Professional Documents

Culture Documents

Carbondioxide As Fire-Extinguishing Media For Fire Pro

Uploaded by

Debajani DekabaruahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbondioxide As Fire-Extinguishing Media For Fire Pro

Uploaded by

Debajani DekabaruahCopyright:

Available Formats

IS 15222:2002

ah-wlzlzihq+

*

&wwl&

faE&

Indian Standard CARBON DIOXIDE AS FIRE EXTINGUISHING MEDIA FOR FIRE PROTECTION SPECIFICATION

ICS 13.220.10

0 BIS 2002

BUREAU

MANAK

OF

BHAVAN,

INDIAN

9 BAHADUR NEW DELHI

STANDARDS

SHAH 110002 ZAFAR MARG

December

2002

Price Group 6

Fire Fighting Sectional

Committee,

CED 22

FOREWORD This Indian Standard was adopted by the Bureau of Indian Standards, after the draft finalized Fighting Sectional Committee had been approved by the Civil Engineering Division Council. by the Fire

This standard is one of the series giving specifications for fire extinguishing media in common use and which are in need of specification for fire fighting purposes. These specifications are designed to establish that the medium in question has at least a minimum useful fire extinguishing capability and can, therefore, be reasonably used for fire extinguishing purposes. Annexes A to C of this standard specify methods for determining, respectively, water, oil and total sulphur compounds contents. Annexes D to G provide important information on and give recommendations relating to the safety and use of carbon dioxide, and they should be read carefully by all concerned with this medium. The composition of the Committee for the formulation of this standard is given at Annex H.

For the purpose of deciding whether observed or calculated, expressing IS 2:1960 Rules for rounding off the rounded off value should be the

a particular requirement of this standard is complied with, the final value, the result of a test or analysis, shall be rounded off in accordance with numerical values (revised). The number of significant places retained in same as that of the specified value in this standard.

IS 15222:2002

Indian Standard CARBON DIOXIDE AS FIRE EXTINGUISHING MEDIA FOR FIRE PROTECTION SPE~IFICATION

1 SCOPE This standard lays down requirements for carbon dioxide for use as a fire extinguishing medium. 2 REFERENCES The standards given below contain provisions which through reference in this text, constitute provision of this standard. At the time of publication, the editions indicated were valid. All standards are subject to revision, and parties to agreements based on this standard are encouraged to investigate the possibility of applying the. most recent editions of the standards indicated below: IS No. 460 (Part 1) :1985 (Part 2): 1985 1117:1975 1997:1982 4152:1989 Title Test sieves Wire cloth test sieves (third revision) Perforated plate test sieves (third revision) One-mark pipettes @t revision) Burettes (second revision) Carbon dioxide cylinders for fire fighting purposes on boardship (second revisi~n) Seamless steel cylinders for permanent and high pressure liquefiable gases (second revision) Table 1 Requirements (Clause 4) Requirementsi) Property 99.5 Purity,percent(v/v),Min 0.015 Watercontent,percent(m/m),IWLX 5 Oil content,ppm by mass,Mu Totalsulphurcompoundscontent, 5.0 Expressedas sulphur,ppmby mass,Mar Ucarbon dioxide obtainedby convertingdryice to liquidwill fSOt usuallycomplywiththeserequirements unlessit hasbeenproperly processedtoremoveexcesswaterand oil. 5.2 Purity Determine the purity by gas-liquid chromatography using generally accepted laboratory techniques or use a volumetric analyser. The method used shall be capable of determining purity with an accuracy of at least 0.1 percent. the

The sample shall not constitute more than 10 percent of the original quantity of carbon dioxide contained in the sample container. 5.3 Water Content ,Determine the water content by the method specified in Annex A. 5.4 Oil Content

7285:1988

3 DEFINITION For the purposes of this standard, definition shall apply. 3.1 Carbon Dioxide 5.5 Total Sulphur Compounds The chemical compound uishing medium. 4 REQUIREMENTS Carbon dioxide shall comply with the requirements of Table 1, when tested by the appropriate method of test specified in 5. 5 METHODS OF TEST 6 PACKING 6.1 Carbon dioxide shall be packed conforming to IS 7285 or IS 4152. 7 MARKING 7.1 Each container shall be legibly and indelibly marked on the outside with the following information: a) b) c) 1 Manufacturers name or trade-mark, if any; in gas cylinder C02 used as a fire extingDetermine the total sulphur compounds method specified in Annex C.. content by the Content the following Determine the oil content by the method specified in Annex B.

5.1 Safety Warning Attention is drawn to the need to design equipment for handling carbon dioxide such that it is either capable of withstanding the pressures involved or protected from them.

Month and year of manufacture; Carbon Dioxide;

1S 15222:2002 d) e) f,) Source, year of manufacture its test pressure; Filled mass of the cylinder. of cylinder and flush the connections, valves and the evaporating device with carbon dioxide before starting to take the sample. 8.3.3 Sampling in Cylinders

Empty mass of the cylinder; and

7.1.1 Carbon dioxide conforming to this standard may also be marked with BIS Standard Mark. 7.1.1.1 The use of the Standard Mark is governed by the provisions of Bureau of Indian Standards Act, 1986 and the Rules and Regulations made thereunder. Details of conditions under which the licence for the use of Standard Mark may be granted to manufacturers or producers may be obtained from the Bureau of Indian Standards. 8 SAMPLING 8.1 General Samples of carbon dioxide needed to perform all the tests required by this standard shall be taken from the same manufacturing lot, using identical sampling procedures. NOTE Attentionis drawnto the need to designequipmentfor handling carbon dioxide such that it is either capable of withstandingthepressuresinvolvedor protectedfromthem. 8.2 Sampling Equipment

