Professional Documents

Culture Documents

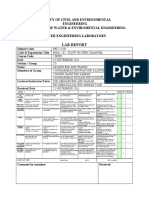

Experiment 12 Fluid Friction

Uploaded by

Hadoosh27Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment 12 Fluid Friction

Uploaded by

Hadoosh27Copyright:

Available Formats

Experiment -12- Fluid Friction

xperiment -12-Fluid Friction

1- LOSSES IN PIPE INTRODUCTION:

Fluid flow in the direction of decreasing pressure and the decrease in pressure is caused by the frictional losses in a pipe network system. It is essential to know the total head loss in a pipe network so that a pump with a suitable power can be employed upstream to overcome the friction and to have the flow of the fluid. he resistance due to the friction on the internal surface of pipe! sudden contraction or expansion! fittings used in plumbing! elbows! valve! "unctions! all cause head losses. In this experiment! the head loss through a smooth bore pipe will be determined experimentally and will be compared with prediction made using the #$$%& diagram. he effect of roughness on head loss and on the friction factor will be investigated. It will be shown that the head loss in a pipe fitting is also proportional to the velocity head of the fluid and the fitting factor is constant for a fitting. Furthermore the use of differential head devices such as venture meter and pitot tube for determination of the fluid flow rate and velocity will be demonstrated.

OBJECTIVE:

o determine the relationship between fluid friction coefficient and 'eynolds number for floe of water through a different type of pipe. o determine the head loss for a fitting

THEORY

Experiment -12- Fluid Friction

he head loss due to wall friction in fully developed flow along a

circular pipe is defined as h f

P1 P2 where (1 and (2 are the static g

pressures of the fluid at location 1 and 2 along the pipeline. )ead loss is generally computed from the %arcy- *eisbach e+uation,

hf = f L V2 D 2g

-1. $ther symbols appearing in the above relations have the following meaning, / and % 0 length and diameter of the pipe! 1 0 average velocity over the cross-section! g 0 acceleration due to gravity!

0 absolute roughness of the pipe wall!

0 density of water 222kg3m4!

0 dynamic viscosity of water 1.15617-4 8s3m2 at 15 79!

0 kinematic viscosity.

:se of E+. -1. re+uires knowledge of the functional dependence between the friction coefficient! relative roughness and 'eynolds number! or the specific functional form for E+. -2.. )owever! this function can be determined analytically only in the case of laminar flow! i.e.! 'e ; 2777. he result is known as the law of )agen(oiseuille! f 0 <=3'e -4.

Experiment -12- Fluid Friction

>ut in the case of turbulent flow the friction factor cannot be represented by simple formula as was case for laminar flow. his is due to the random and fluctuating movement of the fluid particles. For turbulent flow! experiments have shown that the friction factor is function of not only the 'eynolds number but also the relative roughness of the pipe f = f Re,

. D

EXPERIMENTAL DATA

he relative roughness is defined as the pipe inside surface roughness

divided by the pipe inside diameter

'elative roughness 0

o determine the value of the friction factor for use in e+.1 we use the #oody diagram.

2- LOSSES IN VALVES AND FITTING

2.'ough pipe %01? mm Flow A -lBmin. 1elocity 1 -mBs. ) -mm. hf

5.@mooth pipe %0 1<.5 )-mm. hf

Experiment -12- Fluid Friction

In addition to losses due to friction in pipe! there also are energy losses in valves and fitting such as tees! elbows! and bends. Cs a result! experimental techni+ues are used to determine losses. est have shown that head losses in valve and fitting are proportional to the s+uare of the velocity of the fluid,

v2 H L = K 2g

he constant of proportionality -D. is called the D factor of the valve or fitting Flow rate 47.277 elbow 12.=57 elbow 1E. >all valve 1?. Function

You might also like

- Lab Report 2Document16 pagesLab Report 2Limmy Yingran0% (1)

- Fluid FrictionDocument18 pagesFluid Frictioncakhoa100% (2)

- Lab Report 4Document7 pagesLab Report 4api-300265822100% (1)

- Exp 2 Friction LossesDocument15 pagesExp 2 Friction LossesDonna Mae Ramos Galaez0% (1)

- Centre of Hidrostatic PressureDocument16 pagesCentre of Hidrostatic PressureVanithaa Ponnaiah0% (1)

