Professional Documents

Culture Documents

MRPL Mangalore CDU VDU Heaters Welding Procedure Specification

Uploaded by

DeepakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MRPL Mangalore CDU VDU Heaters Welding Procedure Specification

Uploaded by

DeepakCopyright:

Available Formats

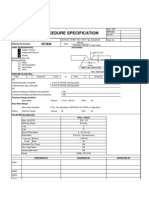

TECHNIP KT INDIA LIMITED

MRPL MANGALORE -CDU VDU HEATERS

WELDING PROCEDURE SPECIFICATION

( QW - 482 AS PER ASME SECTION IX )

: TPKTI/MRPL/772/WPS-01 Welding Procedure Specification No :TPKTI/669/HGU/PQR/001 Supporting PQR No :SMAW Welding Process(es)

Date : 19.04.2010 Date : 06.05.2003 Types : MANUAL Automatic,Semi-automatic, manual,machine Type of joint

JOINTS (QW - 402 )

Joint Design Backing (Yes/No ) Root opening Groove angle Backing gouging

: FILLET 'T'JOINT : Yes PARENT METAL : NIL : NA

Yes / No

BASE METAL (QW - 403)

P.No : Specification Type & Grade Thickness & Dia of test coupon Qualified thickness range Qualified dia range FILLER METALS (QW - 404 ) SFA Specification AWS Specification Filler Metal F No Weld Metal Analysis A No Size of filler metal Deposited weld metal Brand name/make POSITION ( QW - 405 ) Position of groove Weld progression (Uphill/Downhill ) PREHEAT ( QW - 406 ) Preheat Temperature Interpass Temperature Pre-heat method

: NA : NA : NA : NIL : NA

P No. : IS 2062 A : 12 MM

Group No. to

P.No : -

Group No.

Specification Type & Grade : IS 2062 A

: FILLET UP TO 24 MM : NIL

: 5.1 : E 6013 :2 :1 : DIA 2.5 MM / 3.15 MM : FILLET 12 MM : JACOBS APPROVED BRAND

POST WELD HEAT TREATMENT (QW - 407) : NA Temperature range Rate of Heating Rate of cooling Soaking time Others

: NA : NA : NA : NA

Temperature measuring method,if any

: NA

GAS (QW - 408 )

ELECTRICAL CHARACTERISTICS (QW - 40) Percenatge Composition Current :60 - 80 AMPS

Volts :16 - 30 V

Gas(es)

Mixture

(Amps&volts range should be recorded for each electrode size,position and thickness.This Flow rate information may be listed in a tabular form similar to that shown below ) Tungsten electrode size

: NA : NA

Shielding Trailing Backing

: NA

Mode of metal transfer for GMAW

: NA : NA

Electrode Wire feed speed range

: NA

TECHNIQUE (QW - 410 ) Stringe or weave bead Orifice or gas cup size Intial and interpass cleaning Method of back gouging Oscillation Contact tube to work distance Multiple or single pass (per side ) Multiple or single electrode Travel speed range Peening Others Filler metal Weld Layer(s) Process Class / Dia

ROOT I PASS IINDPASS

ST

: Stringe for root weave for others ( Weaving restricted to 2.5 x Dia of electrode)

: NA : CHIPPING AND BRUSHING : NA : NA : NA : MULTIPLE : SINGLE : 40 mm / min. : NA : NIL

Current Type Polarity

EN EN EN

Amps range

60-80 80-110 80-110

Travel speed range

40 mm / min 40 mm / min 40 mm / min

Remar ks

SMAW SMAW SMAW

E 6013 E 6013 E 6013

TPKTI

JACOBS

TECHNIP KT INDIA LIMITED

MRPL MANGALORE -CDU VDU HEATERS

WELDING PROCEDURE SPECIFICATION

( QW - 482 AS PER ASME SECTION IX ) Welding Procedure Specification No : TPKTI/MRPL/772/WPS-02 REV.O Date :PPSL/UNIT-II/TECHNIP/PQR NO-939 Date Supporting PQR No :SMAW Welding Process(es) Types

: 12.05.2010 : 11.03.2010 : MANUAL

JOINTS (QW - 402 )

Joint Design Backing (Yes/No ) Root opening Groove angle Backing gouging

: DOUBLE " V " BUTT :YES FOR BACKGOUGING WELDING :3-4 MM : 60

Automatic,Semi-automatic, Manual, Machine Type of joint

Yes / No Group No. to P.No : Group No. Specification Type & Grade : IS

2062 B

BASE METAL (QW - 403)