Use a cylinder of water capacity 1.4 kg or 2.0 kg, complying with the requirements of IS 7285 and with a valve at each end. An internal copper dip-tube of diameter at least 5 mm and of length equal to one-third of the length of the cylinder shall be brazed to the base of one valve, which shall be clearly identified. The cylinder shall be coated internally with tin [containing 1 percent (m/m) of lead] applied by hot dipping the cylinder after the walls have been descaled. First clean the sampling cylinder by removing both valves and washing the inside of the cylinder with carbon tetrachloride. Purge with a current of dry filtered air. Wash with methanol and repeat the purging. Degrease the valves using carbon tetrachloride, then refit them. The methanol and carbon tetrachloride used shall comply with the requirements specified in B-2. Support the cylinder vertically with its dip-tube valve uppermost. Before taking the sample, thoroughly flush the cylinder with a small quantity of liquid carbon dioxide, first through the top valve and then through the bottom valve. Repeat this flushing procedure, and leave the cylinder connected to the liquid carbon dioxide source via its lower valve. Then, with the upper valve closed, open the lower valve to admit liquid carbon dioxide to the cylinder. Partly open the upper (dip-tube) valve and continue filling until carbon dioxide snow is discharged from this valve. Close both valves. Open the top valve several times for brief intervals until only carbon dioxide gas is discharged from it. The free end of the dip-tube inside the cylinder will then be just above the liquid carbon dioxide level in the cylinder. Samples shall be analyzed as soon as reasonably practicable after collection. To withdraw the sample for analysis, support the sampling cylinder vertically with the dip-tube valve at the top. Connect the bottom valve of the sampling cylinder (liquid carbon dioxide) to an evaporating device and then via a T-piece, the free leg of which is connected to a tube as described in 8.3.2 to the analytical apparatus, Thoroughly flush the connections, valves and the evaporating device with carbon dioxide before starting the anal ysis. When sampling for the determination of water content, the connections to be above the dew-point to prevent condensation during purging. 2

Rigid metal connections or flexible reinforced nylon hose should be used throughout the sampling equipment and shall be kept as short as possible. All components shall have a design pressure of not less than 137 bar. 8.3 Procedure 8.3.1 General Two methods of sampling are specified as follows: a) Direct sampling, in which the sample is passed to an evaporator and then directly to the analytical apparatus; and Sampling in cylinders, sample is transferred laboratory. in which case the in a cylinder to a

b)

Other methods may be used provided shown to give equally representative analysis (see Annexes A to C). 8.3.2 Direct Sampling

that they are samples on

Connect the sampling valve by means of suitable connections (see 8.2) to an evaporating device and then via a T-piece (the free leg of which is connected to the dip-tube of a Drechsel bottle containing 50 mm of mercury covered by a layer of water on the carbon dioxide side) to the analytical apparatus. Thoroughly

IS 15222:2002

ANNEX A (Clause 5.3)

DETERMINATION A-1 PRINCIPLE Gravimetric determination of the water content by passing a sample of the gas over phosphorous pentoxide. A-2 APPARATUS AND MATERIAL Tubes being 100 mm and 12 mm, fitted with stoppers. The tubes (A-2.5) which shall of cotton wool. OF WATER CONTENT Prepare the desiccant in small quantities, A-3 SAMPLING Take the sample in a cylinder by the method described in 8.3.3. About 120 g of carbon dioxide is required for each determination. A-4 DETERMINATION After the evaporating device, connect the exit side of the T-piece to the absorption tubes (A-2.1), the flow meter (A-2.2), and the gas meter (A-2.3) in series, in that order. Carefully open the regulating valve and absorption tube taps and allow the gas to flow at a rate of about 500 ml/min for 10 rein; the carbon dioxide displaces the air in the absorption tubes. Close all taps, disconnect the absorption tubes and wipe the tubes surfaces with a dry, soft cloth. Place the absorption tubes in the balance case, leave for 20 rein, then weigh them to the nearest 0.5 mg. Reconnect the absorption tubes. Note the reading of the gas meter then allow the gas to pass at a steady rate of 500 ml/min to 1000 ml/min for 1 h. Close the taps and reducing valve. Note the gas meter reading. Place the absorption tubes in the balance case, leave for 20 rein, then weigh them to the nearest 0.5 mg. A-5 EXPRESSION OF RESULTS by mass, as required.

A-2.1 Two Absorption

U-shape, the length of the limbs the diameter of the tubes being side arms and ground-glass drilled shall be filled with the desiccant be held in position by small pads A-2.2 Flow Meter

Float type, suitable for measuring a carbon dioxide flow of 200 ml/min to 2000 ml/min. A-2.3 Gas Meter Calibrated for 1 or 2.5 litres per revolution.

A-2.4 Test Sieves Of aperture sizes 425pm and 600 #m, complying with the requirements of IS 460 (Part 1). A-2.5 Desiccant Sift powdered glass or clean, dry, washed sand and retain the portion that passes through a test sieve of aperture size 600 pm but is retained on a test sieve of aperture size 425 pm In general, follow the applicable recommendations and requirements of IS 460 (Part 1) and IS 460 (Part 2). Quickly transfer to a stoppered container (a large weighing bottle or small stoppered jar is suitable) a volume of fresh phosphorus pentoxide and add about half as much by volume of the prepared powdered glass or sand. Vigorously shake the container to mix the components and fill the U-tubes (A-2.1) as quickly as possible with the mixture. lf it is prepared in this way, it should be easy to fill the tube with the desiccant. If it is not easy, it is probable that the phosphorus pentoxide was moist before addition of the powdered glass or sand.

The water content, expressed as a percentage is given by the formula: 54.29 (m, - q)

v

where ml = initial mass, in grams, of the absorption tubes; of the absorption

m2 = final mass, in grams, tubes; and

v=

volume, in litres, at 20 C and 760 mmHg of gas passed, read from the gas meter.