- Lab 2 Flow Through Venturi Tube and Orifice Plate - 23sept2016Document7 pagesLab 2 Flow Through Venturi Tube and Orifice Plate - 23sept2016faezahjalal0% (1)

- Student Code of Ethic (SCE)Document10 pagesStudent Code of Ethic (SCE)Rahim GenesisNo ratings yet

- Flow Meter Demonstration Lab ReportDocument21 pagesFlow Meter Demonstration Lab Reportmhd badhrul bin baharNo ratings yet

- Introduction Impact JetDocument4 pagesIntroduction Impact JetIniaan SaminathanNo ratings yet

- Energy Losses in Pipes: Experiment # 4Document4 pagesEnergy Losses in Pipes: Experiment # 4محمد جوادNo ratings yet

- Experiment 1Document9 pagesExperiment 1Shaun Loo50% (2)

- Impact of A Jet Lab ReportDocument3 pagesImpact of A Jet Lab ReportSaiful IslamNo ratings yet

- Fluids Lab ReportDocument19 pagesFluids Lab Reportdhruv100% (3)

- Lab Manual 3.2 - LEVEL 1 - Determination of Hydraulic Parameters in Uniform Flow For Open Channels.Document4 pagesLab Manual 3.2 - LEVEL 1 - Determination of Hydraulic Parameters in Uniform Flow For Open Channels.Muhamad IzzanNo ratings yet

- Venturi MeterDocument15 pagesVenturi MeterFatimah BadruddinNo ratings yet

- Bernoulli's EquationDocument12 pagesBernoulli's Equationasfand12345100% (1)

- 12 Experiment #2: Bernoulli'S Theorem DemonstrationDocument12 pages12 Experiment #2: Bernoulli'S Theorem DemonstrationYasir A. Al-ShataifNo ratings yet

- Experiment 1 - Friction Losses in PipesDocument34 pagesExperiment 1 - Friction Losses in PipesKhairil Ikram33% (3)

- Impact of Jet Lab ReportDocument7 pagesImpact of Jet Lab ReportMohamad Hilmy HaririeNo ratings yet

- Reynold Number Experiment ReportDocument5 pagesReynold Number Experiment Reportyolandaputriyud4825No ratings yet

- Reynolds Numbers ExperimentDocument7 pagesReynolds Numbers ExperimentSufferedMuch100% (3)

- Fluid Mechanics Lab ReportDocument14 pagesFluid Mechanics Lab ReportEdwin Jesu DassNo ratings yet

- Flow Fluid CharacteristicsDocument4 pagesFlow Fluid Characteristicsakmal hazimNo ratings yet

- Losses in Piping SystemDocument5 pagesLosses in Piping SystemHemashwaryNo ratings yet

- Student Code of Ethics Report TemplateDocument13 pagesStudent Code of Ethics Report TemplateKerol Kerol Kerol0% (1)

- Flow in Open ChannelDocument24 pagesFlow in Open ChannelSue IlaNo ratings yet

- Orifice Jet Flow Experiment GuideDocument3 pagesOrifice Jet Flow Experiment GuideshaneshaneshaneshaneNo ratings yet

- LabDocument6 pagesLabamyNo ratings yet

- Angularity Number SOPDocument5 pagesAngularity Number SOPSolankiNo ratings yet

- Friction Loss in PipesDocument12 pagesFriction Loss in Pipesannussciah suppiah100% (3)

- Theory VenturiDocument7 pagesTheory VenturiMahendranath RamakrishnanNo ratings yet

- Bioproduct Facility Design Lab: Faculty of Engineering Technology Department of Chemical Engineering TechnologyDocument18 pagesBioproduct Facility Design Lab: Faculty of Engineering Technology Department of Chemical Engineering TechnologyAswini Purushothanan0% (1)

- Tutorial Problem SetDocument5 pagesTutorial Problem SetWK PangNo ratings yet

- Bernoilli's Principle Lab ReoprtDocument2 pagesBernoilli's Principle Lab ReoprtJohnConor100% (2)

- Head Loss in Pipe FittingsDocument2 pagesHead Loss in Pipe FittingsKhairul AsyrafNo ratings yet

- Abstract and Summary Aim and Objectives Theory Apparatus Procedure Result Calculation Discussion Conclusion Recommendations AppendicesDocument18 pagesAbstract and Summary Aim and Objectives Theory Apparatus Procedure Result Calculation Discussion Conclusion Recommendations AppendicesHariz MiorNo ratings yet

