Professional Documents

Culture Documents

TLH PDF

Uploaded by

Travis WoodOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TLH PDF

Uploaded by

Travis WoodCopyright:

Available Formats

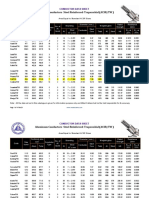

Position Transducers up to 3000 mm TLH Series

Special features

rodless design very high operating speed ball coupling avoids side loads long life > 100 x 106 movements outstanding linearity high resolution better than 0.01 mm real-time capability connector to DIN 43650 (hydraulic connector) protection class IP 54

TLH transducers are designed for the direct, accurate measurement of displacement or length in control, regulation and measuring applications. The rodless design allows the actuator to be driven from the side, along the unit length, this allows the total length of the transducer to be shorter and permits stroke lengths up to 4000 mm. The simplicity of the measuring technique both passive and absolute ensures that the transducer is immune to external electrical interference, and that it does not require any built-in power supply to maintain positional information in the event of power failure. Like other potentiometrics, it is a real-time sensor.

A magnetically restrained stainless steel band completely covers the opening through which the actuator operates. The ball coupling is of a new design which prevents forces, generated through parallel or angular offsets, from being transmitted to bearing surfaces. Due to the design and the selected materials the temperature coefficient of the transducer is extremely small. Careful attention to detail and choice of materials has resulted in a transducer with an extremely low temperature drift. The robust design ensures reliable operation even under harsh environmental conditions such as vibration or temperature changes. The TLH series is designed for clamp mounting. The use of clamps simplifies installation and adjustment.

Description Housing Fixings Sliding parts Coupling Resistance element Wiper assembly Electrical connections aluminum, anodized adjustable clamps aluminum with plastic inserts ball coupling, incorporating a hardened ball, with spring and hardened plate. conductive plastic precious metal multi-finger wiper, elastomer-damped 4-pole socket to DIN 43650 (hydraulic connector)

Novotechnik U.S., Inc.

155 Northboro Road Southborough, MA 01772 Phone: Fax: Email: 508-485-2244 508-485-2430 info@novotechnik.com

Type designations Electrical Data Defined electrical range Electrical stroke Nominal resistance Resistance tolerance Independent linearity Repeatability

TLH 100

TLH 130

TLH 150

TLH 225

TLH 300

TLH 360

TLH 450

TLH 500

TLH 600

TLH 750

TLH 900

TLH 1000

TLH 1250

TLH 1500

TLH 1750

TLH 2000

TLH 2250

TLH 2500

TLH 2750

TLH 3000

100 102 3 20 0.1 0.01

130 132 3

150 152 5

225 228 5

300 304 5

360 366 5

450 457 5

500 508 5

600 610 5

750 762 10

900 914 10

1000 1016 10

1250 1270 10

1500 1520 20

1750 1770 20

2000 2020 20

2250 2270 20

2500 2520 20

2750 2770 20

3000 3020 20

mm mm k %

0.09

0.08

0.07

0.06

0.05

0.05

0.05

0.05

0.04

0.04

0.04

0.03

0.03

0.03

0.02

0.02

0.02

0.02

0.02

% mm A mA V

Recommended operating wiper current 1 Max. wiper current in case of malfunction Max. permissible applied voltage 10 42

Effective temperature coefficient of the outputto-applied voltage ratio 5 (typical) Insulation resistance (500 VDC, 1 bar, 2 s) 10 100

ppm/K M A

Dielectric strength (50 Hz, 2 s, 1 bar, 500 VAC) Mechanical Data Body length (dimension A) Mechanical stroke (dimension B) Total weight Weight of sliding part Permitted movement of ball coupling Operating force (horizontal) vertical 250 108 440 45

280 138 480

300 158 500

376 234 620

452 310 730

514 372 820

605 463 950

656 514 1020

758 616 1170

910 768 1390

1062 920 1600

1164 1022 1750

1418 1276 2110

1668 1526 2470

1918 1776 2830

2168 2026 3200

2418 2276 3560

2668 2526 3920

2918 2776 4280

3168 3026 4650

2 mm 2 mm g g

1 angular offset, 1.5 mm parallel offset 0.4 1.1 N N

Environmental Data Temperature range Vibration -30...+100 5...2000 Amax = 0.75 amax = 20 50 11 > 100 x 10 200 (20 g) IP 40 (DIN 400 50 / IEC 529) IP 54 (DIN 400 50 / IEC 529) mounted upside-down 106 C Hz mm g g ms movem. m/s max. m/s2 max.

