Professional Documents

Culture Documents

Heavy Hex Nuts

Uploaded by

Ahmadreza AminianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heavy Hex Nuts

Uploaded by

Ahmadreza AminianCopyright:

Available Formats

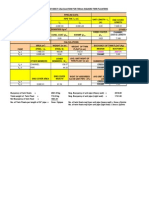

Heavy Hex Nuts - ANSI/ASME B18.2.

Nominal Size

or Basic Major

Thread Diameter

Width

Across Flats

Width

Across Corners

Thickness

Basic

Max

Min

Max

Min

Basic

Max

Min

1/4

.2500

1/2

.500

.488

.577

.556

15/64

.250

.218

5/16

.3125

9/16

.562

.546

.650

.622

19/64

.314

.280

3/8

.3750

11/16

.688

.669

.794

.763

23/64

.377

.341

7/16

.4375

3/4

.750

.728

.866

.830

27/64

.441

.403

1/2

.5000

7/8

.875

.850

1.010

.969

31/64

.504

.464

9/16

.5625

15/16

.938

.909

1.083

1.037

35/64

.568

.526

5/8

.6250

1-1/16

1.062

1.031

1.227

1.175

39/64

.631

.587

3/4

.7500

1-1/4

1.250

1.212

1.443

1.382

47/64

.758

.710

7/8

.8750

1-7/16

1.438

1.394

1.660

1.589

55/64

.885

.833

1.0000

1-5/8

1.325

1.575

1.876

1.796

63/64

1.012

.956

1-1/8

1.1250

1-13/16

1.812

1.756

2.093

2.002

1-7/64

1.139

1.079

1-1/4

1.2500

2.000

1.938

2.309

2.209

1-7/32

1.251

1.187

1-3/8

1.3750

2-3/16

2.188

2.119

2.526

2.416

1-11/32

1.378

1.310

1-1/2

1.5000

2-3/8

2.375

2.300

2.742

2.622

1-15/32

1.505

1.433

1-5/8

1.6250

2-9/16

2.562

2.481

2.959

2.828

1-19/32

1.632

1.556

1-3/4

1.7500

2-3/4

2.750

2.662

3.175

3.035

1-23/32

1.759

1.679

2.0000

3-1/8

3.125

3.025

3.608

3.449

1-31/32

2.013

1.925

2-1/4

2.2500

3-1/2

3.500

3.388

4.041

3.862

2-13/64

2.251

2.155

2-1/2

2.5000

3-7/8

3.875

3.750

4.474

4.275

2-29/64

2.505

2.401

2-3/4

2.7500

4-1/4

4.250

4.112

4.907

4.688

2-45/64

2.759

2.647

3.0000

4-5/8

4.625

4.475

5.340

5.102

2-61/64

3.013

2.893

3-1/4

3.2500

5.000

4.838

5.774

5.515

3-3/16

3.252

3.124

3-1/2

3.5000

5-3/8

5.375

5.200

6.207

5.928

3-7/16

3.506

3.370

3-3/4

3.7500

5-3/4

5.750

5.562

6.640

6.341

3-11/16

3.670

3.616

4.0000

6-1/8

6.125

5.925

7.073

6.755

3-15/16

4.014

3.862

Page 1 of 3

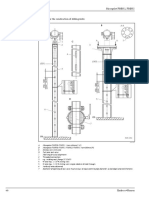

Heavy Hex Nuts - ANSI/ASME B18.2.2

Steel Grades A, C, 2H, DH, DH3 Heavy Hex Nut Properties

Description

A six sided internally threaded fastener which is both thicker and wider than a same-sized

finished nut. Nuts size 7/16 and smaller shall be double chamfered. Larger sizes are either

double chamfered or chamfered on top with a washer faced bearing surface.

Applications

&

Advantages

The strongest of all comparably graded nuts because of its greater length of thread

engegement and greater resistance to dilation (widening or stretching). Grade-A nuts are used

with low carbon heavy hex bolts. Grade-C nuts are recommended for use with A-325

structural bolts. Grade-2H nuts are recommended for use with bolts in high-pressure and hightemperature applications. Grade-DH nuts are recommended for use with A-490, Type-1

structural bolts. Grade-DH3 nuts are for use with A-490, Type-3 structural bolts.

