Professional Documents

Culture Documents

Periodic Maintenance Check List

Uploaded by

Mohan KCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Periodic Maintenance Check List

Uploaded by

Mohan KCopyright:

Available Formats

BRD/PTD

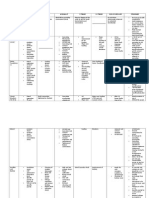

CHECK LIST FOR PERIODIC HEALTH CHECK-UP OF MV PANELS & VCB

Client Location : : Siemens WO/SAP no: Rating: No. VCB Of Sr Operation No. : MV PANELS &VCB Sr No. PURPOSE METHOD OF CHECKING Visually By clean cotton cloth With Special ISOPLAX TOPAZ Grease With Special RITZOL Oil By manually spring charging method By simulating test & service position by Breaker manual ON/OFF operation by Breaker manual ON/OFF operation by Spring charging operation By Double bit key By Double bit key With Resistance measurement meter With Resistance measurement meter as per method explained in O&M manual as per method explained in O&M manual By Puller Guage By GO-NOGO & Filler Guage Cleaning with emery paper/3M buffing If required Silver plating on cotact surface Fixing as per standrd assembly drg. Thru Torque Wrench Phisical checking 5x manual & electrical operations By Timing test kit By Timing test kit By Timing test kit By Timing test kit By Timing test kit By contact resistance meter By 5KV Meggar Date :

Type of Panel : Type of MV PANELS & VCB : SR.NO. WORK DESCRIPTION A VACUUM CIRCUIT BREAKER 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 B 1 2 3 4 5 6 7

Visual Inspection of Breaker. If any damage Thorough Cleaning of the Breaker removing the dust Lubrication of all Moving Parts of Mechanism. lubrication Oiling of Closing & Tripping Coil. lubrication Checking of Gear Box Operation. for smoothness Checking of Test/Service Aux.Switch Operation. for proper contact Checking of Triping Mechanism Operation. for correctness Breaker Aux. Switch Operatoin. for proper contact Spring Charging Limit Switch Operation. for proper contact Checking of Front Drive Key Operation In Test Position. for smoothness & correctness Front Drive Key Operation In Service Position. for smoothness & correctness Checking of Triping Coil Resistance. healthiness Checking of Closing Coil Resistance. healthiness Vacuum Checking of Vacuum Interrupter healthiness of Vaccum interrupter Contact Erosion Checking of vacuum Interrupter healthiness of Vaccum interrupter Chceking of Stroke length mechnical settings correctness Checking of Damper setting mechnical settings correctness Removel of contact arm assembly and complete cleaning of contact surface to improve contact resistance Reconditioning and refurbishment of interconnection joints to improve contact resistance fixing of contact arm assembly and setting as per distance chart for proper alighnment Tightness Checking of Power Connection. avoid local heating Checking of all circlips & lock washers of VCB. for correct fixing Checking of Breaker ON/OFF Operation manually & electrically for correctness Checking of pick-up voltage for Closing & tripping coil as per Siemens standard Checking of Closing Time. as per Siemens standard Checking of Triping Time. as per Siemens standard Checking of pole descripency as per Siemens standard Checking of bounce time as per Siemens standard Checking of Contact Resistance. should be within limits Insulation Resistance Checking of VCB should be within limits BREAKER CHAMBER Thorough Cleaning of Breaker Chamber. Lubrication of Shutter Mechanism. Checking of Shutter Movement. Checking of Front Drive Fixing Plates. Checking of Door Interlocks With Breaker. Checking of Breaker Interlocks With Panel Door. Checking of Front Drive Interlocks.