Order designations Type TLH 100 TLH 130 TLH 150 TLH 225 TLH 300 TLH 360 TLH 450 TLH 500 TLH 600 TLH 750 TLH 900 Art. no. 025304 025305 025306 025309 025312 025314 025318 025320 025324 025330 025336 025340 025350 025360 025370 025380 025381 025383 025384 025385

Important

All values given for this series including linearity, lifetime, microlinearity, resistance to external disturbances and temperature coefficient in voltage dividing mode are quoted for the device operating with the wiper voltage driving an operational amplifier working as a voltage follower where virtually no load is applied to the wiper (le 1 A).

Shock Life Operating speed Operating acceleration Protection class

Included in delivery

fixing clamps Z 43, 1 plug connector GDM 3009, 1 seal GDM 3-16

Recommended accessories

Process-controlled indicators MAP...with display, Signal conditioner MUW.../MUK for standardized output signals

Mounting instructions

It is recommended that the transducer be mounted upsidedown. Only when orientated in this manner, the drop-off-edges which are parallel to the actuator slot work effectively and a buildup of dirt on the sealing band be prevented when the device is used in a dusty environment.

TLH 1000 TLH 1250 TLH 1500 TLH 1750 TLH 2000 TLH 2250

Subject to changes

February 2007 Novotechnik U.S., Inc. All rights reserved.

TLH 2500 TLH 2750 TLH 3000 Other lengths on request

You might also like

- Series TLH: Position Transdcuers Up To 3000 MMDocument4 pagesSeries TLH: Position Transdcuers Up To 3000 MMEuroSMC en América LatinaNo ratings yet

- SensorDocument4 pagesSensorSiva RamNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Transductor GefranDocument2 pagesTransductor GefranMarco Martinez SantiagoNo ratings yet

- Nuflo Ez-InDocument8 pagesNuflo Ez-InAnonymous Wu6FDjbNo ratings yet

- Susol LV Circuit Breakers GuideDocument140 pagesSusol LV Circuit Breakers GuideFakhr-e-AlamNo ratings yet

- Siemens Motor StarterDocument72 pagesSiemens Motor StarterRitesh ChaudharyNo ratings yet

- Rectilinear Displacement Transducer with Ball Tip SpecsDocument3 pagesRectilinear Displacement Transducer with Ball Tip SpecsPaulo SantosNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- ATS Transfer SwitchesDocument4 pagesATS Transfer SwitchesHector Lizardo AndinoNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Sanitary TurbinaDocument4 pagesSanitary TurbinaCindy MateusNo ratings yet

- Datasheet Final de CarreraDocument3 pagesDatasheet Final de CarreraLucas PisitelloNo ratings yet

- 3141E Hall Sensor SwitchDocument9 pages3141E Hall Sensor SwitchbarbosiNo ratings yet

- O SHZV Vacuum OLTC Leaflet-Oct.2009Document5 pagesO SHZV Vacuum OLTC Leaflet-Oct.2009Hung Cuong PhamNo ratings yet

- 2-1393774-1 - P1 Relay V23026Document5 pages2-1393774-1 - P1 Relay V2302606111981No ratings yet

- Switch-disconnectors 16-3150 Amperes Manual and Motorized Operation Technical DataDocument84 pagesSwitch-disconnectors 16-3150 Amperes Manual and Motorized Operation Technical DataGoran PanticNo ratings yet

- LT SfuDocument24 pagesLT Sfurajpre1213No ratings yet

- 100X DatasheetDocument2 pages100X Datasheetbiswasdipankar05No ratings yet

- Series: Toggle or Push/Pull Actuator Thermal P&B Circuit BreakerDocument3 pagesSeries: Toggle or Push/Pull Actuator Thermal P&B Circuit BreakerkpNo ratings yet

- HV Circuit Breaker Dead Tank TypeDocument4 pagesHV Circuit Breaker Dead Tank TypeEsproNo ratings yet

- New - LWH enDocument7 pagesNew - LWH enRodica PuscauNo ratings yet

- Brochure Mercotac PDFDocument8 pagesBrochure Mercotac PDFRoderikus Rendy MNo ratings yet

- AE AccessoriesDocument16 pagesAE AccessoriesmisaelzaNo ratings yet

- Mini BCH Make Limit SwitchesDocument6 pagesMini BCH Make Limit SwitchesAbhinay SuratkarNo ratings yet