P.No : Specification Type & Grade Thickness & Dia of test coupon Qualified thickness range Qualified dia range FILLER METALS (QW - 404 ) SFA Specification AWS Specification Filler Metal F No Weld Metal Analysis A No Size of filler metal Deposited weld metal Brand name/make POSITION ( QW - 405 ) Position of groove Weld progression P No. : IS 2062 B : 16 MM :GROOVE FROM 4.8 TO 32 MM : ABOVE 24" FILLET ALL

: 5.1 : E 7018 :2 :1 : DIA 3.2 MM / 4.0 MM : 16 MM : ADOR X-BOND

: 1G :FOREHAND

( Uphill/Downhill/Forehand/Backhand ) PREHEAT ( QW - 406 ) Preheat Temperature Interpass Temperature Pre-heat method

: 100C MIN. : NA : LPG BURNER

POST WELD HEAT TREATMENT (QW - 407) Temperature range Rate of Heating Rate of cooling Soaking time

: NA : NA : NA : NA : NA

Temperature measuring method,if any

: YES - TEMP.CRAYONS / DIGITAL THERMOMETER

Others

GAS (QW - 408 ) Percenatge Composition

ELECTRICAL CHARACTERISTICS (QW 409)

Current :80 - 170 AMPS Volts :24 - 31 V

Gas(es)

Mixture

Flow rate

(Amps&volts range should be recorded for each electrode size,position and thickness.This information may be listed in a tabular form similar to that shown below ) : NA Tungsten electrode size Mode of metal transfer for GMAW Electrode Wire feed speed range

: NA

Shielding Trailing Backing

: NA : NA : NA

: NA

TECHNIQUE (QW - 410 ) Stringe or weave bead Orifice or gas cup size Intial and interpass cleaning Method of back gouging Oscillation Contact tube to work distance Multiple or single pass (per side ) Multiple or single electrode Travel speed range Peening Others Weld Layer(s)

ROOT I PASS II PASS III

RD ND ST

: Stringe for root weave for others ( Weaving restricted to 2.5 x Dia of electrode)

: NA : CHIPPING AND BRUSHING : NA : NA : NA : MULTIPLE : SINGLE : 100-125 mm / min. : NA : NIL

Filler metal Process Class / Dia in mm

SMAW SMAW SMAW SMAW SMAW SMAW E 7018 / 3.12 E 7018 / 4.00 E 7018 / 4.00 E 7018 / 4.00 E 7018 / 4.00 E 7018 / 4.00

Current Volts Type Polarity

EP EP EP EP EP EP

Amps range

80 - 85 24-26 168-170 26-28 168-170 27-28 150-160 29-30 154-158 29-30 144-146 29-31

Travel speed range

100 - 125 100 - 125 100 - 125 100 - 125 100 - 125 100 - 125

Remarks

PASS

IVTH PASS VTH PASS

BACK CHIPPING

ROOT I PASS II PASS IIIRD PASS

ND ST

SMAW SMAW SMAW SMAW

E 7018/3.2 E 7018/4.00 E 7018/4.00 E 7018/4.00

EP EP EP EP

118-120 27-29 161-164 29-31 162-164 29-30 155-157 29-30

100 - 125 100 - 125 100 - 125 100 - 125

TPKTI

JACOBS

You might also like

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (1)

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- 1035 03Document2 pages1035 03Anuj ShahiNo ratings yet

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- Wps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Document5 pagesWps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Oscar Iván Duque DíazNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónNo ratings yet

- Welding Procedure Specification (WPS) : in The Outer TubeDocument1 pageWelding Procedure Specification (WPS) : in The Outer TubeMohamed AlkhawagaNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- 2010 SECTION IX WPS FORMATDocument5 pages2010 SECTION IX WPS FORMATAjay ChodankarNo ratings yet

- WPS Asme IxDocument4 pagesWPS Asme Ixjcarlosherrerac7100% (1)

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmDocument1 pageWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- WPS PQR FormatsDocument22 pagesWPS PQR Formatsmdharmaraj28No ratings yet

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- wps63 PDFDocument4 pageswps63 PDFErick HoganNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 pagesProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXNo ratings yet

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNo ratings yet

- Material GradesDocument1 pageMaterial GradesshisNo ratings yet

- QW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Document3 pagesQW - 483 Procedure Qualification Record: Wps No. Welding Process (Es) Type (Manual, Automatic, Semi-Auto)Alesol EquipmentNo ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- WPS GTAW Stainless SteelDocument7 pagesWPS GTAW Stainless SteelVarun MalhotraNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- REGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRDocument2 pagesREGISTRO DE CALIFICACION DEL PROCEDIMIENTO (PQRAnonymous Xa5rkMZm9ZNo ratings yet

- Replacement Pipe Welding ProcedureDocument7 pagesReplacement Pipe Welding ProcedureRanjan KumarNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- Welding Report For Tank 1Document1 pageWelding Report For Tank 1Rifki HasyaNo ratings yet

