Professional Documents

Culture Documents

MS 0040

Uploaded by

sujaraghupsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS 0040

Uploaded by

sujaraghupsCopyright:

Available Formats

Click Here & Upgrade

PDF Complete

Documents Page 1 of 4

Expanded Features Unlimited Pages

File No. EL/7.1.31 w.e.f. March 2007

MODIFICATION SHETT NO. RDSO/PE/MS/AC/0040-2007 (REV.0)

GOVERNMENT OF INDIA MINISTRY OF RAILWAYS

RESEARCH DESIGNS AND STANDARDS ORGANISATION MANAK NAGAR, LUCKNOW 226 011

TITLE

TO PREVENT FIRE HAZARD IN CANVAS DUCT IN UNDER SLUNG TYPE AC COACHES

S. No.

Date of amendment Amendment No.

Page No.

Reasons for amendment

APPROVED BY

ED (PS & EMU)

Prepared by

Checked by

Click Here & Upgrade

PDF Complete

Documents Page 2 of 4

Expanded Features Unlimited Pages

File No. EL/7.1.31 w.e.f. March 2007

MODIFICATION SHETT NO. RDSO/PE/MS/AC/0040-2007 (REV.0)

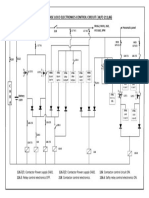

MODIFICATION SHETT NO. RDSO/PE/MS/AC/0040-2007 (REV.0) TO PREVENT FIRE HAZARD IN CANVAS DUCT IN THE UNDER SLUNG TYPE AC COACHES 1.0 2.0 TITLE: To prevent fire hazard in canvas duct in the under slung type AC coaches OBJECT: Some of the earlier design of under slung type air-conditioned coaches have a forced draft arrangement of evaporator/heater, blower unit. . As per this arrangement, the heater coil is placed near the cotton canvas duct, which can be a fire hazard during service. However, some other design of underslung type AC coaches have suck through arrangement which do not have such problem as the possibility of heater element coming in contact with canvas duct totally avoided (Figure). The above was discussed during 21st MSG (TL&AC) meeting and to over come this shortcoming in the design, it was decided that modification sheet may be issured by RDSO for conversion of forced draft arrangement to the suck through arrangement of evaporator/heater & blower unit. 3.0 REFERENCE: i) 4. ICF specification no. ICF/ELEC/846 with CS-4

MATERIAL REQUIRED a) b) c) d) e) f) g) Copper pipe as per IS: 10773,16 mm dia (OD) & 41 mm dia (OD) for refrigerant liquid a suction line as required Canvas duct variety 2 of IS:1424 (latest) with water proof and fire retardant properties. DC motors 130V dc, 0.75 HP, 1500 rpm -2 nos. One each with LHS & RHS extended shaft Heat exchanger for evaporator (R12) & Evaporator coil assembly as per ICF drg. No. ICF/SK.7-2-123 & ICF/SK.7-3-214 respectively. Heater unit assembly & Heater element as per ICF drg. No. ICF/SK.7-2120 & MG/WGSCWAC.7-3-024 respectively. Blower housing assembly & Frame for blower housing as per ICF drg. No. ICF/SK.7-3-205 & ICF/SK.7-3-206 respectively. Other accessories mentioned in ICF specification No. ICF/Elec/846 with CS4.

5.

WORK TO BE DONE : Checked by

Prepared by

Click Here & Upgrade

PDF Complete

Documents Page 3 of 4

1. 2. 3.

Expanded Features Unlimited Pages

File No. EL/7.1.31 w.e.f. March 2007

MODIFICATION SHETT NO. RDSO/PE/MS/AC/0040-2007 (REV.0)

Evacuate the system. Disconnect the power supply from motor. Disconnect refrigerant pipe from evaporator unit (liquid & suction line) and cap them to avoid ingress of moisture/dust in the refrigerant pipeline. Remove canvas duct from coach side as well as from blower & evaporator assembly. Remove blower & evaporator assembly from its base channel. The new evaporator/heater & blower assemblies, refrigerant pipe and other sub-assemblies shall be as per drawing/ICF specification mentioned in para 4 above. Mount new blower and evaporator assembly as shown in enclosed figure after making mounting holes on the base channel. If required, extra base channels may be welded on the coach structure, as per the requirement of the new evaporator/heater & blower unit. Braze the refrigerant pipes as per the requirement on suction and liquid line and connect with evaporator coil. Make canvas duct connection between coach and blower & evaporator coil. Dehydrate the system as per RDSO SMI No. RDSO/SMI/AC/5. Check for any leakage in the system and rectify the same. Charge refrigerant in the system and make sure correct quantity of the same. As per SMI No. AC/SMI/7. Check working of plant for its proper cooling/heating as per the procedure.

4. 5. 6.

7.

8.

9. 10.

11.

