Professional Documents

Culture Documents

Hydraulic Control Valves: Valves Can Be Classified According To Their Functions To Three Main Types

Uploaded by

Omar Eladel Mahmoud0 ratings0% found this document useful (0 votes)

214 views0 pagesLecture notes of hydraulic valves (Types, Design, Selection)

Original Title

Hydraulic Valves

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLecture notes of hydraulic valves (Types, Design, Selection)

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

214 views0 pagesHydraulic Control Valves: Valves Can Be Classified According To Their Functions To Three Main Types

Uploaded by

Omar Eladel MahmoudLecture notes of hydraulic valves (Types, Design, Selection)

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

Hydraulic Valves 1

Hydraulic Control Valves

Valves can be classified according to their functions to three main types

1- Pressure Control Valves

2- Flow Control Valves

3- Directional Control Valves

Pressure Control Valves

It can be used to limit the maximum pressure (a relief valve), to set a back pressure (a

counterbalance valve)or to pass a signal when a certain pressure has been reached (sequence

valves)

Relief Valves

Setting of the main relief valve pressure

It is to be se at 10-20% above the maximum required working pressure.

Dual relief valves: Frequently, RVs are required in pairs to relieve the pressure on either side

of an actuator.

Hydraulic Valves 2

More explanations of the direct acting and indirect acting (pilot operated) relief valve:

Two stage relief vale or indirect acting relief valve or pilot operated relief valve symbol

Unloader Valves

A relief valve can be unloaded in two ways: 1- By pressure signal 2- By venting

Hydraulic Valves 3

Unloading Relief Valve Symbols

Counterbalance Valves (also called load holding valves)

It is basically a relief valve but used in a particular application to set up a back pressure

in a circuit

It is used in load lowering applications such as lift trucks, winched and presses.

The usual load pressure setting is 1.3 times the load-induced pressure, i.e., P

s

=1.3 P

l

Over center Valve (Brake Valve)

A disadvantage of a counter balance valve is that it reduces the available force. This

disadvantage of the counterbalance balance can be overcome by using remote pilot

counterbalance valve or brake valve.

Hydraulic Valves 4

Over center Valve (Brake Valve) and its symbol

So the function of the over-center valve is:

1- Hold the load in the neutral position

2- Prevent over-run during lowering

3- Gently brake the actuator to a halt on switching

Pressure Sequence Valve

It is a pressure relief valve used in a circuit to make sure that a hydraulic line does not open

until a certain pressure requirement at another location meets a certain requirement.

An important feature of all seq. valves is a separate drain connection from the spring

chamber. This is because, unlike a conventional R.V., a high pressure can occur in the

output port during the normal course of operation.

Hydraulic Valves 5

Pressure Reducing Valve

It maintains an output pressure which is lower than the input pressure by venting the

excess flow to tank or limiting the orifice area based on desired and actual output pressure

sensing.

Pressure-Reducing Valves may be:

(a) Non-reliving type: They do not limit any pressure increase downstream of the valve

set up by external force

(b) Relieving type: This limits the pressure downstream of the valve even which it is

increased by an external force.

Hydraulic Valves 6

Flow Control Valves (FCV)

FCV are used to regulate the fluid rate to actuators and so give speed control.

Flow through the control orifice is usually considered to be turbulent and the quantity of a

fluid flowing can be given by:

P x A K Q ) ( =

Where Q is flow, A is orifice area, dP is the pressure drop over the orifice and K is a constant

which may include the function of the orifice characteristics, velocity of the fluid and the

Rynolds Number.

Three specialist forms of flow-control valves are now considered:

1-Decelaration valves

2- Viscosity or temperature compensated valves

3- Pressure-compensated valves

Hydraulic Valves 7

Deceleration Valve

It is used to control deceleration or acceleration in which the throttle opening is controlled

by a roller or roller lever.

It combines two throttles (main and secondary) and one check valve for reverse flow. The

secondary throttle valve is to provide an adjustable minimum flow when the main throttle

is closed.

Viscosity or temperature compensated valves

The simplest way to eliminate the effect of viscosity is to use a sharp-edged orifice, the flow

through which is independent of viscosity.

Pressure-compensated valves

Pressure compensated flow controls must be used when accurate speed control at varying

supply or load pressure is required.

Compensator valves are used in:

1- Circuit where load is variable and the flow rate should not vary as a function of the

load as long as the valve is not saturated.

