Professional Documents

Culture Documents

Generator Construction: Electro Technology

Uploaded by

Anoop VijayakumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Generator Construction: Electro Technology

Uploaded by

Anoop VijayakumarCopyright:

Available Formats

*

ELECTRO TECHNOLOGY

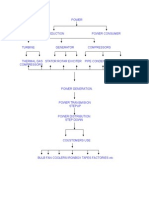

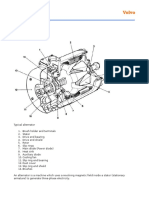

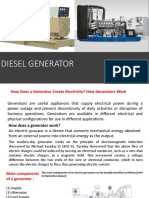

GENERATOR CONSTRUCTION The two main parts of any rotating A.C machine are its Stator and Rotator. The stator frame support the stator core and three A.C phase windings. The Stator core is assembled from laminated steel with the windings housed in slot around the inner periphery of the cylindrical core. The stator coils are interconnected (in the end winding region) to form three separate phase winding with six ends. These phases ends is found in stator terminal box general label A ! C (as shown) or " S T or # $ %. &n some cases only three terminals are a'ailable in the terminal box( here the natural or star point connection forms part of the stator winding arrangement. The main out going cables connected to these terminals conducts the generators electric power to its circuit brea)er at the main switchboard. The rotor of a main A.C generator pro'ides the field excitation from its electromagnetic poles. Two constructional forms of rotor are a'ailable (*) salient pole and (+) cylindrical. Salient pole type has pro,ecting poles bolted or )eyed onto the shaft hub. -ield excitation winding are fitted around each pole. This type of rotor is used with medium and slow shaft speed (* .// rpm and below) and it0s the most common arrangement for marine generator. Cylindrical type rotors are generally used with high speed (* 1// 2 3 4// rpm) steam5 gas turbine dri'es. The excitation windings are wedged into axial slot around the steel rotor. #nwound sections of the rotor from its pole faces between the winding. "6T6" -&789 C6::7CT&6:S The rotor poles are supplied with direct current 9.C from an exciter. &f the exciter re;uirements is con'entional 9.C generator or its static the excitation current is fed into the field windings 'ia carbon brushes on the pairs of shaft mounted slip rings. To eliminate the maintenance program associated with rotating contacts the brushless arrangement is widely used in marine generators. All brush gear communicator and slip ring are eliminated by using an A.C exciter with its out put being rectified by shaft mounted silicon diodes. The diodes mounted on the shaft con'ert the A.C exciter output to 9.C which is they fed directly to the main generator rotor field windings. :otes< The A.C exciter has its own field poles fitted on its stator why the rotor carries its three phase0s A.C exciter out put windings. This construction lay out is in'erted compared with that of the main generator. =7:7"AT6" C668&:= >ower losses typically */? of the generator reading cause internal heating in the winding and cores of both rotor and stator. This heat must be continuously dumped (reduced) elsewhere to pre'ent excessi'e temperature rise causing brea)down of the winding insulation. -orce air circulation in a closed circuit (to pre'ent ingress of dirt) 'ia and a fan on the rotor shaft pressuri@es air cooler. Cooling air is forced through 'entilation ducts in the stator core between rotor poles and through the air gap (a few millimeter wide) between stator and rotor.

ELECTRO TECHNOLOGY

%ater cooling of the circulating air may also be used for generators with a large power rating. Temperature detectors (resistance types thermistors or thermocouples) are used to monitor the temperature of stator winding bearings and the cooling air5 water of the generator. Single or grouped temperature alarms are acti'ated at the main watch )eeping position.

&nspection window 9rain coc) 9ial thermometer Stator lamination

emergency air flat

%ater trap "otor pole Slip ring coupling 7ngine

Air seal Aeater >edesdal bearing (roller or ,ournal) -an !ed plate

%hile the generator is stopped during standBby or maintenance period low power electric heater within the machine pre'ent internal condensation forming on the winding insulation. These heaters may be switches on manually or automatically from auxiliary contacts on the generator circuit brea)er. Aeater power supply are normally ++/$ A.C single phase supply from a distribution box local to the generator.