- Gtaw Smaw 6 Inch 6G CSDocument1 pageGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- WPS FGPDocument1 pageWPS FGPShabbir HussainNo ratings yet

- Welding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesWelding Procedure Qualification Records (WPQR) : (Section IX, ASME Boiler and Pressure Vessel Code)ngonphanhoangNo ratings yet

- WPS PQR-09Document11 pagesWPS PQR-09Ranjan KumarNo ratings yet

- PQR WPS RequirementDocument2 pagesPQR WPS RequirementRameshBaskaranNo ratings yet

- WPS PQR FormatDocument1 pageWPS PQR FormatJatin Kamdar100% (2)

- WPS SampleDocument6 pagesWPS SampleAshishNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi JerbiNo ratings yet

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- WPS, PQR, WPQ PoojaDocument10 pagesWPS, PQR, WPQ PoojaRajmahesh Dakhore100% (1)

- F07-Visual Inspection Report NEWDocument1 pageF07-Visual Inspection Report NEWmohd as shahiddin jafriNo ratings yet

- Loading Unloading Temperature Welding ProgressionDocument5 pagesLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Fit Up ReportDocument5 pagesFit Up ReportAkash Singh Tomar100% (1)

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- BK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldDocument2 pagesBK5TQ4 248 094 - WPS For Ducting & Support Structure Stainless Steel V Groove WeldHarkesh RajputNo ratings yet

- WPS For Structure Mild Steel Fillet WeldDocument2 pagesWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- WPS TITLEDocument2 pagesWPS TITLERichard Periyanayagam86% (14)

- Welding Procedure Specification-1Document8 pagesWelding Procedure Specification-1Suresh Rathod100% (1)

- Icml Mla IiDocument3 pagesIcml Mla IiDeepak100% (2)

- OCTL E Atalogue 2018Document32 pagesOCTL E Atalogue 2018DeepakNo ratings yet

- BS English 17-04-2020Document10 pagesBS English 17-04-2020DeepakNo ratings yet

- 22 7 16Cl4EnglishTestPortionDocument1 page22 7 16Cl4EnglishTestPortionDeepakNo ratings yet

- CL 4 PPT Animal World For Flipped LearningDocument7 pagesCL 4 PPT Animal World For Flipped LearningDeepakNo ratings yet

- 6 1 17Cl4EngtestportionDocument1 page6 1 17Cl4EngtestportionDeepakNo ratings yet

- Icml Mla IDocument3 pagesIcml Mla IDeepak100% (1)

- 29 7 16Cl4EETestPortionDocument1 page29 7 16Cl4EETestPortionDeepakNo ratings yet

- Wireless Product MatrixDocument8 pagesWireless Product MatrixDeepakNo ratings yet

- Syllabus Barc Rtl2 160714Document7 pagesSyllabus Barc Rtl2 160714DeepakNo ratings yet

- Grade 4 Math Test on Multiplication Aug 2016Document1 pageGrade 4 Math Test on Multiplication Aug 2016DeepakNo ratings yet

- 4-Appendix 1 Part 1b Ultrasonic 3rd Edition June 2011Document13 pages4-Appendix 1 Part 1b Ultrasonic 3rd Edition June 2011menn555No ratings yet

- FortiGate 30DDocument4 pagesFortiGate 30DIulianNo ratings yet

- Subject - Hindi Class IV Date of Test: 08-07-16 TopicDocument1 pageSubject - Hindi Class IV Date of Test: 08-07-16 TopicDeepakNo ratings yet

- Ultrasonic inspection report for transmission grillage beamsDocument1 pageUltrasonic inspection report for transmission grillage beamsDeepak100% (1)

- M 8Document2 pagesM 8DeepakNo ratings yet

- Survey Form: Delhi Public School, Bopal, Ahmedabad Topic: Water, Water Everywhere Conservation of WaterDocument2 pagesSurvey Form: Delhi Public School, Bopal, Ahmedabad Topic: Water, Water Everywhere Conservation of WaterDeepakNo ratings yet

- Nozzle Location Plate Identification Thickness Location E W N SDocument9 pagesNozzle Location Plate Identification Thickness Location E W N SDeepakNo ratings yet

- New Text DocumentDocument1 pageNew Text DocumentDeepakNo ratings yet

- Tripride 1 Equivalent PDFDocument4 pagesTripride 1 Equivalent PDFDeepakNo ratings yet

- XL Go Data SheetDocument4 pagesXL Go Data SheetDeepakNo ratings yet

- My Gurukulam: A Look Inside EE-2 Delhi Public SchoolDocument2 pagesMy Gurukulam: A Look Inside EE-2 Delhi Public SchoolDeepakNo ratings yet

