Professional Documents

Culture Documents

Rises Shafts and Ducts

Uploaded by

Yasir_Wafi_1101Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rises Shafts and Ducts

Uploaded by

Yasir_Wafi_1101Copyright:

Available Formats

FIRE RATED SYSTEMS SECTION 4.

Risers, Shafts and Ducts

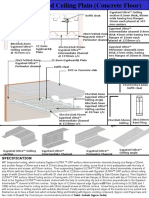

GIB Shaftwall Two Way FRR

SPECIFICATION NUMBER GBSH 30 GBSH 60a GBSH 60b GBSH 90a GBSH 90b GBSH 120a GBSH 120b FIRE RESISTANCE RATING -/30/30 -/60/60 -/60/60 -/90/90 -/90/90 -/120/120 -/120/120 FIRE SIDE Either Side Shaft Side Either Side Shaft Side Either Side Shaft Side Either Side SHAFT SIDE LINING 2 x 13mm GIB Fyreline

JANUARY 2006

LANDING SIDE LINING 1 x 13mm GIB Fyreline 1 x 13mm GIB Fyreline 2 x 13mm GIB Fyreline 2 x 13mm GIB Fyreline

INNER LAYER: 1 x 16mm GIB Fyreline OUTER LAYER: 1 x 13mm GIB Fyreline INNER LAYER: 1 x 16mm GIB Fyreline OUTER LAYER: 1 x 13mm GIB Fyreline

2 x 13mm GIB Fyreline 2 x 13mm GIB Fyreline 2 x 13mm GIB Fyreline

2 x 13mm GIB Fyreline 2 x 13mm GIB Fyreline 2 x 13mm GIB Fyreline

2 x 19mm GIB Fyreline

GIB Shaftwall is constructed from the Landing Side of the shaft. All systems are non-load bearing.

FRAMING & WALL HEIGHT

GIB Shaftwall Framing comprising CH stud, E stud and J-Track. The J-Track is installed at the top and bottom of the wall. Installation starts at one end of the wall using an E stud. CH studs are spaced at 600mm centres maximum and friction fitted into the top and bottom tracks, there is to be no mechanical fixing. Installation is completed at the other end using a J-Track. A 15mm expansion gap is left between the studs and the track at the top of the frame. Maximum wall height is 3 metres.

FASTENING THE LINING

Shaft Side Linings are friction fitted into the CH or E stud. At the end of the wall, linings are fixed to the J track using 40mm x 6g GIB Grabber Self Tapping Drywall Screws at 300mm centres. Landing Side Fix to each stud with 6g GIB Grabber Self Tapping Drywall Screws at 300mm centres with the following lengths: SINGLE or INNER LAYER (13mm or 16mm GIB Plasterboard): 32mm OUTER LAYER (13mm or 16mm GIB Plasterboard): 41mm 19mm GIB Fyreline: INNER LAYER: 32mm; OUTER LAYER: 51mm x 7g screws as above.

LINING

2 layers of 13mm GIB Fyreline on the shaft side and the appropriate number of layers and type of GIB Plasterboard as detailed in the above table on the landing side. On the shaft side a single sheet of 13mm GIB Fyreline is cut lengthwise and placed as a 26mm thick 600mm wide plank vertically in the CH stud as shown. Position the board taper to a cut-end to facilitate easy installation in the CH stud. The board is fixed hard to floor and a 15mm gap is left at the top of the frame which is filled with an appropriate fire rated mastic sealant of equivalent fire rating (consult the sealant supplier or manufacturer) prior to lining the floor side of the wall. Floor side linings are fixed vertically, using full height sheets where possible. Where sheet end butt joints are unavoidable they shall be formed over nogs. All sheet joints must be formed over framing. Linings are fixed hard to the floor. Any gaps that are left at the top of the linings are to be filled with an appropriate fire rated mastic sealant of equivalent fire rating (consult the sealant supplier or manufacturer).

Note: Do not fix to the top and bottom J tracks.

E-stud 2 x 13mm GIB Fyreline Plasterboard CH-stud J-track

Landing Side lining as specified

In order for GIB systems to perform as tested, all components must be installed exactly as prescribed. Substituting components produces an entirely different system and may seriously compromise performance. Follow system specifications.

