Professional Documents

Culture Documents

WWW Mechanicalengineeringblog Com

Uploaded by

Mashudi FikriOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WWW Mechanicalengineeringblog Com

Uploaded by

Mashudi FikriCopyright:

Available Formats

Mechanical Engineering

Home Auto CAD

Conveyor Belt Bulk Conveyor

A Complete Online Guide for Every Mechanical Engineer

Latest Mechanical Interview Q & A

T-Shirt Design

Screw Conveyor

Latest Automobile Topics

Conveyor System

Sponsers

Screw Conveyor Types | Helicoid Screw Flight | Ribbon Flight Conveyor Screws Screw Conveyor Power Calculation | Screw Conveyor Capacity Calculation | Screw Conveyor Formulae

Flexible Feeders

Aug

10 Conveyor | Screw Conveyor Capacity Calculation

Design of Screw Conveyor | Size of Screw | Screw Conveyor Design Calculation

Material Handling, Screw Conveyor

www.Flexomation.com Complete line of Flexible Part Feeders.

Design of Screw Conveyor:

Bucket Conveyor Solutions BOXX Workstations Masters of Engineering ME Conveyors & Components ITT Tech

The size of screw conveyor depends on two factors 1. The capacity of the conveyor 2. The lump size of the material to be conveyed (Maximum dimensions of the particle) Usually there are three ranges of lump sizes which are considered for selection of screw size. These are:

A mixture of lumps and fines in which not more than 10% are lumps ranging from maximum size to one half of the maximum, and 90% are lumps smaller than one half of the maximum size. A mixture of lump and fines in which not more than 25% are lumps ranging from the maximum size to one half of the maximum, and 75% are lumps smaller than one half of the maximum size. A mixture of lump only in which 95% or more are lumps ranging from maximum size to one half of the maximum size and 5% or less are lumps less than one tenth of the maximum size.

Subscribe Now

Enter your email address:

Subscribe

Delivered by FeedBurner

Find us on Facebook

Mechanical Engineering Blog

Like 16,097 people like Mechanical Engineering Blog.

The allowable size of a lump in a screw conveyor is a function of the radial clearance between the outside diameter of the central pipe and the radius of the inside of the screw trough, as well as the proportion of the lumps in the mixture. The lump size of the material affects the selection of screw diameter which should be at least 12

F acebook social plugin

converted by Web2PDFConvert.com

times larger than the lump size of a sized material and four times larger than the largest lumps of an un-sized material. Example, if screw diameter is 250mm means radial clearance is 105mm, & Maximum lump size is 60mm of 10% lumps. Capacity of Screw Conveyor:

Recent Posts

History Of Laser Welding | Laser Light Beam LASER Technology | Properties Of A LASER Beam LASER Beam Welding | LASER Cutting System Pressure Thermite Welding | Thermite Welding Process CAD Welding | CADW ELL Thermite Welding | Exothermic Welding

Recent Comments

vyasjj on CAD Welding | CADW ELL Thermite Welding | Exothermic Welding jeevca on Latest Interview Questions in Mechanical | Mechanical Engineering Interview Questions and Answ ers | Mechanical Engineer Job Interview Questions | Latest Placement Papers | Mechanical Engg Questions saurabh mittal on Interview Mechanical Engineer | Mechanical Engineering Career Paths | Mechanical Engineering Questions saddam on Latest Interview Questions in Mechanical | Mechanical Engineering Interview Questions and Answ ers | Mechanical Engineer Job Interview Questions | Latest Placement Papers | Mechanical Engg Questions kesavan on The Pow er Of Foot Steps into Energy | Electricity Produced By The Piezo Electricity Theory | GE New Piezo Electric Charging

The capacity of a screw conveyor depends on the screw diameter, screw pitch, speed of the screw and the loading efficiency of the cross sectional area of the screw. The capacity of a screw conveyor with a continuous screw: Q = V. Q = 60. (/4).D2.S.n...C Where,

