Professional Documents

Culture Documents

3 - 4point Bend Flexural AppNote Nov11

Uploaded by

طه اللوذعيOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3 - 4point Bend Flexural AppNote Nov11

Uploaded by

طه اللوذعيCopyright:

Available Formats

3 and 4 Point Flexural Testing

Application Note

With ever increasing demand for high quality and reliable electronic components and materials, flexural tests have become an important test method in both the manufacturing process and research and development to define a materials ability to resist deformation under load. A components or materials flexural strength provides critical insight into the modulus of elasticity in bending, flexural stress and flexural strain.

The rising popularity of human interface devices such as touch screens means that everyday devices such as mobile phones are subjected to many cycles of flexing during normal use. As a result manufacturers are committed to ensuring products do not fail within their planned lifetime and of guaranteeing performance across a range of usage scenarios. In order to achieve this, the manufacturing and quality control processes need to be optimised by testing the performance of the material or product.

Bend testing of nal assembly

3 and 4 Point Flexural Testing

Application Note

Test Methods

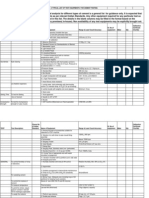

Flexural tests simulate stresses of tensile and compression on a specimen, such as PCB or final assembly. The physical response behaviour of the PCB or assembly is then monitored. Two common methods to test flexural strength involve destructive and non destructive testing. Destructive tests involve applying a uniform force on a PCB or assembly until it fails and recording the maximum force required as well as the distance displaced. Non-destructive tests involve applying a uniform force up to a specified limit and recording the displacement and ensuring the PCB and assembly can tolerate the specified force. Cyclical and fatigue testing, where specified force-displacement and force-time waveforms can be executed. This test method enables different strain rates to be induced onto a sample over a period of time, allowing analysis of cycles to failure as well as force-displacement and force-time characteristics to be determined.

The Nordson DAGE Solution

The Nordson DAGE 4000Plus tester provides the ability to perform 3 and 4 point flexure tests. A combination of fixtures as well as bespoke test solutions conform to a range of international standards including; ASTM D790 and D672, IPC TM-650, IEC 61189-2:TM20 and ISO 14125.

Push/pull 50kg with 3 point bend jig

3 point exure test

The 3 point flexure fixture produces its peak stress at the specimen mid-point with reduced stress elsewhere. This stress localisation is ideal for testing for specific isolation of stress on a component or material.

Bespoke tests

Specimen testing provides one aspect of flexural strength properties. Materials and substrates may go through several phases, such as heat reflow, before a complete product is produced. These steps can reduce the flexural strength of a product.

4 point exure test

The 4 point flexure fixture produces peak stresses along an extended region of the specimen hence exposing a larger length of the specimen with more potential for defects and flaws to be highlighted.

Nordson DAGE provides bespoke test solutions which cater for unique properties and designs in order to aid end product testing. This provides a clear flexural strength of the end product. Please contact Nordson DAGE for further information.

Application Note

3 and 4 Point Flexural Testing

Typical example of test

PCB and SMT technology are constantly facing new challenges in packaging and substrate design, where a typical product such as a mobile phone will undergo many types of mechanical strain and shock. Flexural testing has to be performed in order to determine how the product will react under force or changing forces such as bending or flexing. It is also important to determine the flexural properties of the product so that the design is within the desired tolerance. Cyclical and fatigue testing determine how long the product can sustain certain forces before failure and hence allow correct design of product. A flexural test would allow a range of characteristics to be determined of a PCB, including maximum force to failure, cycles and time to failure, flexural strength and flexural strain. These characteristics can help determine the quality of a bare PCB material or final assembly in order to deduce quality and reliability which was not previously possible on a bond test platform. Nordson DAGE provides a complete solution for 3 point and 4 point testing which coupled with the cyclic and fatigue software capabilities provides for a robust, reliable and repeatable test for research and development, test and inspection as well as process control.