You might also like

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Manufacturing of Turbo GeneratorDocument27 pagesManufacturing of Turbo GeneratorNava Deep100% (2)

- Ships service generators: AC construction and operationDocument32 pagesShips service generators: AC construction and operationdeep4u2009100% (1)

- Introduction To Turbo GeneratorDocument42 pagesIntroduction To Turbo GeneratorTirumalesh ReddyNo ratings yet

- Induction motor-UNIT-IVDocument23 pagesInduction motor-UNIT-IVVaibhav SanNo ratings yet

- Major Component of Large GeneratorsDocument5 pagesMajor Component of Large Generatorsglance nashierNo ratings yet

- Generator BasicsDocument8 pagesGenerator BasicsRajashekarBheemaNo ratings yet

- E2063 Teknologi Elektrik 2 UNIT7Document36 pagesE2063 Teknologi Elektrik 2 UNIT7dbu2952No ratings yet

- Generator & Exciter BasicDocument8 pagesGenerator & Exciter Basictowfiqeee100% (1)

- Unit IvDocument24 pagesUnit IvVaibhav SanNo ratings yet

- Generator & Exciter Basics: Whitby Hydro Energy Services Corporation: Engineering & Construction ServicesDocument8 pagesGenerator & Exciter Basics: Whitby Hydro Energy Services Corporation: Engineering & Construction Services12343567890No ratings yet

- The Copperbelt University: School of TechnologyDocument40 pagesThe Copperbelt University: School of TechnologyMU Len GANo ratings yet

- Inductionmotor DesignDocument31 pagesInductionmotor Designbilalbaig97No ratings yet

- Generator Basics: The Physics of Electromagnetic InductionDocument8 pagesGenerator Basics: The Physics of Electromagnetic InductionAgung PrasetyoNo ratings yet

- Synchronous Motor Construction: GeneralDocument4 pagesSynchronous Motor Construction: Generaljunaidkhattak10No ratings yet

- Generator Testing Project ReportDocument51 pagesGenerator Testing Project Reportsudheer0% (1)

- Alternator Volvo - KnowledgeDocument19 pagesAlternator Volvo - KnowledgeWayank Van Hellsing100% (1)

- Project Bhel 2Document12 pagesProject Bhel 2jatt_yankyNo ratings yet

- My - Project EzejiDocument13 pagesMy - Project EzejiJoseph IsraelNo ratings yet

- Induction Motor Design PDFDocument46 pagesInduction Motor Design PDFdiptiNo ratings yet

- Ltps ElectricalDocument19 pagesLtps ElectricalVikash MaheshwariNo ratings yet

- Notes For Power System 5th SemDocument28 pagesNotes For Power System 5th SemSidhant SharmaNo ratings yet

- How Generators Work: A Guide to Electrical Energy ProductionDocument33 pagesHow Generators Work: A Guide to Electrical Energy ProductionAlvinNo ratings yet

- Aircraft Electrical Generators and Ignition SystemsDocument4 pagesAircraft Electrical Generators and Ignition Systemsbnolasco100% (1)

- AC Generator Operation and ComponentsDocument51 pagesAC Generator Operation and Componentsfaisl abdelgaffarNo ratings yet

- GeneratorDocument71 pagesGeneratorDhanesh VyasNo ratings yet

- A.C. MachineDocument32 pagesA.C. MachinehayikNo ratings yet

- Diesel GeneratorDocument21 pagesDiesel GeneratoreiferjNo ratings yet

- An Introduction To Synchronous AlternatorDocument44 pagesAn Introduction To Synchronous AlternatorPradeep Rajasekeran100% (4)

- Experiment No. 2.4 - The Squirrel-Cage Induction Motor ObjectiveDocument3 pagesExperiment No. 2.4 - The Squirrel-Cage Induction Motor ObjectiveKristine AldayNo ratings yet