Categories

Aerogel Artificial Leaf AutoCAD Automobile Engineering Belt Conveyor Biodiesel Biogas Biomechanical Engineering Bucket Elevator CAD Design Catia Composites Computational Fluid Dynamics-CFD COSMOS Crane Design Durability Analysis Engineering Metrology EOT Crane Failure Analysis FEA Fuel Cell India's Top 10 Mechanical Engineering College Interview Questions Jib Crane Laser Machining LASER Technology Latest Automobile Technology Latest Automotive Technology Latest Interview Questions & Answ ers Latest Mechanical Seminar Topics Manufacturing Engineering Manufacturing process Manufacturing technology Material Handling Material Science & Metallurgy

Conveyor Spare Parts

www.nercon.com Best Price Tabletop Chain Motors, wear strip, Rolco parts

Q = capacity of a screw conveyor V = Volumetric capacity in m3/Hr = Bulk density of the material, kg/m3 D = Nominal diameter of Screw in m S = Screw pitch in m N = RPM of screw = Loading efficiency of the screw C = Factor to take into account the inclination of the conveyor

converted by Web2PDFConvert.com

Screw Pitch: Commonly the screw pitch is taken equal to the diameter of the screw D. However it may range 0.75 1.0 times the diameter of the screw.

Screw Diameter: NominalTrough TroughThicknessTubular Outside Coupling diameter of shaft Size D height width of Tough shaft (d1 diameter from C * of solid center Thickness)shaft of screw shaft to upper edge of the trough Heavy MediumLight Duty Duty Duty 100 125 160 200 250 315 400 500 63 75 90 112 140 180 224 280 120 145 180 220 270 335 420 530 5 5 5 5 5 5 2 2 3.15 3.15 3.15 3.15 3.15 3.15 1.6 1.6 1.6 2 2 33.7*2.5 33.7*2.5 42.4*2.5 48.3*3.5 60.3*4 76.1*5 76.1*5

Material Technology Measurements and Controls Mechanical Engineering Mechanical Projects Mechanical Seminar Topics Mechanical Testing Mechanical Vibration Nano Technology New Product Design Concepts and Product Development Noise Vibration and Harshness Non Destructive Testing And Destructive Testing Methods Opto Electronic Pro-Engineer Rapid Prototyping Renew able Energy Reverse Engineering Screw Conveyor Solar Energy Solar Pow er SolidWorks T-Shirt Design T-Shirt Logo Tidal Top 10 W ind Turbine in USA Total Quality Management Trolley Vibrating Conveyor W ipers World Top 10 Universities

Archives

October 2013 September 2013 3025 2013 August July 2013 3025 June 2013 May 2013 3540 April 2013 March 2013 4040 2013 February January 2013 5050 2012 December November 2012 6050 2012 October September 2012 6075 2012 August July 2012 7075 June 2012 May 2012 April 2012 March 2012 February 2012 January 2012 December 2011 November 2011 October 2011 September 2011 August 2011 July 2011 June 2011 May 2011 April 2011 March 2011 February 2011 January 2011 December 2010

UniTrak Conveyor Systems

www.UniTrak.com Innovative, Material-Specific Bulk Handling Solutions. Since 1969.

88.9*5 RPM of Screw: The usual range of RPM of screw is 10 to 165. It depends on the diameter of screw and the type of material (Max RPM of screw conveyor is 165)

converted by Web2PDFConvert.com

Loading efficiency: The value of loading efficiency should be taken large for materials which are free flowing and non abrasive, while for materials which are not free flowing and or abrasive in nature, the value should be taken low: = 0.12 to 0.15 for abrasive material = 0.25 to 0.3 for mildly abrasive material = 0.4 to 0.45 for non abrasive free flowing materials Inclination Factor: The inclination factor C is determined by the angle of screw conveyor with the horizontal. 0 1 5 0.9 10 0.8 15 0.7 20 0.65

Stats

Angle of screw with the horizontal Value of factor C

Screw Conveyor Types | Helicoid Screw Flight | Ribbon Flight Conveyor Screws Screw Conveyor Power Calculation | Screw Conveyor Capacity Calculation | Screw Conveyor Formulae

You might also like

Screw Conveyor Power Calculation | Screw Conveyor Capacity Calculation | Screw Conveyor Formulae Pow er requirement of Screw Conveyors: The driving pow er of the loaded screw conveyor is given by:...