FOR FURTHER INFORMATION VISIT WWW.GIB.CO.NZ. ISSUE DATE: JANUARY 2006

51

GIB FIRE RATED SYSTEMS

FIRE RATED SYSTEMS SECTION 4.1

Risers, Shafts and Ducts

JOINTING

Shaft Side: Unstopped Floor Side INNER LAYER: Unstopped OUTER LAYER: all screw heads stopped and all sheet joints tape reinforced and stopped in accordance with the GIB Site Guide.

JANUARY 2006

Studs CH-Studs are cut 15mm short of the full height between the top and bottom J-Tracks and placed vertically into the J-Tracks with the H side of the stud towards the Shaft. The stud is then located so that the GIB lining slips into the H of the CH-Stud. Cutting further 600mm wide panels and locating them into the H section this procedure is repeated until the final gap is 600mm or less. End Lining Panel The final lining panel is cut to such a size that it can be angled into the last stud and located into the J-Stud already fixed to the structure. This is screw fixed to the long leg of the J-Stud using 41mm x 6g GIB Grabber Self Tapping Drywall Screws at 300mm centres. To allow entry of the final lining panel, the bottom J-Track floor side upstand will require cutting at the last E-Stud and bent down until the liner is in place and then returned to the vertical. Before lining the floor side of the wall the 15mm gap between board and top J-Track and the gap between board and J-Stud should be completely filled with an appropriate fire rated mastic sealant of equivalent fire rating (consult the sealant supplier or manufacturer). Alternatively the gap can be filled with a GIB Fyreline packer as shown in the bottom detail below.

Tapered edges

INSTALLATION

Top and Bottom Tracks J-Tracks are cut to length and mechanically fixed at each end, and at a maximum of 600mm centres to the floor and upper beam or structural support. Place the long leg of the J-Track toward the shaft. For steel frame construction, install J-Track prior to any fireproofing spray application. End Studs E-Stud is cut to full height and mechanically fixed at a maximum of 600mm centres to columns or support structures prior to any fireproofing spray application. A J-Track is cut and fixed at the opposite end of the wall in the same manner placing the long leg towards the shaft. GIB Plasterboard Linings Using full height sheets where possible, cut tapered edged 13mm GIB Fyreline lengthwise in half leaving two 600mm wide panels. In all cases the panels should be cut to length to leave a 15mm clearance between the top of the panel and the J-Track. Place the lining back to back with a taper at each side of the 600mm width and starting at the E-Stud the two layers are friction fitted into the E-Stud on side nearest the shaft.

Friction fit CH-stud

Fire rated mastic

Top J-Track

Bottom J-Track

or

GIB FIRE RATED SYSTEMS

Fire rated mastic

E-Stud J-Track

GIB Fyreline packers

In order for GIB systems to perform as tested, all components must be installed exactly as prescribed. Substituting components produces an entirely different system and may seriously compromise performance. Follow system specifications.

FOR FURTHER INFORMATION VISIT WWW.GIB.CO.NZ. ISSUE DATE: JANUARY 2006

52

FIRE RATED SYSTEMS SECTION 4.1

Risers, Shafts and Ducts

Landing Side Lining Using full height sheets where possible, tapered edge GIB Plasterboard is fixed vertically to each stud with GIB Grabber Self Tapping Drywall Screws at 300mm centres. In all cases the sheets are to be cut to length. All sheets should be bearing on to the floor and not fixed to

JANUARY 2006

either the top or bottom J-Tracks. Systems with more than one layer of lining must have staggered joints at alternate studs. Any gaps are to be filled with an appropriate fire rated mastic sealant of equivalent fire rating (consult the sealant supplier or manufacturer).

Details

Shaft side

Shaft side Shaft side

Internal Corner

External Corner

Fire rated mastic

Cut and bend down for last liner

General Head Detail and Floor Detail for Last Shaftwall Bay GIB FIRE RATED SYSTEMS

53

In order for GIB systems to perform as tested, all components must be installed exactly as prescribed. Substituting components produces an entirely different system and may seriously compromise performance. Follow system specifications.

FOR FURTHER INFORMATION VISIT WWW.GIB.CO.NZ. ISSUE DATE: JANUARY 2006

FIRE RATED SYSTEMS SECTION 4.2

Risers, Shafts and Ducts

GIB Fyreduct 900 Two Way FRR

SPECIFICATION NUMBER LOADBEARING CAPABILITY FIRE RESISTANCE RATING -/120/120 GBFD 900 NLB -/90/90 -/60/60 -/30/30

JANUARY 2006

LINING REQUIREMENTS 2 layers 19mm GIB Fyreline 2 layers 16mm GIB Fyreline 2 layers 13mm GIB Fyreline 2 layers 10mm GIB Fyreline

DUCT COMPONENTS

GIB Fyreline 63 x 34 x 0.55mm C-section galvanised steel stud. 32 x 32 x 0.55mm galvanised steel angle. GIB Grabber Drywall Self Tapping Screws. 38mm x 10g GIB Grabber Laminator Screws. Rockwool 80kg/m2 Steel duct liner. Duct support system.