- GEN PartsDocument15 pagesGEN PartsWin LinnNo ratings yet

- 3 Phase ImDocument43 pages3 Phase Imvibhash kumar dwivediNo ratings yet

- Main Components of A GeneratorDocument7 pagesMain Components of A GeneratoradhyarthaNo ratings yet

- SYNCHRONOUS GENERATORS EXPLAINEDDocument42 pagesSYNCHRONOUS GENERATORS EXPLAINEDkeshab pandeyNo ratings yet

- Notes For Electrical Fundamental 2 Rev01 - Vol 3Document45 pagesNotes For Electrical Fundamental 2 Rev01 - Vol 3Irfan ZaidiNo ratings yet

- Power generation and AC generators explainedDocument62 pagesPower generation and AC generators explainedBalachakri KothuriNo ratings yet

- Uljanik TESU - Main Catalogue PDFDocument15 pagesUljanik TESU - Main Catalogue PDFAlex19751205No ratings yet

- Automotive Generator and Alternator FundamentalsDocument70 pagesAutomotive Generator and Alternator FundamentalsAneesh UNo ratings yet

- Design of Efficient Induction MotorsDocument43 pagesDesign of Efficient Induction MotorsVivek Pawar83% (6)

- EEN - 499 Training SeminarDocument18 pagesEEN - 499 Training SeminarSonu PatelNo ratings yet

- NIRMA Univ Electrical Power Sys Symmetrical FaultsDocument39 pagesNIRMA Univ Electrical Power Sys Symmetrical FaultsGunjan lalakiya100% (2)

- RAHULSAINIDocument9 pagesRAHULSAINI234shaheenansariNo ratings yet

- Induction MotorDocument46 pagesInduction MotorSyed Muhammad Munavvar Hussain100% (5)

- Alternator Parts and FunctionsDocument3 pagesAlternator Parts and FunctionsJerry PinongpongNo ratings yet

- The StatorDocument2 pagesThe StatorPetrut ValentinNo ratings yet

- Brake Load Test of Squirel Cage Induction Motor 3 PhaseDocument7 pagesBrake Load Test of Squirel Cage Induction Motor 3 Phasejassisc100% (1)

- DC-Motor Description & MaintenanceDocument51 pagesDC-Motor Description & MaintenanceSotila Ionut100% (4)

- Alternator: Parts and Functions of An AlternatorDocument11 pagesAlternator: Parts and Functions of An AlternatorRomari MirandaNo ratings yet

- Brushless Alternators: © 2000 Graig PearenDocument3 pagesBrushless Alternators: © 2000 Graig PearenAboalfotoh Mahmoud100% (2)

- Ac Induction MotorDocument4 pagesAc Induction MotorSaidin DahalanNo ratings yet

- Asynchronous Motor Operating ManualDocument4 pagesAsynchronous Motor Operating ManualDinesh Kumar MehraNo ratings yet

- DC MachineDocument60 pagesDC MachineNebyou DanielNo ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Income and Expenses: Account Date Description Category Income Money IN Expense Money OUT Account Balance Overall BalanceDocument4 pagesIncome and Expenses: Account Date Description Category Income Money IN Expense Money OUT Account Balance Overall BalanceAnoop VijayakumarNo ratings yet

- Personal Financial Budget 2019, V V ANOOP: FEB MAY AUG NOVDocument4 pagesPersonal Financial Budget 2019, V V ANOOP: FEB MAY AUG NOVAnoop VijayakumarNo ratings yet

- Basic ISM Questions and AnswersDocument3 pagesBasic ISM Questions and AnswersVyas Srinivasan100% (2)

- Management Level - Course Exam Dates and Fees 2018-19-0Document3 pagesManagement Level - Course Exam Dates and Fees 2018-19-0Anoop VijayakumarNo ratings yet

- Bye Election Not 16Document7 pagesBye Election Not 16Anoop VijayakumarNo ratings yet

- Policy Terms and Conditions PDFDocument55 pagesPolicy Terms and Conditions PDFAnoop VijayakumarNo ratings yet

- Bye Election Res Not 15Document3 pagesBye Election Res Not 15Anoop VijayakumarNo ratings yet