Screw Conveyors | Screw Conveyor Working Principle | Screw Conveyor Systems Screw Conveyors Screw conveyors w ere used as low height lift pump to irrigate the lands. It comprises...

Screw Conveyor Working | Screw Conveyor Applications | Screw Conveyor Pdf Application of screw conveyors: Screw conveyors are employed for handling a great variety of materials...

Vertical Screw Conveyors | Vertical Screw Pump | Vertical Screw Conveyor Design Vertical screw conveyors: A vertical screw conveyor conveys material upw ard in a vertical path....

converted by Web2PDFConvert.com

You might also like

- Busy Bees T Shirt Company Lesson Plan Questions and T Shirt Design FinalDocument8 pagesBusy Bees T Shirt Company Lesson Plan Questions and T Shirt Design FinalAnonymous py4uE8IeMNo ratings yet

- Preparing Fabrics and Laying Out Patterns and Cutting and Transferring Marks On The FabricDocument13 pagesPreparing Fabrics and Laying Out Patterns and Cutting and Transferring Marks On The FabricNaasonNo ratings yet

- JHK-T-shirt 2013 - NL Catalogus KledijDocument88 pagesJHK-T-shirt 2013 - NL Catalogus KledijSlowSnake TextielhandelNo ratings yet

- UntitledDocument32 pagesUntitledShweta ChauhanNo ratings yet

- MC Design 2Document71 pagesMC Design 2Upayan Ghatak100% (1)

- CNC Machining Codes InterpretationDocument5 pagesCNC Machining Codes InterpretationJonathan RobertNo ratings yet

- Impact of Acid Wash With Pumice Stone On The Performance Attributes of 3T Terry TrousersDocument50 pagesImpact of Acid Wash With Pumice Stone On The Performance Attributes of 3T Terry TrousersAlif SheikhNo ratings yet

- How to Make Flat Felled Seams in 11 StepsDocument7 pagesHow to Make Flat Felled Seams in 11 StepsAshley TltNo ratings yet

- NappingDocument1 pageNappingKingson_786No ratings yet

- L 6: V M I: AB Oltage UltipliersDocument5 pagesL 6: V M I: AB Oltage UltipliersMuhammad Nauman ZakkiNo ratings yet

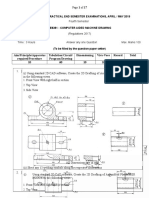

- BE/BTech CAD Machine Drawing Exam QuestionsDocument17 pagesBE/BTech CAD Machine Drawing Exam QuestionsJayaram R S [MECH]0% (1)

- What Is Sewing M/C?: The M/C Which Is Used To Stitch Fabric or Other Material Together With ThreadDocument48 pagesWhat Is Sewing M/C?: The M/C Which Is Used To Stitch Fabric or Other Material Together With ThreadDewan Ajuad Hossain RifatNo ratings yet

- Kansai WX-8800 Series Instruction ManualDocument31 pagesKansai WX-8800 Series Instruction ManualVictor Hugo Tabares HerreraNo ratings yet

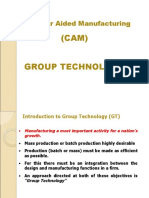

- (CAM) Group Technology: Computer Aided ManufacturingDocument118 pages(CAM) Group Technology: Computer Aided ManufacturingPratik PrajapatiNo ratings yet

- Automatic T-Shirt Folding MachineDocument47 pagesAutomatic T-Shirt Folding MachineERSARANYAPERIYASAMY67% (3)

- Apparel Production Techniques of Formal ShirtDocument19 pagesApparel Production Techniques of Formal ShirtSWARNIKA SRIVASTAVANo ratings yet