Rod encasement enclosing internal hangers to a height of 400mm (if insulation rating of hanger required)

Duct liner support system. Maximum allowed stress per hanger + 10N/mm2 Steel Duct Liner

Fire insulation 25mm thick Rockwool 80kg/m2

Steel Stud ring frame, screw fastened at corners. Frames at maximum 600mm centres

Steel Angle at 4 corners of GIB Fyreduct GIB Fyreduct support system hangers at 2000mm centres maximum. Hangers at wall to be 150mm maximum from wall. Corner Caps screw fixed to GIB Fyreline

GIB FIRE RATED SYSTEMS

Linings 2 layers GIB Fyreline

In order for GIB systems to perform as tested, all components must be installed exactly as prescribed. Substituting components produces an entirely different system and may seriously compromise performance. Follow system specifications.

FOR FURTHER INFORMATION VISIT WWW.GIB.CO.NZ. ISSUE DATE: JANUARY 2006

54

FIRE RATED SYSTEMS SECTION 4.2

Risers, Shafts and Ducts

BUILDING THE DUCT

Step 1 Cut C-section studs and screw together at the corners to form ring frames around the steel duct liner. Fit angles to all corners of the steel frames. Space frames at 900mm centres maximum.

JANUARY 2006

900mm max 900mm max

Step 2 Insert the Rockwool insulation in between the ring frames around all four sides of the duct.

Step 3 Sheets shall be touch fitted. Offset joints between layers by 600mm. All sheet joints must be formed over framing.

INNER LAYER

GIB Grabber Drywall Self Tapping Screws at 300mm centres to sheet perimeter and intermediate studs. The screw length must ensure 12mm penetration into the steel frame.

OUTER LAYER

GIB Grabber Drywall Self Tapping Screws at 300mm centres to sheet perimeter and intermediate studs. The screw length must ensure 12mm penetration into the steel frame.

Step 4 Fit GIB Fyreline caps to all corners. Fix corner caps with 38mm x 10g GIB Grabber Laminator Screws.

INNER LAYER

Unstopped.

OUTER LAYER

All screw heads stopped and all sheet joints tape reinforced and stopped in accordance with the publication entitled GIB Site Guide.

GIB FIRE RATED SYSTEMS

55

In order for GIB systems to perform as tested, all components must be installed exactly as prescribed. Substituting components produces an entirely different system and may seriously compromise performance. Follow system specifications.

FOR FURTHER INFORMATION VISIT WWW.GIB.CO.NZ. ISSUE DATE: JANUARY 2006

FIRE RATED SYSTEMS SECTION 4.3

Risers, Shafts and Ducts

GIB Fyreduct 600 Two Way FRR

SPECIFICATION NUMBER LOADBEARING CAPABILITY FIRE RESISTANCE RATING -/120/120 GBFD 600 NLB -/90/90 -/60/60 -/30/30

JANUARY 2006

LINING REQUIREMENTS 2 layers 19mm GIB Fyreline 2 layers 16mm GIB Fyreline 2 layers 13mm GIB Fyreline 2 layers 10mm GIB Fyreline

DUCT COMPONENTS

GIB Fyreline 63 x 34 x 0.55mm galvanised steel channel. 32mm x 6g GIB Grabber Drywall Self Tapping Screws. 38mm x 10g GIB Grabber Laminator Screws. Rockwool 80kg/m2 Duct support system. Rod encasement enclosing internal hanger to a height of

400mm (if insulation rating of hanger required)

GIB Fyreline

GIB Fyreline

GIB Fyreline Duct liner support system maximum allowable stress per hanger is 10N/mm2

Fire insulation 25mm Rockwool 80kg/m2

GIB FIRE RATED SYSTEMS

GIB Fyreduct support system Hangers at 2000mm centres maximum. Hangers at wall to be 150mm maximum from wall.

