Professional Documents

Culture Documents

Idnet Cards Installation Instructions: Important

Uploaded by

dreamsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Idnet Cards Installation Instructions: Important

Uploaded by

dreamsCopyright:

Available Formats

IDNet Cards Installation Instructions

Introduction

This publication describes the installation procedure for the following: 4100-3101 IDNet Card 250 Devices (742-476) 4100-3104 IDNet Card 127 Devices (742-817) 4100-3105 IDNet Card 64 Devices (742-818) 4100-3106 IDNet Card w/Quick Connect capability 250 Devices (742-954) 4100-9811 IDNet Card 250 Devices (Aftermarket) 4100-9835 IDNet Card 127 Devices (Aftermarket) 4100-9836 IDNet Card 64 Devices (Aftermarket)

This product is compatible with 4100U and 4100ES Fire Alarm Control Panels (FACP). IMPORTANT: Verify FACP System Programmer, Executive, and Slave Software compatibility when installing, or replacing system components. Refer to the Technical Support Information and Downloads website for compatibility information..

Inspecting Contents of Shipment

Upon unpacking your Simplex product, inspect the contents of the carton for shipping damage. If damage is apparent, immediately file a claim with the carrier and notify Simplex. This publication discusses the following topics: Topic Cautions, Warnings, and Regulatory Information Introduction to the IDNet Card Step 1: Installing the IDNet Card into the PDI Step 2: Setting DIP Switch SW1 Step 3: Wiring to IDNet Peripherals Troubleshooting See Page 2 3 5 6 8 11

In this Publication

2003-2011 SimplexGrinnell LP. All rights reserved.

Specifications and other information shown were current as of publication and are subject to change without notice. Simplex and the Simplex logo are trademarks of Tyco International Ltd. and its affiliates and are used under license.

574-800 Rev. D

Cautions, Warnings, and Regulatory Information

Cautions and Warnings

READ AND SAVE THESE INSTRUCTIONS- Follow the instructions in this installation manual. These instructions must be followed to avoid damage to this product and associated equipment. Product operation and reliability depend upon proper installation. DO NOT INSTALL ANY SIMPLEX PRODUCT THAT APPEARS DAMAGED- Upon

unpacking your Simplex product, inspect the contents of the carton for shipping damage. If damage is apparent, immediately file a claim with the carrier and notify an authorized Simplex product supplier.

ELECTRICAL HAZARD - Disconnect electrical field power when making any internal adjustments or repairs. All repairs should be performed by a representative or authorized agent of your local Simplex product supplier. STATIC HAZARD - Static electricity can damage components. Handle as follows:

Ground yourself before opening or installing components. Prior to installation, keep components wrapped in anti-static material at all times.

FCC RULES AND REGULATIONS PART 15 - This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own expense. SYSTEM REACCEPTANCE TEST AFTER SOFTWARE CHANGES To ensure proper system operation, this product must be tested in accordance with NFPA 72 after any programming operation or change in site-specific software. Reacceptance testing is required after any change, addition or deletion of system components, or after any modification, repair or adjustment to system hardware or wiring.

All components, circuits, system operations, or software functions, known to be affected by a change, must be 100% tested. In addition, to ensure that other operations are not inadvertently affected, at least 10% of initiating devices that are not directly affected by the change, up to a maximum of 50 devices, must also be tested and proper system operation verified.

NFPA 72 is a registered trademark of the National Fire Protection Association.

Introduction to the IDNet Card

Overview

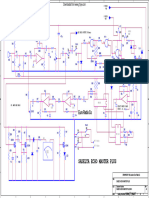

The 4100-series IDNet Card allows the system CPU to communicate with up to 250 IDNet peripherals, such as smoke detectors and pull stations. The IDNet card is a flat, 4 by 5 option card that plugs into the power distribution interface (hereafter referred to as PDI). Figure 1 depicts the IDNet card.