Material

Nuts are to be made from a steel that conforms to the following chemical composition

requirements (heat analysis):

Grades-A and C: Carbon: .55% max Phosphorus: .12% max Sulfur: .023% max

Grade-2H: Carbon: .40% min Manganese: 1.00% max Phosphorus: .12% max Sulfur:

.05% max Silicon: .40% max

Grade-DH: Carbon: .20-.55% Manganese: .60% min Phosphorus: .04% max Sulfur: .05%

max

Grade-DH3: Carbon: .02-.53% Manganese: .40% min Phosphorus: .046% max Sulfur:

.05% max Copper: .20% min Chromium: .45% min (Either Nickel: .20% min or

Molybdenum: 15% min may be used).

Heat

Treatment

Grade-2H" Shall be heat treated by quenching in a liquid medium from a temperature above

the transformation temperature and tempered at a temperature of at least 850F.

Grades- C, DH and DH3: Shall be heat treated by quenching in a liquid medium from a

temperature above the transformation temperature and tempered at a temperature of at least

800F.

Core

Hardness

Grade-A: Rockwell B68 - C32

Grade-C: Rockwell B78 - C38

Grades-2H, DH, and DH3: Rockwell C24 - C38

Proof Load

Grade-A: Course: 100,000 psi Fine: 90,000 psi

Grade-C: 144,000 psi

Grade-2H: 150,000 psi

Grades-DH and DH3: 175,000 psi

Plating

See plating page for plating information.

Page 2 of 3

Heavy Hex Nuts - ANSI/ASME B18.2.2

Product standards require all grade-marked nuts 1/4 inch and larger to have a raised or depressed grade-marking

and insignia identifying its manufacturer. The X in the images above represent one location where suck marking

may appear.

Stainless Steel, 18-8 and 316, Nut Properties

Description

A six sided internally threaded fastener which is both thicker and wider than a same-sized

finished hex nut, made of 18-8 stainless steel. Nuts size 7/16 and smaller shall be double

chamfered. Larger sizes are either double chamfered or chamfered on top with a washer

faced bearing surface.

Applications

&

Advantages

The strongest of all the 18-8 nuts because of its greater thread length and greater resistance

to dilation (widening or stretching).

Material

Nuts shall be made from one of the following austenitic stainless alloys: 303, 302SE, 304

or XM7, all of which are characterized as having a chromium content of 18% and a nickel

content of 8%.

Heat

Treatment

The austenitic alloys develop their strength through work hardening during the

manufacturing process, as seen from their hardness properties below. The only hjeat

treatment normally available on austenitic stainless steel alloys is annealing, which is done

at approximately 1900F to a dead soft condition and is not normally thermally reversible.

Hardness

1/4 thru 5/8: Rockwell B95 - C32 3/4 thru 1 inch: Rockwell B80 - C32

Proof Load

1/4 thru 5/8: 100,000 psi Fine Thread: 85,000 psi

Page 3 of 3

You might also like

- Febolt: Hexagon Covernut Type "Febolt"Document1 pageFebolt: Hexagon Covernut Type "Febolt"Tuntun TatNo ratings yet

- Metric Fine Screw Threads Taper Pipe ThreadsDocument1 pageMetric Fine Screw Threads Taper Pipe Threadsmanuelq9100% (1)

- Structural Equivalency SheetDocument73 pagesStructural Equivalency Sheetboim1234No ratings yet

- Copia de Unit Converter Ver1Document15 pagesCopia de Unit Converter Ver1Brian TuckerNo ratings yet

- Input Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)Document12 pagesInput Parameter Valve and Flange: Fluid Density (KG/M) Insulation Density (KG/M)ibmsherNo ratings yet

- Aspen HX Design ReportDocument78 pagesAspen HX Design ReportberylqzNo ratings yet

- Flange DimensionsDocument30 pagesFlange DimensionshibhavuNo ratings yet

- Asme Pipe Wall ThicknessDocument3 pagesAsme Pipe Wall ThicknessYoke ShuNo ratings yet