- Reynolds NumberDocument11 pagesReynolds NumberNur Falini Mohd Sukkri98% (51)

- Fluid Flow Regimes in PipesDocument16 pagesFluid Flow Regimes in PipesLiyanna Blanda100% (2)

- Hydraulic Laboratory Civil Engineering Department Sultan Azlan Shah Polytechnic Experiment: 2 Title: Impact of Jet TestDocument8 pagesHydraulic Laboratory Civil Engineering Department Sultan Azlan Shah Polytechnic Experiment: 2 Title: Impact of Jet TestAzrol Azmir Long100% (3)

- Lab V - Energy Losses in Bends-LO6Document6 pagesLab V - Energy Losses in Bends-LO6Rymshah MoezNo ratings yet

- Bernoulli's TheoremDocument5 pagesBernoulli's TheoremVrushiket PatilNo ratings yet

- Engineering Lab Report Viscosity & CapillarityDocument10 pagesEngineering Lab Report Viscosity & CapillarityMuhd Farhan Bin IbrahimNo ratings yet

- Flow Rate Measurement Using Venturi, Orifice & RotameterDocument13 pagesFlow Rate Measurement Using Venturi, Orifice & RotameterxxxxxNo ratings yet

- Energy Losses in Bends & FittingsDocument7 pagesEnergy Losses in Bends & Fittingssamama khan100% (1)

- Bernoulli Equation Full ReportDocument6 pagesBernoulli Equation Full ReportChala1989No ratings yet

- MEC2404 Frictional Flow in Pipe Lab RepoDocument10 pagesMEC2404 Frictional Flow in Pipe Lab Repoatik100% (1)

- Title: Energy Loss in Pipes: Name: Vincent Lacey Course Code: DT024/2 Date of Experiment: 11/03/10 Group BDocument5 pagesTitle: Energy Loss in Pipes: Name: Vincent Lacey Course Code: DT024/2 Date of Experiment: 11/03/10 Group BzoostyNo ratings yet

- Reynolds ExperimentDocument4 pagesReynolds ExperimentShubhangi Bansude100% (1)

- Politeknik MalayDocument6 pagesPoliteknik MalaybrianlaksonoNo ratings yet

- Group 3 (Seksyen4)Document15 pagesGroup 3 (Seksyen4)alnzNo ratings yet

- Comparing Accuracy of Flow Measurement DevicesDocument23 pagesComparing Accuracy of Flow Measurement Devicesinterestingese100% (1)

- Experiment 3Document3 pagesExperiment 3MaisarahNo ratings yet

- Experiment To Verify Bernoulli's PrincipleDocument8 pagesExperiment To Verify Bernoulli's PrincipleKarishma JuttunNo ratings yet

- Lab Experiments Losses in PipeDocument14 pagesLab Experiments Losses in Pipesawmag123No ratings yet

- Experiment 12 Fluid Friction 1Document4 pagesExperiment 12 Fluid Friction 1Shahid KhanNo ratings yet

- Lab 5 Thermo FluidsDocument13 pagesLab 5 Thermo FluidsAimiWaniNo ratings yet

- Assignment LabDocument19 pagesAssignment LabHidayah HumairaNo ratings yet

- حسن محمد حنش تقرير مادة جريان الموائعDocument12 pagesحسن محمد حنش تقرير مادة جريان الموائعHassan Al AtabyNo ratings yet

- 9 TH WeekDocument66 pages9 TH WeeknaverfallNo ratings yet

- Head Losses and Equivalent PipesDocument25 pagesHead Losses and Equivalent PipesMohamed RamadanNo ratings yet

- (Progress in Mathematics 1) Herbert Gross (Auth.) - Quadratic Forms in Infinite Dimensional Vector Spaces (1979, Birkhäuser Basel)Document432 pages(Progress in Mathematics 1) Herbert Gross (Auth.) - Quadratic Forms in Infinite Dimensional Vector Spaces (1979, Birkhäuser Basel)jrvv2013gmailNo ratings yet

- Data Rs910Document36 pagesData Rs910Cusco PardoNo ratings yet

- UNIX Concepts: 1. How Are Devices Represented in UNIX?Document15 pagesUNIX Concepts: 1. How Are Devices Represented in UNIX?api-3764166No ratings yet

- 2014 JC2 H2 Econs Prelim Paper 2Document3 pages2014 JC2 H2 Econs Prelim Paper 2Ezra Notsosure WongNo ratings yet

