Professional Documents

Culture Documents

Designing & Constructing Military Construction Projects

Uploaded by

Ralph Gene Trabasas FloraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Designing & Constructing Military Construction Projects

Uploaded by

Ralph Gene Trabasas FloraCopyright:

Available Formats

BY ORDER OF THE SECRETARY OF THE AIR FORCE

AIR FORCE INSTRUCTION 32-1023 21APRIL 2010 Incorporating Change 1, 29 March 2012 Civil Engineering DESIGNING AND CONSTRUCTING MILITARY CONSTRUCTION PROJECTS

COMPLIANCE WITH THIS PUBLICATION IS MANDATORY ACCESSIBILITY: Publications and forms are available on the e-publishing website at www.e-Publishing.af.mil for downloading and ordering. RELEASABILITY: There are no releasability restrictions on this publication. OPR: AFCEE/TDB Supersedes: AFI 32-1023, 19 July 1994 Certified by: AF/A7CP (Col Elizabeth A. Brown) Pages: 40

This instruction implements AFPD 32-10, Installations and Facilities, and Military Standard 3007F (MIL-STD 3007F), Standard Practice for Unified Facilities Criteria and Unified Facilities Guide Specifications. It provides general design criteria and standards, guidance on selecting architect-engineering (A-E) firms, and information on design and construction management. This document provides guidance governing Air Force military construction (MILCON) projects. It also applies to Air Force Reserve Command (AFRC) and Air National Guard facilities constructed on Air Force installations or on non-Air Force Department of Defense (DoD) property. The Chief of the National Guard Bureau and AFRC are responsible for developing instructions/guidance unique to the Air National Guard and AFRC construction programs, and oversee management of those programs. Refer to the United States Air Force Project Managers Guide for Design and Construction for detailed information regarding criteria and design management, procedures, and practices. Refer recommended changes and questions about this publication to the Office of Primary Responsibility (OPR) using the AF Form 847, Recommendation for Change of Publication; route AF Form 847s from the field through the appropriate functionals chain of command. Ensure that all records created as a resul t of processes prescribed in this publication are maintained in accordance with AFMAN 33-363, Management of Records, and disposed of in accordance with the Air Force Records Disposition Schedule (RDS) located at https://www.my.af.mil/gcss-af61a/afrims/afrims/. The use of the name or mark of any specific manufacturer, commercial product, commodity, or service in this publication does not imply endorsement by the Air Force.

2 SUMMARY OF CHANGES

AFI32-1023 21APRIL 2010

This interim change clarifies exemption to criteria procedures, solidifies Air Force precedence in case of conflict with model building codes, and clarifies policy regarding compliance with Title 10 United States Code Section 2807(b). References were also updated. A margin bar indicates newly revised material.

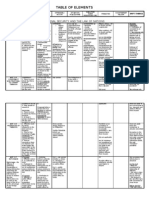

Chapter 1OVERVIEW 1.1. 1.2. 1.3. 1.4. 1.5. 1.6. Scope: ..................................................................................................................... Applicability: ......................................................................................................... Deviations to Criteria: ............................................................................................ Roles and Responsibilities: .................................................................................... Planning: ................................................................................................................ Program Oversight: ................................................................................................ 4 4 4 5 5 8 8 10 10 10 18 19 19 19 22 22 22 24 26 26 26 26 27 27 27 27

Chapter 2DESIGN PROCEDURES 2.1. 2.2. 2.3. 2.4. 2.5. 2.6. Scope: ..................................................................................................................... Applicable Directives: ........................................................................................... Design Management: ............................................................................................. MILCON Design Instructions: .............................................................................. Guidance Unique to the Unspecified Minor Construction (UMC) Program (P341): ....................................................................................................................... Authorities: ............................................................................................................

Chapter 3CONSTRUCTION MANAGEMENT 3.1. 3.2. 3.3. Scope: ..................................................................................................................... Roles and Responsibilities: .................................................................................... Construction Phases: ..............................................................................................

Chapter 4MEDICAL FACILITIES DESIGN AND CONSTRUCTION PROCEDURES 4.1. 4.2. 4.3. 4.4. 4.5. 4.6. 4.7. Scope. ..................................................................................................................... Roles and Responsibilities: .................................................................................... Medical MILCON: ................................................................................................ Project Authorizations. .......................................................................................... Design Approvals. ................................................................................................. Construction Changes. ........................................................................................... Base Realignment and Closure (BRAC) Program. ................................................

AFI32-1023 21APRIL 2010

Chapter 5PRESCRIBED AND ADOPTED FORMS 5.1. 5.2. Prescribed Forms: .................................................................................................. Adopted Forms: .....................................................................................................

3

29 29 29 30 39

Attachment 1GLOSSARY OF REFERENCES AND SUPPORTING INFORMATION Attachment 2SAMPLE ETL FORMAT

AFI32-1023 21APRIL 2010

Chapter 1 OVERVIEW 1.1. Scope: This chapter defines the types of facilities to which this Air Force Instruction (AFI) applies, outlines exemption procedures, and identifies the role and responsibilities of the primary stakeholders in design and construction of Air Force MILCON projects located on Air Force installations and Joint Bases. 1.2. Applicability: This instruction contains criteria for design and construction of Air Force facilities. The criteria in this chapter apply to all MILCON, Medical MILCON, and Unspecified Minor Construction (UMC) projects regardless of funding and apply to: 1.2.1. All Air Force installations in the 50 states, the District of Columbia, Puerto Rico, United States territories and possessions, and as far as practical, at Air Force installations in foreign countries. For purposes of this Instruction, the term Air Force installation includes land owned or leased by the Air Force and provided to states for use by the Air National Guard. 1.2.2. Properties listed or eligible for listing on the National Register of Historic Places. 1.2.3. Medical facilities (addressed further in Chapter 4 of this document). 1.2.4. Reserve Component facilities on Air Force installations or on non-Air Force Department of Defense (DoD) property. 1.2.5. Defense Commissary Agency (DeCA) facilities. Refer to DoDI, 7700.20, Commissary Surcharge, Nonappropriated Fund (NAF), and Privately Financed Construction Policy and Title 10 United States Code, Section 2685, for additional guidance. 1.2.6. Nonappropriated Funds (NAF) facilities. Refer to AFI 34-205, Services Nonappropriated Fund Facility Projects, and AFI 32-1022, Planning and Programming Nonappropriated Fund Facility Construction Projects, for additional guidance. Coordinate all actions related to AF NAF funded facilities with HQ AFSVA/SVXF. 1.2.7. Army and Air Force Exchange Service (AAFES) facilities. Refer to AFI 32-1022 for additional guidance. 1.2.8. Other tenant organization facilities (e.g. other federal agencies, including other military departments) and privately funded facilities (Fisher Houses, museums, banks, credit unions, thrift shops, etc.). Refer to AFI 32-1022 for additional guidance. 1.2.9. Air Force Military Family Housing (MFH). Refer to AFI 32-6002, Family Housing Planning, Programming, Design, and Construction for additional design and construction guidance. 1.2.10. The Chief of the National Guard Bureau is responsible for developing policies unique to the Air National Guard construction programs and oversees management of those programs. The office of the Air National Guard Civil Engineer (NGB/A7) is responsible for Air National Guard construction under Title 10 United States Code Section 1803. Refer to ANGI 32-1023, Criteria and Standards for Air National Guard Construction, for applicable guidance.