- Pipe SpecificationsDocument5 pagesPipe Specificationsbabar.muetNo ratings yet

- 07 Piping BOQDocument54 pages07 Piping BOQHRK65No ratings yet

- AB 520 Finite Element Analysis FEA Requirements PDFDocument4 pagesAB 520 Finite Element Analysis FEA Requirements PDFbello imamNo ratings yet

- Plaster Calculation V6Document34 pagesPlaster Calculation V6bedianchoiNo ratings yet

- PIPE TABLE WIZARD Input Parameters and Component DimensionsDocument2 pagesPIPE TABLE WIZARD Input Parameters and Component DimensionsBangto YibsipNo ratings yet

- Autocad Tip - Line, Spline or Polyline? Creating Linework: SurveyDocument3 pagesAutocad Tip - Line, Spline or Polyline? Creating Linework: SurveyAnonymous dh6DITNo ratings yet

- Thk. S.F. K.R.: Dish - Dish 2100Document3 pagesThk. S.F. K.R.: Dish - Dish 2100jayvant jadhavarNo ratings yet

- Socket Weld X Threaded CouplingDocument1 pageSocket Weld X Threaded Couplingmatthewwalls4386No ratings yet

- 4140 Q&TDocument36 pages4140 Q&TAnderson MarimNo ratings yet

- ANSI B16.5 Slip On Flange, SORF Flange, Class 150LBS, 300LBS, 600LBS - Jinan Hyupshin Flanges Co., LTD - Flanges Manufacturer, Flanges ExporterDocument6 pagesANSI B16.5 Slip On Flange, SORF Flange, Class 150LBS, 300LBS, 600LBS - Jinan Hyupshin Flanges Co., LTD - Flanges Manufacturer, Flanges Exporterkunal shahNo ratings yet

- Aston Fittings BrochureDocument34 pagesAston Fittings BrochurefahedNo ratings yet

- Asme Ix - Welder Id Rev.2Document5 pagesAsme Ix - Welder Id Rev.2Joseph Peter100% (1)

- Global Marketing For Tube & PipeDocument4 pagesGlobal Marketing For Tube & PipedsyashankaNo ratings yet

- K1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzleDocument1 pageK1A&B, K2 3, K8: Type of Element Connected To The Shell: NozzlewhngomjNo ratings yet

- Weight CalculatorDocument2 pagesWeight CalculatorenjoygurujiNo ratings yet

- Lifting Eye Bolts (Rotating) : Technical InformationsDocument3 pagesLifting Eye Bolts (Rotating) : Technical InformationsBruno Thiago DamascenoNo ratings yet

- Tank Calculation Sheet: I. Design Parameters: TK-9291-01 Demulsifier Injection TankDocument1 pageTank Calculation Sheet: I. Design Parameters: TK-9291-01 Demulsifier Injection TanknamasralNo ratings yet

- American Standard Steel Pipe Sizes and Wall ThicknessesDocument3 pagesAmerican Standard Steel Pipe Sizes and Wall ThicknessesFelipa ShanNo ratings yet

- Ring Type Joint Gaskets GuideDocument8 pagesRing Type Joint Gaskets GuideTiffany DacinoNo ratings yet

- API Flange Bolting Data ChartDocument6 pagesAPI Flange Bolting Data ChartkswaghmareNo ratings yet

- Fitter ToolsDocument7 pagesFitter ToolsSainadhReddy100% (1)

- Profile WEIGHT calculation: Q.ty (M) 규 격 total weight 품 명 unit weightDocument55 pagesProfile WEIGHT calculation: Q.ty (M) 규 격 total weight 품 명 unit weightM Zahran KhairyNo ratings yet

- Astm A249 PDFDocument5 pagesAstm A249 PDFgaminNo ratings yet

- Saddle Angle - Formula K - 12.28.20Document2 pagesSaddle Angle - Formula K - 12.28.20Rey FiedacanNo ratings yet

- Pipe Specification and Material ListDocument9 pagesPipe Specification and Material Listjigar_mancityNo ratings yet

- Pipe Dimensions Chart with Nominal Sizes and SchedulesDocument2 pagesPipe Dimensions Chart with Nominal Sizes and SchedulesAtul JainNo ratings yet