IDNET LINE TERMINAL BLOCK (TB1) SHIELD JUMPER (P1) COMM TROUBLE LED (LED1) IDNET TROUBLE LED (LED2)

ADDRESS DIP SWITCH (SW1) PDI CONNECTOR (P2) (on reverse side)

Figure 1. The IDNet Card

LEDs

The IDNet card has the following LEDs: LED1. Normally off. Turns on steady if the IDNet card is not communicating with the 4100 CPU. LED2. Normally off. Illuminates to indicate a problem with the IDNet lines. Steady on indicates channel failure. One repetitive blink indicates a line short. Two repetitive blinks indicate a Class A failure or an open line. Continued on next page

Introduction to the IDNet Card, Continued

Requirements and Limitations

Refer to Table 1 for general system specifications. Table 1. System Specifications Electrical Specifications Voltage Comm/Power Voltage to IDNet Slaves Comm Wiring Distance 24 VDC from FACP 30 VDC (nominal) or 36 VDC @ 350 mA (See note) 40 Ohms line resistance 0.60 F capacitance (line to line and shield to line) 10,000 feet

Environmental Specifications Operating Temperature Humidity Note: 32 to 120 F (0 to 49 C) Up to 93% relative humidity at 94 F (38 C)

Voltage output to IDNet slaves is normally 30 VDC. Output is increased to 36 VDC when it is necessary to activate large numbers of output devices on IDNet peripherals, such as piezo sounders. The system CPU will set the output to 36 VDC when LEDs, piezos, or other outputs are activated, usually in an alarm state.

Up to 250 IDNet devices are supported by one IDNet channel.

IMPORTANT: You must use the 4100-3106 IDNet card when installing Quick Connect devices. The IDNet card keeps track of which LEDs should be on at all times, and displays up to 20 at any given time. Up to 43 coded piezo sounders are supported by one IDNet channel.

Step 1: Installing the IDNet Card into the PDI

Overview

The 4100-series IDNet card is designed to be mounted on the PDI in an FACP expansion cabinet. The card can be mounted on any of the PDI connectors. Use connector P2, labeled on the back side of the IDNet card, to connect to any of the eight PDI connectors as shown in Figure 2, below.

WASHERS STANDOFFS SCREW RETAINERS IDNet CARD #6 SCREWS

PDI CONNECTOR (reverse side)

PDI

Figure 2. Mounting onto the Power Distribution Interface

Step 2. Configuring the Card

Overview

Configuring the card consists of selecting the shield tie point, and setting the device address. This section covers both topics. If a shield is used, use jumper port (P1) to select where the shield will be tied. Positions 1 and 2 connect the shield to 0 V. Positions 2 and 3 connect the shield to Earth.

Setting the Shield Tie Point

Setting the Address

The device address is set via DIP switch SW1, which is a bank of eight switches. From left to right (see Figure 3, below) these switches are designated as SW1-1 through SW1-8. The function of these switches is as follows: SW1-1. This switch sets the baud rate for the internal 4100 communications line running between the card and the 4100 CPU. Set this switch to ON. SW1-2 through SW1-8. These switches set the cards address within the 4100 FACP. Refer to Table 2 for a complete list of the switch settings for all of the possible card addresses. You must set these switches to the value assigned to the card by the Panel Programmer. Dip Switches SW1-2 through SW1-8 set the Card Address. Figure shows an Address of 3.

Note:

