Professional Documents

Culture Documents

SWP-22 Lock Out Tag Out Daiman

Uploaded by

Hassan AbdullahCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SWP-22 Lock Out Tag Out Daiman

Uploaded by

Hassan AbdullahCopyright:

Available Formats

Ryobi Kiso (S) Pte Ltd

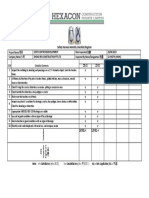

Safe Work Practices (SWP) for LOCK - OUT - TAG - OUT Procedures check for minimum requirements (Please tick):

SWP-22

1.

Permit-to-Work Procedure in place where applicable Logout Tag out S stem where applicable PP! requirements

!mergenc "esponse Plan(!"P) ______________________________________________________________ Purpose : To pre#ent $%S incidents and in&uries due to une'pected energi(ation of machiner and equipment during ser#ice and maintenance This SWP-*+ SWP-** SWP-./ SWP-.1 procedure is applicable to all Pro&ect Sites)

2. .

Scope !efere"ce

: :

,sage of "otating !quipment or -achiner Safe ,se of %and Tools 0ontrol of !lectrical %a(ards -achiner Safet

#. 2)* 2)1 %. 7) * 7) 1 7) /

$efi"itio" : Lock-$ut 3 Putting a lock on the part of the machine that controls the energ 4 for e)g) a circuit breaker4 switch4 block or #al#e4 etc) This pre#ents the machine from starting up or releasing energ accidentall ) Tag-$ut 3 Putting a special tag to warn people of the danger of starting up the machine) 5t is used when the equipment can6t be locked out) !espo"si&i'it( : 5t is the responsibilit of the WS%$8SS to ensure that this procedure is implemented at the pro&ect sites) 5t is the responsibilit of the WS%$8SS to identif equipment and machiner that require Lock-$utTag-$ut (L$T$)) 5t is the responsibilities of all equipment and machiner users to follow the Lock-$ut-Tag-$ut procedure) Proce*ure : +,uip-e"t a"* .ac/i"er( !e,uiri"0 LOTO 9)*)* 9)*)1 The WS%$8SS shall identif a list of equipment and machiner that require Lock$ut-Tag-$ut) L$T$ ma be required for equipment and machiner that runs on electricit 4 h draulic energ (water or other liquid that mo#es through pipes or hoses)4 pneumatic energ (pressuri(ed steam or gases or compressed air) or mechanical energ (stored or built-up energ in springs))

). 9)*

9)1

$nl qualified and trained personnel (whether emplo ees or appointed sub-contractors) shall carr out L$T$ and ser#ice or maintenance of machiner and equipment The authori(ed emplo ee or subcontractors shall follow the following steps to L$T$: :now the machine6s energ t pe4 amount4 and ha(ards4 plus how to control and lock it out) ;otif all affected site personnel (including workers and subcontractors) that equipment will be shut down and locked out for ser#ice and maintenance) Turn off the machine or equipment)

9)/

Page 1 of 2

Ryobi Kiso (S) Pte Ltd

).#

SWP-22

5solate the energ 3 the circuit breaker4 disconnect switch4 or other de#ice that pro#ides energ to the machine or equipment) Lockout and8 or tagout the energ control switches in an <off6 or <safe6 position to pre#ent accidental start-up or energ release) "elease (drain) or block stored energ 4 for e)g) #enting pneumatic lines4 draining or bleeding h draulic lines4 block or brace an gra#it -dri#en mo#ing parts) Test the operating controls4 for e)g) tr to turn on all controls to make sure that no power comes on and the equipment can6t operate4 use a #oltmeter or other testing de#ice to make sure there6s no power to the equipment) "emember to turn the controls back to the <off6 or <safe6 position after performing the test) ;ow4 it should be safe to perform the necessar ser#ice or maintenance) =nother authori(ed person or part ma do this)