AFI32-1023 21APRIL 2010

1.3. Deviations to Criteria: Deviations to Unified Facility Criteria (UFC), Engineering Technical Letters (ETLs), and model building codes may be authorized by submitting an exemption request to the appropriate authority as defined herein. Exemptions to life safety, occupational safety, security, force protection, or other criteria required by public law (US Code) or Department of Defense direction is not permitted unless specifically authorized in legislation or Defense direction. Approved exemptions to criteria apply to a specific facility project and remain in effect indefinitely or until reevaluation/reconfirmation is required by other guidance (AFI, UFC, ETL, etc). 1.3.1. UFCs. Technical design requirements for DoD facilities are given in UFC publications. Designers are required to comply with all mandatory requirements unless the appropriate authority exempts these requirements. In general, the head of the Air Force field operating agency (FOA) having technical responsibility for the UFC content is the approval authority (authority having jurisdiction) for exemption to a UFCs requirements for a given project. Refer to MIL-STD-3007F for further guidance. 1.3.2. ETLs. Designers are required to comply with all mandatory requirements unless the appropriate authority exempts these requirements. The head of the Air Force FOA having technical responsibility for the ETL content is the approval authority (authority having jurisdiction) for exemptions to the ETL requirements for a given project. Requests for exemption shall be sent to AFCESA for processing to the appropriate authority. 1.3.3. Referenced Model Building Codes and Standards. The head of the Air Force FOA having technical responsibility for a UFC or ETL which references a model building code or standard is the approval authority (authority having jurisdiction) for exemptions to the referenced model building code or standard. Requests for exemption shall be sent to AFCESA for processing to the appropriate authority. 1.4. Roles and Responsibilities: 1.4.1. Secretary of the Air Force (SECAF). The SECAF provides guidance for the Air Force construction program through the Deputy Assistant Secretary (Installations), (SAF/IEI). 1.4.2. Deputy Assistant Secretary of the Air Force (Installations) (SAF/IEI). SAF/IEI is responsible for Air Force facility construction planning and programming policy and oversight. 1.4.3. Deputy Assistance Secretary of the Air Force (Energy (SAF/IEN). SAF/IEN is responsible for Air Force energy policy and oversight to include energy as it relates to facilities and infrastructure construction. 1.4.4. Air Force Center for Engineering and the Environment (AFCEE). AFCEE performs project design manager/construction manager (DM/CM) functions for MILCON including Housing, Non-Appropriated (NAF), Base Realignment and Closure (BRAC), Combatant Command (COCOM), and AF Medical MILCON. As the program manager and DM/CM, AFCEE manages execution of design and construction in coordination with the project delivery team (PDT). The DM/CM determines the execution strategy in concert with USAF policies and goals along with MAJCOM and installation engineer PDT members. Additionally, AFCEE formulates comprehensive planning guidance and provides technical planning assistance and support to installations, Major Commands (MAJCOMs), Field

AFI32-1023 21APRIL 2010 Operating Agencies (FOAs) and AF/A7C. AFCEE is also responsible for managing the UFC program for AF/A7C, and his/her representative is a member of the UFC Coordinating Panel and interfaces with the other Services to resolve issues and process UFCs. The AFCEE Director is the Air Force member of the Engineering Senior Executive Panel (ESEP). 1.4.5. Air Force Civil Engineer Support Agency (AFCESA). AFCESA develops, coordinates and interprets UFCs and ETLs, ensuring compliance with SAF/IEI, SAF/IEN, and other applicable DoD policies and directives. UFCs and ETLs specify technical engineering criteria and standards for infrastructure and facilities design, construction, and operation and maintenance in the following subject areas: electrical, mechanical, civil, roofing, anti-terrorism/force protection, structural, fire protection engineering, life safety and life-cycle cost engineering. AFCESA is responsible for managing the ETL system for AF/A7C and the UFC numbering system for all of DoD. AFCESA is also the home of the Air Force Facility Energy Center, responsible for facility energy conservation, metering and renewable energy sources. 1.4.6. Design Agent/Construction Agent (DA/CA). The DA/CA is the DoD component responsible for the technical execution of project construction and performs the duties of the contracting officer (CO). For Air Force MILCON projects, the DA/CA is either U.S. Army Corps of Engineers (USACE), Naval Facilities Engineering Command (NAVFAC), or, for approved projects, AFCEE. The AFCEE Waterbeach office is the DA/CA for the United Kingdom. 1.4.7. MAJCOM. The Requiring/Using MAJCOM has the overall responsibility for requirements identification and preparation of programming documents. MILCON requirements and siting for projects programmed or planned by other organizations must be coordinated by the host base MAJCOM (refer to AFI 32-1021, Planning and Programming Military Construction (MILCON) Projects). The following are definitions/ roles and responsibilities for MAJCOM programming and execution of MILCON projects: 1.4.7.1. Requiring/Using MAJCOM. The Requiring/Using MAJCOM is the command responsible for executing the specific mission being supported by a MILCON requirement. Requiring/Using MAJCOMs are responsible for programming, funding and for pre-coordinating with Host MAJCOMs during the Program Objective Memorandum (POM) process. The Requiring/Using MAJCOM is either a host or tenant unit on an installation. A tenant unit is commonly referred to as the receiver in host-tenant support agreements and receives base support from the Host MAJCOM. Requiring/Using MAJCOMs are responsible for validating the functional requirements during MILCON project programming. 1.4.7.2. Host MAJCOM. The Host MAJCOM is the command that provides base support on an installation and is commonly referred to as the supplier in host-tenant support agreements. The Host MAJCOM oversees the installation where the mission and MILCON are being executed. Host MAJCOMs are responsible for ensuring appropriate siting, architectural, environmental, and master plan integration are completed as necessary during project programming and execution. In addition, Host MAJCOMs may be asked to program MILCON projects on behalf of the Requiring/Using MAJCOM. 1.4.8. Air Force Reserve Command (AFRC). The AFRC develops additional policy unique to AFRC construction programs and oversees management of those programs.

AFI32-1023 21APRIL 2010

1.4.9. Base Civil Engineer (BCE). BCEs are responsible for initiating planning and programming for MILCON projects at their installations. 1.4.10. Host-Tenant Responsibilities. Manage intra-service situations per AFI 25-201, Support Agreements Procedures. By agreement of host and tenant, the tenant organization may fund design and construction. 1.4.10.1. DoD Components or Federal Agencies. Refer to AFI 65-601 V1, Budget Guidance and Procedures, for situations involving other DoD components or federal agencies. 1.4.10.2. Joint Basing. Where two or more Service Component installations have merged into zone installation and one Component has been appointed as the lead, the supporting Component is responsible for providing Installation Support (IS) to the Joint Base (JB). The supported Component(s) transfers installation management to the supporting Component. 1.4.10.2.1. Except as provided below, the supporting Component's policies, procedures, and guidance shall govern facilities planning, acquisition, sustainment, modernization, and disposal actions at Joint Bases. 1.4.10.2.1.1. To the extent it does not conflict with the supporting Component's criteria, the supported Component's unique planning, architectural and/or design criteria shall be used. 1.4.10.2.1.2. To the extent required to provide unique mission capabilities, the supported Component's unique planning, architectural and/or design criteria shall be used, even when conflicting with the supporting Component's criteria. 1.4.10.2.2. Except as provided below, the supporting Component's DA/CA shall be used for all military construction at Joint Bases. 1.4.10.2.2.1. For supported Component projects actively in design, under construction, or pending final acceptance, the supported Component's assigned construction agent shall maintain responsibility for the construction project through final completion, at which point the supporting Component shall conduct the final acceptance transaction. 1.4.10.2.3. Programming New Construction. The component generating a new construction requirement is responsible for programming the necessary planning, design, construction, and sustainment funding. The Component generating an increase to the Joint Base population is responsible for any new construction needed to expand installation support facilities to accommodate the population increase. In all cases, reuse of existing facilities is the preferred approach over new construction whenever feasible. 1.4.10.2.4. Demolition and Disposal. The supporting Component is responsible for facilities demolition and disposal at the Joint Base, except for demolition of facilities that are no longer needed because of new construction. In those cases, the organization requiring the new construction is responsible for demolition. In all cases, demolition of facilities no longer needed as a result of new construction shall be accomplished in a timely manner.

8 1.5. Planning:

