Professional Documents

Culture Documents

Short List of Applied Piping Standard PDF

Uploaded by

mohamad3010Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Short List of Applied Piping Standard PDF

Uploaded by

mohamad3010Copyright:

Available Formats

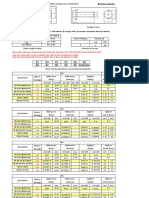

DIMENSIONAL STANDARDS OF PIPE

The most common reference dimensional standards for pipe are as follows:

Material Type Construction Size Range

1

Standard

Carbon steel Stainless steel and other corrosion-resistant alloys

Seamless and welded Seamless and welded

8 80 in. 8 30 in.

AMSE B36.10 ASME B36.19

DIMENSIONAL STANDARDS FOR PIPING COMPONENTS

The most commonly used piping components and the dimensional standards are as follows:

ThreadedSocket-Weld Ends

Type of Component

Function

Butt-Weld Ends

Held between Flanges

90 long radius (LR) elbow 90 short radius (SR) elbow 45 Elbow 180 return Equal tee

Change direction Change direction Change direction Change direction Change direction

ASME B16.9 (12 48 in.) ASME B16.28 (12 48 in.) ASME B16.9 (12 48 in.) ASME B16.9 (12 48 in.) ASME B16.9 (12 48 in.)

ASME B16.11 (12 4 in.)

Not applicable

Not applicable Not applicable

ASME B16.11 Not applicable (12 4 in.) Not applicable Not applicable ASME B16.11 (12 4 in.) Not applicable

Type of Component Function

Butt-Weld Ends

ThreadedSocket-Weld Ends

Held between Flanges

Reducing tee

Reinforced branch (Olet) Eccentric reducer Concentric Change size reducer Flanges Join pipe and components Flanges Join pipe and components Couplings Join pipe and components Join pipe and Unions components Spectacle Isolation blinds, spades and spacers

Change direction and size Change direction and size Change size

ASME B16.9 (12 48 in.)

ASME B16.11 Not applicable (12 4 in.)

Manufacturers Manufacturers Not applicable standard standard ASME B16.9 (12 48 in.) ASME B16.9 (12 48 in.) ASME B16.5 (12 48 in.) ASME B16.47 (2660 in.) Not applicable ASME B16.11 (12 4 in.) ASME B16.11 (12 4 in.) ASME B16.5 (12 24 in.) Not applicable Not applicable Not applicable Not applicable Not applicable

ASME B16.11 Not applicable (12 4 in.) Not applicable BS 3799 Not applicable Not applicable Not applicable API 590 or companys standards

Each piping component type also has one or more methods of being connected to pipe or another component. The end connection chosen can be selected from one of the flowing commonly used alternatives:

. . . .

Butt weld. Plain end or socket weld. Threading. Flanging.

Other, less commonly used methods include hubbed connections and SAE flanges, however the preceding four types cover a vast majority of end connections and on certain projects, all requirements.

Dimensional Standards Covering End Connections of Components

The most commonly used dimensional standards for end connections are as follows:

End Connection Joint Type ASME Standard Size

Weld end (WE) Plain end (PE) Threaded (Thd) Flanged (Flg) Flanged (Flg)

Butt weld Socket weld Screwed Flanged Flanged

ASME ASME ASME ASME ASME

B16.25 B16.11 B1.20.1 B16.5 B16.47

all sizes 4 in. and below 4 in. and below 1 2 24 in. 2660 in.

Generally, a piping component has the same connection at both ends. However, it is possible to have a mixture, especially with valves; for example, flanged by threaded, flanged by socket weld, or threaded by socket weld. This is acceptable as long as both end connections satisfy the design conditions of the fluid being transported in the piping system. As mentioned previously, numerous other national standards cover the dimensional standards for piping components, however, differences in the dimensions and tolerances, in a vast majority of cases, could make the components incompatible.

You might also like

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Dimensional & Material Standards For Piping ComponentsDocument3 pagesDimensional & Material Standards For Piping ComponentsaasattiNo ratings yet

- Copper Fittings For HVACR Applications 082820Document7 pagesCopper Fittings For HVACR Applications 082820Md Saddam HossainNo ratings yet

- 5 Units Separator BOQ Pipe, Flange and Fitting 25-8-15Document24 pages5 Units Separator BOQ Pipe, Flange and Fitting 25-8-15Engr Khurram Jaan RamayNo ratings yet

- MechanicalDocument12 pagesMechanicalsaketNo ratings yet

- S# Item Qty Unit Index Plant - Sloc Shortfall Remarks Availablt QtyDocument1 pageS# Item Qty Unit Index Plant - Sloc Shortfall Remarks Availablt QtyAtif HusaynNo ratings yet