- GRIFFITHS, J.A. - The Vihuela Fantasia. A Comparative Study of Forms and Styles (Monash University, 1983)Document643 pagesGRIFFITHS, J.A. - The Vihuela Fantasia. A Comparative Study of Forms and Styles (Monash University, 1983)Gérard Reyne100% (13)

- Algebra - QuestionsDocument13 pagesAlgebra - Questionsdhruvbhardwaj100% (1)

- Documentary Photography: Exploring Cultural Change in TibetDocument29 pagesDocumentary Photography: Exploring Cultural Change in TibetSofia YosseNo ratings yet

- Paper:: 14 Marketing Management 34, Pricing: Factors Affecting PricingDocument9 pagesPaper:: 14 Marketing Management 34, Pricing: Factors Affecting PricingstudentNo ratings yet

- Protein Structure Prediction Methods (2D and 3DDocument38 pagesProtein Structure Prediction Methods (2D and 3Dth_kiranNo ratings yet

- CBRC Let Ultimate Learning Guide Social ScienceDocument112 pagesCBRC Let Ultimate Learning Guide Social ScienceAigene Pineda100% (2)

- Lesson Plan 1Document8 pagesLesson Plan 1api-573197365No ratings yet

- 101 2015 3 B PDFDocument48 pages101 2015 3 B PDFJamesBandaNo ratings yet

- The Rolle of Surgery in Oncology: Surgery Departement Medical Faculty Ukrida UniversityDocument25 pagesThe Rolle of Surgery in Oncology: Surgery Departement Medical Faculty Ukrida UniversityGian Alodia RisamasuNo ratings yet

- 10, Services Marketing: 6, Segmentation and Targeting of ServicesDocument9 pages10, Services Marketing: 6, Segmentation and Targeting of ServicesPreeti KachhawaNo ratings yet

- Entrepreneurial Mindset and Opportunity RecognitionDocument4 pagesEntrepreneurial Mindset and Opportunity RecognitionDevin RegalaNo ratings yet

- Manuel Figueroa v. The People of Puerto Rico, 232 F.2d 615, 1st Cir. (1956)Document8 pagesManuel Figueroa v. The People of Puerto Rico, 232 F.2d 615, 1st Cir. (1956)Scribd Government DocsNo ratings yet

- PV LITERATURE ROUGHDocument11 pagesPV LITERATURE ROUGHraghudeepaNo ratings yet

- Bio1227 Microbiology and Parasitology Department of Biology Institute of Arts and Sciences Far Eastern UniversityDocument16 pagesBio1227 Microbiology and Parasitology Department of Biology Institute of Arts and Sciences Far Eastern UniversityDannielle EvangelistaNo ratings yet

- Stories of Narada Pancaratra and Lord Krishna's protection of devoteesDocument9 pagesStories of Narada Pancaratra and Lord Krishna's protection of devoteesPedro RamosNo ratings yet

- The Ecology of School PDFDocument37 pagesThe Ecology of School PDFSravyaSreeNo ratings yet

- TASSEOGRAPHY - Your Future in A Coffee CupDocument5 pagesTASSEOGRAPHY - Your Future in A Coffee Cupcharles walkerNo ratings yet

- Anaphylactic ShockDocument19 pagesAnaphylactic ShockrutiranNo ratings yet

- ArgalaDocument4 pagesArgalaTushar Kumar BhowmikNo ratings yet

- SQL SELECT statement examples and explanationsDocument5 pagesSQL SELECT statement examples and explanationsChen ChaNo ratings yet

- Notification of Workplace Violence Form Sarawak General HospitalDocument2 pagesNotification of Workplace Violence Form Sarawak General HospitalRomuald Leo PiongNo ratings yet

- Datos Practicos TIMKENDocument128 pagesDatos Practicos TIMKENneodymioNo ratings yet

- 2011 Daily Bible ReadingsDocument5 pages2011 Daily Bible ReadingsTraci GuckinNo ratings yet

- Women's Health: HysterectomyDocument7 pagesWomen's Health: HysterectomySuci RahmayeniNo ratings yet

- TEST Lop 5Document3 pagesTEST Lop 5tan nguyen vanNo ratings yet

- Earnings Price Anomaly (Ray Ball, 1992)Document27 pagesEarnings Price Anomaly (Ray Ball, 1992)jeetNo ratings yet