Software:

The Nordson DAGE Paragon flexure test software features an easy to use interface allowing minimum test setup time, enabling the following material characteristics to be determined:

Flexural strength: defined as the materials or assemblies ability

to resist deformation under load. Measured at the moment of rupture where the highest stress is experienced within the material.

Stress-strain properties: the relationship between stress and strain.

Usually represented graphically. From this graph the following properties can be determined:

Flexural offset yield strength Tangent modulus of elasticity Secant modulus of elasticity

Flexural stress Flexural stress at break Stress at given strain Flexural strain Chord modulus

In addition, the Paragon flexure test software allows bespoke cyclic testing for custom test procedures, user defined cyclic patterns and selectable load range and speeds. Destructive and non-destructive tests are also featured. These custom test features allow for the determination of fail points of components or materials.

The Nordson DAGEe 4 point bend jig utilises an additional displacement sensor to measure midspan deflection of a sample under test accurately to 50um, this is achieved with a Baumer laser displacement sensor.

4 Point bend Jig

3 and 4 Point Flexural Testing

Paragon Software Flexible Analysis and Reporting

Data Analysis

Paragon provides an incredibly flexible analysis suite suitable for the most demanding of applications including:

On-board statistics and Statistical Process Control (SPC) package complete with histogram distribution curves (mean and current samples) Force trend analysis (with box whisker and optional mini histogram on the same chart) Grade pareto Loop height trend analysis Force/time displacement curves

Application Note

For more information,

Data Manipulation

Data can be manipulated in a number of ways:

ODBC compatibility (locally or via a network link) RS232 including a fixed field option CSV file format availability Copy results to the clip board to paste directly into Microsoft Excel or save direct to Excel or Word

please contact your Nordson DAGE regional ofce or speak with your Nordson DAGE representative, all of which are listed on www.nordsondage.com. Americas +1 510 683 3930 Phone sales@nordsondage.com Email China +86 512 6665 2008 Phone sales.ch@nordsondage.com Email Germany +49 7021 950690 Phone sales.de@nordsondage.com Email Japan +81 432 995851 Phone sales.jp@nordsondage.com Email South East Asia +65 655 27533 Phone sales.sg@nordsondage.com Email United Kingdom +44 1296 317800 Phone globalsales@nordsondage.com Email

Third Party Statistical Process Control (SPC)

Paragon can be configured to output results into industry leading SPC packages. These packages are directly available from, and supported by, the manufacturer.

All combined with a powerful statistical results display, for mean, maximum and minimum range, standard deviation, mean 3s, Cpk and Cp.

Exporting Results

Test results can be saved directly to Microsoft Excel and Word as well as Adobe Acrobat, while graphs can be exported in common picture formats, such as .jpg, .tif and .bmp.

Flexural test results analysis

Nordson DAGE 25 Faraday Road Rabans Lane Industrial Area Aylesbury, Buckinghamshire HP19 8RY, UK

+44(0)1296 317800 Copyright Nordson DAGE www.nordsondage.com AP-BT-34PGT-201011.

You might also like

- 1595Document18 pages1595طه اللوذعيNo ratings yet

- Cookware - Pressure Cookers For Domestic Use: British Standard Bs en 12778:2002Document30 pagesCookware - Pressure Cookers For Domestic Use: British Standard Bs en 12778:2002طه اللوذعيNo ratings yet

- Iso 1817 1999 FR en PDFDocument8 pagesIso 1817 1999 FR en PDFطه اللوذعي0% (1)

- 1176Document7 pages1176طه اللوذعيNo ratings yet

- 1504Document45 pages1504طه اللوذعيNo ratings yet

- 1537Document8 pages1537طه اللوذعيNo ratings yet

- 1545Document17 pages1545طه اللوذعيNo ratings yet

- 1474Document10 pages1474طه اللوذعيNo ratings yet

- المواصفة السورية القياسيةDocument14 pagesالمواصفة السورية القياسيةطه اللوذعيNo ratings yet