- Economical, Miniature Limit Switch Boasting Rigid ConstructionDocument5 pagesEconomical, Miniature Limit Switch Boasting Rigid ConstructionRajeev Saini100% (1)

- Sigma Series DE Meter Technical SpecificationsDocument6 pagesSigma Series DE Meter Technical SpecificationsDragac CifraNo ratings yet

- In Oerlikon CitolineDocument10 pagesIn Oerlikon CitolineJavid Ibrahim MohamedNo ratings yet

- Com-Power NW h1t-h1th, NT h2t With Tesys F - Tds25 (Web)Document6 pagesCom-Power NW h1t-h1th, NT h2t With Tesys F - Tds25 (Web)Anderson TpsNo ratings yet

- Siemens 3VT BrochuresDocument6 pagesSiemens 3VT BrochuresJoeMarieValcarcelNo ratings yet

- Model Number Structure: General-Purpose Limit SwitchDocument9 pagesModel Number Structure: General-Purpose Limit SwitchHung LeNo ratings yet

- Catalogo IndoAsian Switch DisconnectorsDocument8 pagesCatalogo IndoAsian Switch DisconnectorsjackiwongzNo ratings yet

- High Temperature: Industrial VRS Magnetic Speed SensorsDocument8 pagesHigh Temperature: Industrial VRS Magnetic Speed SensorsHernan GirautNo ratings yet

- Fineadjust Applicator Applicator Tooling Specification Order No. 63901-7400Document5 pagesFineadjust Applicator Applicator Tooling Specification Order No. 63901-7400Ernesto VelásquezNo ratings yet

- SICONT Limit Switches: Type 3SE3 Upto 500 VAC, 600 VDC, 10ADocument12 pagesSICONT Limit Switches: Type 3SE3 Upto 500 VAC, 600 VDC, 10Asmail1978No ratings yet

- 200W Low Capacitance Flip Chip Tvs Array Description: Lc0408Fc3.3C - Lc0408Fc36CDocument9 pages200W Low Capacitance Flip Chip Tvs Array Description: Lc0408Fc3.3C - Lc0408Fc36CselocaNo ratings yet

- Sicop Bimetal OL Relay Type 3UA5-6 3UC5-6Document14 pagesSicop Bimetal OL Relay Type 3UA5-6 3UC5-6erkamlakar2234No ratings yet

- K21 aluminum can surge-proof capacitors specificationsDocument4 pagesK21 aluminum can surge-proof capacitors specificationsClaire HamantNo ratings yet

- Actuators Rotary Electric Catalog AirtecnicsDocument12 pagesActuators Rotary Electric Catalog AirtecnicsjoltrajrNo ratings yet

- Rectilinear Displacement Transducer: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer: Technical Data Mechanical DimensionsNguyen Van ChungNo ratings yet

- CAHB 31 DatasheetDocument4 pagesCAHB 31 DatasheetAndreaDeCrescenzoNo ratings yet

- Smootharc Elite MIG 330 Progress Pulse: BOC Technical Data SheetDocument2 pagesSmootharc Elite MIG 330 Progress Pulse: BOC Technical Data Sheetcamelod555No ratings yet

- Product Description Height Control KHC1 ARCDocument2 pagesProduct Description Height Control KHC1 ARChollabackcockNo ratings yet

- Katalogos Genikos Ot-Oetl FortioyDocument82 pagesKatalogos Genikos Ot-Oetl FortioyMarco OlazabalNo ratings yet

- Extenso MetersDocument22 pagesExtenso MetersJavierNo ratings yet

- Subminiature: Main SpecificationsDocument3 pagesSubminiature: Main SpecificationsAidolan UlrichNo ratings yet

- Catalogo Transductores Novotechnik PDFDocument4 pagesCatalogo Transductores Novotechnik PDFGerEspNo ratings yet

- TLH PDFDocument4 pagesTLH PDFhassanchaarNo ratings yet

- TLH PDFDocument4 pagesTLH PDFvalter mNo ratings yet

- Type FN 125 Mechanical Operating CycleDocument19 pagesType FN 125 Mechanical Operating CycleDivyanshu MittalNo ratings yet

- Datasheet Techman OMIT SS 124LMDocument2 pagesDatasheet Techman OMIT SS 124LMSteve MurphyNo ratings yet

- Multimatic 200 MillerDocument4 pagesMultimatic 200 MillerHugo Alfredo Ordóñez ChocanoNo ratings yet

- Motor Starter Switches Product Bulletin - Q-313Document4 pagesMotor Starter Switches Product Bulletin - Q-313Luis LoydeNo ratings yet