2- Multiple parallel hydraulic circuits where all circuit share the same pump supply

pressure, but the load pressure in each cylinder may be different.

Hydraulic Valves 8

Pressure-compensated valve

1 an adjustable metering orifice,

2 the compensating spool,

3 the compensating spring,

4 the compensating orifice,

5 the damping orifice

Hydraulic Valves 9

Speed control of a cylinder

Meter in: The quantity of oil entering the cylinder is controlled

Meter out: The flow valve is installed in the return line metering the fluid discharge.

Bleed off: The flow control valve is arranged to bypass part of the pump output directly to

tank. Bleed off speed control is best employed when the vast majority of the pump flow is

utilized by the cylinder and only a small percentage is by passed.

Bridge Network

It is used for accurate flow control in either direction

Modified Bridge Network to work as a lock valve

Applying a pilot signal at point C through a check valve, P

C

is slightly higher than P

A

and P

B

.

This will shut off the valves V

A

and V

B

Hydraulic Valves 10

Multiple speed systems using flow control valves

Hydraulic Valves 11

Directional Control Valves

Check Valves

Types of moving elements of the Directional Control Valves

a) Poppet

b) Spool

Poppet DCV

Hydraulic Valves 12

Sliding spool-type DCV

Hydraulic Valves 13

Selection of center position of a DCV

Hydraulic Valves 14

Valve Operation

Types of solenoids

Air gab AC solenoid: Very fast switching time(30 ms)

Air gab DC solenoid: Switching time approximately 60 ms

Oil immersed or wet pin solenoid:

Two Stage DCVs

Hydraulic Valves 15

Cartridge Valves

These consist of a valve shell which can be mounted in a standard recess in a valve block or

manifold.

Poppet type cartridge valve

The opening and closing movements of the poppet is a cartridge valve are pressure dependent

and a function of the forces on these areas.

A

X

=A

A

+A

B

Hydraulic Valves 16

Restrictor cartridge poppets

You might also like

- Neutral Position in DCVDocument6 pagesNeutral Position in DCVAimee SpearsNo ratings yet

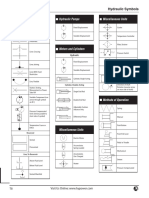

- Hyadraulic SymbolsDocument8 pagesHyadraulic SymbolsDhiraj ShindeNo ratings yet

- Directional Control Valves ExplainedDocument48 pagesDirectional Control Valves ExplainedMohamed ZahranNo ratings yet

- Hydraulic Schematic SymbolsDocument12 pagesHydraulic Schematic SymbolsswainpiyushNo ratings yet

- Pneumatic ValvesDocument25 pagesPneumatic ValvesGurmeet MehmaNo ratings yet

- Chapter 7 - Hydraulic Operation Circuit and ApplicationDocument19 pagesChapter 7 - Hydraulic Operation Circuit and ApplicationMuhammad AbdullahNo ratings yet

- Electron Pneumatic CircuitDocument59 pagesElectron Pneumatic CircuitArun SìvaNo ratings yet

- Hydraulic Circuits GuideDocument61 pagesHydraulic Circuits Guidehamidou100% (2)

- Load Sensing/Pressure Compensated Hydraulics (LS/PC)Document21 pagesLoad Sensing/Pressure Compensated Hydraulics (LS/PC)juan david loyolaNo ratings yet

- FLUID POWER SYSTEMS Theory and PracticeDocument37 pagesFLUID POWER SYSTEMS Theory and PracticeAchmad Ari Dwi P100% (2)

- Pneumatic Symbols GuideDocument3 pagesPneumatic Symbols Guidevishnunair27No ratings yet

- Hydraulic System ObjectivesDocument4 pagesHydraulic System ObjectivesMegha KharcheNo ratings yet

- Basic Pneumatic Circuitry: For Control and AutomationDocument134 pagesBasic Pneumatic Circuitry: For Control and AutomationIpquisNo ratings yet

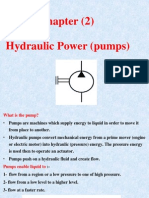

- Fundamentals of Hydraulic PumpsDocument12 pagesFundamentals of Hydraulic Pumpssanjay_lingot100% (1)