GIB Fyreline

Note: All sheet end butt joints are to be back blocked with a 200mm wide strip of GIB Fyreline

In order for GIB systems to perform as tested, all components must be installed exactly as prescribed. Substituting components produces an entirely different system and may seriously compromise performance. Follow system specifications.

FOR FURTHER INFORMATION VISIT WWW.GIB.CO.NZ. ISSUE DATE: JANUARY 2006

56

FIRE RATED SYSTEMS SECTION 4.3

Risers, Shafts and Ducts

BUILDING THE DUCT

Step 1 Cut 600mm wide strips of GIB Fyreline to form the bottom and top of the duct. Attach 63 x 34 x 0.55mm galvanised steel channels to sheet edges with 32mm x 6g GIB Grabber Drywall Self Tapping Screws at 300mm centres. Cut strips of GIB Fyreline to form the sides of the duct. Attach 63 x 34 x 0.55mm galvanised steel channels to sheet edges with 32mm x 6g GIB Grabber Drywall Self Tapping Screws at 300mm centres. Step 2 Fabricate the duct by attaching 63 x 34 x 0.55mm galvanised steel channels at duct corners with 32mm x 6g GIB Grabber Drywall Self Tapping Screws at 300mm centres.

JANUARY 2006

600mm max

600mm max

Step 3 Insert the Rockwool insulation around all four sides of the duct. Cut strips of GIB Fyreline to form the outer layer of the duct.

Step 4 Sheets shall be touch fitted. Offset joints between layers by 600mm. All sheet joints must be back blocked with 200mm wide strips of GIB Fyreline attached to outer lining with 38mm x 10g GIB Grabber Laminator Screws.

OUTER LAYER

32mm x 6g GIB Grabber Drywall Self Tapping Screws at 300mm centres to sheet edges.

Step 5

INNER LAYER: Unstopped. OUTER LAYER: All

screw heads stopped and all sheet joints tape reinforced and stopped in accordance with the publication entitled GIB Site Guide.

In order for GIB systems to perform as tested, all components must be installed exactly as prescribed. Substituting components produces an entirely different system and may seriously compromise performance. Follow system specifications.

FOR FURTHER INFORMATION VISIT WWW.GIB.CO.NZ. ISSUE DATE: JANUARY 2006

57

GIB FIRE RATED SYSTEMS

FIRE RATED SYSTEMS SECTION 4.4

Risers, Shafts and Ducts

GIB Ventshaft Two Way FRR

SPECIFICATION NUMBER GVS60 LOADBEARING CAPACITY NLB FIRE RESISTANCE RATING -/60/60 LINING REQUIREMENTS 3 x 16mm GIB Fyreline

JANUARY 2006

SYSTEM WEIGHT APPROX 45kg/m2

GIB Ventshaft is constructed from the landing side of the shaft.

FRAMING

Primary Horizontal Angles 25mm x 50mm (0.75BMT) metal angles fixed to floor slab and slab soffit on all sides. Ensure a good fit of the angle at the corners. Fix with steel masonry anchors at 400mm centres. Mark the position of the anchors on the slab for future layout reference. Primary Vertical Angles 25mm x 50mm (0.75BMT) metal angles to all corners full height in one continuous straight length ensuring good fit slab to slab. Fix with 16mm panhead self tapping screws. Secondary Angles After the first layer of 16mm GIB Fyreline has been fixed, fix 25 x 50mm (0.75BMT) metal angles to the base and head positions on all sides ensuring a good fit at all corners. Fix with metal anchors at 400mm centres. Stagger anchors 200mm from primary anchors.

LINING AND FASTENING

First Layer Fix the first layer of 16mm GIB Fyreline to the metal angles at 600mm centres horizontally commencing from one end or corner progressively attaching around the shaft using 32mm x 6g GIB Grabber Screws. Fix the 16mm GIB Fyreline to the metal angles at the corners and walls at 400mm centres commencing 200mm up from the base angle using 32mm x 6g GIB Grabber Screws. Plasterboard should be fixed hard to floor slab and slab soffit. Second Layer Lamination Cut sheet to provide a good fit slab to slab and/or intersecting walls. Mark up face of the 16mm GIB Fyreline sheet at 400mm centres vertically, commencing from the recess to provide an even screw stagger. Note the recesses in the previous layer are supported by an additional double line of laminating screws. Mark up the face horizontally at 400mm centres commencing 200mm up from the base. Stagger/overlap sheets by 600mm. Fix second layer of 16mm GIB Fyreline to the metal angles at 600mm centres commencing from one end or corner progressively attaching around the shaft using 41mm GIB Grabber Screws. Laminate to the first sheet using 38mm x 10g GIB Grabber Laminator Screws.