- Pipe Size and Trim Angle CalculatorDocument4 pagesPipe Size and Trim Angle CalculatorThennarasu PanneerselvamNo ratings yet

- FRP RF CalcDocument1 pageFRP RF CalcmukeshNo ratings yet

- Calculation Sheet For 700mm SQ Metal FloatersDocument3 pagesCalculation Sheet For 700mm SQ Metal FloatersAdagharaNo ratings yet

- Preliminary Conical StrainersDocument1 pagePreliminary Conical StrainersrodolfostiNo ratings yet

- Bolt torque sequences and specifications for flangesDocument2 pagesBolt torque sequences and specifications for flangeswentropremNo ratings yet

- 3.3development and Scope of Asme CodeDocument1 page3.3development and Scope of Asme CodeArunraj PoikayilNo ratings yet

- NPT Thread Chart - NPT & NPS Fittings Dimensions & SizesDocument2 pagesNPT Thread Chart - NPT & NPS Fittings Dimensions & SizesMarc EdwardsNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Perfiles AceroDocument156 pagesPerfiles AceroJuan CastilloNo ratings yet

- Stillwell Pipe ArrangementDocument1 pageStillwell Pipe ArrangementVishalDhimanNo ratings yet

- Pipe Weight Formulas & TablesDocument12 pagesPipe Weight Formulas & TablesuzairmetallurgistNo ratings yet

- ASME VIII-1 pressure vessel design code and operating conditionsDocument1 pageASME VIII-1 pressure vessel design code and operating conditionsNomi KhanNo ratings yet

- Bolt and Nut StandardDocument1 pageBolt and Nut Standardcrys suryo prayogoNo ratings yet

- BEL - 6D Through Conduit GateDocument2 pagesBEL - 6D Through Conduit Gateasoka.pwNo ratings yet

- Mar Win SteamDocument33 pagesMar Win SteamChristopher RequintoNo ratings yet

- FlowTek S20Document2 pagesFlowTek S20Gabriel Andrés Barcha AnguloNo ratings yet

- Studbolt Size ChartDocument3 pagesStudbolt Size ChartRenalyn TorioNo ratings yet

- Pipe Schedule Reference ChartDocument10 pagesPipe Schedule Reference ChartRamadossK100% (1)

- BS 46 :1958 Parallel Keys and Keyway Dimensions StandardDocument3 pagesBS 46 :1958 Parallel Keys and Keyway Dimensions StandardAnatta RahardjoNo ratings yet

- S# Item Qty Unit Index Plant - Sloc Shortfall Remarks Availablt QtyDocument1 pageS# Item Qty Unit Index Plant - Sloc Shortfall Remarks Availablt QtyAtif HusaynNo ratings yet

- Engineering All in OneDocument245 pagesEngineering All in OneozchrisNo ratings yet

- 1 Beam Fails Ub305x165x54Document4 pages1 Beam Fails Ub305x165x54Elencheliyan PandeeyanNo ratings yet

- Bolting Information Pertaining To ASTM A193Document25 pagesBolting Information Pertaining To ASTM A193dirtylsu100% (2)

- Stud Bolt SpecificationDocument8 pagesStud Bolt SpecificationsantoshblonkarNo ratings yet

- Mechanical Properties Inch Fasteners ThruwayDocument4 pagesMechanical Properties Inch Fasteners Thruwayapply19842371No ratings yet

- Improving Chain LubricationDocument5 pagesImproving Chain LubricationAhmadreza AminianNo ratings yet

- Advice For Chain Lubrication PDFDocument2 pagesAdvice For Chain Lubrication PDFAhmadreza AminianNo ratings yet

- Improving Oven Chain LubricationDocument6 pagesImproving Oven Chain LubricationAhmadreza AminianNo ratings yet

- Professional Resume (English) PDFDocument5 pagesProfessional Resume (English) PDFAhmadreza AminianNo ratings yet

- Professional Resume (English) PDFDocument5 pagesProfessional Resume (English) PDFAhmadreza AminianNo ratings yet

- Lubrication of High-Temperature ChainsDocument2 pagesLubrication of High-Temperature ChainsAhmadreza AminianNo ratings yet