AFI32-1023 21APRIL 2010

1.5.1. Base General Plan. Base General Plans, which include specific Area Development Plans, are required at Air Force installations. The Base General Plan is a summary document that provides information at an appropriate level of detail for the installation, the command, and other decision-makers to understand the character and structure of the installation, and its development potential. Refer to AFI 32-7062, Air Force Comprehensive Planning which provides responsibilities and requirements for comprehensive planning and describes procedures for developing, implementing, and maintaining the Base General Plan. 1.5.2. Area Development Plan (ADP). An ADP is developed for a specific area and/or functional use. The ADP provides the vision necessary to assess the project and outline mitigation for future use with a special focus on the area facility use and mission capacity. Refer to AFPAM 32-1010, Land Use Planning for requirements on an ADP. 1.5.3. Requirements Document (RD). The purpose of the RD is to provide a basis for understanding the project requirements. The BCE initiates part 1 of the RD (RD-1), involving as many of the project delivery team (PDT) as practical (at a minimum, including user and all installation-level stakeholders). Next, the BCE and MAJCOM engage the PDT to complete the RD Part 2 (RD-2), including as many PDT/stakeholders as possible. This document may also be referred to as a Customer Concept Document (CCD). Note: for NAF projects, the funding organization is included in the PDT and plays a role in determining the execution strategy. 1.5.4. Project Management Plan (PMP). The PMP presents the strategic decisions on design, acquisition, and construction methods that are agreed upon by the project stakeholders. The DM/CM will take the lead in preparing the PMP. 1.5.5. Project Siting. Project siting will comply with the installation commanders approved General Plan and applicable ADP. Refer to AFI 32-7062, Air Force Comprehensive Planning, and AFI 32-1021. 1.5.6. National Environmental Policy Act (NEPA). If the project management plan is of sufficient maturity that meaningful NEPA analysis can be conducted, refer to paragraph 2.2.2.2 for guidance on the Environmental Impact Analysis Process (EIAP). 1.6. Program Oversight: 1.6.1. Goals and Metrics. The Air Force management tool for performance measurement of the MILCON program is a set of cradle-to-grave metrics to provide accountability and program management capability from planning through financial closeout. It is intended to measure performance of all members of the PDT, especially DM/CMs, DA/CAs, and project programmers. The goals and metrics are codified in the Air Force Military Construction Program Management Plans published by USACE and NAVFAC. AFCEE/CM manages the program and is responsible for managing data during Design and Execution. 1.6.2. Automated Civil Engineering System-Project Management (ACES-PM). ACESPM is the Air Force management information system used by Air Force Civil Engineering to manage planning, design, and construction programs. It is used to provide management assessments of project cost, major milestones, and to provide an indicator for Air Staff to position construction funds with the CA. Timely, accurate ACES-PM data entry is essential

AFI32-1023 21APRIL 2010

through the course of the project life. The DM/CM will be the primary person that manages and updates ACES-PM during Design and Execution. The DM/CM will update and track NAF projects in ACES-PM.

10

AFI32-1023 21APRIL 2010

Chapter 2 DESIGN PROCEDURES 2.1. Scope: This chapter addresses design procedures and directives for Air Force MILCON projects. It also describes the design management process, Design Instructions (DIs), Engineering Technical Letter (ETLs), guidance for Unspecified Minor Construction (P-341) projects, authorities for funding, cost controls, reprogramming and change orders. 2.2. Applicable Directives: 2.2.1. General. The objective for all Air Force facilities is to enable mission execution and enhance occupant safety and quality of life by providing sustainable facilities. The application of asset management principles to include space optimization, energy efficiency and similar efforts to reduce facility life cycle costs is critical to long term value for the Air Force. Excellence in design is a primary goal for all MILCON projects. In addition to the guidance below, designers must also comply with installation architectural compatibility and facilities excellence standards. Site adaptation and modular construction techniques should be considered where appropriate. 2.2.1.1. Functional and Flexible Design. Air Force facilities shall be designed to meet mission requirements with the flexibility to accommodate changes in use with a minimum expenditure of resources. Functional and flexible aspects shall be defined in the RD. 2.2.1.2. Design for Accessibility. Comply with the most recent DoD accessibility policy when providing for people with disabilities. 2.2.1.3. Cost Management. Use life-cycle cost analysis and value engineering (VE) to manage projects costs. Cost control requires continual systematic cost management beginning at design and continuing throughout the life of the facility. The working estimate, cost-benefit analysis, and life-cycle cost analysis are methods for evaluating project cost effectiveness. 2.2.1.3.1. Life-Cycle Cost. Programming and design decisions for all types of construction will be based on life-cycle cost of the facility. Use the present value discounting approach described in AFI 65-501, Economic Analysis, and AFMAN 65506, Economic Analysis, unless otherwise specified. NAF funded projects may use a different decision-making process; contact the funding organization for further information. All life-cycle cost analyses, as defined by Title 10 Code of Federal Regulations Part 436, Federal Energy Management and Planning Programs, will use the National Institute of Standards and Technology (NIST) Handbook 135, Life-Cycle Costing Manual for the Federal Energy Management Program, and the Annual Supplement to Handbook 135, Energy Price Indices and Discount Factors for LifeCycle Cost Analysis. 2.2.1.3.2. Value Engineering (VE). VE is a method for optimizing facilities where designers and constructors can show savings through process efficiencies and use of alternative and equitable materials with similar performance characteristics. An informal (in-house, Agent) VE analysis, incorporating VE principles/guidelines, will

AFI32-1023 21APRIL 2010

11

be done for all projects over $2 million. A formal, 3rd party, VE study is required for each project with a programmed amount (PA) over $10 million, with the exception of 1) projects executed by design-build, or 2) classified projects or projects in classified areas. Implementation of VE analysis recommendations shall not compromise the functional and quality requirements of the facility. A VE study should not eliminate features used to meet Leadership in Energy and Environmental Design (LEED) requirements or certification per the most current Air Force policy. A VE study shall not eliminate features required to comply with Occupational Safety and Health Act (OSHA) standards. See paragraph 2.2.1.14. 2.2.1.4. A-E Selection. The A-E selection process must be conducted in accordance with FAR 36.6 and all other applicable laws and regulations. A-E services are described below: 2.2.1.4.1. Title I: These services are related to a specific construction project and consist of conducting field surveys and investigations to obtain design data and preparing contract plans, specifications, and cost estimates. 2.2.1.4.2. Title II: These services are related to a specific or proposed construction project and consist of supervision and inspection of construction. 2.2.1.4.3. Base Comprehensive Plans (BCP): These services consist of conducting field surveys and investigations to obtain data and producing base development plans. 2.2.1.4.4. Other A-E Services: These services are design and construction-related services, but are not connected with a specific construction project. The services consist of developing design criteria, fact finding studies, surveys, investigations, and the performance of environmental projects involving prevention, compliance, and restoration when the services of registered architects or engineers are required. Excluded are services that need not be performed by a registered engineer or architect such as providing design and construction equipment or computer programs. 2.2.1.4.5. Authorities. Title 10 United States Code Sections 2807(a), Architectural and Engineering Services and Design, Title 10 United States Code Section 9540(a), Architectural and Engineering Services, and the Defense Federal Acquisition Regulation Supplement (DFARS) 236.606-70 authorize contracting for and administration of A-E services for project design. Title 10 United States Code, Sections 4540, 7212 and 9540 limit the portion of the A-Es fee for producing contract plans and specifications to six percent of the estimated cost of the construction project. This does not include site investigations, studies and surveys. Title 40 United States Code, Sections 1101 1104, or commonly called the Brooks Act, provides the authority, definitions, and basic procedures for Federal Governments selection of A-E firms for professional services on facility projects. Title 10 United States Code, Section 2855(a) applies the Brooks Act to military construction (however the Brooks Act is not applicable to NAF contracting). For additional guidance, refer to Defense Federal Acquisition Regulation Supplement (DFARS) Subpart 236.6, Architect-Engineer Services and Air Force Federal Acquisition Regulation Supplement (AFFARS), Part 5336, Construction and Architect-Engineer Contracts.

12

AFI32-1023 21APRIL 2010 2.2.1.4.6. The Federal Business Opportunities (FBO) Synopsis Review. The FBO announcement is a key document in the A-E selection process. It identifies proposed, specific contract actions. In the case of indefinite delivery/indefinite quantity (IDIQ) contracts, the FBO synopsis identifies contract requirements based on projected, yet uncertain requirements. 2.2.1.4.6.1. A-E Contracts on Specific Projects. The MAJCOM/A7 in the case of installation contracts, or the respective commanders of AFCEE or AFCESA in the case of AFCEE or AFCESA contracts, shall approve the technical data to be included in the FBO synopsis, prior to submitting this information to the CO, to ensure it properly describes the requirement. 2.2.1.4.6.2. IDIQ Contracts. The MAJCOM /A7 in the case of installation contracts, or the Air Force Deputy Civil Engineer (AF/A7C-2), in the case of AFCEE and AFCESA contracts, shall approve the technical data to be included in the FBO synopsis, prior to submitting this information to the CO, to ensure it properly describes the requirements, the geographical coverage and provides an appropriate capacity relative to projected requirements. NAF contracting offices may have their own NAF IDIQ A-E contracts. Contact the funding organization for guidance. 2.2.1.4.7. A-E Slate Selection Approval. Approval authority for A-E selection is outlined in DFARS 236.6. 2.2.1.4.7.1. Approval Authority. For all A-E services, (Title I, Title II, BCPs, Other Services, and IDIQs), the BCE will obtain slate selection approval authority for services exceeding $1,000,000 per contract, per year plus option years, from the MAJCOM/A7. Similarly, for contracts at MAJCOM/A7, AFCEE, or AFCESA, slate selection approval authority for services exceeding $1,000,000 per contract, per year plus option years, will be obtained from SAF/IEI. 2.2.1.4.7.2. Notification Action (A-E Fees Greater than $1,000,000). When the cost of A-E design services for a project, or a group of related projects, is estimated to exceed $1,000,000, Congress must be notified in accordance with 10 USC 2807(b), Architectural & Engineering Services and Construction Design, before award or obligation of funds. Notification action is also required for project design undertaken by government personnel, as well as for A-E services and construction design planned for projects that are Congressional inserts or directed designs. AF/A7CP will initiate this Congressional notification, notify AFCEE when it has been sent to SAF/IEI, and notify the MAJCOM and AFCEE when SAF/IEI (through SAF/LL and SAF/FMBL) submits the notification package to Congress. (See DFARS Subpart 236.601 for the content of the Congressional notification and timeline requirements.) Notification must be completed (including the wait period) prior to start of any design, including that performed by government personnel. Staffing actions for 2807 notification typically take 3045 days. During the notification waiting period, public announcement of the plan to initiate design on a particular military construction project may be made and administrative actions leading to award of the A-E contract may be started, but no actions that obligate government funds may be

AFI32-1023 21APRIL 2010 undertaken.