WALL HEIGHT

The wall height is limited to 3000mm.

GIB FIRE RATED SYSTEMS

In order for GIB systems to perform as tested, all components must be installed exactly as prescribed. Substituting components produces an entirely different system and may seriously compromise performance. Follow system specifications.

FOR FURTHER INFORMATION VISIT WWW.GIB.CO.NZ AND SEARCH SPECIFICATION CODE: GVS 60. ISSUE DATE: JANUARY 2006

58

FIRE RATED SYSTEMS SECTION 4.4

Risers, Shafts and Ducts

Third Layer Lamination Cut sheet to provide a 10-13mm gap at the base and head where intersecting walls/structures of dissimilar materials occur. Mark up the face of the 16mm GIB Fyreline at 400mm centres vertically commencing from the recess to provide an even screw stagger. Mark up the face horizontally at 400mm centres commencing from base. Note the recess in the previous layer is supported by an additional double line of laminating screws. Stagger/overlap sheets by 600mm. Screw fix at the perimeter to the metal angles using 63mm GIB Grabber Screws ensuring 10-13mm gap is provide for fire rated sealant. Laminate to second layer as first layer

JANUARY 2006

sheets using 38mm x 10g GIB Grabber Laminator Screws. Apply fire rated sealant to the perimeter. Ensure boards overlap at corners, fix external GIB Goldline trims.

JOINTING

INNER LAYERS: OUTER LAYER:

Unstopped.

All screw heads stopped and all sheet joints tape reinforced and stopped in accordance with the publication entitled GIB Site Guide.

Steel masonry anchors at 400mm centres

Fire rated sealant Primary 50 x 25mm angles Secondary 50 x 25mm angles

Fire rated sealant

16mm GIB Fyreline

GIB Goldline trim

In order for GIB systems to perform as tested, all components must be installed exactly as prescribed. Substituting components produces an entirely different system and may seriously compromise performance. Follow system specifications.

FOR FURTHER INFORMATION VISIT WWW.GIB.CO.NZ AND SEARCH SPECIFICATION CODE: GVS 60. ISSUE DATE: JANUARY 2006

59

GIB FIRE RATED SYSTEMS

You might also like

- FIRE RATED WALL SYSTEMS – SECTION 2.3Document1 pageFIRE RATED WALL SYSTEMS – SECTION 2.3Scott McKerrowNo ratings yet

- Site Book ShaftwallDocument26 pagesSite Book Shaftwalliulian_xroNo ratings yet

- Montare Pereti Rigips PDFDocument12 pagesMontare Pereti Rigips PDFAndrei GhebuNo ratings yet

- British Gypsum BS Sub ClausesDocument8 pagesBritish Gypsum BS Sub ClausesVincentelli Jean lucNo ratings yet

- WB09 Floor Ceiling and Soffit Systems 10Document84 pagesWB09 Floor Ceiling and Soffit Systems 10Krish DoodnauthNo ratings yet

- GypFloor SILENT sound insulating floorDocument14 pagesGypFloor SILENT sound insulating floorAnna AldokhinaNo ratings yet

- PDS Gyproc CoreBoardDocument2 pagesPDS Gyproc CoreBoardShannon HopkinsNo ratings yet

- Fireline Ceilings DetailsDocument14 pagesFireline Ceilings DetailsconorNo ratings yet

- C016038Document2 pagesC016038JNo ratings yet

- Ibeam CostructionDocument28 pagesIbeam CostructionJaco100% (3)

- PDS Glasroc-F-FIRECASE ENGL 1 PDFDocument3 pagesPDS Glasroc-F-FIRECASE ENGL 1 PDFVlad TirzianNo ratings yet

- GPLamDocument24 pagesGPLammurdicksNo ratings yet

- SB07 Quantity Take Off Details 04Document20 pagesSB07 Quantity Take Off Details 04Praveen SalindaNo ratings yet

- Innovative Interior Solutions Method StatementDocument17 pagesInnovative Interior Solutions Method StatementNonie N50% (2)

- GIB Site Guide 2018 GenInstallDocument26 pagesGIB Site Guide 2018 GenInstallLucas RibeiroNo ratings yet