removing the dust By Vacuum Cleaner & Plain Cotton cloth lubrication for smooth operation With Special ISOPLAX TOPAZ Grease for smoothness By manually operating the shutter for proper fixing Operation with Double bit key & Rack in/out for correctness and smooth operation Operation with Double bit key & Rack in/out for correctness and smooth operation Operation with Double bit key & Rack in/out for correctness and smooth operation Operation with Double bit key & Rack in/out

handle handle handle handle

1/3

BRD/PTD

SR.NO. WORK DESCRIPTION PURPOSE 8 Cleaning of Top & Bottom bushings ( Shutdown is must) removing the dust Cleaning of Top & Bottom fixed contacts and checking of smooth contact surface for healthiness 9 10 Checking of thermostate wiring and its fixing for healthiness 11 Checking the complete sealing of the breaker chamber for vermin proofing 12 Checking of Breaker Rack IN/OUT Inside the Panel. for proper alignment C BUS BAR CHAMBER (SHUTDOWN IS MUST) 1 2 3 4 5 6 7 D 1 2 3 4 5 6 Thorough Cleaning of Bas Bar Chamber Removal of busbar shrouds & checking of Bus Bar Joining Bolts Tightness Tightness of Bus Bar Support Insulator. Fixing of Busbar shrouds Checking the complete sealing of the busbar chamber Insulation Resistance Checking ( 5 KV Megger ) Rear cover fixng CT / CABLE CHAMBER (SHUTDOWN OF FEEDER IS MUST)

METHOD OF CHECKING By plain cotton cloth By plain cotton cloth & Reconditioning if required wiring continuty Phisical inspection and correction wherever reqd. by Insertion & removal of breaker inside the panel

removing the dust By Vacuum Cleaner & Plain Cotton cloth tightning as per torque tightness chart Busbar tightness checking thru Torque wrench for proper fixing by Ring & Flat spanner for insulation of joints By hand for vermin proofing Phisical inspection and correction wherever reqd. for insulation of joints By 5KV Magger for proper fixing Each bolt to be tightned with spanner By Vacuum Cleaner & Plain Cotton cloth If required Silver plating on cotact surface by Ring & Flat spanner with proper care Thru Screw driver Phisical inspection and correction wherever reqd. By 5KV Magger

Thorough Cleaning of CT/ Cable chamber removing the dust Reconditioning and refurbishment of interconnection joints to improve contact resistance Tightness checking of all the power connection joints including CT primary terminal for proper connection Checking of CT secondary wiring tightness for proper connection Checking the complete sealing of the CT chamber for vermin proofing Rear cover fixng for proper fixing

LIST OF DOCUMENTS TO BE CARRIED 1 PANEL & VCB Operating Manual 2 Standard Test Chart for Timing & contact resistance 3 Standard test chart for stroke length, damper settings, contact arm distance chart LIST OF TOOLS TO BE CARRIED 1 Timing test kit 2 Contact resistance test kit 3 Portable silver plating test kit 4 Puller guage for stroke length checking 5 GO-NOGO guage for damper settings 6 filler guage 7 Standard tools includes flat, ring & box spaner set 8 Portable grinder with birla 3M Pads Consumables to be carried 1 Special Grease & Oil 2 Emery Paper ( Sze:) 3 CRC Bottels 4 Circlips & Lock washers 5 Cleaning cloths

2/3

You might also like

- 2 Check List For 4.16KV VCBDocument6 pages2 Check List For 4.16KV VCBmatthew_70% (1)

- Commissioning Test Report For Circuit Breaker SiteDocument3 pagesCommissioning Test Report For Circuit Breaker SiteGuru MishraNo ratings yet

- Liquid-Cooled Generator Startup ChecklistDocument2 pagesLiquid-Cooled Generator Startup ChecklistHaroon ZafarNo ratings yet

- Transformer Erection ChecklistDocument2 pagesTransformer Erection Checklistmohan babu100% (2)

- Site Test Report: Under Ground Cables Precommissioning Test SheetDocument1 pageSite Test Report: Under Ground Cables Precommissioning Test SheetNaser MahamidNo ratings yet

- Test Procedure - CT & PTDocument6 pagesTest Procedure - CT & PTmayur dhande100% (1)

- Tnstrument Transformers (CT, PT) TheoryDocument6 pagesTnstrument Transformers (CT, PT) TheorySARAVANANo ratings yet

- Work - Instruction Transformer 33-11KV TRANSFORMERDocument5 pagesWork - Instruction Transformer 33-11KV TRANSFORMERTAHIR HUSAINNo ratings yet