Steps to !estart +,uip-e"t or .ac/i"er( $nce the maintenance or repair work is completed on the machine4 follow the following steps to restart: 5nspect the equipment or machiner to be sure all tools and other materials ha#e been remo#ed4 the machine is full re-assembled4 and that guards and other safet features are in place) ;otif all rele#ant personnel (emplo ees as well as subcontractors) that equipment will be starting) "emo#e all lockout de#ices) "emember that onl the person who put the lock ma remo#e it) T(pe of Locks 9)7)* The WS%$8SS shall identif the t pe of locks appro#ed for L$T$) These locks shall be durable to withstand heat4 cold4 humidit or corrosi#eness4 standardi(ed in color4 shape or si(e throughout the site4 strong (can6t be remo#ed without hea# force or tools) and identified b the name of the authorised personnel who installs and remo#es it)

).%

).)

T(pe of Ta0s 9)9)* The WS%$8SS shall identif appropriate tags to be used for Tagouts) These tags shall ha#e the same print and format throughout the site4 be eas to read and understand4 tough enough so the can6t be remo#ed accidentall ) The ties for tagouts shall be self-locking4 can6t be re-used4 and can be attached b hand (e)g) made of n lon)) Tags shall displa warnings such as >$O 1OT STA!T?4 >$O 1OT OP+1? or >$O 1OT OP+!AT+?)

9)9)1

Prepared @ : -r Aaiman Aesignation: WS%$ Aate: *2 $ct 1.*.

"e#iewed @ : -r ;g 0hoon %uat Aesignation: Senior Pro&ect -anager Aate: *2 $ct 1.*.

Prepared @ : -r Aaiman Aesignation: WS%$ Aate: *2 Bune 1.*.

"e#iewed @ : -r ;g 0hoon %uat

Page Aesignation: Senior Pro&ect -anager

Aate: *2 Bune 1.*.

2 of 2

You might also like

- LBNL Construction Safety ChecklistDocument12 pagesLBNL Construction Safety ChecklistAdriana EscobarNo ratings yet

- Ryobi Kiso SWP titleDocument2 pagesRyobi Kiso SWP titleHassan AbdullahNo ratings yet

- SWP-20 Usage of Ladder DaimanDocument1 pageSWP-20 Usage of Ladder DaimanHassan AbdullahNo ratings yet

- SWP-06 Lifting Operation DaimanDocument4 pagesSWP-06 Lifting Operation DaimanHassan AbdullahNo ratings yet

- SWP-12 Excavation DaimanDocument3 pagesSWP-12 Excavation DaimanHassan AbdullahNo ratings yet

- SWP-03 Electrical Safety DaimanDocument4 pagesSWP-03 Electrical Safety DaimanHassan AbdullahNo ratings yet

- TBT Storage and Use of Fuels and Oils PDFDocument1 pageTBT Storage and Use of Fuels and Oils PDFHassan AbdullahNo ratings yet

- TBT Pneumatic Tools PDFDocument1 pageTBT Pneumatic Tools PDFHassan AbdullahNo ratings yet

- Hazard Identification, Risk Assessment & Risk Control (HIRARC)Document1 pageHazard Identification, Risk Assessment & Risk Control (HIRARC)Siti Nursakinah Abdul HadiNo ratings yet

- SWP-23 Maintenance Machinery Regime DaimanDocument1 pageSWP-23 Maintenance Machinery Regime DaimanHassan AbdullahNo ratings yet

- FirmDocument3 pagesFirmTatiana Garcia MendozaNo ratings yet

- TBT Site Security PDFDocument1 pageTBT Site Security PDFHassan AbdullahNo ratings yet

- EOHSMS-02-C20 LOA Scaffold SupervisorDocument1 pageEOHSMS-02-C20 LOA Scaffold SupervisorHassan AbdullahNo ratings yet

- EOHSMS-02-F05 Confined Space PermitDocument1 pageEOHSMS-02-F05 Confined Space PermitHassan AbdullahNo ratings yet

- Ramapo College Vehicle Fueling SOPDocument1 pageRamapo College Vehicle Fueling SOPAnees EkNo ratings yet