- GIB Site Guide 2014 PDFDocument114 pagesGIB Site Guide 2014 PDFqinyuan1234No ratings yet

- General Catalogue VOL2Document296 pagesGeneral Catalogue VOL2Harish ManglaNo ratings yet

- Forticrete Gemini 2 Page Leaflet FINAL 31st May 2011Document2 pagesForticrete Gemini 2 Page Leaflet FINAL 31st May 2011Steven_Frost_262No ratings yet

- Egg CrateDocument6 pagesEgg CrateZaw Moe KhineNo ratings yet

- Fire Damper - FDDocument7 pagesFire Damper - FDZaw Moe KhineNo ratings yet

- Site Book Timber JoistDocument16 pagesSite Book Timber JoistarkiNo ratings yet

- PDS Gyproc SoundBlocDocument2 pagesPDS Gyproc SoundBlocneeelNo ratings yet

- 225-08Document2 pages225-08nafishchaudhary422No ratings yet

- Product Data Sheet - Gyproc FirelineDocument3 pagesProduct Data Sheet - Gyproc FirelineSugumarNo ratings yet

- SB07 Decorative Effects 04Document14 pagesSB07 Decorative Effects 04Mohamed AliNo ratings yet

- Gin Rab Board SystemDocument11 pagesGin Rab Board SystemRihab AbukhdairNo ratings yet

- Guy Grip Dead EndDocument8 pagesGuy Grip Dead EndsalgatranNo ratings yet

- PDS Gyproc SoundBloc FDocument2 pagesPDS Gyproc SoundBloc FhartzcarzNo ratings yet

- Gyproc Specification - 1st OptionDocument11 pagesGyproc Specification - 1st Optionabdalla gamalNo ratings yet

- Sectional Press for Strong, Long Lasting SplicesDocument4 pagesSectional Press for Strong, Long Lasting SplicesLuis CarlosNo ratings yet

- Specguide Gypwall 74s55z dlfl15Document2 pagesSpecguide Gypwall 74s55z dlfl15parathasiNo ratings yet

- PDS Gyproc WallBoard DUPLEX PDFDocument3 pagesPDS Gyproc WallBoard DUPLEX PDFRATHEESH P.KNo ratings yet

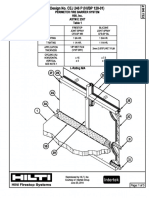

- CEJ114PDocument2 pagesCEJ114PGauri Calderon TrujilloNo ratings yet

- Specguide Casoline Grid 600x600 CasopranoDocument2 pagesSpecguide Casoline Grid 600x600 CasopranoJiawen WeiNo ratings yet

- Fixgrid18 Fixgrid18: Product Sheet Product SheetDocument8 pagesFixgrid18 Fixgrid18: Product Sheet Product SheetCesar Santiago Zambrano DiazNo ratings yet

- Gyproc HabitoDocument3 pagesGyproc HabitoumaNo ratings yet

- PDS Gyproc FireLineDocument2 pagesPDS Gyproc FireLineSugumarNo ratings yet

- Timber Frame Solutions 03Document20 pagesTimber Frame Solutions 03sertackcdgNo ratings yet

- Gyproc HabitoooDocument2 pagesGyproc HabitoooumaNo ratings yet

- Clearly Safe and Strong: The High Performance Glazing That'S Built Tough To Keep You SafeDocument2 pagesClearly Safe and Strong: The High Performance Glazing That'S Built Tough To Keep You Safeapuhapuh_153349No ratings yet

- Us G Shaft and Stair Wall SystemsDocument11 pagesUs G Shaft and Stair Wall SystemsanhnguyenhaiNo ratings yet

- Alcoa Lock Bolt PDFDocument8 pagesAlcoa Lock Bolt PDFMurugan PalanisamyNo ratings yet

- Ezt-Fc 60-06Document3 pagesEzt-Fc 60-06ashenafiiNo ratings yet

- Ceiling SpecDocument8 pagesCeiling Specagrima100% (3)

- Gyproc Regular Ceiling Plasterboard: Technical & Safety DatasheetDocument6 pagesGyproc Regular Ceiling Plasterboard: Technical & Safety DatasheetAbdelmuneimNo ratings yet

- Foam Fillers Tapes Sealants BrochureDocument8 pagesFoam Fillers Tapes Sealants BrochureAppavoo DeelenNo ratings yet

- Stage 1 Shroud For FS7001BDocument1 pageStage 1 Shroud For FS7001Bteedee1No ratings yet