- Electrical MotorDocument35 pagesElectrical MotorTshering Peljor100% (3)

- National Transmission and Despatch Company Mechanicalchecks, Visualinspections and ElectricaltestsDocument22 pagesNational Transmission and Despatch Company Mechanicalchecks, Visualinspections and Electricaltestsmirmunum100% (1)

- Vacuum Circuit Breaker Capacitor Switching TechnologyDocument12 pagesVacuum Circuit Breaker Capacitor Switching TechnologyMohan K100% (2)

- Vacuum Circuit Breaker Capacitor Switching TechnologyDocument12 pagesVacuum Circuit Breaker Capacitor Switching TechnologyMohan K100% (2)

- Transformer Site TestsDocument14 pagesTransformer Site TestsAhmad KalbounahNo ratings yet

- Etp-03 Test Procedure For Oil Filled TransformerDocument2 pagesEtp-03 Test Procedure For Oil Filled TransformeralekyaNo ratings yet

- MCC Testing & Commissioning MethodDocument3 pagesMCC Testing & Commissioning MethodHumaid Shaikh75% (4)

- Motor ProtectionDocument50 pagesMotor ProtectionYajidNo ratings yet

- Check List For Power TransformerDocument7 pagesCheck List For Power Transformermatthew_7No ratings yet

- Basic Math For Cable TerminationDocument17 pagesBasic Math For Cable TerminationAbraham JyothimonNo ratings yet

- Isolation & Maintenance of Power Transformers.Document4 pagesIsolation & Maintenance of Power Transformers.अभिषेक कुमार उपाध्यायNo ratings yet

- Inspection Test Plan (ITP) Procedure-DigabungkanDocument9 pagesInspection Test Plan (ITP) Procedure-Digabungkanpankrasius herbudiNo ratings yet

- Megger Testing Method StatementDocument7 pagesMegger Testing Method StatementRay Agacia0% (1)

- ACB ManualDocument24 pagesACB Manual4usangeet100% (1)

- 6.6kv Apfc PanelDocument4 pages6.6kv Apfc PanelMohan KNo ratings yet

- Annexure 4 - TransformerDocument36 pagesAnnexure 4 - TransformerBala MNo ratings yet

- Maintenance Check ListDocument6 pagesMaintenance Check ListGunadevan ChandrasekaranNo ratings yet

- Method Statement of Pipe Painting Rev02Document44 pagesMethod Statement of Pipe Painting Rev02Abdelaziz MohamedNo ratings yet

- Erection & Commissioning of Trfr.-Sh.c.p.deshmukhDocument25 pagesErection & Commissioning of Trfr.-Sh.c.p.deshmukhKaran Tripathi100% (2)

- Electrical Pre-Commissioning ProtocolsDocument85 pagesElectrical Pre-Commissioning ProtocolsAlok NayakNo ratings yet

- IR Test ReportDocument4 pagesIR Test Reportabou bakarNo ratings yet

- Guide to Pre-Commissioning Tests at New SubstationsDocument9 pagesGuide to Pre-Commissioning Tests at New Substationsخالد المصرى100% (1)

- Electrical MaintenanceDocument7 pagesElectrical MaintenanceKHUSHBOO198450% (2)

- Test Procedure TXDocument4 pagesTest Procedure TXVasu100% (1)

- Equipme NT Daily/Weely Monthly Annually 5 Years 10 Years Non-Scheduled StandardDocument4 pagesEquipme NT Daily/Weely Monthly Annually 5 Years 10 Years Non-Scheduled StandardmuhammadfurQanmirzaNo ratings yet

- 415V AC Distribution Board ChecklistDocument136 pages415V AC Distribution Board ChecklistRama Krishna Reddy Donthireddy100% (2)

- Power Transformer Pre Commisioning ChecklistDocument26 pagesPower Transformer Pre Commisioning ChecklistRajesh TK100% (2)

- Training Manual PDFDocument12 pagesTraining Manual PDFOwen kamazizwaNo ratings yet

- Southern power equipment maintenance guideDocument11 pagesSouthern power equipment maintenance guideshivaramNo ratings yet