IS 1.5222:2002

ANNEX B (Clause 5.4)

DETERMINATION B-1 PRINCIPLE Vapouriza[ion of a liquid sample and removal of any oil by passing the gas through carbon tetrachloride. Removal of residual oil in the cylinder by washing with more carbon tetrachloride and combination of the two carbon tetrachloride solutions. Spectrometric measurement of the oil content at 3460 nm (the C-H stretching frequency) by means of an in fra-red spectrometer. B-2 REAGENTS All reagents shall be of recognized B-2.1 Carbon Tetrachloride, analytical grade. OF OIL CONTENT of the evaporating device and then to the Drechsel bottle, the two bubblers, the flow meter and the gas meter in series, in that order, using short rubber connections. No carbon dioxide shall be allowed to pass to the atmosphere through the outlet of the T-piece. Weigh the cylinder, totally expand the contents of the cylinder through the absorption train at a flow rate of about 1000 ml/min, and read the volume of gas passed (this serves as a check on the amount of carbon dioxide used for the test). NOTES 1 Someevaporationof the carbon tetrachloride will take place.If thk is excessive,stop the flow of gas and refill the absorption bottles,notingthe volumeof carbontetrachloride. 2 In viewof the toxicnatureof carbontetrachloride,the effluent gas from this determinationshouldbe dischargedto the outside air. Reweigh the sampling cylinder, taking care to use the same valve fittings as at the first weighing. Remove the valve not attached to the dip-tube and wash the inside of the cylinder with 25 ml of the carbon tetrachloride. Wash the interior of the evaporating device and valves with carbon tetrachloride and combine this solution with the cylinder washings and the contents of the bubblers. Make up the combined solutions to some suitable, definite volume. B-5.2 Preparation of Blank Test Solution

Distilled absorption

The reagent shall not show an infra-red peak a{ 3460 nm. B-2.2 Standard Oil Solution

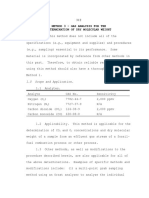

Dissolve 0.0200 g of liquid paraffin in carbon tetrachloride, transfer quantitatively to a 100 ml onemark volumetric flask and dilute to the mark with carbon tetrachloride. One ml of this solution B-3 APPARATUS B-3.1 Two bubblers as shown in Fig. 1. B-3.2 Drechsel bottle of capacity 250 ml. B-3.3 Flow meter, float type, suitable for measuring carbon dioxide flow of 200 ml/min to 2000 ml/min. B-3.4 Gas meter, calibrated revolution. for 1 litre or 2.5 litres per contains 200 pg of oil.

B-3.5 Infra-red spectrometer and accessories, for making measurements at 3460 nm. B-4 SAMPLING

suitable

Evaporate a volume of carbon tetrachloride, equal to the total volume (including any additions) of carbon tetrachloride used in the absorption train plus washings, to the volume of the combined solution (see B-5.1) and subsequently treat it in the same way as the test solution. B-5.3 Spectrometric Measurements

Take the sample by the method desclibed in 8.3.3. About 700 g to 1000 g is required for each determination.

NOTE A set of cylinders should preferably be retained for samplingfor the determination of oil content and should not be used for other purposes.

Following the manufacturers instructions for the operation of the instrument, determine the absorbance of the test solution and of the blank test solution at the wavelength of maximum absorption (approxi~ mately 3460 rim). From the calibration graph (B-5.4), deduce the masses of oil corresponding to the measured absorbance. B-5.4 Preparation of the Calibration Graph

B-5 PROCEDURE B-5.1 Preparation of Test Solution Prepare suitable dilutions of the standard solution (B-2.2) to cover the range within which the mass of oil in the sample is expected to be found. Measure the absorbance of each of these solutions as described in B-5.3. Prepare a calibration graph by plotting the masses of oil against the corresponding absorbance. 4

Place 100 ml of the carbon tetrachloride (B-2.1) in the Drechsel bottle (B-3.2) and 25 ml in each bubbler (B-3.1). Support the weighed sampling cylinder with the dip-tube valve at the top, connect the bottom valve of the weighed cylinder to theT-piece

IS 15222:2002

DIRECTION

OF GAS

FLOW

700+

-700

I 19/26 JOINT

14/23 JOINT

I

150

16

Alldimensionsin millimetres.

FIG.

1 BUBBLER FOR THE DETERMINATION OF OIL CONTENT

B-6 EXPRESSION

OF RESULTS

where

m3 =

The oil content, expressed in parts per million by mass, is given by the formula: m3 m4

m5

mass, in micrograms, of oil in test solution; of oil in blank test

m4 = mass, in micrograms, solution; and %

= mass, in grams, of sample taken.

NOTE The mass, m5 can be checked by calculation from the mass of 1 Iitre of carbon dioxide at 20C and 1 013 mbar (760 mm Hg),whichis 1.84g.

IS 15222:2002

ANNEX C

(Ckuw 5.5)

DETERMINATION C-1 PRINCIPLE Reduction of any sulphur compounds present by passing equal volumes of the sample and purified hydrogen over silica wool at 900C. Removal of the hydrogen sulphide thus produced by passing the gases through neutral cadmium chloride solution. Determination of sttlphur by adding a known amount of iodine solution and determining the excess iodine by titration with standard volumetric sodium thiosulphate solution. C-2 REAGENTS All reagents shall be of recognized analytical grade and the water used shall be distilled water or water of equivalent purity. C-2.1 Hydrogen Gas produced electrolytically. C-2.2 Hydrochloric With concentration C-2.3 Soda Lime In lumps which pass a test sieve of aperture size 2 mm but retained on a test sieve of aperture size 1.8 mm.

NOTE The soda lime should not have been used in other determinations where oxygen has been used, as explosions may occur.

OF TOTAL SULPHUR

COMPOUNDS

CONTENT

pour the paste with constant stirring into 100 ml of boiling water and boil for 1 min. Allow to cool. C-3 APPARATUS The apparatus is shown diagrammatically in Fig. 2.

C-3.1 F1OWMeter Float type, suitable for measuring 200 ml/min to 2000 ml/min. C-3.2 F1OWMeter Float type, suitable for measuring carbon dioxide flow of 200 ml/min to 2000 ml/min. C-3.3 llvo Furnace Ihbes Made of transparent silica, each 500 mm long, of internal diameter 16 mm with one end reduced to 3 mm internal diameter. Place a loose 200 mm long wool near the the polyvinyl packing of silica wool not less than in the tube with a small plug of silica wide end to reduce radiation heating of chloride connection. hydrogen flow of

Acid of 1.18 g/ml.