- Using The Global Positioning System in 4-h ProgrammingDocument62 pagesUsing The Global Positioning System in 4-h ProgrammingrunnealsNo ratings yet

- Brother EF4-N11, - N21 MA4-N31 Instruction ManualDocument53 pagesBrother EF4-N11, - N21 MA4-N31 Instruction ManualCatalin PrecubNo ratings yet

- Electronic & Conductive Textiles: Submitted ToDocument32 pagesElectronic & Conductive Textiles: Submitted ToShehad ChowdhuryNo ratings yet

- Sewing MachineDocument24 pagesSewing Machinemksanalrajraj100% (1)

- Blind StitchDocument27 pagesBlind StitchSiddharth JhaNo ratings yet

- Memminger Networker Monitoring SystemDocument16 pagesMemminger Networker Monitoring SystemsentyNo ratings yet

- Button Hole Machine 1Document4 pagesButton Hole Machine 1Kumar RahulNo ratings yet

- Sewn Products Machinery and Equipment - II (Pre & Post Production Machines & Equipment)Document14 pagesSewn Products Machinery and Equipment - II (Pre & Post Production Machines & Equipment)Suganya ArumugamNo ratings yet

- Impact of RFIDDocument23 pagesImpact of RFIDKaren ShuiNo ratings yet

- Dsa 5500Document12 pagesDsa 5500Nguyen Van ToanNo ratings yet

- Practical No. 3: Use Measuring Instruments: Ammeter, Voltmeter, and WattmeterDocument4 pagesPractical No. 3: Use Measuring Instruments: Ammeter, Voltmeter, and Wattmeter166CMYashvardhan ShindeNo ratings yet

- How to sew an inflatable kite in 21 stepsDocument15 pagesHow to sew an inflatable kite in 21 stepsJavier Vich BerlangaNo ratings yet

- Thread Consumption TemplateDocument7 pagesThread Consumption TemplateEmdad ApmNo ratings yet

- Aggregate Crushing Value Test: Experiment No. 1Document5 pagesAggregate Crushing Value Test: Experiment No. 1Vishakha Patel100% (1)

- 01 Asparagus ProcessingDocument8 pages01 Asparagus Processingraghukulkarni2005No ratings yet

- Capacity - 2000 Shirts Per DayDocument4 pagesCapacity - 2000 Shirts Per DayAyush GautamNo ratings yet

- 203916E - Magic-Force Bifold Door SystemsDocument25 pages203916E - Magic-Force Bifold Door SystemsAngelo Colombo RauterNo ratings yet

- May 2016Document124 pagesMay 2016Treatment Plant Operator Magazine100% (2)

- Press Tool DesignDocument5 pagesPress Tool DesignjealousyNo ratings yet

- Husqvarna Viking Designer SE User ManualDocument100 pagesHusqvarna Viking Designer SE User Manualmrviper108100% (1)

- EeeDocument88 pagesEeeShalom HaileNo ratings yet

- Tolerances and Fits ExercisesDocument7 pagesTolerances and Fits ExercisesXacobe PiñeiroNo ratings yet

- Juki mf7800 Coverstitch Sewing MachineDocument14 pagesJuki mf7800 Coverstitch Sewing MachineMd Sahadat UllahNo ratings yet

- Knitting Tote: More ColorwaysDocument3 pagesKnitting Tote: More ColorwaysNanu NosayureNo ratings yet

- BGMEA UNIVERSITY OF FASHION & TECHNOLOGY T-SHIRT PATTERN DRAFTING GUIDE USING GERBER SOFTWAREDocument25 pagesBGMEA UNIVERSITY OF FASHION & TECHNOLOGY T-SHIRT PATTERN DRAFTING GUIDE USING GERBER SOFTWAREMahbub Hassan TawsifNo ratings yet