4100 Comm. Baud Rate. Switch (SW1-1) Must Be Set to ON

ON OFF

1 2 3 4 5 6 7 8

Figure 3. DIP Switch SW1 Continued on next page

Step 2. Configuring the Card, Continued

Setting the Address,

Table 2. 4100-3101 Card Addresses

Address 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 SW 1-2 ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON SW 1-3 ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON OFF OFF ON OFF OFF ON OFF OFF ON OFF OFF ON OFF OFF ON OFF OFF ON OFF OFF ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF ON ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF ON ON ON ON ON ON ON ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF ON ON ON ON ON ON ON ON SW 1-4 SW 1-5 ON ON ON ON ON ON ON OFF OFF OFF OFF OFF OFF OFF OFF ON ON ON ON ON ON ON ON OFF OFF OFF OFF OFF OFF OFF OFF ON ON ON ON ON ON ON ON OFF OFF OFF OFF OFF OFF OFF OFF ON ON ON ON ON ON ON ON OFF OFF OFF OFF OFF SW 1-6 ON ON ON ON OFF OFF ON OFF OFF OFF ON ON ON ON OFF OFF OFF ON ON ON ON ON OFF OFF ON OFF OFF OFF ON ON ON ON OFF OFF OFF OFF ON ON ON ON OFF OFF ON OFF OFF OFF ON ON ON ON OFF OFF OFF OFF ON ON ON ON ON OFF OFF ON OFF OFF OFF ON ON ON ON OFF OFF ON OFF OFF OFF ON ON OFF ON OFF ON OFF ON ON OFF OFF ON ON ON OFF OFF ON ON ON OFF ON OFF ON OFF OFF ON ON OFF ON OFF ON OFF ON OFF ON ON ON OFF OFF ON ON OFF OFF ON ON ON OFF ON OFF ON OFF OFF ON ON OFF ON OFF ON OFF ON OFF ON OFF OFF ON OFF OFF ON ON OFF OFF ON ON OFF ON ON OFF ON OFF ON OFF ON OFF ON ON OFF ON OFF ON OFF OFF ON SW 1-7 SW 1-8 OFF ON OFF ON Address 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 SW 1-2 ON ON ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF SW 1-3 OFF OFF OFF ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON OFF ON ON ON OFF ON ON ON OFF ON ON ON OFF ON ON ON OFF ON ON OFF ON ON OFF ON ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF ON ON ON ON ON ON ON ON ON ON OFF ON ON OFF ON ON OFF ON ON OFF OFF OFF ON ON ON ON ON ON ON ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF ON ON ON ON ON ON ON ON OFF OFF ON OFF ON OFF ON SW 1-4 OFF OFF OFF OFF ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON ON OFF OFF OFF OFF OFF OFF OFF OFF OFF ON ON ON ON ON ON SW 1-5 OFF OFF SW 1-6 OFF OFF OFF ON ON ON ON OFF OFF OFF OFF ON ON ON ON OFF OFF OFF OFF ON ON ON ON OFF OFF OFF OFF ON ON ON ON OFF OFF OFF OFF ON ON ON ON OFF OFF OFF OFF ON ON ON ON OFF OFF OFF OFF ON ON ON ON OFF OFF OFF OFF SW 1-7 ON OFF OFF OFF OFF ON ON OFF OFF ON ON OFF OFF OFF ON ON OFF OFF ON ON OFF OFF OFF ON ON OFF OFF ON ON OFF OFF OFF ON ON OFF OFF ON ON OFF OFF OFF OFF ON ON OFF OFF ON ON OFF OFF OFF OFF ON ON OFF OFF ON ON OFF OFF OFF OFF ON ON OFF OFF ON ON OFF OFF OFF OFF ON ON OFF ON OFF ON ON ON OFF ON OFF ON ON ON OFF ON OFF ON ON ON OFF ON OFF ON OFF ON ON OFF ON OFF ON OFF ON ON OFF ON OFF ON OFF ON ON OFF ON OFF ON ON SW 1-8

OFF OFF OFF

OFF OFF OFF

OFF OFF OFF

Step 3. Wiring to IDNet Peripherals

Overview

Up to 250 IDNet slave devices, such as smoke detectors and pull stations, can be connected to the IDNet card. Class A or Class B wiring can be used to connect the IDNet card to peripherals. IMPORTANT: You must use the 4100-3106 IDNet card when installing Quick Connect devices. Class A wiring allows IDNet appliances to communicate with the IDNet card even in the event of an open circuit somewhere in the loop. Class A wiring requires that two wires are routed from the IDNet card to each IDNet appliance, and then back again to the IDNet card. Class B wiring allows T tapping, and therefore requires less wiring distance per installation than Class A. IDNet wiring does not require end-of-line resistors, because each IDNet device communicates directly to the IDNet card.

Guidelines

Review these guidelines before wiring the IDNet card. Refer to 4100 Field Wiring Specification Document 900-242 for further information. All wiring is shielded, 18 AWG (minimum) to 12 AWG (maximum). Refer to Table 3, below, for specifications on each type of wire. Table 3. IDNet Card Wiring Lengths Wire Gauge 18 AWG 16 AWG 14 AWG 12 AWG All wiring is supervised and power-limited. IDNet communications power is 36.25 V (maximum) at 0.5 A, 3333 BPS. All wiring that leaves the building requires overvoltage protection. Install module 2081-9044 wherever wire enters or exits the building. A maximum of four 2081-9044 Modules may be connected to one channel. The maximum line distance with two suppressors is 2500 feet. With an additional two suppressors, the maximum line distance is 1500 feet. For Style 4 operation: - The maximum distance to any device is 10,000 feet or 40 Ohms. - T taps are allowed. - The total distance for one IDNet line is 10,000 feet. - Maximum allowed line-to-line capacitance (+ to - terminals) is 0.60 F. For applications with shielded wire, be sure that the total capacitance from line to line plus the shield to either line is no more than 0.60 F. For Style 6 operation, the maximum loop distance is 2500 feet. T taps are not allowed. Loop wires once through the supplied ferrite bead(s) as shown in Figure 3. Continued on next page Maximum Distance 7.14 Ohms/10,000 ft 4.59 Ohms/10,000 ft 2.82 Ohms/10,000 ft 1.77 Ohms/10,000 ft