- Here Is The MoonDocument2 pagesHere Is The MoonDeepakNo ratings yet

- Cover PageDocument192 pagesCover PageDeepakNo ratings yet

- Check List & Proforma Permit.Document3 pagesCheck List & Proforma Permit.DeepakNo ratings yet

- Q.1) Pick Out Three Adjectives and Write Them in The Place Given BelowDocument2 pagesQ.1) Pick Out Three Adjectives and Write Them in The Place Given BelowDeepakNo ratings yet

- Life Without LimitsDocument31 pagesLife Without LimitsDeepakNo ratings yet

- CaptionsDocument3 pagesCaptionsDeepakNo ratings yet

- NDT Methods AvailableDocument1 pageNDT Methods AvailableDeepakNo ratings yet

- KS6 6Document4 pagesKS6 6Gitika DekaNo ratings yet

- Material Data Sheet SB482 Steel Grade 38MnVS6Document3 pagesMaterial Data Sheet SB482 Steel Grade 38MnVS6Jaison JacobNo ratings yet

- Spot WeldDocument8 pagesSpot Weld0502raviNo ratings yet

- Question With Answer Mechanic Trade May-13Document51 pagesQuestion With Answer Mechanic Trade May-13Pawan Porwal71% (42)

- BS en Iso 11114-4-2017Document28 pagesBS en Iso 11114-4-2017Giovanni ZamagnaNo ratings yet

- Reinforced Brickwork Strengths and UsesDocument35 pagesReinforced Brickwork Strengths and Usesthushara100% (1)

- GIS E6 2006-Gas Industry StandardDocument15 pagesGIS E6 2006-Gas Industry StandardQualidadeTFNo ratings yet

- Contents 1Document1 pageContents 1qaNo ratings yet

- ArcelorMittal SWOT AnalysisDocument2 pagesArcelorMittal SWOT AnalysisUmer RazzaqNo ratings yet

- Stainless Steel DifferenceDocument4 pagesStainless Steel DifferenceGiri DharanNo ratings yet

- JIS F 7121 Shipbuilding - Can Water Filters: To TitleDocument8 pagesJIS F 7121 Shipbuilding - Can Water Filters: To TitlePhúc nguyễnNo ratings yet

- Avishesh Chemistry AlloyDocument22 pagesAvishesh Chemistry AlloyAdarsh HackologyNo ratings yet

- CV - Linkedin 3Document5 pagesCV - Linkedin 3Samir ChaudharyNo ratings yet

- Analysis of Current Problems Caused by Localized Corrosion. Study of Their Idustrial Impact and Proposals For ActionDocument164 pagesAnalysis of Current Problems Caused by Localized Corrosion. Study of Their Idustrial Impact and Proposals For ActionRuth Noemi Ballena GuerreroNo ratings yet

- Iso 16120 4 2017Document9 pagesIso 16120 4 2017Emmanuel Jiménez EcheverríaNo ratings yet

- Screw Jack Question - KPRDocument1 pageScrew Jack Question - KPRDr.P.Arivalagan ASST. PROFNo ratings yet

- Mini a-LOK BookletDocument162 pagesMini a-LOK BookletjcastelohNo ratings yet

- Paper & Board Machine Doctoring Training CourseDocument32 pagesPaper & Board Machine Doctoring Training Coursetao dao ngocNo ratings yet

- Surface Preparation EssentialsDocument4 pagesSurface Preparation EssentialsPJOE81No ratings yet

- 1 Way Continous SlabDocument5 pages1 Way Continous SlabZayyan RomjonNo ratings yet

- Gerber 2022Document92 pagesGerber 2022Thomas ColmicheNo ratings yet

- METALLURGICAL DAMAGE MECHANISM AND ASSESSMENTDocument61 pagesMETALLURGICAL DAMAGE MECHANISM AND ASSESSMENTSACHIN PETKARNo ratings yet

- AISI Steel Plate Engineering Data Volumes 1 and 2Document135 pagesAISI Steel Plate Engineering Data Volumes 1 and 2Dinh Nguyen Dao100% (1)

- Asme Section Ix-Welding - Practice Quest PDFDocument3 pagesAsme Section Ix-Welding - Practice Quest PDFRajesh KumarNo ratings yet

- ASTM A234 Quality of Inspection (2016)Document4 pagesASTM A234 Quality of Inspection (2016)eko kusumoNo ratings yet

- Gas Industry Standard: GIS/V7-1:2007Document31 pagesGas Industry Standard: GIS/V7-1:2007ankit7588No ratings yet

- A455Document2 pagesA455doshi78No ratings yet

- CAD Drawing M1911ADocument59 pagesCAD Drawing M1911AAngela Uselton100% (1)

- Historical Industry OverviewDocument2 pagesHistorical Industry OverviewSyed FaridNo ratings yet