12. 13. 6

AGENCY FOR MODIFICATION Workshop staff during POH 7. DISTRIBUTION As per enclosed list.

Prepared by

Checked by

Click Here & Upgrade

PDF Complete

Documents Page 4 of 4

DISTRIBUTION

Expanded Features Unlimited Pages

File No. EL/7.1.31 w.e.f. March 2007

MODIFICATION SHETT NO. RDSO/PE/MS/AC/0040-2007 (REV.0)

Chief Electrical Engineer 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Eastern Railway, Fairlie Place, Kolkata - 700 001 Northern Railway, Baroda House, New Delhi-110 001 Central Railway, Mumbai CST 400 001 Northeast Frontier Railway, Maligaon, Guwahati -781 001 North Eastern Railway, Gorakhpur -273 001 South Central Railway, Secunderabad 500 371 Southern Railway, Park Town, Chennai 600 003 South Eastern Railway, Kolkata 700 043 Western Railway, Churchgate, Mumbai 400 020 North Central Railway, Hasting Road, Allahabad-211 001 West Central Railway, Jabalpur-482 001 East Central Railway ,Hajipur-844 101 North Western Railway , Jaipur-302 006 South Western Railway, Hubli-560 023 South East Central Railway, Bilaspur 495 004 East Coast Railway, Bhuvneshwar Orrisa-751 016 Konkan Railway, Belapur Bhawan, Sector-11, Belapur, Mumbai- 400 614

Prepared by

Checked by

You might also like

- ce1Document1 pagece1sujaraghupsNo ratings yet

- 5_6057415857582114918Document15 pages5_6057415857582114918sujaraghupsNo ratings yet

- Metallurgical ChemicalDocument10 pagesMetallurgical ChemicalsujaraghupsNo ratings yet

- TH HD Chennai 17~03~2024Document20 pagesTH HD Chennai 17~03~2024sujaraghupsNo ratings yet

- CONNECTNEXT USER GUIDE Nexon Touchscreen Infotainment ManualDocument153 pagesCONNECTNEXT USER GUIDE Nexon Touchscreen Infotainment ManualFaraz MirzaNo ratings yet

- Risk Reduction Guide0.2Document1 pageRisk Reduction Guide0.2sujaraghupsNo ratings yet

- Ba Cap MeterDocument3 pagesBa Cap MetersujaraghupsNo ratings yet

- cell 1 5 vDocument2 pagescell 1 5 vsujaraghupsNo ratings yet

- 4065936Document2 pages4065936sujaraghupsNo ratings yet

- DewaltDocument2 pagesDewaltsujaraghupsNo ratings yet

- LUG PO LGDDocument3 pagesLUG PO LGDsujaraghupsNo ratings yet

- New SpecDocument18 pagesNew SpecsujaraghupsNo ratings yet

- Upgrading Railway Bridge DesignDocument25 pagesUpgrading Railway Bridge DesignsujaraghupsNo ratings yet

- BRFACH16GB 11 2017 I GB Klauke Technical ArticleDocument44 pagesBRFACH16GB 11 2017 I GB Klauke Technical ArticlesujaraghupsNo ratings yet

- CONNECTNEXT USER GUIDE Nexon Touchscreen Infotainment ManualDocument153 pagesCONNECTNEXT USER GUIDE Nexon Touchscreen Infotainment ManualFaraz MirzaNo ratings yet

- Limits Fits VIIISeDocument18 pagesLimits Fits VIIISecprabhakaranNo ratings yet

- SPECIFICATION FOR 6531 KVA TFP Steel TankDocument17 pagesSPECIFICATION FOR 6531 KVA TFP Steel TanksujaraghupsNo ratings yet

- Brbestofr17gb 03 2017 I GBDocument2 pagesBrbestofr17gb 03 2017 I GBsujaraghupsNo ratings yet

- General FAQDocument2 pagesGeneral FAQsujaraghupsNo ratings yet

- 5 219677166189674788Document10 pages5 219677166189674788sujaraghupsNo ratings yet

- Rajbhasha ActDocument3 pagesRajbhasha Actsahilsinha68100% (1)

- Handheld Thermal Imaging Camera Model - TE-02Document9 pagesHandheld Thermal Imaging Camera Model - TE-02sujaraghupsNo ratings yet

- Act With AmendmentDocument134 pagesAct With AmendmentSowjanya BondaNo ratings yet

- MS - 304 - Dated 09.02.2001Document5 pagesMS - 304 - Dated 09.02.2001sujaraghupsNo ratings yet

- GreenCo Book Abridged Version 2017Document28 pagesGreenCo Book Abridged Version 2017sujaraghupsNo ratings yet

- DC DCDocument1 pageDC DCsujaraghupsNo ratings yet

- Duties CEEDocument1 pageDuties CEEsujaraghupsNo ratings yet

- Tolerances, Limits, Fits and Surface FinishDocument6 pagesTolerances, Limits, Fits and Surface FinishRap itttt100% (5)