- Brother MA4 B551Document74 pagesBrother MA4 B551alvins officialNo ratings yet

- CAEDPDocument2 pagesCAEDPDurgaprasad DhanivireddyNo ratings yet

- Wgw10927-Pl Ss Crew Neck ... Shirt Top-wgw10927-Pl - Ss22-Us - 08262021 - W's Initial Tech PackDocument12 pagesWgw10927-Pl Ss Crew Neck ... Shirt Top-wgw10927-Pl - Ss22-Us - 08262021 - W's Initial Tech PackVidhi KamraNo ratings yet

- Easy Pleated Skirt PayhipDocument20 pagesEasy Pleated Skirt PayhipMornisa MagisperanNo ratings yet

- WWW Mechanicalengineeringblog Com 2Document6 pagesWWW Mechanicalengineeringblog Com 2Mashudi FikriNo ratings yet

- Screw Conveyor Design Analysis MatlabDocument21 pagesScrew Conveyor Design Analysis Matlabavinash1987No ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- ProjectDocument17 pagesProjectRavi ChotaliyaNo ratings yet

- Katalog Hoist PDFDocument12 pagesKatalog Hoist PDFsupriadi90315No ratings yet

- TT Platform Rig Evaluation Matrix - FINALDocument9 pagesTT Platform Rig Evaluation Matrix - FINALrdos14100% (1)

- CEMC Screw Conveyor Manual 2.20Document107 pagesCEMC Screw Conveyor Manual 2.20Angel Alvarez100% (7)

- Screw Conveyor Design CalculationDocument5 pagesScrew Conveyor Design CalculationSaron Yayneshet100% (4)

- Aircraft Design Competition v171013Document10 pagesAircraft Design Competition v171013JagadishRajNo ratings yet

- Conveyor Belt Literature ReviewDocument8 pagesConveyor Belt Literature Reviewjylavupovip2100% (1)

- Project Report On Design of Belt ConveyorDocument13 pagesProject Report On Design of Belt Conveyorsrinithi99100% (1)

- Methodology of Crossflow TurbineDocument15 pagesMethodology of Crossflow TurbineAdemola Olakunle AjayiNo ratings yet

- Artigo - An Optimization Procedure For Overhead Gantry Crane Exposed To Buckling and Yield Criteria - IRA v.8 I.2 2017 - Ali Ahmid Et Al PDFDocument11 pagesArtigo - An Optimization Procedure For Overhead Gantry Crane Exposed To Buckling and Yield Criteria - IRA v.8 I.2 2017 - Ali Ahmid Et Al PDFKaique CavalcanteNo ratings yet

- Screw Conveyor CatalogueDocument100 pagesScrew Conveyor CatalogueAhmedManamaNo ratings yet

- Design and Optimization of Roller Conveyor SystemDocument5 pagesDesign and Optimization of Roller Conveyor SystemAnkit SrivastavaNo ratings yet

- En Wikipedia Org Wiki Turboexpander PDFDocument12 pagesEn Wikipedia Org Wiki Turboexpander PDFMashudi FikriNo ratings yet

- 9 Tes KoranDocument70 pages9 Tes KoranDebi Anggun SariNo ratings yet

- Semikron Manual de Aplicaciones PDFDocument464 pagesSemikron Manual de Aplicaciones PDFhsrairNo ratings yet

- Pipe Fitters HandbookDocument306 pagesPipe Fitters HandbookAto Kwamina AndersenNo ratings yet

- Ingress Fabrikator SDN - BHD Painting Daily Report-Spool: Painting Out Date 31 Oktober 2014Document2 pagesIngress Fabrikator SDN - BHD Painting Daily Report-Spool: Painting Out Date 31 Oktober 2014Mashudi FikriNo ratings yet

- Ral Color CatalogDocument7 pagesRal Color Catalogkant8123456No ratings yet

- Fermenter Design 1Document18 pagesFermenter Design 1Mashudi FikriNo ratings yet

- Ikan Baung Serawak PDFDocument13 pagesIkan Baung Serawak PDFMashudi FikriNo ratings yet

- Kaleidoscope Me Issue 10Document12 pagesKaleidoscope Me Issue 10Mashudi FikriNo ratings yet