13

2.2.1.4.7.2.1. When a large project or several projects for the same functional purpose costing $1,000,000 or more are undertaken, notification is required prior to the start of design for any portion of the undertaking, even though the project design may be subdivided into several A-E contracts or a combination of A-E contracts and design performed in-house by government personnel. Notification is required even though the design costs for such portion may be less than the reporting threshold specified by law. 2.2.1.4.7.2.2. Planning and design (P&D) funds expended to USACE and NAVFAC to award and administer A-E contracts are separate from the services themselves and do not apply to the 10 USC 2807 threshold. All other costs funded with P&D funds apply to the threshold. For a design-build contract, the design effort accomplished by the construction contractor and funded with construction dollars is not applicable to the threshold. However, preparation of a request for proposal for a design-build contract is considered A-E services and construction design and is subject to the 10 USC 2807 notification requirements. 2.2.1.4.7.2.3. For projects executed as design-build, a project-specific design cost estimate will normally be made and used as the basis for determining the notification requirements. In the absence of a design cost estimate, six percent of the programmed amount will be used by AF/A7CP as the estimated design cost for the purpose of determining notification requirements. 2.2.1.4.7.2.4. The level of effort authorized by a design instruction (3%, 15%, 30%, 100%, etc.) has no bearing on the notification requirement, as notification must be completed prior to start of any design. 2.2.1.4.7.2.5. If there is any perceived potential for reaching the threshold, prior notification should be made. In the case where no notification has been made and the threshold is approached after start of design, project managers should notify AF/A7CP and request further guidance. 2.2.1.4.7.2.6. Notwithstanding 10 USC 2807 requirements, procurement/financial management regulations may, in some cases, also require Congressional notification. The guidance provided here does not relieve the requirement to comply with procurement/financial management regulations governing notification. 2.2.1.5. Cost-Plus-Fixed-Fee Contracts. Advanced approval by the Secretary of Defense or designee is required for the use of cost-plus-fixed-fee contracts that are funded by a military construction appropriations act; are estimated to exceed $25,000; and will be performed within the U.S., except Alaska. Refer to DFARS, Subpart 216.306, Cost-Plus-Fixed-Fee Contracts for further guidance. 2.2.1.6. Commercial and DoD Facility and Infrastructure Design and Construction Standards and Criteria.

14

AFI32-1023 21APRIL 2010 2.2.1.6.1. Unified Facilities Criteria (UFC) Program. The UFC program is implemented by MIL-STD-3007F, and for the Air Force by this AFI. AFCEE is responsible for managing the UFC program for AF/A7C. 2.2.1.6.2. Commercial Standards. It is Congressional and DoD direction to use private sector criteria and technical standards based on their suitability for military use. The UFC unification process maximizes the use of commercial standards. 2.2.1.6.3. Engineering Technical Letters (ETL). This AFI implements the ETL system to provide specific AF design and construction guidance, procedures, criteria and standards. The ETL system serves to implement SAF/IEI and SAF/IEN policies and contributes to the Secretariats oversight of the MILCON program. ETLs are directive and apply to all levels of command, unless stated otherwise. ETLs supplement the UFCs, providing specific Air Force technical execution guidance. ETLs apply to all facilities constructed on Air Force installations except for MFH. An ETL remains in effect until canceled, rescinded or superseded by a later ETL. The Air Force Civil Engineer Support Agency (AFCESA) is responsible for managing the ETL system for AF/A7C. See Attachment 2 for ETL sample format. 2.2.1.6.4. Whole Building Design Guide (WBDG). The WBDG website, with its Construction Criteria Base (CCB) electronic library, is the official distribution medium for all non-sensitive technical DoD facility-related documents and contains the latest UFCs, ETLs and Unified Facilities Guide Specifications (UFGS). All UFC, ETL and UFGS documents can be viewed at: http://www.wbdg.org. 2.2.1.7. Space Criteria. Facility sizes shall be based on functional analyses while minimizing overall designed space to the maximum extent possible. AFMAN 32-1084, Facility Requirements, provides general planning and programming guidance. For Air Force Reserve facilities, refer to AFRCH 32-1001, Standard Facility Requirements. For Air National Guard facilities, refer to ANGH 32-1084, Standard Facility Requirements. Medical Facilities use DOD and Service-specific medical space planning criteria that is maintained and applied by the Office of the Assistant Secretary of Defense (Health Affairs), TRICARE Management Activity (OASD/HA TMA) and the AF Health Facilities Division. 2.2.1.8. Relationship to Community and Local Development. Base plans will be developed with full consideration of the planning goals and objectives of communities surrounding Air Force bases to enhance our value to the public. Refer to Executive Order 13327, Federal Real Property Asset Management, DoDD 4165.06, Real Property, and AFPD 32-90, Real Property Asset Management, for further guidance. In addition, federal agencies operating airfields shall work with local, regional, state, and other federal officials on compatible land use planning and ensure their programs serve to foster compatible land use and protect the airspace. Refer to AFI 32-7063, Air Installation Compatible Use Zone Program; Title 14, Code of Federal Regulations Part 77, Objects Affecting the Navigable Airspace; and UFC 3-260-01, Airfield and Heliport Planning and Design. 2.2.1.9. Preservation of Historic Resources. DoDI 4715.16, Cultural Resources Management, provides policy, prescribes procedures, and assigns responsibilities for managing archaeological and historic resources in and on properties and lands under DoD

AFI32-1023 21APRIL 2010

15

control. Refer to AFPD 32-70, Environmental Quality, AFI 32-7064, Integrated Natural Resources Management, and AFI 32-7065, Cultural Resources Management Program for guidance and compliance requirements. 2.2.1.10. Antiterrorism/Force Protection (AT/FP). All DoD facilities must comply with the latest UFCs and directives governing AT/FP standards for facilities. Refer to UFC 4-010-01, DoD Minimum Antiterrorism Standards for Buildings, including Change 1, for further guidance. Refer to UFC 4-022-01, Security Engineering: Entry Control Facilities/Access Control Points, for further guidance on Entry Control Facilities (ECFs) 2.2.1.11. Model Building Codes. Refer to UFC 1-200-01, General Building Requirements, and the United States Air Force Project Managers Guide for Design and Construction for specific guidance. In the case of conflicts between the model codes and Air Force criteria, the Air Force criteria shall take precedence. 2.2.1.12. Sustainable Design and Development. The Air Force has adopted the United States Green Building Councils (USGBC) LEED Green Building Rating System as a tool to incorporate sustainable design principles and subsequently to measure the sustainability achieved during the design and construction process. The Air Force Sustainable Facilities Guide provides tools, templates and suggested guidelines to help incorporate sustainable design throughout all the phases of facility development. The WBDG further explains the environmental issues related to building materials and provides technical guidance on green building material selection and environmental issues. See also ETL 08-13, Incorporating Sustainable Design and Development (SDD) and Facility Energy Attributes in the Air Force Construction Program; UFC 4-030-01, Sustainable Development; and UFC 3-210-10, Design for Low Impact Development. 2.2.1.12.1. The United States Green Building Councils (USGBC) Leadership in Energy and Environmental Design (LEED) Green Building Rating System. All Air Force MILCON projects, regardless of scope or funding source, shall use the LEED rating system as their self-assessment metric and comply with the most recent Air Force sustainable policy, laws and executive orders. AFPD 90-17, Energy Management and AFI 90-1701, Energy Management outline the Air Force energy management goals and objectives supported by this effort. Refer to the United States Air Force Project Managers Guide for Design and Construction for additional guidance. Costs for sustainable features must be identified on the DD Form 1391, FY__ Military Construction Project Data and cannot be eliminated to save scope or cut costs. 2.2.1.12.2. Energy Efficiency and Compliance. Designers will use a life-cycle cost analysis on all new facility designs, revitalization, and modification projects to reduce energy and water consumption and increase energy security in accordance with Title 10 Code of Federal Regulation, Parts 433, 434, 435 and 436; Public Law 109-58, Energy Policy Act of 2005 (EPAct05); EO 13514, Federal Leadership in Environmental, Energy, and Economic Performance; EO 13423, Strengthening Federal Environmental, Energy, and Transportation Management or updates or superseding executive orders; and Public Law 110-140, Energy Independence and Security Act (EISA) of 2007. (Refer to paragraph 2.2.1.3.1 for further life-cycle cost