- 01-Chains For Drives and Conveyors - Lube 'Em To LastDocument8 pages01-Chains For Drives and Conveyors - Lube 'Em To LastAhmadreza AminianNo ratings yet

- CV2 PDFDocument5 pagesCV2 PDFAhmadreza AminianNo ratings yet

- Standard Wire RopeDocument5 pagesStandard Wire RopeAhmadreza AminianNo ratings yet

- English Verb That Useful in The TofelDocument5 pagesEnglish Verb That Useful in The TofelAhmadreza AminianNo ratings yet

- CV2 PDFDocument5 pagesCV2 PDFAhmadreza AminianNo ratings yet

- Document 1Document5 pagesDocument 1Ahmadreza AminianNo ratings yet

- Steel GradesDocument7 pagesSteel GradesAhmadreza AminianNo ratings yet

- English Verb That Useful in The TofelDocument5 pagesEnglish Verb That Useful in The TofelAhmadreza AminianNo ratings yet

- International Steel Grade EquivalencyDocument6 pagesInternational Steel Grade EquivalencyAhmadreza AminianNo ratings yet

- FEM Method in 2D Heat Conduction PDFDocument52 pagesFEM Method in 2D Heat Conduction PDFAhmadreza AminianNo ratings yet

- CMC Zaw I Er Cie Product PortfolioDocument19 pagesCMC Zaw I Er Cie Product PortfolioAhmadreza AminianNo ratings yet

- Threading SystemDocument3 pagesThreading SystemAhmadreza AminianNo ratings yet

- Asphalt Concrete and Asphalt Binder BehaviorsDocument46 pagesAsphalt Concrete and Asphalt Binder BehaviorsAhmadreza AminianNo ratings yet

- Flame Types & DynamicsDocument15 pagesFlame Types & DynamicsAhmadreza AminianNo ratings yet

- Heat Transfer Model and Numerical Simulation For Microwave Hot In-Place Recycling of Asphalt Pavements PDFDocument6 pagesHeat Transfer Model and Numerical Simulation For Microwave Hot In-Place Recycling of Asphalt Pavements PDFAhmadreza AminianNo ratings yet

- Principles of Bituminous Pavement Design and The Recent TrendsDocument6 pagesPrinciples of Bituminous Pavement Design and The Recent TrendsAhmadreza AminianNo ratings yet

- Computational Heat Transfer, VOL1 Mathematical Modelling - 1995 PDFDocument417 pagesComputational Heat Transfer, VOL1 Mathematical Modelling - 1995 PDFAhmadreza Aminian100% (9)

- Innovative Hot In-Place Recycling of Hot-Mix Asphalt Pavement in Mississippi PDFDocument7 pagesInnovative Hot In-Place Recycling of Hot-Mix Asphalt Pavement in Mississippi PDFAhmadreza AminianNo ratings yet

- CFD Graphical Interface in MATLAB PDFDocument7 pagesCFD Graphical Interface in MATLAB PDFAhmadreza AminianNo ratings yet

- 1st Project-2D HT in SQR Plate With MATLAB PDFDocument11 pages1st Project-2D HT in SQR Plate With MATLAB PDFAhmadreza AminianNo ratings yet

- Sarfasle EnergyDocument2 pagesSarfasle EnergyAhmadreza AminianNo ratings yet

- Principles of Bituminous Pavement Design and The Recent TrendsDocument6 pagesPrinciples of Bituminous Pavement Design and The Recent TrendsAhmadreza AminianNo ratings yet

- Principles of Bituminous Pavement Design and The Recent TrendsDocument6 pagesPrinciples of Bituminous Pavement Design and The Recent TrendsAhmadreza AminianNo ratings yet

- NOVI KATALOG GASOVA MESSER - EnG Inert Gas Welding Indert Gas Welding Selected Reference TablesDocument6 pagesNOVI KATALOG GASOVA MESSER - EnG Inert Gas Welding Indert Gas Welding Selected Reference TablesIvan DulicNo ratings yet

- MalleabilityDocument10 pagesMalleabilityChristine Jane RodriguezNo ratings yet

- Preservation by NitrogenDocument3 pagesPreservation by NitrogenHesham badawy50% (2)