- Check ListDocument36 pagesCheck ListChief Engineer TransOMNo ratings yet

- Transformer maintenance checklist and scheduleDocument15 pagesTransformer maintenance checklist and schedulemabmanik100% (2)

- Checking of Electrical Panel BoardDocument7 pagesChecking of Electrical Panel BoardReneboy Lambarte100% (1)

- 57-Power Transformer Installation ChecklistDocument4 pages57-Power Transformer Installation Checklistprithiviraj50% (2)

- Checklist ElectricalDocument34 pagesChecklist ElectricalDhirendra Singh100% (1)

- Condition Assessment Manual: Transformer Inspection Form and ChecklistDocument9 pagesCondition Assessment Manual: Transformer Inspection Form and ChecklistmuhardionoNo ratings yet

- Circuit BreakersDocument64 pagesCircuit BreakersPhani Kumar100% (1)

- ESPDocument5 pagesESPKuntal SatpathiNo ratings yet

- Chemistry The Central Science NotesDocument8 pagesChemistry The Central Science Noteslucykipper100% (1)

- Electrical PM Course (40chDocument3 pagesElectrical PM Course (40chSayed NagyNo ratings yet

- Transformer Daily Checklist Month:: Description of The Equipment Location CapacityDocument10 pagesTransformer Daily Checklist Month:: Description of The Equipment Location Capacityabdulkadir aliNo ratings yet

- Panel Testing Procedure 1Document9 pagesPanel Testing Procedure 1ArunkumarNo ratings yet

- Transformer MaintenanceDocument118 pagesTransformer Maintenancehamada13100% (2)

- Commissioning Procedure MCCDocument55 pagesCommissioning Procedure MCCRavi Mani100% (1)

- Oil Filled Transformers Standard Testing ProcedureDocument17 pagesOil Filled Transformers Standard Testing ProcedureNajeeb AbbasiNo ratings yet

- Transformer Maintenance Checklist - 5 Must Do Routine ChecksDocument3 pagesTransformer Maintenance Checklist - 5 Must Do Routine Checksmurthy237No ratings yet

- Guidelines for Small Hydro Switchyard Equipment SelectionDocument98 pagesGuidelines for Small Hydro Switchyard Equipment SelectionMohan KNo ratings yet

- CT145 Thermal Study of LV Electric SwitchboardsDocument28 pagesCT145 Thermal Study of LV Electric SwitchboardslcatelaniNo ratings yet

- GS-F34 - Generator Set System (Off Load Test)Document2 pagesGS-F34 - Generator Set System (Off Load Test)Mohamed Firdaus Bin ZakariaNo ratings yet

- GTU Course on Testing and Commissioning of Electrical EquipmentDocument4 pagesGTU Course on Testing and Commissioning of Electrical EquipmentMitesh Gandhi100% (2)

- PREVENTIVE MAINTENANCE CHECKLIST FOR POWER PRESS MACHINEDocument1 pagePREVENTIVE MAINTENANCE CHECKLIST FOR POWER PRESS MACHINESanjay MalhotraNo ratings yet

- Maintenance and Testing of 33kV and 11kV Substation EquipmentDocument23 pagesMaintenance and Testing of 33kV and 11kV Substation EquipmentSaff MdNo ratings yet

- Genset Maintenance Checklist for BTS SitesDocument1 pageGenset Maintenance Checklist for BTS SitesHarry IrawanNo ratings yet

- Check and Inspect The Surrounding Area of The Workplace and Check, If Any Honeybee or Any Other Hazards Stop Work and Inform The Area OperatorDocument4 pagesCheck and Inspect The Surrounding Area of The Workplace and Check, If Any Honeybee or Any Other Hazards Stop Work and Inform The Area OperatorVitthal PatnechaNo ratings yet

- Capacitor Bank ChecklistDocument2 pagesCapacitor Bank Checklistgaladrial0% (1)

- Fire PUMPS T&C ChecklistDocument6 pagesFire PUMPS T&C ChecklistUmair BaBerNo ratings yet

- Logbook FormatDocument35 pagesLogbook FormatpernetiNo ratings yet

- CVT vs EMVT ComparisonDocument1 pageCVT vs EMVT ComparisondseshireddyNo ratings yet