16

AFI32-1023 21APRIL 2010 guidance). Consult UFC 3-400-01, Energy Conservation, with Change 4 for guidance and compliance requirements. 2.2.1.12.3. Renewable Energy. Evaluate renewable forms of energy in accordance with Title 10 United States Code Section 2915, New Construction: Use of Renewable Forms of Energy and Energy Efficient Products. 2.2.1.12.4. Metering. All Air Force buildings require metering where "cost effective". Required facilities will be in compliance with ETL 09-11, Civil Engineering Industrial Control System Information Assurance Compliance. All required meters will be in compliance with UFGS 26 27 13.10 30, Electric Meters; UFGS 33 12 33.00 30, Water Meters; UFGS 33 51 13.00 30, Natural-Gas Meters. At installations where an advanced meter reading system (AMRS) exists, all new building meters will become part of that system. Designers shall consider impacts of utility privatization as it relates to metering. 2.2.1.12.5. Energy Efficient Products. The designer will specify ENERGY STAR or Federal Energy Management Program (FEMP) designated products for all designs except if an ENERGY STAR product or FEMP-designated product is not cost-effective over the lifetime of the product, or no ENERGY STAR product or FEMP-designated product is reasonably available to meet the functional requirements of the Air Force. Refer to EPAct05 and EISA for further guidance and compliance requirements. 2.2.1.12.6. Solar Design. Use of active and passive solar energy systems shall be considered when practical and economically feasible. Refer to EISA for the latest compliance requirements. Additional information is available in UFC 3-440-01, Active Solar Preheat Systems, with Change 1 and UFC 3-440-04N, Solar Heating of Buildings and Domestic Hot Water. 2.2.1.13. Fire Protection. Fire protection will be in accordance with UFC 3-600-01, Fire Protection Engineering for Facilities. Additional information and specific Fire Protection technical guidance is published on the WBDG website. 2.2.1.14. Occupational Safety and Health Act (OSHA). Air Force facilities will conform to all applicable standards published under OSHA. Standards issued that affect facilities are found primarily in Title 29 Code of Federal Regulations, Part 1910, General Industry Standards and Title 29 Code of Federal Regulations, Part 1926, Safety and Health Regulations for Construction. Refer to AFI 91-302, Air Force Occupational and Environmental Safety, Fire Protection, and Health Standards. 2.2.1.15. Explosive Safety Standards. Modification of ammunition and explosives facilities or any planned facilities near ammunition and explosives facilities will be reviewed by the DoD Explosive Safety Board in accordance with DoD 6055.09-STD, Department of Defense Ammunition and Explosives Safety Standards; DoD Directive 6055.9E, Explosives Safety Management and the DoD Explosives Safety Board, and AFMAN 91-201, Explosives Safety Standards. 2.2.2. Environmental Criteria:

AFI32-1023 21APRIL 2010

17

2.2.2.1. Environmental Quality Standards. All projects must meet applicable federal, state, and local environmental standards and regulations in the U.S., its trust territories and possessions. For overseas locations, follow the guidance specified in host nationspecific Final Governing Standards, or if none exists, the current DoD Overseas Environmental Baseline Guidance Document (OEBGD) and applicable host nation laws. Also consult AFI 32-7006, Environmental Program in Foreign Countries. 2.2.2.2. Environmental Impact Analysis Process (EIAP). EIAP is the Air Force procedure for complying with NEPA. Ensure all construction projects comply with Title 32 Code of Federal Regulations, Part 989, Environmental Impact Analysis Process, and that all design and construction decisions are consistent with the results of the process. The process, including permits, should be complete prior to concept design completion to facilitate incorporation of mitigation and/or required actions into the design; in all cases this must be done prior to advertising for construction. The EIAP should address all environmental constraints within and surrounding the construction project footprint. Follow the requirements and work practices in Title 40 Code of Federal Regulations, Parts 1500-1508, National Environmental Policy Act of 1969, as Amended; EO 12114, Environmental Effects Abroad of Major Federal Actions; DoD Directive 6050.7, Environmental Effects Abroad of Major Department of Defense Actions ; AFI 32-7061, The Environmental Impact Analysis Process, and AFI 32-7066, Environmental Baseline Surveys (EBS) in Real Estate Transactions. The AF Form 813, Request for Environmental Impact Analysis, is used for documenting the need to conduct environmental analysis or the application of certain Categorical Exclusions (CATEXs). AFI 32-1021 requires a Certificate of Compliance addressing the status on compliance with various environmental regulations including EIAP. The Certificate of Compliance is summarized in the DD Form 1391. 2.2.2.3. Floodplains and Wetlands Regulations. All Air Force construction projects in the U.S., its trust territories and possessions must conform to EO 11988, Floodplains Management; EO 11990, Protection of Wetlands, and AFI 32-7064, Integrated Natural Resources Management. 2.2.2.4. Environmentally Preferable Products and Materials. Comply with the DoD Green Procurement Program (GPP) by using products and materials that are environmentally preferable. Refer to Title 42 United States Code, Section 6901, Solid Waste Disposal/Resource Conservation and Recovery Act and Major Amendments; Title 42 United States Code, Section 8262, National Energy Conservation Policy Act; Title 42 United States Code, Section 133, Pollution Prevention; EO 13423; EO 13514; and ETL 00-1, EPA Guideline Items in Construction and Other Civil Engineering Specification. 2.2.2.5. Toxic and Hazardous Materials. Follow the requirements and work practices provided in Title 29 United States Code, Section 651, Occupational Safety and Health Act of 1970; Title 29 Code of Federal Regulations, Part 1926.62, Lead Exposure In Construction; Interim Final Rule--Inspection and Compliance Procedures; Title 29 Code of Federal Regulations, Part 1910.134, Respiratory Protection; UFC 1-900-01, Selection of Methods for the Reduction, Reuse, and Recycling of Demolition Waste; and AFI 327042, Waste Management.

18

AFI32-1023 21APRIL 2010 2.2.2.6. Lead-Based Paint. Follow the requirements and work practices in Title 42 United States Code, Section 4831, The Lead-Based Paint Poisoning Prevention Act of 1971; Title 40 Code of Federal Regulations, Part 745, Lead-Based Paint Poisoning Prevention in Certain Residential Structures; Public Law 102-550, The Residential LeadBased Paint Hazard Reduction Act of 1992; Title 15 United States Code, Section 2601, Control of Toxic Substances, Findings, Policy, and Intent; Title 42 United States Code, Section 9601, The Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA); Title 40 Code of Federal Regulations, Part 302, Designation, Reportable Quantities, and Notification; UFC 3-190-06, Protective Coatings and Paints; Air Force Policy and Guidance on Lead-Based Paint in Facilities, HQ USAF/CC (24 May 93); Asbestos, Lead Paint and Radon Policies in BRAC Facilities, USAF (10 Nov 94); LeadBased Paint (LBP) Instruction for Facilities at Closure Installations, HQ USAF/SGPA (2 Dec 93); and Policy and Guidance on LBP Final Disclosure Rule, HQ USAF/CEV (19 Aug 96). 2.2.2.7. Solid Waste Management. AFI 32-7042, and Tracking and Reporting Solid Waste Disposal and Diversion from Landfill, (6 Feb 01), require Air Force installations to track and report the amount of construction and demolition debris that is recycled and disposed of in landfills. Refer to UFC 3-250-07, Standard Practice for Pavement Recycling; UFC 1-900-01 and UFGS-02 41 00, Demolition and Deconstruction Guide, for additional guidance. 2.2.2.8. Ozone Depleting Substances (ODSs). The regulations in Title 40 Code of Federal Regulations, Part 82, Protection of Stratosphere Ozone establish requirements regarding the service, maintenance, repair, and/or disposal of a wide array of equipment containing ODSs, and apply to all Air Force installations. For further detail on the ODS program, refer to AFI 32-7080, Pollution Prevention Program; AFI 32-7086, Hazardous Materials Management; and AFI 32-7040, Air Quality Compliance and Resource Management. 2.2.2.9. Storm Water Management During Construction. Refer to AFI 32-7041, Water Quality Compliance, and ETL 03-1, Stormwater Construction Standards.