- ERP Material List 01.18.19Document23 pagesERP Material List 01.18.19Wellmorc AgetroNo ratings yet

- Dimensions of Bolts and Nuts BS3692Document6 pagesDimensions of Bolts and Nuts BS3692azam RazzaqNo ratings yet

- S.NO. Description Unit QTY Remarks 1.0 Pipe: 1.1 A B: Total (Usd) Rate (USD /unit)Document6 pagesS.NO. Description Unit QTY Remarks 1.0 Pipe: 1.1 A B: Total (Usd) Rate (USD /unit)Mavia KhanNo ratings yet

- Technical Requirements for Mechanical & Piping WorksDocument18 pagesTechnical Requirements for Mechanical & Piping WorksElias EliasNo ratings yet

- Buried Pipes and Fittings Painting SpecDocument5 pagesBuried Pipes and Fittings Painting SpecRohan Sharma50% (2)

- Piping Line List: Ventech Engineers, Inc. Pasadena, Texas, P.O.Box 4261Document3 pagesPiping Line List: Ventech Engineers, Inc. Pasadena, Texas, P.O.Box 4261samer8saifNo ratings yet

- Butt Weld Stainless Steel FittingsDocument16 pagesButt Weld Stainless Steel Fittingsbayu susiloNo ratings yet

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocument2 pagesEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganNo ratings yet

- Flange Pipe Support for 4-36Document1 pageFlange Pipe Support for 4-36indeskeyNo ratings yet

- Isometric Layout Drawing Isometric Offsets Calculating Isometric Offsets Isometric Dimensioning & LabelingDocument18 pagesIsometric Layout Drawing Isometric Offsets Calculating Isometric Offsets Isometric Dimensioning & LabelingA K NairNo ratings yet

- 2017 03436 01 002 - Bom 320Document8 pages2017 03436 01 002 - Bom 320sundyaNo ratings yet

- Dots in ASME B36.10 Under Schedule TableDocument5 pagesDots in ASME B36.10 Under Schedule TableIbrahim BashaNo ratings yet

- Udhe 2.standardsDocument1 pageUdhe 2.standardsom dhamnikarNo ratings yet

- Why Insulate Pipes: 3 Key Benefits of InsulationDocument13 pagesWhy Insulate Pipes: 3 Key Benefits of InsulationnguyenNo ratings yet

- Piping Spec C ClassDocument1 pagePiping Spec C Classnestor ferrel floresNo ratings yet

- Compressor Inlet Piping - Compressed Air Best PracticesDocument10 pagesCompressor Inlet Piping - Compressed Air Best PracticesBehroozRaadNo ratings yet

- Pipingpresentationmaster 170219125347Document61 pagesPipingpresentationmaster 170219125347Vignesh Nadimuthu100% (1)

- Grounding - 1501479512Document74 pagesGrounding - 1501479512zaheer2931No ratings yet

- TEM-En-001-00 - Spring Support Data SheetDocument2 pagesTEM-En-001-00 - Spring Support Data SheetPhilippe AlexandreNo ratings yet

- 2015-Xii. P&id PDFDocument71 pages2015-Xii. P&id PDFFitria Nur HayatiNo ratings yet

- Gas supply pig launcher datasheetDocument9 pagesGas supply pig launcher datasheetOlusayoNo ratings yet

- Air Reciver Vessel-1 (Compressor Unit-2)Document5 pagesAir Reciver Vessel-1 (Compressor Unit-2)MD Shadikul Huq ShezanNo ratings yet

- Sec 05100 - Structural SteelDocument10 pagesSec 05100 - Structural Steeltiju2005hereNo ratings yet

- Valve DetailDocument5 pagesValve DetailRakesh RanjanNo ratings yet

- PL Re 401 - 00Document5 pagesPL Re 401 - 00SinaNo ratings yet

- KF Check-Valves PDFDocument24 pagesKF Check-Valves PDFTaylor RamirezNo ratings yet

- Swagelok Needle ValvesDocument12 pagesSwagelok Needle Valvesnegg 348No ratings yet

- Piping Material EquivalentsDocument1 pagePiping Material EquivalentspejnorozyNo ratings yet

- Datasheet For Steel Grades Special Alloy Gs-25Crmo4Document2 pagesDatasheet For Steel Grades Special Alloy Gs-25Crmo4ssvrNo ratings yet

- Bond Strand 5000 eDocument8 pagesBond Strand 5000 eUmar KidaNo ratings yet

- Universal Y StrainerDocument2 pagesUniversal Y Strainerabdi zakiNo ratings yet

- 91Document12 pages91Zoran DanilovNo ratings yet

- J3X & JF3X PDFDocument2 pagesJ3X & JF3X PDFMukiara LuffyNo ratings yet

- FS 2004 A - Rev-7Document78 pagesFS 2004 A - Rev-7Maffone NumerounoNo ratings yet