- Basic Schematic Symbols Chart (Hydraulic and Pneumatic Circuit DesignDocument10 pagesBasic Schematic Symbols Chart (Hydraulic and Pneumatic Circuit DesignMohammad Jahid Alam100% (3)

- 13 Pneumatic CircuitsDocument9 pages13 Pneumatic CircuitsUday Bagade100% (1)

- Hydraulics and PneumaticDocument112 pagesHydraulics and Pneumaticsurendar100% (2)

- Module - Time Delay ValveDocument9 pagesModule - Time Delay ValvescribdNo ratings yet

- TRAINING MANUAL PNEUMATICS PROJECT EXERCISESDocument17 pagesTRAINING MANUAL PNEUMATICS PROJECT EXERCISESSriram SastryNo ratings yet

- Operation Principle of Counterbalance ValveDocument3 pagesOperation Principle of Counterbalance Valvemihalikj2190No ratings yet

- Control Components in Hydraulic SystemsDocument20 pagesControl Components in Hydraulic SystemsfazliNo ratings yet

- Mechatronics Lab ManualDocument54 pagesMechatronics Lab ManualAjay Chacko100% (1)

- 3-En2200-B - 4VP01Document15 pages3-En2200-B - 4VP01najafali1No ratings yet

- Servo Solenoid ValvesDocument204 pagesServo Solenoid Valveschandushar1604100% (1)

- Directional Control Valves ExplainedDocument19 pagesDirectional Control Valves ExplainedMANOJ MNo ratings yet

- 3 - Hydraulic System DesignDocument33 pages3 - Hydraulic System DesignAbere GetachewNo ratings yet

- 555 Delay OFF Timer Circuit For Delay Before Turn OFF Circuit PDFDocument11 pages555 Delay OFF Timer Circuit For Delay Before Turn OFF Circuit PDFdhanysiregar100% (1)

- Directional Control Valves GuideDocument193 pagesDirectional Control Valves GuidephaindikaNo ratings yet

- c3 - Pneumatics Circuit DesignDocument126 pagesc3 - Pneumatics Circuit DesignBazil Suhaimi100% (2)

- Hydraulic Pumps and MotorsDocument24 pagesHydraulic Pumps and MotorsMohammed Al-OdatNo ratings yet

- 2017 Industrial Hydraulics & Pneumatics Reference ManualDocument115 pages2017 Industrial Hydraulics & Pneumatics Reference ManualFati Mah100% (1)

- Hyd SymbolsDocument1 pageHyd SymbolsAdi Surya Herysusanto100% (2)

- Hydraulic ValvesDocument84 pagesHydraulic ValvestharinduNo ratings yet

- Hydraulic PumpsDocument36 pagesHydraulic Pumpsmohananc67No ratings yet

- Fluid Power Symbols PDFDocument4 pagesFluid Power Symbols PDFsanisah1245100% (1)

- Learn Basic Hydraulics Concepts in 40 CharactersDocument85 pagesLearn Basic Hydraulics Concepts in 40 CharactersRamesh Babu K KNo ratings yet

- Engine System ComponentsDocument10 pagesEngine System Componentskeval patel100% (2)

- Diagnosis of Inductive Crankshaft and Camshaft SensorsDocument3 pagesDiagnosis of Inductive Crankshaft and Camshaft SensorsWilliam BelascoNo ratings yet

- Hydraulic PumpsDocument63 pagesHydraulic PumpsSergio Juan67% (6)

- HydraulicPowerUnit PowerTransmissionDocument4 pagesHydraulicPowerUnit PowerTransmissionCesar Ruben SosaNo ratings yet

- H Electro Hydraulic Controls YukenDocument142 pagesH Electro Hydraulic Controls Yukenchidambaram kasi100% (1)

- Hydraulic PumpsDocument35 pagesHydraulic PumpsMohammed Al-Odat100% (1)

- Hydraulics Circuit Design and AnalysisDocument24 pagesHydraulics Circuit Design and AnalysisPranav PandeyNo ratings yet

- Hydraulic OverviewDocument32 pagesHydraulic OverviewMACHINERY101GEAR100% (3)

- Hydraulic and Pneumatic Circuit Symbols ChartDocument12 pagesHydraulic and Pneumatic Circuit Symbols ChartSaurabh SharmaNo ratings yet

- 11 Main Hydraulic PumpDocument4 pages11 Main Hydraulic PumpZawminhtun100% (1)