Figure 4. The Ferrite Bead

Step 3. Wiring to IDNet Peripherals, Continued

Class A Wiring

To connect the IDNet card to devices using Class A wiring, read the following instructions and refer to Figure 5, below. 1. Route wire between 12 and 18 AWG from the IDNetB+, IDNetB-, and SHIELD outputs on TB1 of the IDNet card to the appropriate inputs on a peripheral IDNet appliance. Note: 2. 3. Use ferrite beads as shown.

Route wire from the first IDNet appliance to the next one. Repeat for each appliance. Route wire from the last IDNet appliance to the IDNetA+ and IDNetA- inputs on TB1 of the IDNet card.

IDNET DEVICES

1 2 1 2

2 +

12 to 18 AWG FERRITE BEAD (required) IDNET CARD SHIELD SHIELD FERRITE BEAD (required)

Figure 5. Class A Wiring Continued on next page

Step 3. Wiring to IDNet Peripherals, Continued

Class B Wiring

To connect the IDNet card to appliances using Class B wiring, read the following instructions. 1. On TB1, jumper IDNetB+ to IDNet A+, and jumper IDNetB- to IDNetA-. If the jumper is absent, a Class A Trouble will be indicated on LED 2. Note: 2. Use ferrite bead as shown.

Route wire between 12 and 18 AWG from the IDNetA+, IDNetA-, and SHIELD outputs on TB1 of the IDNet card to a junction box. Begin T tapping at the junction box. The maximum wiring distance for any IDNet circuit is 10,000 feet or 0.60 F.

The illustration below shows Class B wiring.

IDNET DEVICES

1 2 1 2 1 2 1 2 +

12 to 18 AWG

FERRITE BEAD (required)

IDNET CARD

Figure 6. Class B Wiring Note: Maintain correct polarity on terminal connections. Do not loop wires under terminals.

10

Troubleshooting

Overview

This section describes the messages that may appear on the 4100 display when using the IDNet card. Trouble messages appear on the left as titles, and possible causes are listed to the right in the text. There is no output voltage from the IDNet power supply. Replace the IDNet card. Appears if one or more extra devices (i.e., devices that have not been configured for the IDNet channel) are found on the system, or if a device is at an incorrect address. Only one message appears, regardless of the number of extra devices found. Viewing the trouble log will reveal the extra device address. There is an open on the IDNet channel. After fixing the wiring fault, a hardware reset is required to reset the trouble. Appears while the IDNet card is searching for earth faults on the IDNet line. When this message is displayed, the IDNet card cannot show any alarms or other statuses. Appears when a short is detected on the IDNet channel. This status clears automatically when the short circuit is removed. Appears when devices have been configured, but none of the devices are communicating on the channel. This message does not appear if there are no configured devices on the IDNet channel. Appears when a device is missing. Appears when there is a faulty device or a noisy communications channel. Occurs during any of these conditions: 24 V is not present on TrueAlarm devices. TrueAlarm sensor bases with relay driver outputs are not properly supervised. Isolator devices are in isolation mode.