- Reactor piping design guideDocument19 pagesReactor piping design guidesyedahmad39No ratings yet

- Valves, fittings and gasketsDocument32 pagesValves, fittings and gasketsPeter RodriguezNo ratings yet

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayNo ratings yet

- Buttweld Fittings Accesorios SoldadosDocument5 pagesButtweld Fittings Accesorios SoldadosJuan CadenaNo ratings yet

- L&T Aquaseal Butterfly Check Valves PDFDocument28 pagesL&T Aquaseal Butterfly Check Valves PDFSanjay SahulNo ratings yet

- ANSI FlangeDocument10 pagesANSI FlangemechftpNo ratings yet

- P-193 - Pipeline Pump Station and Terminal Valves in Crude Oil Service (API 6D Valves)Document34 pagesP-193 - Pipeline Pump Station and Terminal Valves in Crude Oil Service (API 6D Valves)MatteoNo ratings yet

- Steam Trap and Drain Trap FunctionsDocument23 pagesSteam Trap and Drain Trap FunctionsMallela Sampath KumarNo ratings yet

- Tube Bundle DrawingDocument1 pageTube Bundle DrawingVeera ManiNo ratings yet

- Rfi Request FormDocument1 pageRfi Request Formvishnu300022No ratings yet

- Pipe Hangers, Pipe Supports, Variable and Constant Spring HangersDocument2 pagesPipe Hangers, Pipe Supports, Variable and Constant Spring Hangerskaiju85No ratings yet

- Erection Manual For Class 800 Counterflow Cooling TowerDocument17 pagesErection Manual For Class 800 Counterflow Cooling TowerEdy SuprayitnoNo ratings yet

- 6 44 0005 A2Document25 pages6 44 0005 A2S.selvakumarNo ratings yet

- Swagelok Fitting PDFDocument16 pagesSwagelok Fitting PDFmattuiffNo ratings yet

- Piping Engineering.nDocument6 pagesPiping Engineering.nAjay KumarNo ratings yet

- Piping 5.0 - Introduction to Piping EngineeringDocument32 pagesPiping 5.0 - Introduction to Piping EngineeringSteve WanNo ratings yet

- Ansi B16.5 Flange PDFDocument45 pagesAnsi B16.5 Flange PDFeldaniel00067416No ratings yet

- Ansi Flange HandbookDocument76 pagesAnsi Flange HandbookSuperstarVirgo100% (1)

- Codes Standards For YANBU ProjectDocument7 pagesCodes Standards For YANBU ProjectBehçet Serdal CanbazNo ratings yet

- Piping Guide BookDocument15 pagesPiping Guide BookJagankumar100% (1)

- Hybrid Force Control 6666d W Hardware ComponentDocument11 pagesHybrid Force Control 6666d W Hardware Componentmohamad3010No ratings yet

- Kalman Filters: Tracking and Kalman Filtering Made EasyDocument1 pageKalman Filters: Tracking and Kalman Filtering Made Easymohamad3010No ratings yet

- Corrosion and Materials Selection For Amine ServiceDocument5 pagesCorrosion and Materials Selection For Amine Servicedj22500100% (1)

- Guidelines to Prevent Environmental Cracking of Carbon Steel WeldmentsDocument1 pageGuidelines to Prevent Environmental Cracking of Carbon Steel Weldmentsmohamad3010No ratings yet

- Pumps With Variable Frequency DriveDocument2 pagesPumps With Variable Frequency Drivemohamad3010No ratings yet

- PD Vs Cetrifugal Pump PDFDocument3 pagesPD Vs Cetrifugal Pump PDFneharoybhushanNo ratings yet

- Astm A312Document2 pagesAstm A312faisi778No ratings yet

- Professional Pilot December 2016Document104 pagesProfessional Pilot December 2016tugayyoung100% (1)

- Podem - Electric Chain Hoists - CLF & CLW (En)Document8 pagesPodem - Electric Chain Hoists - CLF & CLW (En)GogyNo ratings yet

- A4 Motorsport Flyer Mar 2013 A2Document2 pagesA4 Motorsport Flyer Mar 2013 A2Angel LagrañaNo ratings yet

- Anchor Rods and Base Plates ExplainedDocument3 pagesAnchor Rods and Base Plates Explainedpenneng0% (2)

- Atrita Pulverizer Products and ServicesDocument36 pagesAtrita Pulverizer Products and ServicesYousuf AliNo ratings yet