C-3.4 Furnace and Control A twin-tube furnace, about 460 mm long, to operate at 900C, and fitted with a thermocouple and temperature indicator. C-3.5 Soda Lime Tower Or suitable absorption tube. C-3.6 Y Ihbe C-3.7 Bubbler As shown in Fig. 1. C-3.8 Burette Of capacity 10 ml, complying of IS 1997. C-3.9 Pipette Of capacity 2 ml, complying IS 1117. solution cHJ = 0.01 mol/1 C-3.1O Test Sieves Of aperture size 2 mm and 1.8 mm, complying the requirements of IS 460 (Part 1). C-4 SAMPLING Take the sample in a cylinder by the method described in 8.3.3. About 120 g is required for each determination. 6 with with the requirements of with the requirements

C-2.4 Cadmium

Chloride

50 g/1 neutral solution. Dissolve 5 g of cadmium chloride in 100 ml of water and add, drop by drop, approximately 1 mol/1 solution hydroxide solution until the first cloudiness appears. C-2.5 Sodium Thlosulphate

Standard volumetric solution, c (Na2 S2 OS ) = 0.02 mol/1 solution: Hitherto expressed as 0.02 N standard volumetric solution. C-2.6 Iodine Standard volumetric solution). C-2.7 Starch Indicator

Solution

Make a paste of 1 g of soluble starch with a little water:

I~ 0.02 N standard volumetric SOhMiOII.

IS 15222:2002

FLOW \

METER

s~m

/r~/cAwOOLOL .-.-. --.-=; 4 $

L

SILICA

-----;S.:;*:Y%CP:l,?<YSP .&.- L-a-<2..&L&L ----- ~.:, . -----------{ -------------

SODA LIME+

Ilii

NV

1 #

LFURNACE

- v

WOOL PACKING

1/ v

JI

II

HYDROGEN SUPPLY

A8 SORBER

FLOW METER-&_

FIG.

2 APPARATUS FOR THE DETERMINATION OF TOTAL SULPHUR COMPOUND CONTENT

Connect the outlet of the evaporating device to the apparatus shown in Fig. 2. All connections shall be as short as possible and shall be made of polyethylene or polyvinyl chloride. C-5 PROCEDURE Place 25 ml of the neutral cadmium chloride solution (C-2.4) in the absorber and connect it to the apparatus. Pass the hydrogen (C-2.1) at a flow rate of 500 ml/min through the cold furnace tubes for about 5 min to purge the system of air before heating is commenced. Then raise the temperature of the furnace to 900C. Pass carbon dioxide and hydrogen into the system at an accurately known and steady flow rate (500 ml/min for each gas) for about 2 h with the furnace maintained at 900C & 10 C. Note the times at which the determination was begun and ended or expand a known mass of carbon dioxide through the apparatus. Disconnect the bubbler and close the hydrogen cylinder. Remove the jet of the absorber and wash it with a small volume of water, adding the washings to the remainder of the cadmium chloride solution. By means of the pipette (C-3.9), add 2 ml of the

standard volumetric iodine solution (C-2.6) to the bubbler, followed by 2 ml of the concentrated hydrochloric acid (C-2.?). Back titrate the excess iodine with the standard volumetric sodium thiosulphate solution (C-2.5), using the starch solution (C-2.7) as indicator. C-6 EXPRESSION OF RESULTS

The total sulphur compounds content, expressed as st.dphur in parts per million by mass, is given by the formula: 320 (2.00mb where V = volume, in millimetres, of sodium sulphate solution used; and thioV)

mb = mass, in grams, of sample taken.

NOTE The mass, mb may be obtained calculation using the formula m6=0.00184x where A t = = flow rate, in mrn/min, at 20C and 1013 mbar (760 mm Hg), of carbon dloxidq and time of flow, in minutes. Axt by weighing or by

IS 15222:2002

ANNEX D (Foreword)

GENERAL D-1 PHYSICAL PROPERTIES properties of PROPERTIES sparks which atmosphere. can be hazardous in an explosive

A number of the important physical carbon dioxide are given in Table 2.

Table 2 Physical Properties

of Carbon Dioxide

D-2 ELECTRICAL

CONDUCTIVITY Property

(Clause D-1) Value

44 -78.5 31 73.8 0.00215 466.1 57.3 1.84 774 -56.6 5.19

Carbon dioxide complying with the requi: ements for purity specified in this standard has a very low electrical conductivity and can be used to extinguish fires involving live electrical equipment. D-3 EFFECTS Carbon dioxide materials. D-4 STATIC ON MATERIALS is stable and inert to most common

Relative molecular mass Sublimation point at atmospheric pressure, C Critical temperature, C Critical pressure, bar CriticaI volume, m3/kg Critical density, kg/m3 Equilibrium vapour pressure at 20C, bar Vapour density at 20C and 1 bar, kg/m3 Equilibrium vapour density at 20C, kg/m3 TtipIe point, C Bar

ELECTRICITY

D-5 TOXICOLOGY Information on the toxicology given in Annex G. of carbon dioxide is

In some circumstances, the discharge of carbon dioxide can cause a build-up of static electricity. This can cause

ANNEX E (Foreword)

SAFETY PRECAUTIONS E-1 Carbon dioxide is shipped/transported from the manufacturer as a liquefied gas in bulk under pressure at low temperature; and in cylinders under higher pressure at ambient temperatures. All precautions pertaining to the safe handling and operation of containers, piping and equipment under pressure should be observed when filling fire fighting equipment with the medium. E-2 During the discharge of containers of carbon dioxide, low temperatures can arise through expansion of the FOR HANDLING liquid togas and solid. This can present a hazard of frost bum. Gloves and eye protection should be worn when transferring carbon dioxide from one container to another. E-3 Transfer of carbon dioxide should be carried out in a well-ventilated area or in the open air. E-4 Carbon dioxide is much heavier than air and can collect in pits, cellars and low lying areas. Care should be taken when entering such areas on sites where carbon dioxide has been used.