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerNo ratings yet

- Safety Harness Monthly Checklist-Register JAN23Document1 pageSafety Harness Monthly Checklist-Register JAN23Iqbal HossainNo ratings yet

- FORM 3 For Maintaining Records of Hazardous Waste at FacilityDocument1 pageFORM 3 For Maintaining Records of Hazardous Waste at Facilitysandeep MNo ratings yet

- Fall Protection GRP 4Document9 pagesFall Protection GRP 4Ruben SibayanNo ratings yet

- SPI HSE FR 02 Tower Erection ChecklistDocument1 pageSPI HSE FR 02 Tower Erection ChecklistChandan KumarNo ratings yet

- HSE guidance on safety devices for rapid roller doorsDocument11 pagesHSE guidance on safety devices for rapid roller doorsmsc920138No ratings yet

- Ryobi Kiso Piling PermitDocument1 pageRyobi Kiso Piling PermitHassan AbdullahNo ratings yet

- EOHSMS-02-F06 Hot Work PermitDocument2 pagesEOHSMS-02-F06 Hot Work PermitHassan AbdullahNo ratings yet

- Lockout Tagout FormDocument1 pageLockout Tagout FormSrinivas MurthyNo ratings yet

- Safe Work Method StatementDocument4 pagesSafe Work Method StatementsimoneNo ratings yet

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaNo ratings yet

- EHS 2-F8 PTW LiftingDocument2 pagesEHS 2-F8 PTW LiftingLee Xiao YuNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocument4 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohnNo ratings yet

- General Work PermitDocument2 pagesGeneral Work Permitloganathan0% (1)

- High Risk Job Safety Analysis: Contractor ArgonneDocument13 pagesHigh Risk Job Safety Analysis: Contractor ArgonneVwoke OyibogareNo ratings yet

- ARA - For Emergency Diesel GeneratorDocument4 pagesARA - For Emergency Diesel GeneratorShaikh AftabNo ratings yet

- Work at Heights Self Assessment SheetDocument4 pagesWork at Heights Self Assessment SheetBalogun IsaacNo ratings yet

- Mobile Scaffold Inspection ChecklistDocument3 pagesMobile Scaffold Inspection Checklistanthony murphyNo ratings yet

- SWP-07 For Office Safety and Health DaimanDocument1 pageSWP-07 For Office Safety and Health DaimanHassan AbdullahNo ratings yet

- Operate Portalifts and Econolifts SafelyDocument7 pagesOperate Portalifts and Econolifts SafelyMuhammad Zefrian SyahputraNo ratings yet

- Overhead Crane Safety GuideDocument11 pagesOverhead Crane Safety GuideAhsan Farooq100% (1)

- 28.1.1 Mobile Equipment Inspection ChecklistDocument1 page28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemNo ratings yet

- Fire Safety - Fire InspectionDocument42 pagesFire Safety - Fire InspectionSaid Massinissa Elhadj AliNo ratings yet

- Working at Height Rescue Plan: WHS-FM-008Document2 pagesWorking at Height Rescue Plan: WHS-FM-008Purwo PrihartonoNo ratings yet

- CIVE3707 Risk Assessment Steel Beam LiftingDocument1 pageCIVE3707 Risk Assessment Steel Beam LiftingJosh Booth100% (2)

- Jobsite Safety Checklist Long Ver 1Document5 pagesJobsite Safety Checklist Long Ver 1Usman ShahidNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- DSTI Supervisors Daily Safet Task Instruction PDFDocument1 pageDSTI Supervisors Daily Safet Task Instruction PDFRicoNo ratings yet

- Effluent Discharge Mock Emergency and Evalaution ReportDocument3 pagesEffluent Discharge Mock Emergency and Evalaution Reportremember0% (1)

- Permit Working at HeightDocument4 pagesPermit Working at HeightkinaNo ratings yet

- Trestles and StagingDocument2 pagesTrestles and Stagingdak comeiNo ratings yet

- 2.0 Windsock Wind SpeedsDocument1 page2.0 Windsock Wind SpeedsSoham Mukherjee100% (2)