- BW25Document8 pagesBW25msalem73No ratings yet

- Aluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Document4 pagesAluminum Conductors Steel Reinforced-Trapezoidal (ACSR/TW)Travis WoodNo ratings yet

- Ehv Disconnectors For Smart GridDocument2 pagesEhv Disconnectors For Smart GridTravis WoodNo ratings yet

- Re Voltage StabilityDocument27 pagesRe Voltage StabilityTravis WoodNo ratings yet

- Anandaram BaruaDocument1 pageAnandaram BaruaTravis WoodNo ratings yet

- En 10204-2004 Metallic Products - Types of Inspection DocumentsDocument10 pagesEn 10204-2004 Metallic Products - Types of Inspection DocumentsDalamagas KwnstantinosNo ratings yet

- Enhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Document6 pagesEnhanced Performance of Zinc Oxide Arrester by Simple Modification in Processing and Design 2169 0022.1000135Travis WoodNo ratings yet

- Gear Design For Quiet Reduction GearDocument8 pagesGear Design For Quiet Reduction GearTravis WoodNo ratings yet

- April Is The Cruellest MonthDocument1 pageApril Is The Cruellest MonthTravis WoodNo ratings yet

- KSEB Technical SPec PDFDocument279 pagesKSEB Technical SPec PDFTravis WoodNo ratings yet

- Ceramic Manufacturing PDFDocument41 pagesCeramic Manufacturing PDFTravis WoodNo ratings yet

- 1363 Bolts and Nut Standard PDFDocument7 pages1363 Bolts and Nut Standard PDFTravis WoodNo ratings yet

- Transformer Factory Assembly Area LayoutDocument55 pagesTransformer Factory Assembly Area LayoutTravis Wood100% (2)

- Analysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceDocument7 pagesAnalysis of Grading Ring and Heat Sink Impact on Surge Arrester PerformanceTravis WoodNo ratings yet

- Overhead Conductor Installation Guide: Recommended PracticesDocument20 pagesOverhead Conductor Installation Guide: Recommended Practicesvjs270385No ratings yet

- Double Sampling-Wha It Means PDFDocument17 pagesDouble Sampling-Wha It Means PDFTravis WoodNo ratings yet

- Unidirectional Corona RingDocument2 pagesUnidirectional Corona RingTravis WoodNo ratings yet

- Fretting Fatigue in Overhead ConductorsDocument16 pagesFretting Fatigue in Overhead ConductorsTravis WoodNo ratings yet

- Study of Single and Double Sampling PlansDocument14 pagesStudy of Single and Double Sampling PlansTravis WoodNo ratings yet

- ElectricalDocument34 pagesElectricalTravis WoodNo ratings yet

- SPEED Continuous Panels Plants Design IssuesDocument18 pagesSPEED Continuous Panels Plants Design IssuesTravis WoodNo ratings yet

- 3 Sec-III-Hardware Fittings & AccessoriesDocument49 pages3 Sec-III-Hardware Fittings & AccessoriesTravis WoodNo ratings yet

- CT Grounding To Avoid Nuisance TrippingDocument2 pagesCT Grounding To Avoid Nuisance TrippingTravis WoodNo ratings yet

- Innovative Adhesive For Sandwich SystemsDocument20 pagesInnovative Adhesive For Sandwich SystemsTravis WoodNo ratings yet

- Spacer Damper IssuesDocument5 pagesSpacer Damper IssuesTravis WoodNo ratings yet

- Anil Agarwal: Research: Mud As A Traditional Building MaterialDocument10 pagesAnil Agarwal: Research: Mud As A Traditional Building MaterialTravis WoodNo ratings yet

- SPEED Continuous Panels Plants Design IssuesDocument18 pagesSPEED Continuous Panels Plants Design IssuesTravis WoodNo ratings yet

- Mud Architecture: I J I R S E TDocument6 pagesMud Architecture: I J I R S E TJazzNo ratings yet

- Bolt InterlocksDocument5 pagesBolt InterlocksTravis WoodNo ratings yet

- An Introduction To Conway's Games and NumbersDocument30 pagesAn Introduction To Conway's Games and NumbersSilentSparrow98No ratings yet

- CB Spec SvenskaDocument44 pagesCB Spec SvenskaTravis WoodNo ratings yet

- Lab 01 - HCV and LCV by Gas CalorimeterDocument6 pagesLab 01 - HCV and LCV by Gas CalorimeterTakreem SindhuNo ratings yet