- AOH checklist for LT and HT motorsDocument8 pagesAOH checklist for LT and HT motorsElectrical Team100% (1)

- Void SubstationDocument46 pagesVoid SubstationPrabhat HambireNo ratings yet

- Tinywow MVTC-SG-ITP 12925367Document21 pagesTinywow MVTC-SG-ITP 12925367Kumar ShanuNo ratings yet

- Prevent Electrical Breaker Failure with Regular MaintenanceDocument9 pagesPrevent Electrical Breaker Failure with Regular MaintenancessvasavaongcNo ratings yet

- Fiber Optics For Sale Co.: 90 Degree Boot Fiber Optic Patch CablesDocument1 pageFiber Optics For Sale Co.: 90 Degree Boot Fiber Optic Patch CablesMohan KNo ratings yet

- MU Patch Cable Spec SheetDocument2 pagesMU Patch Cable Spec SheetMohan KNo ratings yet

- FC Patch Cable Spec SheetDocument2 pagesFC Patch Cable Spec SheetMohan KNo ratings yet

- Single Core Cables - 600/1000 V: Dimensions & WeightsDocument5 pagesSingle Core Cables - 600/1000 V: Dimensions & WeightsMohan KNo ratings yet

- Patch Cable ConnectorDocument10 pagesPatch Cable ConnectorMohan KNo ratings yet

- Installation Contactors ESB Noiseless DC CoilDocument8 pagesInstallation Contactors ESB Noiseless DC CoilMohan KNo ratings yet

- ST Patch Cable Spec SheetDocument2 pagesST Patch Cable Spec SheetMohan KNo ratings yet

- MTRJ Patch Cable Spec SheetDocument2 pagesMTRJ Patch Cable Spec SheetMohan KNo ratings yet

- Family - Fiber Optic Patch Cords: MT Mpo/Mtp/MtDocument2 pagesFamily - Fiber Optic Patch Cords: MT Mpo/Mtp/MtMohan KNo ratings yet

- LC Patch Cable Spec SheetDocument2 pagesLC Patch Cable Spec SheetMohan KNo ratings yet

- Openphaseconditionsintransformersanalysisandprotectionalgorithm PDFDocument14 pagesOpenphaseconditionsintransformersanalysisandprotectionalgorithm PDFEmmanuel Entzana HdzNo ratings yet

- Bend Insensitive Fiber CableDocument1 pageBend Insensitive Fiber CableMohan KNo ratings yet

- 2CDC002157D0202 View PDFDocument12 pages2CDC002157D0202 View PDFicovinyNo ratings yet

- Digistart D2 Korisnično UpustvoDocument22 pagesDigistart D2 Korisnično UpustvoDankoNo ratings yet

- Selection Tables: Auxiliary Elements and Accessories For Mcbs and RcdsDocument1 pageSelection Tables: Auxiliary Elements and Accessories For Mcbs and RcdsMohan KNo ratings yet

- Ex Protection PDFDocument41 pagesEx Protection PDFSiddharth Sahu100% (1)

- FT Louver PDFDocument1 pageFT Louver PDFMohan KNo ratings yet

- Measuring Pro ProtectionDocument1 pageMeasuring Pro ProtectionMohan KNo ratings yet

- 2CDS273001R0064 Miniature Circuit Breaker s200m 3p CDocument4 pages2CDS273001R0064 Miniature Circuit Breaker s200m 3p CMohan KNo ratings yet

- BMK DrawingDocument7 pagesBMK DrawingMohan KNo ratings yet

- ANSI FunctionsDocument1 pageANSI FunctionsMohan KNo ratings yet

- Capcitance Switching With Vacuum Circuit BreakerDocument9 pagesCapcitance Switching With Vacuum Circuit BreakerMohan KNo ratings yet

- LV Fuse Technical DetailsDocument8 pagesLV Fuse Technical DetailsMohan KNo ratings yet

- Annunciators Baseline San 200 SeriesDocument1 pageAnnunciators Baseline San 200 SeriesMohan KNo ratings yet