- Appointment Of Contractor Confined Space AssessorDocument2 pagesAppointment Of Contractor Confined Space AssessorHassan Abdullah100% (1)

- Specific Risk Assessment For Civil Work - Kijitonyama Shule SiteDocument5 pagesSpecific Risk Assessment For Civil Work - Kijitonyama Shule SiteemnelNo ratings yet

- Plant EQUIPMENT Check SheetDocument1 pagePlant EQUIPMENT Check SheetSparrow Green StudiosNo ratings yet

- EOHSMS 02 F03 Excavation PermitDocument1 pageEOHSMS 02 F03 Excavation PermitHassan AbdullahNo ratings yet

- Ryobi Kiso appointment letter WSH coordinatorDocument2 pagesRyobi Kiso appointment letter WSH coordinatorHassan AbdullahNo ratings yet

- Work Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Document15 pagesWork Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Vinaye GopaulNo ratings yet

- Near Miss Report FormDocument1 pageNear Miss Report Formsieged_rj3165No ratings yet

- Daily Safety ChecklistDocument4 pagesDaily Safety ChecklistKalyan ReddyNo ratings yet

- Working at Height Rescue PlanDocument3 pagesWorking at Height Rescue Plankhurram0% (1)

- Quarterly Safety ChecklistDocument2 pagesQuarterly Safety ChecklistAJ CompilationNo ratings yet

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiNo ratings yet

- Environmental Risk Assessment MatrixDocument1 pageEnvironmental Risk Assessment MatrixHassan Abdullah100% (1)

- Appointment of Contractor WelderDocument1 pageAppointment of Contractor WelderHassan Abdullah0% (1)

- Ryobi Kiso appointment letterDocument1 pageRyobi Kiso appointment letterHassan AbdullahNo ratings yet

- Eohsms-02-C21 Loa Crane OperatorDocument2 pagesEohsms-02-C21 Loa Crane OperatorHassan AbdullahNo ratings yet

- Ryobi Kiso appointment letter WSH coordinatorDocument2 pagesRyobi Kiso appointment letter WSH coordinatorHassan AbdullahNo ratings yet

- EOHSMS-02-C27 LOA Explosive Power Tool UserDocument1 pageEOHSMS-02-C27 LOA Explosive Power Tool UserHassan AbdullahNo ratings yet

- Appointment Of Contractor Confined Space AssessorDocument2 pagesAppointment Of Contractor Confined Space AssessorHassan Abdullah100% (1)

- EOHSMS-02-C22 LOA Lifting SupervisorDocument3 pagesEOHSMS-02-C22 LOA Lifting SupervisorHassan Abdullah100% (1)

- Eohsms-02-C25 Loa First AiderDocument1 pageEohsms-02-C25 Loa First AiderHassan AbdullahNo ratings yet

- Appointment Letter SignalmanDocument1 pageAppointment Letter SignalmanHassan AbdullahNo ratings yet

- Appointment of Lifting RiggermanDocument2 pagesAppointment of Lifting RiggermanHassan AbdullahNo ratings yet

- EOHSMS-02-C20 LOA Scaffold SupervisorDocument1 pageEOHSMS-02-C20 LOA Scaffold SupervisorHassan AbdullahNo ratings yet

- EOHSMS-02-C12 - RV 0 Monthly Fire Extinguisher ChecklistDocument1 pageEOHSMS-02-C12 - RV 0 Monthly Fire Extinguisher ChecklistHassan AbdullahNo ratings yet

- EOHSMS-02-C16 - RV 0 Monthly Concrete Breaker Inspection FormDocument1 pageEOHSMS-02-C16 - RV 0 Monthly Concrete Breaker Inspection FormHassan AbdullahNo ratings yet

- EOHSMS-02-C19 LOA Scaffold ErectorDocument1 pageEOHSMS-02-C19 LOA Scaffold ErectorHassan AbdullahNo ratings yet

- Crane Pre-Inspection FormDocument2 pagesCrane Pre-Inspection FormHassan AbdullahNo ratings yet