IS 15222:2002

ANNEX F (Foreword)

COMPATIBILITY Carbon dioxide may be used simultaneously with other types of fire extinguishing media for fire fighting purposes, with no known indications extinguishing efficiency is affected. that

ANNEX G (Foreword)

TOXICOLOGY G-1 GENERAL The principal action of carbon dioxide is to cause suffocation, although it is mildly toxic in its own right. At concentrations of 3 percent to 4 percent (v/v) in air, the respiration rate is increased and headaches can be caused. At concentrations of 9 percent (v/v), personnel can lose consciousness within minutes, this being preceded by disorientation, visual disturbance, ringing in the ears, tremors, etc. At a concentration of about 20 percent (v/v), death will follow in 20 min to 30 min. G-2 PRECAUTIONS AND TREATMENT

In practice, concentrations of 30 percent (v/v) or more are employed for total flooding systems. Similarly, high concentrations could be encountered near to the nozzles of hand extinguishers or local application systems. Such concentrations are highly hazardous for persons and special precautions should be taken depending upon the specific conditions of use. Persons suffering from exposure to carbon dioxide should immediately move or be moved to fresh air. Medical aid should always be sought in the event of such over-exposure.

IS 15222:2002

ANNEX H (Foreword)

COMMITTEE COMPOSITION Committee, CED 22

Representative(s) SHRJOM PRARASH (Chairman) SHRIL. C, GUnA SHJOH. S. RAWA~ (Alternate) SHRS SWMt.ANJm SEN CHIEFFIR: OFFICER CHIEPFIREOFFICER SHRJG. S. SAWANT (Alterna!e) DR T, P. SHARiVJA DR A. K. CiUPTA (Alternate) DEPUTY INSPE~R GENERAL (FULE) SHRIS. L. NAGARKAR (Alternate) CHIEF ENGINEER (E) I SHRJA. K. KAPCOR SHRJH. S, KAPARWAN (Akmare) SHRIR. RAMAKRJSHNAN COLG. P. KRJSHNAMURTHY DREJXOR(Fw.ESAFETY) DEPUTY DIRECTOR (FtRESAFETY) (Alternate) SHRIR. C. SHARMA SHRISURJNDER KUMAR (Alternate) SHRJM. GANGARAJU SHRJV. K. VERMA (Alternate) SHRJR. A. DUBEY SHRIAJAYSHANKAR (Altemafe) SHJU S. N. KUNDU DEPUTY DUtECTOR (FJRESAFETY) DtRJXTOR DEPUTY DIRECTOR (Alternate) SHRJG. B. MENON SHRJS. K. DHEJU PWsrDEm-r GENERAL SECRErARY (Akemafe) SHIUP. H, SEIWNA SHRIN. T. PANIWAN[ (Alternate) SHRJH, M. SABADRA MANAGING DJJtKTOR SHRJD. K, SARKAR (Alternate) SHRJ DEEPAK AGARWAL SHRJR. N. CHACHRA SHRJSUNtLDAS(Alternate) SHRID. K. SHAMI SHRJB. J. SHAH SHRIA. M. SHAH(Altemare) SHRI1. M. MANSWXt Debra !XJn SHRJR. P. SAXENA SHRJNEERAJ SHARMA (Alternate)

Fire Fighting Sectional

Organization Minls[ry of Home Atlairs, New Delhi Awpor1Acthority of India, New Delhi Andbm Pradesh Fke Services, Hydembad Blmbha Atomic Research Centre, Mumbai Bombay Fire Brigade, Mumbai Centml Building Research Institute, Roorkee Cmtrd Industrial Security Force, New Delhi

Central Public Works Department, New Delhi Centre for Environment and Explosive Safety, Delhi Concord Arai Pvt Limited, Chennai Control lemte of Quality Assurance (Fire), Pune Defence Research and Development Organization, Delhi Delhi Fire Service, New Delhi Directorate General of Supplies and Disposals, Hyderabad Engineer-in-Chiefs Branch, Army Headquarter, New Delhi

Fire and Safety Appliances Company, Kolkata Hmme (Police Department), Hyderabad t {mne Department (Fire Service), Chennai in personal capacity (33/2965-A, Venmda High School, Vennala, Cochin)

III

personal capacity (29/25, Rajendra Nagac New Delhi)

Imsti[utiorr of Fire Engineers (India), New Delhi Ktwverji Devshl & Co (P) Limited, Mumbai K.V Fire Chemicals, Navi Mumbai Loss Prevention Association of India, Mumbai Mathcr and Platt (India) Limited, New Delhi MECON Limited, Ranchi Ministry of Home Affairs, New Delhi N cwage Industries, M canbai N!ordmrn Railway, New Delhi Oil and Na{ural Gas Commission,

(Continued

on page 11)

10

IS 15222:2002

Organ izatio]l Oil Industry S~fety Directorate, New Delhi Real Value Appliances Limited, New Delhi Satex Fire Services Limited, Mumbai State Bank of India, Mumbai State Fire Tmining Centre, Mumbai Steel Authority of India, Rorukela S[eel Authority of India, Bokaro Steelage Industries Limited, New Delhi Surex Production and Sales (P) Limited, Kolkata Twiff Advisory Committee, Chenmti Twiff P.dvisory Committee, Mumbai Vijay Fire Protection Systems Pvt Limited, Mumbai West Beng~lFire Service, Kolkata BIS DirectorateGeneral

Representative(s) JOINT DIRECTOR (PROCESS) SHRtASHWSH MANGAL Stutt JtTENDRA SHAH SHRISANDLP SHAH(Alfemate) SHRIJ. S. GAHLAUI DR NAVINCHANDRA JAIN SHRIB. N, DAS SHRJB. P. DAS (Alternate) SHRIA. RAOTELA SHMC. P. SINGH (Alternate) SHRISHIVNATH SHRIV. KAMALANAITtA (Alternate) SHRITARtTSUR SHRID. NEOG[(Alfernafe) SHRIA MUKHERIEE SHRIH. C. MAHESH KUMAR (Alternate) SHIU T. R, A. KMSHNANL SHRtHAMSH SAL~ SHWB. PATHAK SHRIS. K. JAIN,D]rector C% Head (Civ Engg) [Representing Dkector General (Zix-oficio)] Member Secretary SHRIS. CHATORVEDI Joint Director (Civ Engg), BIS