- Cat Marine 3412 Bundled Repair Brochure PDFDocument5 pagesCat Marine 3412 Bundled Repair Brochure PDFAnoop VijayakumarNo ratings yet

- Install Guide For Sandisk® Memory Zone App To Use Along With Your Sandisk Ultra® Dual DrivesDocument7 pagesInstall Guide For Sandisk® Memory Zone App To Use Along With Your Sandisk Ultra® Dual DrivesGalih PranayudhaNo ratings yet

- Min Zar TarDocument247 pagesMin Zar Tarjohndmariner123100% (12)

- Income Expense WorksheetDocument4 pagesIncome Expense WorksheetAnoop VijayakumarNo ratings yet

- Coc Class 1 and 2 Marine Engineer Officer (Part B) : Chat With Sparky!Document5 pagesCoc Class 1 and 2 Marine Engineer Officer (Part B) : Chat With Sparky!Anoop VijayakumarNo ratings yet

- Fta Channel ListDocument3 pagesFta Channel ListKrishna PramodNo ratings yet

- BST Pack 100 ChannelDocument22 pagesBST Pack 100 ChannelAnoop VijayakumarNo ratings yet

- KASP Package RateDocument502 pagesKASP Package RateAnoop VijayakumarNo ratings yet

- Fta Channel ListDocument4 pagesFta Channel ListAnoop VijayakumarNo ratings yet

- Curriculam Vitae AnandDocument1 pageCurriculam Vitae AnandAnoop VijayakumarNo ratings yet

- Syllabus For Mech Engg Degree Level and AboveDocument15 pagesSyllabus For Mech Engg Degree Level and AboveAnoop VijayakumarNo ratings yet

- High Hour Runner Caterpillar 3412 DIT 540HP Diesel Marine EngineDocument2 pagesHigh Hour Runner Caterpillar 3412 DIT 540HP Diesel Marine EngineAnoop VijayakumarNo ratings yet

- Personal Financial Budget 2019, V V ANOOP: FEB MAY AUG NOVDocument4 pagesPersonal Financial Budget 2019, V V ANOOP: FEB MAY AUG NOVAnoop VijayakumarNo ratings yet

- Mohon. Boiler CorrosionDocument25 pagesMohon. Boiler CorrosionAnoop VijayakumarNo ratings yet

- Anoop CVDocument2 pagesAnoop CVAnoop VijayakumarNo ratings yet

- Ss College Solved Question AnswerDocument64 pagesSs College Solved Question AnswerSumeet SawantNo ratings yet

- 02-03-2019 (Saturday) From 01:30 PM To 03:15 PM: ADMISSION TICKET (Provisional) ThiruvananthapuramDocument3 pages02-03-2019 (Saturday) From 01:30 PM To 03:15 PM: ADMISSION TICKET (Provisional) ThiruvananthapuramAnoop VijayakumarNo ratings yet

- Anoop CVDocument2 pagesAnoop CVAnoop VijayakumarNo ratings yet

- Marine Engineering PracticeDocument19 pagesMarine Engineering PracticeAnoop Vijayakumar100% (1)

- DRDO JobsDocument4 pagesDRDO JobsPankaj KumarNo ratings yet

- 01 10Document10 pages01 10rohizatNo ratings yet

- Alarms and TripsDocument4 pagesAlarms and TripsAnoop Vijayakumar100% (2)

- Material Test (D.T & N.D.T)Document2 pagesMaterial Test (D.T & N.D.T)Anoop VijayakumarNo ratings yet

- Spare Parts Manual of AM6 SHN RH VERSION, Doc - No. 80154016, Edition - Jun'10 PDFDocument107 pagesSpare Parts Manual of AM6 SHN RH VERSION, Doc - No. 80154016, Edition - Jun'10 PDFMohammad Aslam100% (1)

- 14M R9J Schematic PDFDocument8 pages14M R9J Schematic PDFJhun HunkNo ratings yet

- Rotary Vane Type Compressor: ConstructionDocument5 pagesRotary Vane Type Compressor: ConstructionMoiz TinwalaNo ratings yet