- Hilti Firestop DesignDocument3 pagesHilti Firestop DesignAristo OnanNo ratings yet

- Concealed False Ceiling Installation GuideDocument13 pagesConcealed False Ceiling Installation GuideSury0% (1)

- PDS Gyproc HandiBoard PDFDocument2 pagesPDS Gyproc HandiBoard PDFYudi PermanaNo ratings yet

- PDS Gyproc HandiBoardDocument2 pagesPDS Gyproc HandiBoardyudi permanaNo ratings yet

- Gyproc Habito Board DatasheetDocument6 pagesGyproc Habito Board DatasheetJanna BakeerNo ratings yet

- SarfDocument51 pagesSarfSantosh ThakurNo ratings yet

- NSW Roofing Walling Rainwater and Structural Products BrochureDocument8 pagesNSW Roofing Walling Rainwater and Structural Products BrochurebarouniamineNo ratings yet

- Installation Instructions for Kilargo IFD-CE1 Fire Rated Plasterboard Ceiling SystemDocument1 pageInstallation Instructions for Kilargo IFD-CE1 Fire Rated Plasterboard Ceiling SystemAnonymous 59kfV93pf4No ratings yet

- Kingspan - Trapezoidal Wall KS1000 RW - Installation Guide - Vertically Laid - January 2020 - AU NZ - ENDocument12 pagesKingspan - Trapezoidal Wall KS1000 RW - Installation Guide - Vertically Laid - January 2020 - AU NZ - ENlames1No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- BAtching Plant Capex and Opex GuidlinesDocument12 pagesBAtching Plant Capex and Opex GuidlinesYasir_Wafi_1101No ratings yet

- Ready Mixconcretebatchingplant Businessplan 140407135613 Phpapp01Document52 pagesReady Mixconcretebatchingplant Businessplan 140407135613 Phpapp01Prosenjit RoyNo ratings yet

- Costing of The Production and Delivery of Ready-Mix-ConcreteDocument12 pagesCosting of The Production and Delivery of Ready-Mix-ConcreteYasir_Wafi_1101No ratings yet

- Concrete Plant OperationsDocument28 pagesConcrete Plant OperationsJuned Hamid Khan100% (2)

- Construction Template 16x9Document5 pagesConstruction Template 16x9KekeNo ratings yet

- MGI Reinventing Construction A Route To Higher Productivity Full ReportDocument1 pageMGI Reinventing Construction A Route To Higher Productivity Full ReportYasir_Wafi_1101No ratings yet

- Ready Mixconcretebatchingplant Businessplan 140407135613 Phpapp01Document52 pagesReady Mixconcretebatchingplant Businessplan 140407135613 Phpapp01Prosenjit RoyNo ratings yet

- BAtching Plant Capex and Opex GuidlinesDocument12 pagesBAtching Plant Capex and Opex GuidlinesYasir_Wafi_1101No ratings yet

- Safety Culture Maturity ModelDocument12 pagesSafety Culture Maturity Modelgarozo100% (1)

- Viewpoint Uer GuideDocument12 pagesViewpoint Uer GuideYasir_Wafi_1101No ratings yet

- Safety Culture Maturity ModelDocument12 pagesSafety Culture Maturity Modelgarozo100% (1)

- MGI Reinventing Construction Full ReportDocument168 pagesMGI Reinventing Construction Full ReportVishy Bhatia100% (1)

- Programme LogisticsDocument1 pageProgramme LogisticsYasir_Wafi_1101No ratings yet

- Deliverables Log TemplateDocument9 pagesDeliverables Log TemplateYasir_Wafi_1101No ratings yet

- Resume AsafDocument4 pagesResume AsafYasir_Wafi_1101No ratings yet

- Lessons Learned PDFDocument1 pageLessons Learned PDFYasir_Wafi_1101No ratings yet

- SA 8000 2008 StandardDocument10 pagesSA 8000 2008 StandardAamir MukhtarNo ratings yet

- Cabletrays 2006Document176 pagesCabletrays 2006ABDUL NAZEER ABDU MAJEEDNo ratings yet

- Implementation Plan Rev. 0Document23 pagesImplementation Plan Rev. 0Yasir_Wafi_1101100% (1)

- Preview DW144Document8 pagesPreview DW144mendebour33% (3)