- Import & Export of Major Textile ItemsDocument4 pagesImport & Export of Major Textile Itemsgizex2013No ratings yet

- Logistics Collaboration Survey of Bangladesh CompaniesDocument187 pagesLogistics Collaboration Survey of Bangladesh CompaniesGolam Samdanee TaneemNo ratings yet

- American Welding Society Chattanooga Section: Welding Contest Rules and Score Sheet 2013 3GDocument8 pagesAmerican Welding Society Chattanooga Section: Welding Contest Rules and Score Sheet 2013 3GxaviereduardoNo ratings yet

- Nitoseal 290Document4 pagesNitoseal 290Venkata RaoNo ratings yet

- Steel Vessels 2000: Notices and General InformationDocument206 pagesSteel Vessels 2000: Notices and General Informationzam13723285No ratings yet

- Foundry and Forging VivaDocument20 pagesFoundry and Forging VivaharoldjoysonNo ratings yet

- Casr Regulatory StructureDocument1 pageCasr Regulatory Structureabdul waqarNo ratings yet

- 2007 - 01 January - Italys Tecnam Sierra and BravoDocument3 pages2007 - 01 January - Italys Tecnam Sierra and Bravoalbix58No ratings yet

- Method Statement (SHR1 MES NAP ELV 00004 - 00)Document23 pagesMethod Statement (SHR1 MES NAP ELV 00004 - 00)waseem2016No ratings yet

- Sheet Metal FormingDocument25 pagesSheet Metal Formingankushkapoor2003No ratings yet

- 2Document10 pages2VivekChaudharyNo ratings yet

- What is ASTM C1729 standardDocument2 pagesWhat is ASTM C1729 standardLữ Hành ShutoNo ratings yet

- The Shard: Key StrategiesDocument2 pagesThe Shard: Key StrategiesfirthousiyaNo ratings yet

- Tamer GroupDocument4 pagesTamer GroupCharles JohnNo ratings yet

- August 2013 DMHI PresentationDocument46 pagesAugust 2013 DMHI PresentationFlorin MacinicNo ratings yet

- TRANSPORTATION CASE DIGEST ON PROTEST REQUIREMENTDocument3 pagesTRANSPORTATION CASE DIGEST ON PROTEST REQUIREMENTFrancis Francisco100% (1)

- Ihara Fittings For High PressureDocument45 pagesIhara Fittings For High PressureQuang Thanh NguyenNo ratings yet

- Syllabus For 2nd Mate OralsDocument2 pagesSyllabus For 2nd Mate Oralsinkugeorge100% (1)

- Sintercast Vs HardfacingDocument21 pagesSintercast Vs Hardfacinganrulo75% (4)

- BRIDGE Steel Welding GuideDocument2 pagesBRIDGE Steel Welding GuideANTONYLEONo ratings yet

- NDE Testing Requirements for Forged Steel and Alloy FlangesDocument2 pagesNDE Testing Requirements for Forged Steel and Alloy FlangesfarjadulhaqNo ratings yet

- Elematic Battery Mould Process GuideDocument22 pagesElematic Battery Mould Process Guidesimple_aniNo ratings yet

- Chemrite AG 200Document3 pagesChemrite AG 200ghazanfarNo ratings yet

- Competition Concerns in Shipping ConferencesDocument125 pagesCompetition Concerns in Shipping ConferencesJeet ParikhNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionFrom EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionRating: 3 out of 5 stars3/5 (1)

- The Rights of Nature: A Legal Revolution That Could Save the WorldFrom EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldRating: 5 out of 5 stars5/5 (1)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Transmission Pipeline Calculations and Simulations ManualFrom EverandTransmission Pipeline Calculations and Simulations ManualRating: 4.5 out of 5 stars4.5/5 (10)

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Waste: One Woman’s Fight Against America’s Dirty SecretFrom EverandWaste: One Woman’s Fight Against America’s Dirty SecretRating: 5 out of 5 stars5/5 (1)

- Built: The Hidden Stories Behind Our StructuresFrom EverandBuilt: The Hidden Stories Behind Our StructuresRating: 4 out of 5 stars4/5 (27)

- Piezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringFrom EverandPiezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringNo ratings yet

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionFrom Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionNo ratings yet

- Design and Construction of Soil Anchor PlatesFrom EverandDesign and Construction of Soil Anchor PlatesRating: 5 out of 5 stars5/5 (1)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsFrom EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsRating: 4 out of 5 stars4/5 (16)

- Pipeline Planning and Construction Field ManualFrom EverandPipeline Planning and Construction Field ManualRating: 5 out of 5 stars5/5 (3)