- WWW Spiraxsarco Com Resources Steam Engineering Tutorials ST 3Document12 pagesWWW Spiraxsarco Com Resources Steam Engineering Tutorials ST 3Mashudi FikriNo ratings yet

- Pipe Cage ClampsDocument1 pagePipe Cage Clampsxxpiwko5646No ratings yet

- E-Z Fit Pipe Chain ClampsDocument2 pagesE-Z Fit Pipe Chain ClampsMashudi FikriNo ratings yet

- Internal Alignment ClampsDocument2 pagesInternal Alignment ClampsMashudi FikriNo ratings yet

- Project Consultant Calculator for Pump Pipe SizingDocument1 pageProject Consultant Calculator for Pump Pipe SizingMuhamad Irvan100% (1)

- Hempel Coating Reference Handbook GBDocument145 pagesHempel Coating Reference Handbook GBGerardo Castillo100% (2)

- Hempel Coating Reference Handbook GBDocument145 pagesHempel Coating Reference Handbook GBGerardo Castillo100% (2)

- Hempel Code of ConductDocument2 pagesHempel Code of ConductMashudi FikriNo ratings yet

- E-Z Fit' Red E-Z Fit' Red: Pipe Welding Clamp 1-12" O/dDocument1 pageE-Z Fit' Red E-Z Fit' Red: Pipe Welding Clamp 1-12" O/dMashudi FikriNo ratings yet

- PROTECT STEEL WITH MOST USED PAINTSDocument12 pagesPROTECT STEEL WITH MOST USED PAINTSsmartcharlinNo ratings yet

- PROTECT STEEL WITH MOST USED PAINTSDocument12 pagesPROTECT STEEL WITH MOST USED PAINTSsmartcharlinNo ratings yet

- En Wikipedia Org 2Document4 pagesEn Wikipedia Org 2Mashudi FikriNo ratings yet

- E-Z Fit Double Chain ClampsDocument2 pagesE-Z Fit Double Chain ClampsMashudi FikriNo ratings yet

- FenomasticPDF 2Document2 pagesFenomasticPDF 2Mashudi FikriNo ratings yet

- Hempel Colour ChartDocument2 pagesHempel Colour Chartkhalid76467% (6)

- E-Z Fit Gold Pipe ClampsDocument1 pageE-Z Fit Gold Pipe ClampsMashudi FikriNo ratings yet

- En Wikipedia Org 3Document4 pagesEn Wikipedia Org 3Mashudi FikriNo ratings yet

- En Softonic ComDocument4 pagesEn Softonic ComMashudi FikriNo ratings yet

- Color ChartDocument0 pagesColor ChartMashudi FikriNo ratings yet

- Explanatory Notes Upd Sep2013Document21 pagesExplanatory Notes Upd Sep2013Mashudi FikriNo ratings yet

- En Wikipedia OrgDocument2 pagesEn Wikipedia OrgMashudi FikriNo ratings yet

- MT 3000-2i Offset: Special ClassDocument19 pagesMT 3000-2i Offset: Special ClassConsorcio El dorado 2019No ratings yet

- World class dry solids volumetric feedersDocument3 pagesWorld class dry solids volumetric feedersEmerson FerreiraNo ratings yet

- Vx750m750mh Vx950m950mh Comp Vx750m Vx950m Vx750m Vx750mh Vx950mh 2 Steps GearedDocument12 pagesVx750m750mh Vx950m950mh Comp Vx750m Vx950m Vx750m Vx750mh Vx950mh 2 Steps GearedMachinestoreNo ratings yet

- Whitepaper: Shaftless Screw ConveyorsDocument18 pagesWhitepaper: Shaftless Screw ConveyorsPraveen KumarNo ratings yet

- Shahzaib NaseerDocument4 pagesShahzaib NaseerDarshan SrirangacharNo ratings yet