2.3. Design Management: 2.3.1. Design Funds (MILCON). Use Planning and Design (P&D) funds to fund design services for MILCON. Refer to AFI 65-601 V1 for further clarification on use of funds. For NAF funded projects, contact the organization funding the project for guidance. 2.3.2. Design Reviews. The DA is responsible for the technical adequacy of the project and will provide technical reviews. The DM, BCE, MAJCOM and customers are responsible for the functional adequacy of the project. 2.3.2.1. Bidability and Constructability. Design reviews will include consideration of these issues to ensure clarity and accuracy of contract documents so the project can be successfully awarded and constructed with minimal modifications and duration and within budget. 2.3.2.2. Operability and Maintainability. Design reviews will include consideration of these issues to ensure the completed facility can be run economically and reliably over its lifetime. Use ETL 01-1, Reliability and Maintainability (R&M) Design Checklist.

AFI32-1023 21APRIL 2010 2.3.3. Interior Design. Refer to UFC 3-120-10, Interior Design, with Change 1.

19

2.3.4. Landscape Architecture. Refer to the Master Landscape Construction Specifications, the Architecture Compatibility Guide (both available digitally at: http://www.afcee.af.mil/), and the applicable installations Architectural Compatibility Plan. Consult UFC 3-201-02, Landscape Architecture for additional guidance. 2.4. MILCON Design Instructions: 2.4.1. Planning and Design Instructions. AF/A7CP issues Planning Instructions (PI) and Design Instruction (DI) to the DM/CM who in turn issues a DI to the DA. 2.4.2. AFRC Program Managers (PM). AFRC PMs issue the DI using the Air Force approved financial tracking database system. 2.5. Guidance Unique to the Unspecified Minor Construction (UMC) Program (P-341): 2.5.1. AF/A7CP Roles and Responsibilities: 2.5.1.1. Obtains project validation and approval through AF/A7C and SAF/IEI. AF/A7C validates the UMC projects and SAF/IEI approves the projects and notifies House and Senate Armed Services and Appropriations Committees of the intent to accomplish the project (refer to AFI 32-1021). The congressional notification requires a 21-calendar day waiting period (14 calendar days if notification is in electronic format) before construction funds can be obligated. Electronic notification is the current method used; if no committee raises an objection within 14 calendar days after notification, the notification process is complete, and AF/A7C advises the DM/CM to proceed with the project. 2.5.1.2. Issues the PI for the project to the DM/CM through ACES-PM. 2.5.1.3. Sends the P-341 construction program authorization to the DM/CM. 2.5.1.4. Authorizes construction advertising via a DI through the ACES-PM system. 2.5.1.5. Evaluates cost variations and submits them to AF/A7C or SAF/IEI for approval. 2.5.1.6. Approves transfer of P-341 funds between projects. 2.5.2. DM Roles and Responsibilities: 2.5.2.1. Manages projects according to ACES-PM financial tracking database system. 2.5.2.2. Sends the final design cost estimates, bid opening, contract award reports and funds requests, due to construction changes, to AF/A7CP through ACES-PM. 2.5.2.3. After construction contract award, uses P-341 funds to support DA or A-E, Title II construction supervision and inspection services and any required A-E design services (engineering and design or post contract award services). 2.6. Authorities: 2.6.1. Expiration of Authorizations and Appropriations. Refer to AFI 65-601 V1, Budget Guidance and Procedure. 2.6.1.1. Authorizations for Air Force MILCON projects expire after 30 September of the second year after the FY of the original authorization (A project authorized in FY08

20

AFI32-1023 21APRIL 2010 expires at the end of FY10) or on the date the President signs the new National Defense Authorization Act in the third FY (FY11 from the previous example), whichever date is later. 2.6.1.2. Congress must enact an extension of the authorization in the third year of the act or the authorization will expire. The DM/CM should submit requests for extension of authorization to AF/A7CP no later than 30 November each year. 2.6.1.3. Partial awards (intended to keep an authorization from expiring) must involve a construction placement rather than the purchase of government-furnished material or equipment. 2.6.1.4. Funds appropriated in an FY for a MILCON project may remain available for obligations beyond that FY to the extent provided in appropriation acts. MILCON appropriations generally are available for obligation for five FYs. Refer to Title 10 United States Code, Section 2860, Availability of Appropriations and AFI 65-601 V1 for use of expired funds. 2.6.2. Cost and Scope Control: 2.6.2.1. MILCON. Congress approves each MILCON project at a specific authorized and appropriated cost and scope. Title 10 United States Code Section 2853 authorizes a cost increase or decrease of not more than 25 percent of the amount appropriated or 200 percent of the minor construction project ceiling, whichever is less. The project scope may be reduced by not more than 25 percent of that specified to Congress; however there is no provision for an increase in the project scope identified on the DD Form 1391. It is imperative that managers understand that a cost variation shall not be used to increase project scope. The Program Management Plan for the Management of the Air Force Capital Construction Program (MILCON PgMP) summarizes and updates the controls in place to manage the MILCON execution program. This plan is located on the AFCEE MILCON Program Management Office Community of Practice website and can also be obtained by contacting AFCEE/CM directly. MILCON program managers at all levels must be familiar with these controls to ensure proper authority and/or notification is sought in the appropriate situation. Use the tables in the MILCON PgMP as an initial source for taking appropriate MILCON execution actions. 2.6.2.2. Reprogramming and Notification. Reprogramming and notification actions will be performed in accordance with all applicable regulations as outlined in the MILCON PgMP. AFCEE will prepare all documentation, coordinate with the MAJCOMs for project reprogramming and submit requests to AF/A7CP for further action. 2.6.2.3. Funding Changes. Funding changes with expired funds involve special rules. Refer to AFI 65-601 V1 for further clarification on use of funds. 2.6.3. Post Award Change Order Control: 2.6.3.1. Scope Changes. Refer to AFI 65-601 V1 for further clarification on use of funds. Refer to the United States Air Force Project Managers Guide for Design and Construction for additional guidance.

AFI32-1023 21APRIL 2010

21

2.6.4. Funding Guidance for Facility Acquisition. The DM/CM is required to determine and document the key factors leading to the selection of the most cost effective and appropriate design delivery acquisition strategy for each MILCON project. The use of Design Build (D-B) is the preferred method. Use construction funds for design after the D-B contract is awarded. 2.6.5. Funding and Project Management Guidance for Air Force Services Nonappropriated Fund Projects. The Air Force Services Agency (AFSVA) is the office of primary responsibility for administering and managing NAFs used to build projects funded with AF central nonappropriated funds. Refer to AFI 32-1022 and AFI 34-205 for additional guidance. 2.6.6. Expedited Construction Project. The use of MILCON funds to absorb extra cost of expediting a project is authorized under certain conditions described in Title 10 United States Code, Section 2858, Limitation on the Use of Funds for Expediting a Construction Project.