- Tolerances, Limits, Fits and Surface FinishDocument6 pagesTolerances, Limits, Fits and Surface FinishRap itttt100% (5)

- Roller Bearing Lubrication PDFDocument70 pagesRoller Bearing Lubrication PDFsujaraghupsNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Low Temperature RefrigerationDocument9 pagesLow Temperature Refrigerationguadalupe_cortes_21100% (2)

- Cogen LiteratureDocument6 pagesCogen LiteratureDennis RamsumairNo ratings yet

- Vizag Steel Plant ReportDocument54 pagesVizag Steel Plant ReportKalyan HalderNo ratings yet

- Automobile Air Conditioning SystemDocument8 pagesAutomobile Air Conditioning SystemAyyan Gaonkhadkar100% (1)

- IDPlus 961-974 SMPS Instruction Sheet 9IS54437 en Rel.0316Document28 pagesIDPlus 961-974 SMPS Instruction Sheet 9IS54437 en Rel.0316Meji arjuansyahNo ratings yet

- Chapter GNDocument25 pagesChapter GNBayu D-scyzorNo ratings yet

- 2000MGT1Document305 pages2000MGT1InnerXNo ratings yet

- Process Development For Separation of Lignin From OrganoCat LignocelluloseDocument14 pagesProcess Development For Separation of Lignin From OrganoCat LignocelluloseYudanis TaqwinNo ratings yet

- Controller For Temperature Control: - AK-CC 210Document24 pagesController For Temperature Control: - AK-CC 210Vasti Diaz AguilarNo ratings yet

- UHDE - Nitrate Fertilizers PDFDocument24 pagesUHDE - Nitrate Fertilizers PDFvzgscribdNo ratings yet

- Secador Por Atomización para Deshidratar Leche en PolvoDocument14 pagesSecador Por Atomización para Deshidratar Leche en PolvoValeria AlarcónNo ratings yet

- Pre - Board Examination in Power and Industrial Plant EngineeringDocument5 pagesPre - Board Examination in Power and Industrial Plant Engineeringeuphris starfell100% (1)

- Extraction of Tocotrienols From Palm Fatty Acid DistillatesDocument10 pagesExtraction of Tocotrienols From Palm Fatty Acid DistillatesArguri ToNo ratings yet

- Refrigeration Lab ReportDocument27 pagesRefrigeration Lab ReportLeejat Pradhan78% (27)

- YD Dual Centrifugal Compressor Liquid Chillers: Design Level BDocument56 pagesYD Dual Centrifugal Compressor Liquid Chillers: Design Level BSharon Lambert100% (1)

- Lorentzen1994 PDFDocument10 pagesLorentzen1994 PDFSURAJ NAGNo ratings yet

- Refrigeration With Hot and Cooled BoxDocument69 pagesRefrigeration With Hot and Cooled Boxkris_soneNo ratings yet

- Automobile Chassis Short Notes Unit 1Document56 pagesAutomobile Chassis Short Notes Unit 1Ranjit Rajendran100% (5)

- Specifications and Troubleshooting Guide for Automotive Air Conditioning SystemDocument78 pagesSpecifications and Troubleshooting Guide for Automotive Air Conditioning SystemRufino De GuzmanNo ratings yet

- MVS-SVE Chapter18 PDFDocument78 pagesMVS-SVE Chapter18 PDFDarwin MacalaladNo ratings yet

- Design and Operation of EvaporatorsDocument128 pagesDesign and Operation of EvaporatorsAJITHNo ratings yet

- I.E.S-(Conv.)-2000 Air Conditioning Design CalculationsDocument6 pagesI.E.S-(Conv.)-2000 Air Conditioning Design CalculationsYogesh DanekarNo ratings yet

- Recover More: Extract More Profit From Every Kernel With Advanced Corn Oil Recovery Technology From BuckmanDocument2 pagesRecover More: Extract More Profit From Every Kernel With Advanced Corn Oil Recovery Technology From BuckmanBruno SeixasNo ratings yet

- Catalogo IbtDocument28 pagesCatalogo IbtGuizza GuizzaaNo ratings yet

- Lesson II Simple Vapor Compn SystemDocument19 pagesLesson II Simple Vapor Compn SystemNELMIDA AIRISH JOY N.No ratings yet

- M.Sc. MFT II 2009-2011Document21 pagesM.Sc. MFT II 2009-2011RahulNo ratings yet

- Waste Heat Recovery Methods and Technologies ReviewDocument11 pagesWaste Heat Recovery Methods and Technologies ReviewChem.Engg100% (2)

- Chem ENgg Board Exam QuestionsDocument42 pagesChem ENgg Board Exam QuestionsAllyana Marie TiemsimNo ratings yet

- Ms 20832 PDFDocument114 pagesMs 20832 PDFNaqqash SajidNo ratings yet

- Chillers TraneDocument52 pagesChillers TranesnakelostNo ratings yet