- Syrians StandardsDocument157 pagesSyrians Standardsطه اللوذعي100% (5)

- GSO-ASTM-C-615 الجرانيتE PDFDocument7 pagesGSO-ASTM-C-615 الجرانيتE PDFطه اللوذعيNo ratings yet

- Sasmo CementDocument11 pagesSasmo Cementطه اللوذعيNo ratings yet

- G223 Spherical Seated Compression Platens Handle Angular MovementDocument1 pageG223 Spherical Seated Compression Platens Handle Angular Movementطه اللوذعيNo ratings yet

- ADMET FF-T Bend Fixture 50kN-100kN PDFDocument1 pageADMET FF-T Bend Fixture 50kN-100kN PDFطه اللوذعيNo ratings yet

- GSO-ASTM-C-615 الجرانيتE PDFDocument7 pagesGSO-ASTM-C-615 الجرانيتE PDFطه اللوذعيNo ratings yet

- Calibrating UTM, Creep and Torsion Testing MachinesDocument31 pagesCalibrating UTM, Creep and Torsion Testing Machineszilangamba_s4535No ratings yet

- 0751testing SingleDocument3 pages0751testing Singleطه اللوذعيNo ratings yet

- .In Cert TestequipmentDocument3 pages.In Cert Testequipmentsunilkumarpatel55No ratings yet

- Complete Materials Testing List EngDocument10 pagesComplete Materials Testing List Engطه اللوذعيNo ratings yet

- Mastertop P10 TDSDocument2 pagesMastertop P10 TDSطه اللوذعيNo ratings yet

- Appendix A FinalDocument9 pagesAppendix A Finalطه اللوذعيNo ratings yet

- Tensile TestDocument3 pagesTensile Testطه اللوذعيNo ratings yet

- Scholarship Cover LetterDocument2 pagesScholarship Cover LetterSalim Kitaka Jr.No ratings yet

- 03 Bond Design of Gravity WallsDocument42 pages03 Bond Design of Gravity WallsKen OkoyeNo ratings yet

- High Early Strength Cement - PdsDocument1 pageHigh Early Strength Cement - Pdsطه اللوذعيNo ratings yet

- Analysis of Portland CementDocument4 pagesAnalysis of Portland CementDipmalya Basak33% (3)

- Mechanical PropertiesDocument4 pagesMechanical PropertiesSh KittanehNo ratings yet

- 18-Silica Sand Foundry Requirements by DawsonDocument8 pages18-Silica Sand Foundry Requirements by Dawsonksvinyk7193No ratings yet

- Portland (W/C 0.485) 242: (Air-Entraining Portland (W/C 0.460) 230 Non-Portland (As Required For Flow of 110) )Document3 pagesPortland (W/C 0.485) 242: (Air-Entraining Portland (W/C 0.460) 230 Non-Portland (As Required For Flow of 110) )Anuradha RumeshNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- MCQ Unit 2 Centroid and FrictionDocument9 pagesMCQ Unit 2 Centroid and FrictionAnurag Patil100% (1)

- Kerbin to Laythe Mission PlannerDocument29 pagesKerbin to Laythe Mission PlannerumangdigheNo ratings yet

- 06-SpiritAerosys Boshers PaperDocument28 pages06-SpiritAerosys Boshers PaperCan YörütenNo ratings yet

- KGKJB CVDocument29 pagesKGKJB CVAalaya Housing Private LimitedNo ratings yet

- Dynamic Wetting by Nanofluids-Gui Lu (Auth.)Document122 pagesDynamic Wetting by Nanofluids-Gui Lu (Auth.)Paulo UtargNo ratings yet

- Super Computing Applications in Internal Combustion Engine Design andDocument8 pagesSuper Computing Applications in Internal Combustion Engine Design andMadhusudan BarotNo ratings yet