- Sulzer MC EquipmentDocument12 pagesSulzer MC EquipmentsnthmlgtNo ratings yet

- The Godfather Term One Sample Basic Six Annual Scheme of Learning Termly Scheme of Learning WEEK 1 - 12Document313 pagesThe Godfather Term One Sample Basic Six Annual Scheme of Learning Termly Scheme of Learning WEEK 1 - 12justice hayfordNo ratings yet

- Country Wing Auto-Mobile GarageDocument25 pagesCountry Wing Auto-Mobile GarageDmitry PigulNo ratings yet

- 2VAA001695 en S Control NTCS04 Controller Station Termination UnitDocument43 pages2VAA001695 en S Control NTCS04 Controller Station Termination UnitanbarasanNo ratings yet

- Lab Report 1Document8 pagesLab Report 1Hammad SattiNo ratings yet

- Action Plan On GadDocument1 pageAction Plan On GadCherish Devora ArtatesNo ratings yet

- Ethanol: Safety Data SheetDocument19 pagesEthanol: Safety Data SheetNitika SinhaNo ratings yet

- 16SEE - Schedule of PapersDocument36 pages16SEE - Schedule of PapersPiyush Jain0% (1)

- Wiley Wesleyan UniversityDocument36 pagesWiley Wesleyan UniversityBirunda SilvaNo ratings yet

- CHM 127 Exp 1Document4 pagesCHM 127 Exp 1shelby hartwigNo ratings yet

- Face To Face Pre-Intermediate B1Document162 pagesFace To Face Pre-Intermediate B1Andra OlariNo ratings yet

- Language II Module 2 Adjectives and AdverbsDocument25 pagesLanguage II Module 2 Adjectives and AdverbsCarla Arredondo MagnereNo ratings yet

- Pricelist Hardware Jayacom Disember 2018Document2 pagesPricelist Hardware Jayacom Disember 2018ContempGamelan PerformingGroupNo ratings yet

- BA 302 Lesson 3Document26 pagesBA 302 Lesson 3ピザンメルビンNo ratings yet

- 21st Century Literature Exam SpecsDocument2 pages21st Century Literature Exam SpecsRachel Anne Valois LptNo ratings yet

- Mil B 49430BDocument36 pagesMil B 49430Bparam.vennelaNo ratings yet

- Campbell Soup Case-StudyDocument3 pagesCampbell Soup Case-StudyraghudeepaNo ratings yet

- Main Sulci & Fissures: Cerebral FissureDocument17 pagesMain Sulci & Fissures: Cerebral FissureNagbhushan BmNo ratings yet

- Overhead Water Tank Structural AnalysisDocument28 pagesOverhead Water Tank Structural Analysiscollins unanka100% (3)

- Board of Intermediate & Secondary Education, Lahore: Tahir Hussain JafriDocument2 pagesBoard of Intermediate & Secondary Education, Lahore: Tahir Hussain Jafridr_azharhayatNo ratings yet

- G String v5 User ManualDocument53 pagesG String v5 User ManualFarid MawardiNo ratings yet

- COP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDocument4 pagesCOP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDavid CarrilloNo ratings yet

- Small Healthcare Organization: National Accreditation Board For Hospitals & Healthcare Providers (Nabh)Document20 pagesSmall Healthcare Organization: National Accreditation Board For Hospitals & Healthcare Providers (Nabh)Dipti PatilNo ratings yet

- Unit 5 - Assessment of One'S Teaching Practice: Universidad de ManilaDocument15 pagesUnit 5 - Assessment of One'S Teaching Practice: Universidad de ManilaDoc Joey100% (3)

- Naaqs 2009Document2 pagesNaaqs 2009sreenNo ratings yet

- Smell Detectives: An Olfactory History of Nineteenth-Century Urban AmericaDocument35 pagesSmell Detectives: An Olfactory History of Nineteenth-Century Urban AmericaUniversity of Washington PressNo ratings yet

- 6 Main Rotor Config DesignDocument44 pages6 Main Rotor Config DesignDeepak Paul TirkeyNo ratings yet

- Republic of The Philippines Iba, Zambales: President Ramon Magsaysay State UniversityDocument3 pagesRepublic of The Philippines Iba, Zambales: President Ramon Magsaysay State UniversityErika Joy EscobarNo ratings yet

- Proposed - TIA - 1392 - NFPA - 221Document2 pagesProposed - TIA - 1392 - NFPA - 221Junior TorrejónNo ratings yet