Management Trainee PostsAnusha PalakurthyNo ratings yet

- UV Jitender 10001033Document5 pagesUV Jitender 10001033Jitender YadavNo ratings yet

- SBHS2Document2 pagesSBHS2Jitender YadavNo ratings yet

- Use of HPLC in Food Industry Group FDocument2 pagesUse of HPLC in Food Industry Group FJitender YadavNo ratings yet

- Pendulum Underdamped SystemDocument7 pagesPendulum Underdamped SystemJitender YadavNo ratings yet

- High Performance Liquid Chromatography (HPLC)Document3 pagesHigh Performance Liquid Chromatography (HPLC)Jitender YadavNo ratings yet

- Non Interacting SystemDocument5 pagesNon Interacting SystemJitender YadavNo ratings yet

- Mess Menu - 19 AugDocument2 pagesMess Menu - 19 AugJitender YadavNo ratings yet

- Experiment 5 - On-Off ControllerDocument7 pagesExperiment 5 - On-Off ControllerJitender YadavNo ratings yet

- Experiment 3 ThermowellDocument4 pagesExperiment 3 ThermowellJitender Yadav100% (2)

- Core B.tech EE Sanjay Kumar GillDocument1 pageCore B.tech EE Sanjay Kumar GillJitender YadavNo ratings yet

- Agitated VesselDocument7 pagesAgitated VesselJitender YadavNo ratings yet

- Preparing For Civil Services ExaminationDocument122 pagesPreparing For Civil Services ExaminationAlok Ranjan TripathiNo ratings yet

- 123Document1 page123Jitender YadavNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Science - Book 10Document312 pagesScience - Book 10Jaishree RamNo ratings yet

- Crankweb Deflections 9 Cyl ELANDocument2 pagesCrankweb Deflections 9 Cyl ELANСлавик МосинNo ratings yet

- NX Nastran 3 Release GuideDocument28 pagesNX Nastran 3 Release GuideMSC Nastran BeginnerNo ratings yet

- EL MOSSALLAMY Modelling The Behaviour of Piled Raft PDFDocument4 pagesEL MOSSALLAMY Modelling The Behaviour of Piled Raft PDFera210No ratings yet

- Corrosion Resistance of Surface Treated 42crmo4 Steel: D. Kusmič, V. Hrubý, L. BachárováDocument6 pagesCorrosion Resistance of Surface Treated 42crmo4 Steel: D. Kusmič, V. Hrubý, L. BachárovárachidradouaniNo ratings yet

- Romax 4000 PDFDocument2 pagesRomax 4000 PDFALEKSANDARNo ratings yet

- Assignment 4 PDFDocument2 pagesAssignment 4 PDFAhmed Attalla100% (1)

- Bagh Bon BondukDocument105 pagesBagh Bon BondukAdnan RahmanNo ratings yet

- IS 1570 Part 5Document18 pagesIS 1570 Part 5Sheetal JindalNo ratings yet

- MV Drop TestDocument5 pagesMV Drop Testrajinipre-1No ratings yet

- 11 HW ChemistryDocument6 pages11 HW ChemistryJ BalanNo ratings yet

- Literature ReviewDocument17 pagesLiterature ReviewSyafiq ShaffiaiNo ratings yet

- 06 - 3D Embankment ConsolidationDocument28 pages06 - 3D Embankment ConsolidationRaynaldo JodistiroNo ratings yet

- O Repensar Da Fonoaudiologia Na Epistemologia CienDocument5 pagesO Repensar Da Fonoaudiologia Na Epistemologia CienClaudilla L.No ratings yet

- Torque NotesDocument3 pagesTorque NotesKudzai MashayaNo ratings yet

- Harmonic excitation of 1-degree-of-freedom systemsDocument1 pageHarmonic excitation of 1-degree-of-freedom systemsLetty VianaNo ratings yet

- Siesmic Protection Ufc 3 310 04Document128 pagesSiesmic Protection Ufc 3 310 04irastemhemNo ratings yet

- Physics of Liq GasesDocument21 pagesPhysics of Liq GasesOctavianNo ratings yet

- Cooling PDFDocument656 pagesCooling PDFTrầnNgọcCườngNo ratings yet

- Introduction to Solid Modeling Using SolidWorks 2012 SolidWorks Simulation TutorialDocument8 pagesIntroduction to Solid Modeling Using SolidWorks 2012 SolidWorks Simulation TutorialAYAUWU LOVEDAYNo ratings yet

- Learning Objectives-2: Uniform MotionDocument7 pagesLearning Objectives-2: Uniform MotionBryanHarold BrooNo ratings yet

- Cantilever Calculation ToolDocument10 pagesCantilever Calculation ToolEnoch Twumasi50% (2)

- Physical Computing NotesDocument2 pagesPhysical Computing NotesAnonymous W9MgRBVtYCNo ratings yet

- 2SD2525 Datasheet en 20061121Document5 pages2SD2525 Datasheet en 20061121Giannis MartinosNo ratings yet

- Analysis of Statically Determinate Structures: Support ConnectionDocument7 pagesAnalysis of Statically Determinate Structures: Support ConnectionejlNo ratings yet

- Grade 12 English Test Review: Key Terms, Grammar, Reading ComprehensionDocument5 pagesGrade 12 English Test Review: Key Terms, Grammar, Reading ComprehensionLinh HuongNo ratings yet

- Research Paper On Artificial IntelligenceDocument3 pagesResearch Paper On Artificial IntelligenceasdasdasdNo ratings yet

- Storage and Flow of Powder: Mass Flow Funnel FlowDocument9 pagesStorage and Flow of Powder: Mass Flow Funnel FlowDuc HuynhNo ratings yet

- Jan Corné Olivier - Linear Systems and Signals (2019)Document304 pagesJan Corné Olivier - Linear Systems and Signals (2019)fawNo ratings yet

- 1 BelzonaDocument41 pages1 BelzonashakeelahmadjsrNo ratings yet