- Copyof SWOTMatrixDocument1 pageCopyof SWOTMatrixYasir_Wafi_1101No ratings yet

- Basic Installation Guide For Lightning Protection StructuralDocument6 pagesBasic Installation Guide For Lightning Protection StructuralYasir_Wafi_1101No ratings yet

- Basic Installation Guide For Lightning Protection StructuralDocument6 pagesBasic Installation Guide For Lightning Protection StructuralYasir_Wafi_1101No ratings yet

- Recommended Erection Instructions For Steel FramesDocument32 pagesRecommended Erection Instructions For Steel FramesYel DGNo ratings yet

- TQM Reporting Group 7 1Document42 pagesTQM Reporting Group 7 1Alvin SantosNo ratings yet

- False CeilingDocument54 pagesFalse CeilingYadhu .msa1750% (2)

- Quiz Questions - Heat Loss and Gain-1Document3 pagesQuiz Questions - Heat Loss and Gain-1PatrickNo ratings yet

- Kuwait Building Code. Draft Contents Scope and Application. 1.1 General. 1.2 Applicability. 2. Administration and EnforcementDocument10 pagesKuwait Building Code. Draft Contents Scope and Application. 1.1 General. 1.2 Applicability. 2. Administration and Enforcementnicolas.lelorrainNo ratings yet

- Knauf EgyptDocument13 pagesKnauf EgyptJeisonRiveraNo ratings yet

- Rondo Steel Stud Drywall Framing Systems Installation GuideDocument6 pagesRondo Steel Stud Drywall Framing Systems Installation GuidesabbirNo ratings yet

- Boq Dec Civil Finishes Boq For QuotationDocument12 pagesBoq Dec Civil Finishes Boq For QuotationHasan JamalNo ratings yet

- GipsDocument6 pagesGipsMila KuzmanovićNo ratings yet

- Doha Clinic-Revised (7 Months)Document4 pagesDoha Clinic-Revised (7 Months)DU A NENo ratings yet

- Improve room acoustics and indoor air qualityDocument4 pagesImprove room acoustics and indoor air qualityMohamedNo ratings yet

- Gypsum Properties & Uses in ConstructionDocument16 pagesGypsum Properties & Uses in ConstructionMeenu Priya100% (1)

- Astm C 645Document6 pagesAstm C 645Camilo OrozcoNo ratings yet

- BRC1E73 Installation ManualDocument68 pagesBRC1E73 Installation ManualMạnhLưuNo ratings yet

- Standard For Elec RoomDocument4 pagesStandard For Elec RoomHo Dac ThanhNo ratings yet

- Carlos New CityDocument3 pagesCarlos New CityJacqueline Ponce PinosNo ratings yet

- Conventional CeilingDocument3 pagesConventional CeilingImadNo ratings yet

- Bailey Platinum Plus Steel Stud Track For Drywall FramingDocument4 pagesBailey Platinum Plus Steel Stud Track For Drywall FramingHenryNo ratings yet

- PLASTERBOARD PRODUCT GUIDEDocument32 pagesPLASTERBOARD PRODUCT GUIDERUPESHKSNo ratings yet

- Ceiling SpecsDocument2 pagesCeiling SpecsKurt Darryl SabelloNo ratings yet

- Work Category Codes: Code DescriptionDocument36 pagesWork Category Codes: Code DescriptionBrian PhillipNo ratings yet

- National Gypsum Plaster Products (Veneer Systems)Document28 pagesNational Gypsum Plaster Products (Veneer Systems)mtim360No ratings yet

- How To Install Ceiling TilesDocument9 pagesHow To Install Ceiling Tilesirawan syadzali gunawanNo ratings yet

- SikaCeram - 100 Basic PDFDocument3 pagesSikaCeram - 100 Basic PDFMoatz HamedNo ratings yet

- WB09 Loadbearing Timber Stud 10Document10 pagesWB09 Loadbearing Timber Stud 10Michael WoodNo ratings yet

- Gypsum Board Systems Manual EngDocument52 pagesGypsum Board Systems Manual EngDGWNo ratings yet

- GYPROC LEEDv4 GenericBrochureDocument40 pagesGYPROC LEEDv4 GenericBrochureKoala Tube88No ratings yet

- Quotation False Ceiling Works To Asam Phase-1 Residential Development at Yas Island, Abu Dhabi - U.a.E.Document36 pagesQuotation False Ceiling Works To Asam Phase-1 Residential Development at Yas Island, Abu Dhabi - U.a.E.Øwięs MØhãmmedNo ratings yet