- AP2120 Description Pin Assignments: High Speed, Extremely Low Noise Ldo RegulatorDocument19 pagesAP2120 Description Pin Assignments: High Speed, Extremely Low Noise Ldo RegulatorHitesh GambhavaNo ratings yet

- Multipath - Conf HITACHIDocument3 pagesMultipath - Conf HITACHIBreno RodriguesNo ratings yet

- Cme2100 Quick Manual English v.3.0 0Document59 pagesCme2100 Quick Manual English v.3.0 0mgugiNo ratings yet

- EasyLogic PM2000 Series - METSEPM2210Document3 pagesEasyLogic PM2000 Series - METSEPM2210Vinay SakethNo ratings yet

- SIPROTEC Easy 7SJ46 Numerical Overcurrent Protection RelayDocument2 pagesSIPROTEC Easy 7SJ46 Numerical Overcurrent Protection RelayVictor Manuel BonettoNo ratings yet

- Ecx4233 Tma1 2016Document6 pagesEcx4233 Tma1 2016ParasecNo ratings yet

- IOT Based Women Security System SeminarDocument21 pagesIOT Based Women Security System SeminarRutuja KurkelliNo ratings yet

- Electrical Safety ChecklistDocument2 pagesElectrical Safety ChecklistmailxzNo ratings yet

- Electricity HOTS Questions and Answers from www.studiestoday.comDocument2 pagesElectricity HOTS Questions and Answers from www.studiestoday.comDeepak PatelNo ratings yet

- Product Sheet: Nibp100D Noninvasive Blood Pressure Monitoring SystemDocument3 pagesProduct Sheet: Nibp100D Noninvasive Blood Pressure Monitoring SystemSadegh ShebaniNo ratings yet

- 1176 PDFDocument169 pages1176 PDFJoshua PalizaNo ratings yet

- Lista de Libros y SolucionariosDocument3 pagesLista de Libros y SolucionariosEddy Ramirez Quiroga100% (1)

- Bio BatteryDocument11 pagesBio BatteryGurubasamma LNo ratings yet

- Panasonic Ag dvx100 Ag Dvx100be Manual Do UtilizadorDocument12 pagesPanasonic Ag dvx100 Ag Dvx100be Manual Do UtilizadorAnderson Assis MansanoNo ratings yet

- James HughesDocument2 pagesJames HughesKelly RoseNo ratings yet

- DANFOSS - Esquema de Ligação IHM MCD3000Document2 pagesDANFOSS - Esquema de Ligação IHM MCD3000JardelNo ratings yet

- Electric Contact Water Level Gauge, Water Level Electrode, DJM1615-87Detailed IntroductionDocument2 pagesElectric Contact Water Level Gauge, Water Level Electrode, DJM1615-87Detailed IntroductionAchmad Nuriel AnwarNo ratings yet

- KDL W600B Service Manual PDFDocument28 pagesKDL W600B Service Manual PDFMihaela Caciumarciuc0% (1)

- BUBT Lab Report on Performance Analysis of Half-Wave & Full-Wave RectifiersDocument5 pagesBUBT Lab Report on Performance Analysis of Half-Wave & Full-Wave Rectifiers23 - 017 - Md. Imran HossainNo ratings yet

- PowerDocument2 pagesPowerraymond baliteNo ratings yet

- Hall Effect PDFDocument11 pagesHall Effect PDFArum WulandariNo ratings yet

- Lorenz NumberDocument25 pagesLorenz NumberArum AnggrahiniNo ratings yet

- 03 Rig InstrumentationDocument34 pages03 Rig InstrumentationArkhatTompakovNo ratings yet

- 7thAnd8thSemSyllabus MEDocument67 pages7thAnd8thSemSyllabus MEahmadNo ratings yet

- Abt36rba3w SMDocument26 pagesAbt36rba3w SMaircoolplusNo ratings yet

- TT Products eDocument163 pagesTT Products eOana CimpulungeanuNo ratings yet

- SpaceLogic TC903 ThermostatDocument3 pagesSpaceLogic TC903 ThermostatIonut Viorel TudorNo ratings yet