22

AFI32-1023 21APRIL 2010

Chapter 3 CONSTRUCTION MANAGEMENT 3.1. Scope: This chapter applies to construction management as it applies to the Air Force MILCON construction process. It defines the roles and responsibilities of the construction management team and typical construction phases. 3.2. Roles and Responsibilities: 3.2.1. AF/A7C: 3.2.1.1. Processes MILCON construction funds requests from CM and works with the requiring MAJCOM or AFCEE to identify and verify sources of funds. 3.2.1.2. Authorizes contract awards and cost and scope changes in accordance with the MILCON PgMP. 3.2.1.3. Submits reports, cost variations, re-programming, scope changes and other congressional notifications to Congress through the SAF based on justifications from the requiring MAJCOM. 3.2.2. Construction Manager (CM): 3.2.2.1. Evaluates construction progress. 3.2.2.2. Reports progress and manages the construction change request process. Keeps ACES-PM database system up-to-date or ensures others enter data in a timely manner. 3.2.2.3. Ensures CA provides government cost estimate with change request and secures approval prior to CA issuance to contractor. Verifies all construction changes are within the scope of work. Tracks and reports cost growth. 3.2.2.4. Monitors construction progress in relation to the schedule approved and administered by the CA. 3.2.2.5. Reviews all changes that impact functionality, appearance or maintainability, and coordinates changes with the BCE and Requiring/Using MAJCOM. Approves or disapproves changes affecting the functionality, and exterior appearance or maintainability. 3.2.2.6. Approves user change requests, within funds available, in accordance with the MILCON PgMP. Reviews change request promptly and restricts approval consideration to those requests necessary to meet the mission. 3.2.2.7. Directs the CA to implement approved user changes. 3.2.2.8. Makes a request (based on the CAs cost estimate) to AF/A7C through ACESPM when the CA requires additional funds above the established current working estimate (CWE). On Air Force Services NAF projects, the CM must make the request to AFSVA. 3.2.2.9. Ensures construction meets Air Force standards and user needs. 3.2.2.10. Works with the CA to assist in correcting design errors and omissions.

AFI32-1023 21APRIL 2010

23

3.2.2.11. Schedules a Red Zone meeting at 80 percent of construction completion with all participants to discuss, define, and achieve consensus on remaining construction activities, physical completion, and financial closeout of the project. 3.2.2.12. Makes site visits, as appropriate. 3.2.2.13. Participates in pre-final and final inspections as required. 3.2.2.14. Submits reprogramming. justification packages for cost and scope variations and

3.2.2.15. Ensures the CA delivers warranty and guarantee information to the BCE in transferring facility ownership responsibility. 3.2.2.16. Ensures CA delivers as-built drawings in requested media and format to the BCE within specified contract requirements. 3.2.2.17. Ensures the CA has the contractor conduct operations and maintenance training, LEED required Commissioning and delivers operations and maintenance manuals to the BCE at the Beneficial Occupancy Date (BOD), or as determined in MILCON Red Zone meeting. 3.2.2.18. Ensures CA conducts post-occupancy inspections as required. 3.2.2.19. Ensures the CA conducts end-of-warranty inspection with the user and CE Operations. Coordinates and disseminates all lessons learned reports. 3.2.2.20. Monitors financial completion of a project to enable withdrawal of unused funds in a timely manner. 3.2.2.21. Requests withdrawal of funds at project completion when all outstanding claims have been paid or found to have no merit by the CA. 3.2.2.22. During settlement of an appeals proceeding, submits the request and justification for additional funds to AF/A7C. 3.2.3. MAJCOM: 3.2.3.1. Works with the BCE to ensure timely delivery of government-furnished property/equipment. 3.2.3.2. Requests the user to participate in the pre-final and final inspections, to help the BCE identify deficiencies to the CM. 3.2.3.3. Attends final and post-occupancy inspection, as required. 3.2.3.4. Reviews scope variations and reprogramming packages. 3.2.4. BCE: 3.2.4.1. Participates in the pre-bid and site visits, and the pre-construction conference. 3.2.4.2. Reviews and approves material submittals for exterior/interior finishes, including systems furniture. Reviews equipment submittals for maintainability and compatibility with other base systems in compliance with the installations Architectural Compatibility Plan. Sends recommendations to the CM and MAJCOM. 3.2.4.3. Ensures base agencies facilitate timely start of construction.

24

AFI32-1023 21APRIL 2010 3.2.4.4. Coordinates all environmental permits and certifications with environmental flight and governing bodies. Sends all required documentation to the CM. 3.2.4.5. Verifies the quality of construction. Reports problems through the CM. Verifies facility systems meet requirements before the BOD. Advises the CM of design and construction deficiencies. Verifies deficiencies are corrected and promptly elevates unresolved issues to the CM for resolution. 3.2.4.6. Reports any potential hazards and dangerous conditions to the CA, and notifies the CM of schedule slippages or phasing deviations that impact the need date. Refer to the AFCEE MILCON Change Order Management Plan (available digitally at: http://www.afcee.af.mil/), for procedures regarding construction changes. 3.2.4.7. Invites the user to accompany BCE personnel on site visits to ensure construction meets user needs. 3.2.4.8. Serves as property/equipment. the CA's point of contact for government-furnished

3.2.4.9. Promptly sends users change requests to the appropriate office for approval and monitors status. 3.2.4.10. Participates in the pre-final and final inspections, and receives from the CA operations and maintenance manuals, training on equipment, warranty and guarantee information, as-built drawings. 3.2.4.11. Ensures that newly constructed facilities are not modified within 12 months of the BOD unless the modification meets the requirements outlined in AFI 32-1032, Planning and Programming Appropriated Funded Maintenance, Repair, and Construction Projects. 3.3. Construction Phases: 3.3.1. Construction Management Plan (CMP). As determined by the CM, a CMP will be developed to identify and prescribe organizational responsibilities, management procedures, and approval processes in detail. 3.3.2. Red Zone Meeting. Red Zone Meetings are required for all MILCON projects. The Red Zone approach begins with a meeting held at 80 percent of construction completion. As a minimum, participants will include the contractor, CM, CA, BCE, facility user, and other stakeholders. At the meeting, participants will discuss, define and achieve consensus on actions necessary to complete construction, support user occupancy, perform financial closeout and document the fiscal closeout of the project in the Real Property Records. 3.3.3. Construction Acceptance: 3.3.3.1. Applicable Programs. Additional information can be found in UFC 1-300-08, Criteria for Transfer and Acceptance of Military Real Property. 3.3.3.2. Commissioning. All new facilities and major renovation projects will include commissioning to the extent practicable. Refer to the Corps of Engineers Engineering and Construction Bulletin No. 2003-19, Directory of Expertise on Design Construction Commissioning and UFC 3-410-01FA, Heating, Ventilating, and Air Conditioning, with Change 3 for additional guidance.

AFI32-1023 21APRIL 2010 3.3.4. Joint Occupancy:

25

3.3.4.1. Approval. The CM may recommend approval of joint occupancy to the CA when it is advantageous to the government. 3.3.4.2. Joint Occupancy Date. The CM, working with the using MAJCOM and the CA, jointly determine the joint occupancy date. 3.3.4.3. Facility Maintenance Responsibility. When agreeing to joint occupancy, the Air Force assumes responsibility for maintenance and repair of items not under warranty and for operations of portions of the facility occupied during joint occupancy. 3.3.4.4. Contractor Occupancy After Joint Occupancy. When the Air Force agrees to let a contractor continue to occupy or use a facility after it has accepted the facility, for any purpose other than to finish correcting deficiencies, the Air Force treats the contractor as a tenant and receives payment in accordance with AFI 65-601 V1, for logistical support that the Air Force provides to the contractor. 3.3.5. Construction Quality: 3.3.5.1. Responsibilities. The CM and the CA share the primary responsibility for delivering the user a quality facility. If CM responsibilities have been delegated to the BCE, then that office shares the responsibility with the CA. The contractor is responsible for inspecting, testing, and documenting those tests and inspections that are required by the contract to control material quality and workmanship. 3.3.5.2. Quality Assurance (QA). The contractor is required by the terms of the contract to employ a Quality Control (QC) representative. The CA, through the QA program, oversees the Contractor Quality Control (CQC) program. Government personnel (from the CA for MILCON and from the BCE otherwise) perform QA performance assessment. 3.3.6. Post-Occupancy Inspections: 3.3.6.1. Requirement. When required by the MAJCOM and CM, the post-occupancy evaluation team conducts post-occupancy inspections 9 to 11 months after the contractor completes construction. 3.3.6.2. Responsibilities. The CM will schedule post-occupancy inspections with all stake holders. The CM sends items of interest concerning criteria to AF/A7CP. BCE personnel check one-year warranty items even when a post-occupancy evaluation team inspection does not take place. BCE personnel will coordinate with the DA any corrective action for discrepancies discovered during the one-year warranty check.