- EOHSMS-02-C17 - RV 0 Ladder Inspection FormDocument1 pageEOHSMS-02-C17 - RV 0 Ladder Inspection FormHassan AbdullahNo ratings yet

- EOHSMS-02-C15 - RV 0 Monthly Electrical Equipment Tools Inspection ChecklistDocument1 pageEOHSMS-02-C15 - RV 0 Monthly Electrical Equipment Tools Inspection ChecklistHassan AbdullahNo ratings yet

- EOHSMS-02-C07 - RV 0 Monthly Lifting Gear Inspection FormDocument1 pageEOHSMS-02-C07 - RV 0 Monthly Lifting Gear Inspection FormHassan Abdullah100% (2)

- EOHSMS-02-C13 - RV 0 Air Receiver Compressor Pre InspectionDocument1 pageEOHSMS-02-C13 - RV 0 Air Receiver Compressor Pre InspectionHassan AbdullahNo ratings yet

- Ryobi Gas Cutting Tool ChecklistDocument1 pageRyobi Gas Cutting Tool ChecklistHassan AbdullahNo ratings yet

- EOHSMS-02-C14 - RV 0 Air Receiver & Compressor ChecklistDocument1 pageEOHSMS-02-C14 - RV 0 Air Receiver & Compressor ChecklistHassan AbdullahNo ratings yet

- EOHSMS-02-C10 - RV 0 Electric Welding Inspection ChecklistDocument1 pageEOHSMS-02-C10 - RV 0 Electric Welding Inspection ChecklistHassan AbdullahNo ratings yet

- Mobile & Lorry Crane Checklist Form: Ryobi Kiso (S) Pte LTDDocument1 pageMobile & Lorry Crane Checklist Form: Ryobi Kiso (S) Pte LTDHassan AbdullahNo ratings yet

- EOHSMS-02-C09 - RV 0 Pre Inspection Generator - Welding ChecklistDocument2 pagesEOHSMS-02-C09 - RV 0 Pre Inspection Generator - Welding ChecklistHassan AbdullahNo ratings yet

- EOHSMS-02-C04 - RV 0 Test Pile Operation ChecklistDocument1 pageEOHSMS-02-C04 - RV 0 Test Pile Operation ChecklistHassan AbdullahNo ratings yet

- EOHSMS-02-C08 - RV 0 Lifting Supervisor ChecklistDocument2 pagesEOHSMS-02-C08 - RV 0 Lifting Supervisor ChecklistHassan Abdullah100% (1)

- Ryobi Piling Rig Checklist EOHSMS-02-C03Document1 pageRyobi Piling Rig Checklist EOHSMS-02-C03Hassan AbdullahNo ratings yet

- Static pile load test using kentledge stackDocument2 pagesStatic pile load test using kentledge stackHassan Abdullah100% (1)

- EOHSMS-02-C02 - RV 0 Excavator ChecklistDocument3 pagesEOHSMS-02-C02 - RV 0 Excavator ChecklistHassan AbdullahNo ratings yet

- Understanding the nonlinear dynamics of liquid flow with surge tanksDocument12 pagesUnderstanding the nonlinear dynamics of liquid flow with surge tanksLouie Fajardo AbadNo ratings yet

- International GCSE Chemistry Teacher Resource Pack SampleDocument25 pagesInternational GCSE Chemistry Teacher Resource Pack SampleRaneem HaddadinNo ratings yet

- Applications and Uncertainties Associated With Measurements Using FTIR SpectrometryDocument37 pagesApplications and Uncertainties Associated With Measurements Using FTIR Spectrometrysalekojic5332No ratings yet

- HW Hydraulics (setII) Ch3Document4 pagesHW Hydraulics (setII) Ch3Zairah Francisco100% (1)

- Carbon Dioxide MsdsDocument6 pagesCarbon Dioxide MsdsrashaesharpeNo ratings yet

- CALC PID ReferenceDocument121 pagesCALC PID ReferenceJohn CebNo ratings yet

- Investigation of The Foaming Capacity of Different Washing Soaps and The Effect of Addition of Sodium Carbonate On ItDocument10 pagesInvestigation of The Foaming Capacity of Different Washing Soaps and The Effect of Addition of Sodium Carbonate On ItPrasanna kudale100% (1)