- CH No. 6 Fundamentals of WeldingDocument42 pagesCH No. 6 Fundamentals of WeldingAbid HussainNo ratings yet

- Prefabricated Steel Supports for PipingDocument9 pagesPrefabricated Steel Supports for PipingMuhammed SulfeekNo ratings yet

- Report BM2 Water SystemDocument16 pagesReport BM2 Water Systemmalekabdul9413No ratings yet

- Steel Techology - Slag Removal and Manipulator Tools NewsletterDocument92 pagesSteel Techology - Slag Removal and Manipulator Tools NewsletterlouisgatewayNo ratings yet

- Sa 455Document4 pagesSa 455Widya widya0% (1)

- Welding Procedure Specification (WPS)Document30 pagesWelding Procedure Specification (WPS)ganathaNo ratings yet

- Ch-27.7 Alloying Element of Steel and Alloy SteelDocument50 pagesCh-27.7 Alloying Element of Steel and Alloy SteelJyotilal SahuNo ratings yet

- © Boardworks LTD 2006 1 of 49Document31 pages© Boardworks LTD 2006 1 of 49Jason Dequin VillarosaNo ratings yet

- Weld Details For QsDocument1 pageWeld Details For QsSam JoseNo ratings yet

- Iron Ore Railway Movement 02 07 2018Document89 pagesIron Ore Railway Movement 02 07 2018Bhavin SagarNo ratings yet

- Brazil: Geography, Population, Agriculture, Minerals, Energy, Industries and TradeDocument4 pagesBrazil: Geography, Population, Agriculture, Minerals, Energy, Industries and TradeXain RanaNo ratings yet

- Questions For CSWIP Question Answers Solved Past Papers Cswip 3 1Document87 pagesQuestions For CSWIP Question Answers Solved Past Papers Cswip 3 1Makhfud Edy80% (5)

- Delhi Parliament Library PDFDocument4 pagesDelhi Parliament Library PDFHimanshu SainiNo ratings yet

- TIG Welding Process GuideDocument20 pagesTIG Welding Process GuideEnache DaniNo ratings yet

- DN 32 Connection ArchiDocument40 pagesDN 32 Connection ArchiAjit SinghNo ratings yet

- SOW Fabrikasi C-335-01 - 19.116.1Document1 pageSOW Fabrikasi C-335-01 - 19.116.1AlfanNo ratings yet

- Fisher ES and EAS Sliding-Stem Control ValvesDocument32 pagesFisher ES and EAS Sliding-Stem Control Valvessugeng wahyudiNo ratings yet

- Cuzr0,15: Uns:C15100 En:Cw120CDocument17 pagesCuzr0,15: Uns:C15100 En:Cw120CNut AssanaiNo ratings yet

- Corrosion Under Insulation On Offshore FacilitiesDocument165 pagesCorrosion Under Insulation On Offshore Facilitiesengr_ahmednassar100% (2)

- Werkstoffe E PDFDocument12 pagesWerkstoffe E PDFirajfarji2481No ratings yet

- Hilti Kiwi BoltsDocument31 pagesHilti Kiwi BoltsKiranNo ratings yet

- WPRK Pack Preparation PDFDocument42 pagesWPRK Pack Preparation PDFYusufNo ratings yet

- Development of High Strength Hot Rolled Coils With Enhanced Formability PropertyDocument5 pagesDevelopment of High Strength Hot Rolled Coils With Enhanced Formability PropertyparmindersinNo ratings yet

- Density of SteelDocument4 pagesDensity of SteelMongia MoghiNo ratings yet

- Calcul Des Structures Acier: EN 1993-1:2005/AC:2009, Eurocode 3: Design of Steel StructuresDocument2 pagesCalcul Des Structures Acier: EN 1993-1:2005/AC:2009, Eurocode 3: Design of Steel StructuresMouhaNo ratings yet

- Duplex 2304Document7 pagesDuplex 2304ivanoliveira3261No ratings yet

- Dresser 3 Way ValveDocument24 pagesDresser 3 Way ValveAmjath Pallas100% (1)