IDNet Power Monitor Trouble Extra Device

Class A Trouble

Earth Fault Search

Short Circuit

Channel Fail

No Answer

Bad Answer

Output Abnormal

11

574-800 Rev. D

You might also like

- TW5201 Remote Control Unit - Operators ManualDocument20 pagesTW5201 Remote Control Unit - Operators ManualAlexander J RokowetzNo ratings yet

- Herbal Viagra and Nitric Oxide How Hard Is The EvidenceDocument28 pagesHerbal Viagra and Nitric Oxide How Hard Is The Evidencesunni (aamil) spiritual healerNo ratings yet

- Herbal Viagra and Nitric Oxide How Hard Is The EvidenceDocument28 pagesHerbal Viagra and Nitric Oxide How Hard Is The Evidencesunni (aamil) spiritual healerNo ratings yet

- Dell Inspiron 15R 5537 Compal LA-9982P Rev 3.0 SchematicsDocument57 pagesDell Inspiron 15R 5537 Compal LA-9982P Rev 3.0 SchematicsRobertNo ratings yet

- The Facts On File Dictionary of Forensic Science PDFDocument289 pagesThe Facts On File Dictionary of Forensic Science PDFAdrian Alberto Romero BernalNo ratings yet

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- Introduction To Kelly Radionic AntennasDocument11 pagesIntroduction To Kelly Radionic AntennasGavrila Lucian100% (1)

- VT022Document14 pagesVT022Toni RenedoNo ratings yet

- Essence of Materia Medica George Vithoulkas.00063 1contentsDocument4 pagesEssence of Materia Medica George Vithoulkas.00063 1contentsdreams0% (2)

- 6-38GHz 17/34MB Digital Microwave Radio System ManualDocument316 pages6-38GHz 17/34MB Digital Microwave Radio System ManualescalimetroNo ratings yet

- Fibres To FabricDocument23 pagesFibres To FabricPallavi Luthra KapoorNo ratings yet

- Fibres To FabricDocument23 pagesFibres To FabricPallavi Luthra KapoorNo ratings yet

- TNMS Alarms PDFDocument17 pagesTNMS Alarms PDFAlexander SarafovNo ratings yet

- 1/16 Din Microbased Controller: Operators ManualDocument69 pages1/16 Din Microbased Controller: Operators ManualJosue Camacho100% (2)

- Drivecon XT Series Instruction ManualDocument120 pagesDrivecon XT Series Instruction ManualHochimidNo ratings yet

- Electrical Document ReviewDocument15 pagesElectrical Document ReviewJoselito Peñaranda Cruz Jr.No ratings yet

- C 3417 MeDocument16 pagesC 3417 Medem_121129No ratings yet

- Simplex Installation 4100 6048 VESDA Interface CardDocument20 pagesSimplex Installation 4100 6048 VESDA Interface CardRaja Prathap SinghNo ratings yet

- Diagnostico SLC 500Document28 pagesDiagnostico SLC 500James Howlett HudsonNo ratings yet

- MRC5000 CDocument32 pagesMRC5000 CblueedemonNo ratings yet

- CF 18NHHZXBMDocument95 pagesCF 18NHHZXBMZedecuxNo ratings yet

- v350 35 Ta24 Instal GuideDocument10 pagesv350 35 Ta24 Instal GuideDejan IlievNo ratings yet

- 579-1169 Manual Instalacion Tarjeta IdnetDocument14 pages579-1169 Manual Instalacion Tarjeta IdnetMiguelNo ratings yet

- v570 57 t34 Vision Oplc Device ManualDocument20 pagesv570 57 t34 Vision Oplc Device Manualpoblemator12345No ratings yet

- Installation, Wiring, Operation Manua: One and Two Pen Circular Chart RecorderDocument32 pagesInstallation, Wiring, Operation Manua: One and Two Pen Circular Chart RecorderkmpoulosNo ratings yet

- VLP33Document46 pagesVLP33pesmeraldaNo ratings yet

- Imm Ex510-Gen1-X73 TFP46GBDocument1 pageImm Ex510-Gen1-X73 TFP46GBFranzKafkaNo ratings yet

- Parker SSD Drives 650 Series Quick Start GuideDocument2 pagesParker SSD Drives 650 Series Quick Start Guideeng_karamazabNo ratings yet

- Rapier Switch: Quick Install GuideDocument12 pagesRapier Switch: Quick Install GuideEnzoNo ratings yet

- Powercore Model Mpc-10 Installation Manual: 00-02-0938 2016-02-19 Section 40Document15 pagesPowercore Model Mpc-10 Installation Manual: 00-02-0938 2016-02-19 Section 40George QuijijeNo ratings yet

- v570 57 t20b t40b J Instal GuideDocument8 pagesv570 57 t20b t40b J Instal GuidecetadminNo ratings yet

- Guia Usuario Dolev800vDocument75 pagesGuia Usuario Dolev800vmininakristyNo ratings yet