26

AFI32-1023 21APRIL 2010

Chapter 4 MEDICAL FACILITIES DESIGN AND CONSTRUCTION PROCEDURES 4.1. Scope. This chapter applies to the design and construction of all Air Force medical and medical related facilities. Planning, programming and design procedures for medical facility projects are covered in DoDI 6015.17, Planning and Acquisition of Military Health Facilities; AFI 32-1021; UFC 1-200-01; and UFC 4-510-01, Design: Medical Military Facilities. 4.2. Roles and Responsibilities: 4.2.1. Office of the Assistant Secretary of Defense (Health Affairs)/TRICARE Management Activity (OASD/HA TMA (PPMD)). The OASD/HA TMA provides program management for the DoD medical MILCON program and funds medical MILCON through the Defense Wide MILCON program. 4.2.2. Office of the Surgeon General, United States Air Force (USAF/SG). The USAF/SG is the using agency for all Air Force medical facilities. 4.2.3. Air Force Health Facilities Division (HFD). The HFD represents HQ USAF/SG on all Air Force medical MILCON design and construction issues. They provide planning and programming documents for medical projects to OASD/HA TMA. HFD provides space, functional, and operational requirements for medical facility projects, reviews and approves medical functional aspects of designs and monitors medical functional aspects of construction projects. The HFD provides direct support to the MAJCOM Surgeon General and the installation Medical Group for all aspects of medical facility acquisition, design, and construction. HFD jointly accepts medical facilities with the BCE. Once the CA determines the contractor has met contract requirements, the CA will arrange for the Base Civil Engineer to formally accept the facility for the Air Force. The CA provides the BCE with the completed DD Form 1354, Transfer and Acceptance of Military Real Property, after the acceptance inspection. 4.2.4. DM/CM. AFCEE provides centralized DM/CM expertise for all CONUS Air Force medical facilities projects. The DM/CM is responsible for medical MILCON projects at any base where the medical facility is to be constructed. The DM/CM shall be involved early on in the medical MILCON project, and shall work with the HFD project managers throughout the process to ensure successful project execution including conformance to the Base General Plan, base architectural standards and compatibility requirements. DM/CM also provides official AF position in coordination with HFD when working issues with the DA/CA. 4.2.5. DA/CA. The HQs level Medical Facilities Office of the appropriate DA/CA provides project management and technical oversight for medical MILCON projects. Other DA/CA roles and responsibilities are similar to regular AF MILCON projects. 4.3. Medical MILCON: This program is managed by OASD/HA TMA and funded under Defense Wide MILCON. This section applies to all medical and medical related facilities; it does not apply to ANG medical facilities. 4.3.1. Facility Functional Requirements. With input from the installation Medical Group, the MAJCOM Surgeon General and AF/SG staff, HFD develops a Program for Design, indicating room-by-room space requirements, and a Medical Facility Room Contents Listing,

AFI32-1023 21APRIL 2010

27

indicating room-by-room equipment and furniture requirements; OASD/HA TMA provides final approval of the Departmental Level Program for Design. The DM/CM supports HFD in preparing the DD Form 1391; supporting facility costs; selecting and recommending the site for installation approval; coordinating requirements/approval documents with MAJCOM and Base representatives. 4.3.2. Project Justification and Submittal. The OASD/HA TMA conducts a biennial TriService scoring process called the Capital Investment Decision Model (CIDM). The Medical Treatment Facility Commander (MTF) will provide functional inputs to HFD to prepare the DD Form 1391 and other programming documents. Concurrently, the MTF establishes a requirement for the work or project with the BCE and provides the DD Form 1391 being developed by HFD. This enables the BCE to input the project and its programming data into ACES-PM and initiate the Environmental Assessment (EA) process, which for medical projects is paid for by the Defense Health Program. If an EA is required for medical projects, the design may typically not begin until a Finding of No Significant Impact (FONSI) is made. HFD works with BCE to develop the Requirements Document (RD)/Project Book (PB)* for the project and AFCEE assists in validating the supporting facility costs and infrastructure for the project. AF/SG integrates and prioritizes the MAJCOM projects and forwards them to OASD/HA TMA for CIDM scoring. * Many installations have combined the RD and PB or use the terms interchangeably. 4.3.3. Medical Unspecified Minor Construction (UMC) Requirements. Unforeseen or urgent construction projects that should not be delayed for inclusion in the next regular annual MILCON program are UMC or P-341 candidates. Installation and MAJCOM staffs will process Medical UMC requirements in the same way as medical MILCON projects. OASD/HA TMA funds approved projects from their Defense Wide MILCON account. Projects programmed under the UMC authority must comply with DoDI 6015.17. 4.4. Project Authorizations. OASD/HA issues all design and construction authorizations, including A-E selection, design initiation, and contract advertising and award. 4.5. Design Approvals. OASD/HA reviews and approves concept designs, and approves significant changes in project scope due to changes in concepts of operation and addition or deletion of medical functions. 4.6. Construction Changes. OASD/HA TMA (PPMD) must approve changes that add significant new features to the project, which were not originally contemplated in the design. All non-mandatory change orders with cost estimates in excess of $100,000, must be reported to TMA(PPMD). These proposed changes will be coordinated thru the DM/CM prior to submission to TMA(PPMD). If funds are required for changes that exceed the amount available and the management reserve account is inadequate, the Construction Agent will notify and request additional funds from TMA-PPMD in writing along with justification for additional contingency funds and/or source of funds as appropriate. The DM/CM approves construction changes less than $100,000. 4.7. Base Realignment and Closure (BRAC) Program. Some medical projects in the BRAC program receive funding from the Air Force BRAC MILCON program. Larger medical projects in the BRAC receive funding and authorization through OASD/HA TMA. However, design and construction submittal procedures follow the medical MILCON procedures. The DM/CM

28

AFI32-1023 21APRIL 2010

acquires the required funding and issues all design and construction authorizations to the DA/CA, as appropriate.

AFI32-1023 21APRIL 2010

29

Chapter 5 PRESCRIBED AND ADOPTED FORMS 5.1. Prescribed Forms: DELETED. 5.2. Adopted Forms: DELETED.

JUDITH A. FEDDER, Lieutenant General, USAF DCS/Logistics, Installations & Mission Support

30 Attachment 1

AFI32-1023 21APRIL 2010

GLOSSARY OF REFERENCES AND SUPPORTING INFORMATION References 10 CFR Part 433, Energy Efficiency Standards for the Design and Construction of New Federal Commercial and Multi-Family High-Rise Residential Buildings, current edition 10 CFR Part 434, Energy Code for New Federal Commercial and Multi-Family High Rise Residential Buildings, current edition 10 CFR Part 435, Energy Efficiency Standards for New Federal Low-Rise Residential Buildings, current edition 10 CFR Part 436, Federal Energy Management and Planning Programs, current edition 10 USC 1803, Facilities for Reserve Components 10 USC 2807, Architectural and Engineering Services and Construction Design 10 USC 2853, Authorized Cost and Scope of Work Variations 10 USC 2858, Limitation on the Use of Funds for Expediting a Construction Project 10 USC 2860, Availability of Appropriations 10 USC 2685, Adjustment of or Surcharge on Selling Prices in Commissary Stores to Provide Funds for Construction and Improvement of Commissary Store Facilities 10 USC 2855, Law Applicable to Contracts for Architectural and Engineering Services and Construction Design 10 USC 2915, New Construction: Use of Renewable Forms of Energy and Energy Efficient Products 10 USC 9540, Architectural and Engineering Services 14 CFR Part 77, Objects Affecting the Navigable Airspace, current edition 15 USC 2601, Control of Toxic Substances, Findings, Policy, and Intent 29 CFR Part 1910, Occupational Safety and Health Standards, current edition 29 CFR Part 1910.134, Respiratory Protection, current edition 29 CFR Part 1926, Safety and Health Regulations for Construction, current edition 29 CFR Part 1926.62, Lead Exposure In Construction; Interim Final Rule--Inspection and Compliance Procedures, current edition 29 USC 651, Occupational Safety and Health Act of 1970 32 CFR Part 989, Environmental Impact Analysis Process, current edition 40 CFR Part 1500-1508, National Environmental Policy Act, current edition 40 CFR Part 302, Designation, Reportable Quantities, and Notification, current edition

AFI32-1023 21APRIL 2010 40 CFR Part 745, Lead-Based Paint Poisoning Prevention in Certain Residential Structures, current edition 40 USC 1101 - 1104, Selection of Architects and Engineers 40 CFR Part 82, Protection of Stratosphere Ozone, current edition 42 USC 133, Pollution Prevention 42 USC 6901, Solid Waste Disposal/Resource Conservation and Recovery Act and Major Amendments 42 USC 6911, Office of Solid Waste; Authorities of the Administrator 42 USC 8252 et seq, National Energy Conservation Policy Act 42 USC 4831, Lead-Based Paint Poisoning Prevention Act of 1971

31