- 2 - W 220 Genset & Datasht PDFDocument80 pages2 - W 220 Genset & Datasht PDFshahin gholamiNo ratings yet

- By-Controls 89614 BCXLXDDocument24 pagesBy-Controls 89614 BCXLXDWADENo ratings yet

- Electrico 416 CDocument2 pagesElectrico 416 COswaldo Andrade100% (2)

- EN 733 Centrifugal Pumps GuideDocument3 pagesEN 733 Centrifugal Pumps Guidegentleman457No ratings yet

- MANN Filters for Industrial LiquidsDocument48 pagesMANN Filters for Industrial LiquidsRoccinanteNo ratings yet

- RENK Integrated Front-End Power System enDocument8 pagesRENK Integrated Front-End Power System enhumayun121No ratings yet

- 3.internal Combustion Engine-21-30Document10 pages3.internal Combustion Engine-21-30Aqsa KanwalNo ratings yet

- Machine Design Lecture: Keys, Couplings and ColumnsDocument16 pagesMachine Design Lecture: Keys, Couplings and ColumnsPotatoFryNo ratings yet

- Choose The Letter of The Best Answer and Write Your Answer On A Separate Sheet of PaperDocument10 pagesChoose The Letter of The Best Answer and Write Your Answer On A Separate Sheet of PaperJussa Leilady AlberbaNo ratings yet

- Tier 4i Error Code ListDocument15 pagesTier 4i Error Code ListRicardo Costa100% (2)

- Motor & Gear Box Selection for Slat Chain ConveyorDocument15 pagesMotor & Gear Box Selection for Slat Chain ConveyorNgô Văn ĐạtNo ratings yet

- Catalogo Pacbrake Caterpillar Series 3116,3126, c9Document2 pagesCatalogo Pacbrake Caterpillar Series 3116,3126, c9Alexis SanchezNo ratings yet

- Pump BS-BDocument4 pagesPump BS-BmateusT850No ratings yet

- Allison Transmission Oil ChangeDocument3 pagesAllison Transmission Oil ChangeMelissa GrayNo ratings yet

- P-1NN Control PDFDocument2 pagesP-1NN Control PDFAnonymous crr7XhCw65No ratings yet

- NGS Ipg 0001 PDFDocument16 pagesNGS Ipg 0001 PDFRoderick WineNo ratings yet

- Chapter 6: Asynchronous (Induction) Motor (Part 1)Document4 pagesChapter 6: Asynchronous (Induction) Motor (Part 1)Slim ShaddysNo ratings yet

- WoodPlans Online - Drill Press TableDocument6 pagesWoodPlans Online - Drill Press TableЧедомир Арнаут100% (1)

- Training On Hydro Power PlantDocument172 pagesTraining On Hydro Power PlantMallikarjun ReddyNo ratings yet

- Operating & Maintenance manual-RM-290AC'J'Document33 pagesOperating & Maintenance manual-RM-290AC'J'faqdaniNo ratings yet

- RX50Document519 pagesRX50Vinícius FerrazNo ratings yet

- Ducati Monster 620 Owner's ManualDocument80 pagesDucati Monster 620 Owner's ManualManuelmpg MotosNo ratings yet

- PowerKit Engine 6M26 Series SpecsDocument2 pagesPowerKit Engine 6M26 Series SpecsquocthinhNo ratings yet

- PC40MR-2: IntroductoryDocument2 pagesPC40MR-2: IntroductoryFrederikusNo ratings yet

- 730e 81 PDFDocument16 pages730e 81 PDFNicole SmithNo ratings yet

- Course Number: Me 433 Fluidics Fluidics 3 Credit Hour: PFMHBB R Prof. Mahbubur RazzaqueDocument11 pagesCourse Number: Me 433 Fluidics Fluidics 3 Credit Hour: PFMHBB R Prof. Mahbubur RazzaqueMuhammed RazzaqueNo ratings yet

- Lab6maquinas HampdenDocument5 pagesLab6maquinas HampdenJose Ricardo hernandezNo ratings yet