11

Bureau

of Indian

Standards

BIS is a statutory institution established under the Bureau of Indian Standards Act, 1986 to promote harmonious development of the activities of standardization, marking and quality certification of goods and attending to connected matters in the country. Copyright BIS has the copyright of all its publications. No part of these publications maybe reproduced in any form without the prior permission in writing of BIS. This does not preclude the free use, in the course of implementing the standard, of necessary details, such as symbols and sizes, type or grade designations. Enquiries relating to copyright be addressed to the Director (Publication), BIS. Review of Indian Standards

Amendments are issued to standards as the need arises on the basis of comments. Standards are also reviewed periodically a standard along with amendments is rea.tllrrned when such review indicates that no changes are needed; if the review indicates that changes are needed, it is taken up for revision. Users of Indian Standards should ascertain that they are in possession of the latest amendments or edition by referring to the latest issue of BIS Catalogue and Standards: Monthly Additions. This Indian Standard has been developed from Dot: No. CED 22 (5951).

Amendments Amend No.

Issued Since Publication Text Affected

Date of Issue

BUREAU OF INDIAN STANDARDS Headquarters: Man.ak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002 Telephones: 3230131,3233375,323 9402 Regional Oftlces: Central Eastern Northern Southern Western Branches : Manak Bhavan, 9 Bahadur Shah Zafar Marg NEW DELHI 110002 : 1/14 C.I.T. Scheme VII M, V.I.P. Road, Kankurgachi KOLKATA 700054 : SCO 335-336, Sector 34-A, CHANDIGARH 160022 Telegrams: Manaksanstha (Common to all ofilces) Telephone 3237617,3233841 3378499,3378561 { 3378626,3379120 603843 { 602025 2541216,2541442 { 2542519,2541315 8329295,8327858 { 8327891,8327892

: C.I.T. Campus, IV Cross Road, CHENNAI 600113 : Manakalaya, E9 MIDC, Ma?ol, Andheri (East) MUMBAI 400093

: AHMEDABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE. F.MUDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANIWIR. LUCKNOW. NAGPUR. NALAGARH. PATNA. PUNE. RAJKOT. THIRUVANANTHXWWRAM. VISAKHAPATNAM.

Printed at Simco Printing Press, Delhi

You might also like

- Starry Abode, Imbolc RitualDocument9 pagesStarry Abode, Imbolc RitualHarmony Pax100% (1)

- Food Cost Control Techniques at Hotel Ramanashree BruntonDocument7 pagesFood Cost Control Techniques at Hotel Ramanashree BruntonAtul Mishra100% (1)

- Mobile Catering Business Plan TemplateDocument45 pagesMobile Catering Business Plan TemplateBill Humphreys100% (4)

- Design of CulvertDocument12 pagesDesign of CulvertDebajani DekabaruahNo ratings yet

- Design of RC FootingDocument17 pagesDesign of RC FootingSwopnilOjhaNo ratings yet

- Astm d943.Hsxk3536Document11 pagesAstm d943.Hsxk3536labinfoNo ratings yet

- Is-4927 Unlined Flax Canvas HoseDocument10 pagesIs-4927 Unlined Flax Canvas HoseCharls JamesNo ratings yet

- Bs 1881 - 112 (1983) PDFDocument11 pagesBs 1881 - 112 (1983) PDFAdesina AlabiNo ratings yet

- BS 1881 Part 5 (1970)Document18 pagesBS 1881 Part 5 (1970)thurais75100% (1)

- D2784Document7 pagesD2784rimi7alNo ratings yet

- Astm G85Document13 pagesAstm G85Rajumhaveri Haveri100% (3)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Astm D189Document7 pagesAstm D189sayonara_3No ratings yet

- Dynamic Well Testing in Petroleum Exploration and DevelopmentFrom EverandDynamic Well Testing in Petroleum Exploration and DevelopmentNo ratings yet

- Is 785 1998 Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDocument10 pagesIs 785 1998 Reinforced Concrete Poles For Overhead Power and Telecommunication Lines - SpecificationDebajani DekabaruahNo ratings yet

- Gpa 2377 1986Document8 pagesGpa 2377 1986Claudio PratesiNo ratings yet

- D130-12 Corrosiveness To Copper From Petroleum Products PDFDocument10 pagesD130-12 Corrosiveness To Copper From Petroleum Products PDFL Ayquipa MerinoNo ratings yet

- Server Training ManualDocument18 pagesServer Training Manualgovindarajan100% (1)

- Astm D 3612 - 01Document24 pagesAstm D 3612 - 01mtuankctNo ratings yet

- Metodo ASTM D402Document5 pagesMetodo ASTM D402Roberto ChamorroNo ratings yet

- D 2472 - 00 - Rdi0nziDocument2 pagesD 2472 - 00 - Rdi0nziphonghoa121No ratings yet

- GMW 14872 PDFDocument21 pagesGMW 14872 PDFJetesh Devgun100% (2)

- Astm D789-98Document6 pagesAstm D789-98Adam GordonNo ratings yet

- Astm D3612 2009 PDFDocument22 pagesAstm D3612 2009 PDFMarlon AsanzaNo ratings yet

- Cryogenics Safety Manual: A Guide to Good PracticeFrom EverandCryogenics Safety Manual: A Guide to Good PracticeNo ratings yet

- IRC SP 54 Manual Bridges PDFDocument27 pagesIRC SP 54 Manual Bridges PDFdubeyvivek50% (2)

- Astm d1603Document4 pagesAstm d1603zeqs9No ratings yet

- Lp4 Ro TVL He BPP Ncii Grade 11 q1 EditedDocument7 pagesLp4 Ro TVL He BPP Ncii Grade 11 q1 EditedSalgie SernalNo ratings yet