- Msds NaoclDocument6 pagesMsds NaoclJuan ChristopherNo ratings yet

- Solar System and Solar Electricity: Subject Code: EC 38106Document94 pagesSolar System and Solar Electricity: Subject Code: EC 38106Raj TalrejaNo ratings yet

- (Semiconductors and Semimetals 56) Robert Hull and John C. Bean (Eds.) - Germanium Silicon - Physics and Materials-Elsevier, Academic Press (1998)Document459 pages(Semiconductors and Semimetals 56) Robert Hull and John C. Bean (Eds.) - Germanium Silicon - Physics and Materials-Elsevier, Academic Press (1998)Domenico BarillariNo ratings yet

- Calculations and units in analytical chemistryDocument17 pagesCalculations and units in analytical chemistryangelaNo ratings yet

- Zam Brochure 0cef0f7dd4Document6 pagesZam Brochure 0cef0f7dd4Ivens LealNo ratings yet

- Void Former SD Filcor Cordek RampDocument1 pageVoid Former SD Filcor Cordek RampShamaNo ratings yet

- D473 - Sedimetnos Por ExtracciónDocument6 pagesD473 - Sedimetnos Por ExtracciónCarito LopezNo ratings yet

- Sellos T-5610 T-5610QDocument8 pagesSellos T-5610 T-5610QBenicio Joaquín Ferrero BrebesNo ratings yet

- Factors Affecting Solubility and Rate of Solution NotesDocument3 pagesFactors Affecting Solubility and Rate of Solution Notesscribduser0811972No ratings yet

- Karkim Kar Ben enDocument1 pageKarkim Kar Ben enIqbal batchaNo ratings yet

- Coherent and Incoherent ScatteringDocument22 pagesCoherent and Incoherent ScatteringAlberto Rasa'No ratings yet

- Tratamientos de FlotacionDocument35 pagesTratamientos de FlotacionGiroshi Roberth Reyes VillarNo ratings yet

- Dapust 21Document5 pagesDapust 21Dewo BontangNo ratings yet

- Physica A: H. Hassanabadi, S. Sargolzaeipor, W.S. ChungDocument8 pagesPhysica A: H. Hassanabadi, S. Sargolzaeipor, W.S. ChungMilton David SernaNo ratings yet

- en 10213 2007 Steel Castings For Pressure Purposes PDFDocument29 pagesen 10213 2007 Steel Castings For Pressure Purposes PDFPramod NautiyalNo ratings yet

- Fibre Optics GuideDocument34 pagesFibre Optics GuideMuthu EzhilanNo ratings yet

- GAMSAT TopicsDocument7 pagesGAMSAT TopicsSewon KimNo ratings yet

- Lewatit Monoplus TP 260: Product InformationDocument5 pagesLewatit Monoplus TP 260: Product InformationChang Chee HongNo ratings yet

- Fractional Distillation: Experiment #5Document14 pagesFractional Distillation: Experiment #5jamesNo ratings yet

- D 2669Document5 pagesD 2669Asep TheaNo ratings yet

- Pyruvate and Hydroxycitrate:carnitine May Synergize To Promote Reverse Electron Transport in Hepatocyte Mitochondria, Effectively Uncoupling' The Oxidation of Fatty AcidsDocument10 pagesPyruvate and Hydroxycitrate:carnitine May Synergize To Promote Reverse Electron Transport in Hepatocyte Mitochondria, Effectively Uncoupling' The Oxidation of Fatty AcidsmreadesNo ratings yet

- ChemistryDocument5 pagesChemistryapi-248750786No ratings yet

- Collection of Surface Wipe Samples For Analysis of Semi Volatile Organic Compounds (SVOCs)Document2 pagesCollection of Surface Wipe Samples For Analysis of Semi Volatile Organic Compounds (SVOCs)Berkeley AnalyticalNo ratings yet