- Numark CDN 22 S Owner ManualDocument16 pagesNumark CDN 22 S Owner Manualnaupas007No ratings yet

- UPD78F0511 RenesasElectronicsDocument730 pagesUPD78F0511 RenesasElectronicsUbaldo BritoNo ratings yet

- MAPNET II Transceiver Installation Instructions: Topic See Page #Document22 pagesMAPNET II Transceiver Installation Instructions: Topic See Page #william jovelNo ratings yet

- Service Manual PDFDocument95 pagesService Manual PDFFrancisco José EscuderoNo ratings yet

- CT V900 A DiagrammDocument1 pageCT V900 A Diagrammsxn69c2703No ratings yet

- Honeywell 4219 Install GuideDocument2 pagesHoneywell 4219 Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Zeners 1N4370A - 1N4372A 1N746A - 1N759A: Absolute Maximum RatingsDocument5 pagesZeners 1N4370A - 1N4372A 1N746A - 1N759A: Absolute Maximum RatingsAxel JacobNo ratings yet

- FRENIC-Eco Starting GuideDocument49 pagesFRENIC-Eco Starting GuideMikhail YudhiantaraNo ratings yet

- Mini Dome Camera: Installation and Operation Manual ForDocument17 pagesMini Dome Camera: Installation and Operation Manual ForÁsgeirr Ánsgar Ósgar CanuroNo ratings yet

- Man 125Document10 pagesMan 125pt.Sentra media cemerlangNo ratings yet

- Vision™ OPLC™: V350-35-TR20/V350-J-TR20 Installation GuideDocument8 pagesVision™ OPLC™: V350-35-TR20/V350-J-TR20 Installation GuideKikis GalloNo ratings yet

- Measuring Flow of High-Viscosity Liquids - PGJ - July07Document6 pagesMeasuring Flow of High-Viscosity Liquids - PGJ - July07Svetozar YolovNo ratings yet

- ConneXium TCSESM Installation Manual V6Document36 pagesConneXium TCSESM Installation Manual V6Vinicius Mello AlmeidaNo ratings yet

- Installation, Wiring, Operation Manua: Form 2844 Edition 11 © August 1993 Updated March 1997Document72 pagesInstallation, Wiring, Operation Manua: Form 2844 Edition 11 © August 1993 Updated March 1997kmpoulosNo ratings yet

- Vision v35035tr34Document10 pagesVision v35035tr34Erasmo Franco SNo ratings yet

- Wireless-N Range Extender and Access Point Setup GuideDocument31 pagesWireless-N Range Extender and Access Point Setup Guideparacaman52No ratings yet

- Universal Kit Installation ManualDocument70 pagesUniversal Kit Installation Manualnelutuanv-1No ratings yet

- Acer LCD x193hq Sm080904v1 Model Id Ra19waanuDocument36 pagesAcer LCD x193hq Sm080904v1 Model Id Ra19waanuFrancis Gilbey Joson ArnaizNo ratings yet

- Manual 1 Carrier Infinity TermostatoDocument18 pagesManual 1 Carrier Infinity TermostatoJhonatan Sepulveda100% (1)

- Simplex Installation Instructions IDNet+ ModuleDocument16 pagesSimplex Installation Instructions IDNet+ ModuleRaja Prathap SinghNo ratings yet

- Instruction Manual - ThinkTop DeviceNet - enDocument40 pagesInstruction Manual - ThinkTop DeviceNet - enRaul Guevara TorresNo ratings yet

- Rose Mount Analytical 1056 ManualDocument12 pagesRose Mount Analytical 1056 ManualFrancisco RomoNo ratings yet

- Man-1200 Elite RS Installation and Operation Manual Apollo Protocol PDFDocument156 pagesMan-1200 Elite RS Installation and Operation Manual Apollo Protocol PDFMostafa Ali100% (1)

- Samba Oplc SeriesDocument12 pagesSamba Oplc SeriesSlavko MitrovicNo ratings yet

- SGN-500 Instruction ManualDocument33 pagesSGN-500 Instruction ManualHira SinghNo ratings yet

- Manual Technics 717Document60 pagesManual Technics 717hsilvab0% (1)

- Owner'S Manual: UA-101 - e.book 1 ページ 2006年1月19日 木曜日 午後2時38分Document64 pagesOwner'S Manual: UA-101 - e.book 1 ページ 2006年1月19日 木曜日 午後2時38分studskirbyNo ratings yet