- The Charging System Has Three Main Components: The Alternator, The Voltage Regulator, and The BatteriesDocument20 pagesThe Charging System Has Three Main Components: The Alternator, The Voltage Regulator, and The BatteriesMae CherryNo ratings yet

- Hydraulic CircuitsDocument30 pagesHydraulic CircuitsKarthikn Altoc100% (3)

- Hydraulics and Pneumatics SystemsDocument4 pagesHydraulics and Pneumatics SystemsKrista JacksonNo ratings yet

- Hydrostatic DriveDocument13 pagesHydrostatic DriveDhanraj PatilNo ratings yet

- Simbolo GiaDocument1 pageSimbolo GiaFernando Gutierrez100% (1)

- 4 TH Unit ValvesDocument43 pages4 TH Unit ValvesBahaa EmadNo ratings yet

- Industrial Hydraulic CircuitsDocument43 pagesIndustrial Hydraulic CircuitsFidel Garcia GarciaNo ratings yet

- Hydraulic ValvesDocument7 pagesHydraulic ValvestylersfergusonNo ratings yet

- L3 Control ValvesDocument36 pagesL3 Control Valvesgebremicael legesseNo ratings yet

- Chapter 4Document46 pagesChapter 4Thành CôngNo ratings yet

- Fluid Control ValvesDocument41 pagesFluid Control ValvesgaurangmarvaniaNo ratings yet

- Extra Notes Pneumatic 2Document27 pagesExtra Notes Pneumatic 2olivia curtisNo ratings yet

- Sequence ValveDocument8 pagesSequence Valvemr3478No ratings yet

- HTTP WWW - Hydraulicspneumatics.com Classes Article Article Draw P23Document11 pagesHTTP WWW - Hydraulicspneumatics.com Classes Article Article Draw P23jorsueNo ratings yet

- Precision Machine Design GuideDocument6 pagesPrecision Machine Design Guidemariomato100% (1)

- Climax Keyless Locking Device CatalogDocument32 pagesClimax Keyless Locking Device CatalogkeikunbrNo ratings yet

- Osha 3433Document96 pagesOsha 3433morcuyoNo ratings yet

- A Method of Calculus of Residual Lifetime For Lifting InstallationDocument7 pagesA Method of Calculus of Residual Lifetime For Lifting InstallationArisNo ratings yet

- Din 15061 Translate EngDocument1 pageDin 15061 Translate EngMaey Akim50% (2)

- Osha 3433Document96 pagesOsha 3433morcuyoNo ratings yet

- NORSOK Lifting Equipment Standard GuideDocument37 pagesNORSOK Lifting Equipment Standard GuideHuget St100% (1)

- prEN 13001 3 1 2010Document105 pagesprEN 13001 3 1 2010Gogy100% (1)

- Section 11 Cranes and Derricks: Health & Safety Policy and Procedures ManualDocument8 pagesSection 11 Cranes and Derricks: Health & Safety Policy and Procedures ManualzviNo ratings yet

- R002u2u2 Med Warning PDFDocument173 pagesR002u2u2 Med Warning PDFmuamer1No ratings yet

- Holterlevpdf PDFDocument75 pagesHolterlevpdf PDFzviNo ratings yet

- Din 15061 Translate EngDocument1 pageDin 15061 Translate EngMaey Akim50% (2)

- SKF VRing ProductsDocument20 pagesSKF VRing ProductsmadairkifNo ratings yet

- Design of Hydraulic Systems For Lift TrucksDocument264 pagesDesign of Hydraulic Systems For Lift TrucksThuan LeNo ratings yet

- PDFDocument598 pagesPDFVagner BaldassoNo ratings yet

- Micro SelfDocument1 pageMicro SelfzviNo ratings yet

- Design of Hydraulic Systems For Lift TrucksDocument264 pagesDesign of Hydraulic Systems For Lift TrucksThuan LeNo ratings yet

- Welders Visual Inspection Handbook-2013 WEB PDFDocument77 pagesWelders Visual Inspection Handbook-2013 WEB PDFquiron2014No ratings yet

- Micro SelfDocument1 pageMicro SelfzviNo ratings yet

- SKF VRing ProductsDocument20 pagesSKF VRing ProductsmadairkifNo ratings yet

- SKF VRing ProductsDocument20 pagesSKF VRing ProductsmadairkifNo ratings yet