- CE 632 Shallow Foundations Part-1Document39 pagesCE 632 Shallow Foundations Part-1Abdul KabasyNo ratings yet

- D3427Document5 pagesD3427Fabian Antonio RoldanNo ratings yet

- Astm D 1265Document5 pagesAstm D 1265Jorge Kovach Alvarado50% (2)

- Astm D 2504 - 88Document5 pagesAstm D 2504 - 88Sinisa Gale GacicNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- A Weale Sea FeverDocument185 pagesA Weale Sea FeverMiss Kitty Reads85% (13)

- D4530Document5 pagesD4530rimi7al100% (1)

- The Night Is Short, Walk On Girl - 2Document199 pagesThe Night Is Short, Walk On Girl - 2Kafka ErgensNo ratings yet

- Marketing Project On MaggieDocument28 pagesMarketing Project On MaggieSudipRanjanDas0% (1)

- Retaining Wall DesignDocument180 pagesRetaining Wall DesignMayco Velasco100% (1)

- Natural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryFrom EverandNatural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryNo ratings yet

- PROBA SCRIS - FILOLOGIE ModelDocument2 pagesPROBA SCRIS - FILOLOGIE Modeljuly JNo ratings yet

- Astm D1657Document5 pagesAstm D1657EbenezersklNo ratings yet

- ASTM D 3178 - 89 (Reapproved 2002) CokeDocument4 pagesASTM D 3178 - 89 (Reapproved 2002) Cokealin2005No ratings yet

- Astm D 3178 - 89 R02Document5 pagesAstm D 3178 - 89 R02phaindikaNo ratings yet

- Astm D 1265Document5 pagesAstm D 1265Gonzalo ChirinoNo ratings yet

- Standard Test Method For Oxidation Stability of GasolineDocument7 pagesStandard Test Method For Oxidation Stability of Gasolinejohn tanNo ratings yet

- Astm D721Document7 pagesAstm D721ebalideNo ratings yet

- Astmd2272 02Document12 pagesAstmd2272 02karlitox123No ratings yet

- Method 25E - Determination of Vapor Phase Organic Concentration in Waste SamplesDocument14 pagesMethod 25E - Determination of Vapor Phase Organic Concentration in Waste SamplesĐàm QuânNo ratings yet

- D 1018 - 91 R95 RdewmtgtukveDocument6 pagesD 1018 - 91 R95 RdewmtgtukveMarco A. Rodríguez DíazNo ratings yet

- Method 15 - Determination of Hydrogen Sulfide, Carbonyl Sulfide, and Carbon Disulfide Emissions From Stationary SourcesDocument13 pagesMethod 15 - Determination of Hydrogen Sulfide, Carbonyl Sulfide, and Carbon Disulfide Emissions From Stationary SourcesAnh TuanNo ratings yet

- Astm D1160.2012Document19 pagesAstm D1160.2012Leny PortoNo ratings yet

- D 6558 Â " 00 RDY1NTGTUKVEDocument6 pagesD 6558 Â " 00 RDY1NTGTUKVEVictor fajardoNo ratings yet

- T-MEET324LA Experiment No.8 ORSAT ANALYSIS MEE31Document18 pagesT-MEET324LA Experiment No.8 ORSAT ANALYSIS MEE31Paul Ryan GeneralNo ratings yet

- D2361-Standard Test Method For Chlorine in CoalDocument4 pagesD2361-Standard Test Method For Chlorine in CoalPradjnaParamitaMicheleNo ratings yet

- ASTM D323 - Gage RVP For Liquified PetroleumDocument5 pagesASTM D323 - Gage RVP For Liquified PetroleumPramitha RosyidhiNo ratings yet

- D 5762 - 98 - Rdu3njitoDocument6 pagesD 5762 - 98 - Rdu3njitodelta lab sangliNo ratings yet

- D4208 (Total Chlorine in Coal by The Oxygen Bomb CombustionIon V)Document3 pagesD4208 (Total Chlorine in Coal by The Oxygen Bomb CombustionIon V)Ale Hurtado MartinezNo ratings yet

- Ts Avgas 100ll En!!!Document6 pagesTs Avgas 100ll En!!!Piranha Tourniquet100% (1)

- Astmd4530 2003Document7 pagesAstmd4530 2003सचिन उरुणकर100% (1)

- ASTM D 1603 - 01 Standard Test Method Carbon Black in Olefin PlasticsDocument4 pagesASTM D 1603 - 01 Standard Test Method Carbon Black in Olefin Plasticsuocmogiandi_a100% (1)

- Density or Relative Density Test Method for Light HydrocarbonsDocument6 pagesDensity or Relative Density Test Method for Light HydrocarbonsGonzalo ChirinoNo ratings yet

- Corrosion Astm D 1838-07Document5 pagesCorrosion Astm D 1838-07Cecilia Cruz Toribio100% (1)

- Astm D-2361Document4 pagesAstm D-2361Claudia Da Rolt0% (1)

- D1160Document18 pagesD1160guadalupegomezperezNo ratings yet

- Is 4984 PVC PipesDocument21 pagesIs 4984 PVC PipesKathiravan ManimegalaiNo ratings yet

- ASTM D6549 - Determination of Cooling Characteristics of QuenchantsDocument7 pagesASTM D6549 - Determination of Cooling Characteristics of QuenchantsjesusladoNo ratings yet

- M 03Document18 pagesM 03Ivan RosasNo ratings yet

- D6721-Standard Test Method For Determination of Chlorine in Coal by Oxidative Hydrolysis MicrocoulometryDocument4 pagesD6721-Standard Test Method For Determination of Chlorine in Coal by Oxidative Hydrolysis MicrocoulometryAyaNo ratings yet

- EPA Method 0010Document50 pagesEPA Method 0010محمد شاهينNo ratings yet

- DOT 3E (HSE) Specification for Seamless Steel Transportable Pressure ReceptaclesDocument15 pagesDOT 3E (HSE) Specification for Seamless Steel Transportable Pressure ReceptaclessajawalNo ratings yet