- Types of Screw Conveyors - Engineering Guide: Traducir Esta PáginaDocument8 pagesTypes of Screw Conveyors - Engineering Guide: Traducir Esta PáginaDIEGO FERNANDO CADENA ARANGONo ratings yet

- Design and Analysis of U-Shaped Ribbon Blender With Screw ConveyorDocument9 pagesDesign and Analysis of U-Shaped Ribbon Blender With Screw ConveyorPhượng NguyễnNo ratings yet

- Cbe Auger Care and Maintenance ManualDocument26 pagesCbe Auger Care and Maintenance ManualKrishna Bhanu SinghNo ratings yet

- Design and Fabrication of Screw ConveyorDocument2 pagesDesign and Fabrication of Screw ConveyorAhmad JobNo ratings yet

- Petro Carbon Chemicals Process EngineeringDocument24 pagesPetro Carbon Chemicals Process EngineeringAni LrbNo ratings yet

- Hawe Folder Ulw s20 GBDocument20 pagesHawe Folder Ulw s20 GBService AgroMONDONo ratings yet

- Super: Tracked PaverDocument14 pagesSuper: Tracked Paverabdelrhmangbr86No ratings yet

- Design of Single Screw Extruder For Homogenizing Bulk SolidsDocument11 pagesDesign of Single Screw Extruder For Homogenizing Bulk SolidsRicham HamzeNo ratings yet

- Cema Standard 550Document14 pagesCema Standard 550Nurul Haque100% (4)

- Sbf-215 Gel-Gun PCM Operation and Parts Intouch 5520722Document44 pagesSbf-215 Gel-Gun PCM Operation and Parts Intouch 5520722YamenNo ratings yet

- Screw Conveyor Design Calculation: ApplicationDocument4 pagesScrew Conveyor Design Calculation: ApplicationPranetr R.No ratings yet

- Chapter 9 Screw ConveyorsDocument7 pagesChapter 9 Screw ConveyorsMarew Getie100% (1)

- Section 14B ContainmentDocument18 pagesSection 14B ContainmentLazharNo ratings yet

- Super - 2100-2 Vogele WrgtenDocument14 pagesSuper - 2100-2 Vogele WrgtenRobinson GuanemeNo ratings yet

- Mak Grills 1-Star General Owners Manual & RecipesDocument41 pagesMak Grills 1-Star General Owners Manual & RecipeschrisNo ratings yet

- 2 - Fully Automatic System 5 Tiers H Type Layer Chicken CageDocument3 pages2 - Fully Automatic System 5 Tiers H Type Layer Chicken CageNasim KurdistanNo ratings yet

- Llustrated Arts Anual: 600-Series Snow ThrowersDocument68 pagesLlustrated Arts Anual: 600-Series Snow ThrowersDustin ChurchNo ratings yet

- Paver Finisher DF 65 C: Operating InstructionsDocument126 pagesPaver Finisher DF 65 C: Operating InstructionsІлля ШведNo ratings yet

- MMHE Lab 1Document9 pagesMMHE Lab 1Mohammad TooneerNo ratings yet

- Abrham, Agmas, BiraraN2ST Flour FactoryDocument21 pagesAbrham, Agmas, BiraraN2ST Flour FactoryBba Hab AleneNo ratings yet

- Modification and Optimization of Groundnut (Arachis Hypogaea) Roasting MachineDocument14 pagesModification and Optimization of Groundnut (Arachis Hypogaea) Roasting MachineTimmy0% (1)

- Processing - April 2015Document53 pagesProcessing - April 2015Supatmono NAINo ratings yet

- Power Curb 5700-CDocument20 pagesPower Curb 5700-CMohamed shehataNo ratings yet

- Screw Conveyor Design CalculationDocument5 pagesScrew Conveyor Design CalculationSaron Yayneshet100% (4)

- AW70V - BODY (2016-06) - 0CNP6-M02700 - en Dan AW82 BaruDocument166 pagesAW70V - BODY (2016-06) - 0CNP6-M02700 - en Dan AW82 BaruReksi AnggaraNo ratings yet