- Applied Thermo DynamicsDocument3 pagesApplied Thermo DynamicsAshley_RulzzzzzzzNo ratings yet

- Subject: KTM (3131906) Semester: 3rd UNIT-1 Introduction To Mechanism & MachinesDocument4 pagesSubject: KTM (3131906) Semester: 3rd UNIT-1 Introduction To Mechanism & MachinesJay Sathwara0% (1)

- Projectile Motion Honors PhysicsDocument29 pagesProjectile Motion Honors PhysicsDeepanshu GautamNo ratings yet

- ANSYS Case Study - Three Dimensional Elasticity Problem 2: Laporan Metode Elemen HinggaDocument5 pagesANSYS Case Study - Three Dimensional Elasticity Problem 2: Laporan Metode Elemen Hinggairfan najmudinNo ratings yet

- TS 4001 Lecture Summary on Ship Resistance ComponentsDocument66 pagesTS 4001 Lecture Summary on Ship Resistance Componentskhalaf1987No ratings yet

- Shear and Moment Equations in BeamsDocument53 pagesShear and Moment Equations in BeamsKd CaisedoNo ratings yet

- 9 Worksheet 1: Intermediate LevelDocument3 pages9 Worksheet 1: Intermediate LeveltuvvacNo ratings yet

- Physics Sindh Board MCQDocument9 pagesPhysics Sindh Board MCQAbdul RazaqueNo ratings yet

- Fatigue Analysis For Typical AircraftDocument10 pagesFatigue Analysis For Typical AircraftSonu KumarNo ratings yet

- Clap Users Manual Rev 4Document68 pagesClap Users Manual Rev 4Birendra KumarNo ratings yet

- General Wave Properties IGCSE Physics MSDocument2 pagesGeneral Wave Properties IGCSE Physics MSeren parkNo ratings yet

- Design of Bearing Bolts Subjected To Eccentric Loading Causing Moment in The Plane Perpendicular To The Plane of Group of BoltsDocument8 pagesDesign of Bearing Bolts Subjected To Eccentric Loading Causing Moment in The Plane Perpendicular To The Plane of Group of BoltsKathleen RossNo ratings yet

- 2 Modeling DC Servo MotorsDocument4 pages2 Modeling DC Servo MotorsAnuradha Gupta67% (3)

- Module 4 - Design of Tension MembersDocument30 pagesModule 4 - Design of Tension MembersSreelakshmi GNo ratings yet

- Fluid Structure Interaction Analysis With Abaqus and FLUENTDocument4 pagesFluid Structure Interaction Analysis With Abaqus and FLUENTAbdel Salam AlsabaghNo ratings yet

- TB Lecture10 Braced Frame StructuresDocument33 pagesTB Lecture10 Braced Frame StructuresSaeed Khawam100% (2)

- Fluids Past Papers PDFDocument65 pagesFluids Past Papers PDFAnushaBheenuckNo ratings yet

- Aqa MM2B QP Jan13 PDFDocument24 pagesAqa MM2B QP Jan13 PDFastargroupNo ratings yet

- Thermal and Statistical Physics - Mallett - BlumlerDocument27 pagesThermal and Statistical Physics - Mallett - BlumlerOswaldo Avalos QuispeNo ratings yet

- Wind Tunnel LabDocument11 pagesWind Tunnel LabshmomenyNo ratings yet

- Scale Up MetallurgyDocument36 pagesScale Up Metallurgyindependent_mindNo ratings yet

- Hydraulics exam questions on flow, channels and modelingDocument3 pagesHydraulics exam questions on flow, channels and modelingPraveen ChaudharyNo ratings yet

- Pandit 1998Document51 pagesPandit 1998debaprasad ghoshNo ratings yet

- Topic 6-DCC40163 Theory of StructureDocument29 pagesTopic 6-DCC40163 Theory of StructurenrhdyaaNo ratings yet