- C 1524 Â " 02 QZE1MJQTUKVEDocument5 pagesC 1524 Â " 02 QZE1MJQTUKVEJorge CarrascoNo ratings yet

- Astm d2029 Dew PTDocument6 pagesAstm d2029 Dew PTvlcmstne04No ratings yet

- Astm G85Document6 pagesAstm G85Abdul MunirNo ratings yet

- BS 812-109-1990 PDFDocument12 pagesBS 812-109-1990 PDFMohammad Twaha Jaumbocus100% (1)

- ISSMGE CPRF Guideline Final July 2013 PDFDocument28 pagesISSMGE CPRF Guideline Final July 2013 PDFDebajani DekabaruahNo ratings yet

- STAAD - Pro: Department of Civil Engineering, Iit RoorkeeDocument21 pagesSTAAD - Pro: Department of Civil Engineering, Iit RoorkeeNayan FataniaNo ratings yet

- Canalcrossing 139Document3 pagesCanalcrossing 139Subuk NgaboNo ratings yet

- Suction Hose Couplings For Fire Fighting Purposes - SpecificationDocument9 pagesSuction Hose Couplings For Fire Fighting Purposes - SpecificationDebajani DekabaruahNo ratings yet

- 4308 Dry Chemical Powder For Fighting B and C Class FiresDocument16 pages4308 Dry Chemical Powder For Fighting B and C Class FiresDebajani DekabaruahNo ratings yet

- Tips and Tricks For Using STAADDocument2 pagesTips and Tricks For Using STAADYusak Santoso UseNo ratings yet

- I S 901 - 1988Document5 pagesI S 901 - 1988Hariprasad gantyalaNo ratings yet

- List of Indian Standards Related To Building Construction, Management and Quality Control 1Document27 pagesList of Indian Standards Related To Building Construction, Management and Quality Control 1Debajani DekabaruahNo ratings yet

- Is-903 Couplings, Branch Pipe, NozzlesDocument13 pagesIs-903 Couplings, Branch Pipe, NozzlesCharls JamesNo ratings yet

- 940 Portable Fire Extinguisher Water Type PDFDocument11 pages940 Portable Fire Extinguisher Water Type PDFDebajani DekabaruahNo ratings yet

- Is-884 First-Aid Hose-Reel For Fire FightingDocument12 pagesIs-884 First-Aid Hose-Reel For Fire FightingCharls JamesNo ratings yet

- Is-884 First-Aid Hose-Reel For Fire FightingDocument12 pagesIs-884 First-Aid Hose-Reel For Fire FightingCharls JamesNo ratings yet

- Method of Testing and Sampling The Concrete 1199 PDFDocument46 pagesMethod of Testing and Sampling The Concrete 1199 PDFSravan KumarNo ratings yet

- Bridge Me 1Document333 pagesBridge Me 1amawauceNo ratings yet

- Bridge Me 1Document333 pagesBridge Me 1amawauceNo ratings yet

- Shallow)Document9 pagesShallow)SACHIN H. DHAMAPURKARNo ratings yet

- 1597-Part1+ Stone MasonaryDocument15 pages1597-Part1+ Stone MasonaryPoly EdayanalNo ratings yet

- Is 13828 Earthquake Resistance of Low Strength BuildingsDocument19 pagesIs 13828 Earthquake Resistance of Low Strength BuildingsDebajani DekabaruahNo ratings yet

- Lyn-Genet 3-Day Detox PlanDocument3 pagesLyn-Genet 3-Day Detox PlanKeith AlvarezNo ratings yet

- Malt specs & brewing performanceDocument4 pagesMalt specs & brewing performanceLeandrosampaNo ratings yet

- Basic Sentence Punctuation PracticeDocument1 pageBasic Sentence Punctuation PracticeLucia MeloNo ratings yet

- 52nd International Congress on Medieval Studies - May 2017Document259 pages52nd International Congress on Medieval Studies - May 2017jaredrodNo ratings yet

- Pri Chen Catalog 2012Document20 pagesPri Chen Catalog 2012Israel ExporterNo ratings yet

- Bar Glassware and PersonnelDocument13 pagesBar Glassware and PersonnelMr. Jaymar AragoNo ratings yet

- Resume Chef Sanjay JamwalDocument8 pagesResume Chef Sanjay JamwalSanjay JamwalNo ratings yet

- Imperial Units (4º ESO)Document4 pagesImperial Units (4º ESO)lumaromartinNo ratings yet

- Demand and ForecastingDocument4 pagesDemand and Forecastingsana abbasNo ratings yet

- English WorkshopDocument2 pagesEnglish Workshopyari lealNo ratings yet

- Cabalen RatesDocument2 pagesCabalen RatesMarrize Vicmudo Dela CruzNo ratings yet

- Banquet Sales Kit1Document2 pagesBanquet Sales Kit1Edwin_Iswandi_820No ratings yet

- Newsletter 0715Document4 pagesNewsletter 0715MountLockyerNo ratings yet

- Product List of DaburDocument5 pagesProduct List of DaburNischal Solanki85% (13)

- Example of A Healthy Meal Plan For A 45 Year Old ManDocument12 pagesExample of A Healthy Meal Plan For A 45 Year Old ManzyloexNo ratings yet

- The Milk Teas Habits of 18 Year Onld Female Students in ISBADocument23 pagesThe Milk Teas Habits of 18 Year Onld Female Students in ISBAQuang HuyNo ratings yet

- Gueridon ServiceDocument79 pagesGueridon Servicejoginder_punia8454No ratings yet

- Heathrow T4 MapDocument5 pagesHeathrow T4 MapP177264No ratings yet

- La Mohea, AndaluciaDocument1 pageLa Mohea, AndaluciaMiss_M90No ratings yet

- FCE Practice TestDocument23 pagesFCE Practice TestValeriaSantaCruz0% (1)

- Travels With My Cats July 2009Document18 pagesTravels With My Cats July 2009Diego Shirley Medina ArandiaNo ratings yet