- Fast Ethernet PCI Adapter ManualDocument7 pagesFast Ethernet PCI Adapter Manualthanos69bNo ratings yet

- Biamp Manual Tesira Hd-1 Oct15-1Document16 pagesBiamp Manual Tesira Hd-1 Oct15-1Rachmat Guntur Dwi PutraNo ratings yet

- User Guide and Technical Manual: Soundcraft Ddps-33 Ppower SsupplyDocument16 pagesUser Guide and Technical Manual: Soundcraft Ddps-33 Ppower SsupplyMalay K GhoshNo ratings yet

- CV7300 Instruction Manual 11-05Document132 pagesCV7300 Instruction Manual 11-05boomdenNo ratings yet

- 1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00Document71 pages1/4 Din Microbased Controller Operators Manual: FORM 3665 Edition 1 © OCT. 1995 PRICE $10.00kmpoulos100% (1)

- Acer Switch: User's GuideDocument16 pagesAcer Switch: User's GuideAnonymous 6pjf8y52No ratings yet

- 615-LS 42 ManualDocument48 pages615-LS 42 ManualmelisaBNo ratings yet

- LDK5310 5inch Viewfinder SDTVDocument44 pagesLDK5310 5inch Viewfinder SDTVspeedyeduNo ratings yet

- Installation and Setup Guide: ADEMCO 4208U Universal Eight Zone Remote Point ModuleDocument4 pagesInstallation and Setup Guide: ADEMCO 4208U Universal Eight Zone Remote Point ModuleCarlos StandardNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet

- UjjDocument2 pagesUjjdreamsNo ratings yet

- CVDGDocument3 pagesCVDGdreamsNo ratings yet

- Book 1Document1 pageBook 1dreamsNo ratings yet

- Save Energy with Smart Lighting and Appliance ControlsDocument2 pagesSave Energy with Smart Lighting and Appliance ControlsdreamsNo ratings yet

- 321 e Lesson 22Document13 pages321 e Lesson 22mahmudtexNo ratings yet

- Check List PDDDocument4 pagesCheck List PDDdreamsNo ratings yet

- Introduction To Internet: 52:: Computer and Office ApplicationsDocument18 pagesIntroduction To Internet: 52:: Computer and Office ApplicationsPrince DalupeNo ratings yet

- BookDocument1 pageBookdreamsNo ratings yet

- A Case of Renal Stone With Moderate Hepatospleenomegaly and ?cystitisDocument6 pagesA Case of Renal Stone With Moderate Hepatospleenomegaly and ?cystitisHomoeopathic PulseNo ratings yet

- Check List PDDDocument4 pagesCheck List PDDdreamsNo ratings yet

- For DNLDDocument1 pageFor DNLDdreamsNo ratings yet

- FAMILY MAJLIS (Fire Alarm System) Office 16 (First Floor)Document4 pagesFAMILY MAJLIS (Fire Alarm System) Office 16 (First Floor)dreamsNo ratings yet

- MicrosoftDocument1 pageMicrosoftdreamsNo ratings yet

- For DNLDocument1 pageFor DNLdreamsNo ratings yet

- Homoeopathic Treatment of FeverDocument1 pageHomoeopathic Treatment of FeverdreamsNo ratings yet

- My DAP DownloadsDocument1 pageMy DAP DownloadsdreamsNo ratings yet

- Raja Abdul Majid Javid: Personal ProfileDocument2 pagesRaja Abdul Majid Javid: Personal ProfiledreamsNo ratings yet

- Madhya Pradesh Homoeopathic Medical CollegeDocument3 pagesMadhya Pradesh Homoeopathic Medical CollegedreamsNo ratings yet

- Kidney's CareDocument21 pagesKidney's CaredreamsNo ratings yet

- Madhya Pradesh Homoeopathic Medical CollegeDocument3 pagesMadhya Pradesh Homoeopathic Medical CollegedreamsNo ratings yet

- Dil-e-Wehshi by Ibn-e-InshaDocument126 pagesDil-e-Wehshi by Ibn-e-Inshaheera100% (2)

- Lable Type: Dip SwitchDocument2 pagesLable Type: Dip SwitchdreamsNo ratings yet

- Dil-e-Wehshi by Ibn-e-InshaDocument126 pagesDil-e-Wehshi by Ibn-e-Inshaheera100% (2)

- VSX-D411 Audio/Video Receiver Service ManualDocument82 pagesVSX-D411 Audio/Video Receiver Service ManualSilvioNo ratings yet

- Ada4898 1 - 4898 2Document20 pagesAda4898 1 - 4898 2FilipBlachaNo ratings yet

- M1 GPRP Guide: Paddle Shift System Setup and OperationDocument41 pagesM1 GPRP Guide: Paddle Shift System Setup and OperationRadomír MachačNo ratings yet

- Em Pump Specifications March2013 NW - SuntecDocument6 pagesEm Pump Specifications March2013 NW - SuntecPetrr RavvNo ratings yet

- Applications of MicrocontrollerDocument12 pagesApplications of MicrocontrollerBabak DanyalNo ratings yet

- Pinout Drawing Rev0Document1 pagePinout Drawing Rev0manh nguyenvanNo ratings yet

- DN - 61097 Detector PuntualDocument2 pagesDN - 61097 Detector PuntualfedcortesNo ratings yet

- Stepper Motor Set UpDocument3 pagesStepper Motor Set UpChockalingam ʀᴏʙᴏᴛɪᴄsNo ratings yet

- Predicting Solenoid Valve Spool Displacement Through Current AnalysisDocument8 pagesPredicting Solenoid Valve Spool Displacement Through Current AnalysisilhamNo ratings yet

- Line at High Frequencies Standing Waves and Standing Wave Ratio On A LineDocument13 pagesLine at High Frequencies Standing Waves and Standing Wave Ratio On A LineSaravanan ManavalanNo ratings yet

- Sadelta Echo Master Plus SchematicDocument1 pageSadelta Echo Master Plus SchematicSebastian PettersNo ratings yet

- User Manual: CLT1 - Hand Held A/C Test - Module For Externally Controlled A/C CompressorsDocument9 pagesUser Manual: CLT1 - Hand Held A/C Test - Module For Externally Controlled A/C CompressorsBilal al zeitawiNo ratings yet

- Chapter 7Document69 pagesChapter 7Amit DostNo ratings yet

- Module 15Document14 pagesModule 15lanceadriano06No ratings yet

- Ir21531D (S) & (PBF) : Self-Oscillating Half-Bridge DriverDocument9 pagesIr21531D (S) & (PBF) : Self-Oscillating Half-Bridge DriverErasmo Franco SNo ratings yet

- Effect of Compression Loads On The Solder Joint Reliability of FDocument7 pagesEffect of Compression Loads On The Solder Joint Reliability of Fjabin johnsonNo ratings yet

- Guide pathway separation between telecom and power cablesDocument4 pagesGuide pathway separation between telecom and power cablesMilanNo ratings yet

- 007 Troubleshooting UENR5483-2Document102 pages007 Troubleshooting UENR5483-2Jamiyan DorjNo ratings yet

- DGV 275 ST: 1. General Technical DataDocument12 pagesDGV 275 ST: 1. General Technical Dataابرار عمرNo ratings yet

- DL 1002Document2 pagesDL 1002Gagan SLNo ratings yet

- How Does Your Capacitor WorkDocument51 pagesHow Does Your Capacitor WorkVishal MahireNo ratings yet

- Optimize DC motor datasheetDocument62 pagesOptimize DC motor datasheetmanuNo ratings yet

- Digital Electronics Multiple Choice QuestionsDocument22 pagesDigital Electronics Multiple Choice QuestionsSenthilkumar KrishnamoorthyNo ratings yet

- Acer Aspire One A110 - A150 (Quanta ZG5) SchematicsDocument33 pagesAcer Aspire One A110 - A150 (Quanta ZG5) SchematicsMayank Mani Singh0% (1)

- Compiling Occam Into Field-Programmable Gate Arrays: Ian Page and Wayne LukDocument13 pagesCompiling Occam Into Field-Programmable Gate Arrays: Ian Page and Wayne LukTamiltamil TamilNo ratings yet

- Constant Current Fuzzy Logic Controller For Grid Connected Electric Vehicle ChargingDocument6 pagesConstant Current Fuzzy Logic Controller For Grid Connected Electric Vehicle ChargingNik UrlaubNo ratings yet