Professional Documents

Culture Documents

01

Uploaded by

Lincs lincolnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01

Uploaded by

Lincs lincolnCopyright:

Available Formats

Chapter 1

Introduction

1.1 Preliminary Remarks The ability of proportional integral (PI) and proportional integral derivative (PID) controllers to compensate most practical industrial processes has led to their wide acceptance in industrial applications. Koivo and Tanttu (1991), for example, suggest that there are perhaps 510% of control loops that cannot be controlled by single input, single output (SISO) PI or PID controllers; in particular, these controllers perform well for processes with benign dynamics and modest performance requirements (Hwang, 1993; strm and Hgglund, 1995). It has been stated that 98% of control loops in the pulp and paper industries are controlled by SISO PI controllers (Bialkowski, 1996) and that in process control applications, more than 95% of the controllers are of PID type (strm and Hgglund, 1995). PI or PID controller implementation has been recommended for the control of processes of low to medium order, with small time delays, when parameter setting must be done using tuning rules and when controller synthesis is performed either once or more often (Isermann, 1989). However, despite decades of development work, surveys indicating the state of the art of control in industrial practice report sobering results. For example, Ender (1993) states that in his testing of thousands of control loops in hundreds of plants, it has been found that more than 30% of installed controllers are operating in manual mode and 65% of loops operating in automatic mode produce less variance in manual than in automatic (i.e. the automatic controllers are poorly tuned). The situation does not appear to have improved more recently, as Van Overschee and De Moor (2000) report that 80% of PID controllers are badly tuned; 30% of PID controllers operate in manual with another 30% of the controlled loops increasing the short term variability of the process to be controlled (typically due to too strong integral action). The authors state that 25%

Handbook of PI and PID Controller Tuning Rules

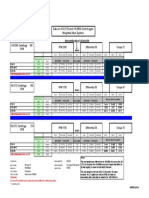

of all PID controller loops use default factory settings, implying that they have not been tuned at all. These and other surveys (well summarised by Yu, 1999, pp. 12) show that the determination of PI and PID controller tuning parameters is a vexing problem in many applications. The most direct way to set up controller parameters is the use of tuning rules; obviously, the wealth of information on this topic available in the literature has been poorly communicated to the industrial community. One reason is that this information is scattered in a variety of media, including journal papers, conference papers, websites and books for a period of over seventy years. The purpose of this book is to bring together, in summary form, the tuning rules for PI and PID controllers that have been developed to compensate SISO processes with time delay. 1.2 Structure of the Book Tuning rules are set out in the book in tabular form. This form allows the rules to be represented compactly. The tables have four or five columns, according to whether the controller considered is of PI or PID form, respectively. The first column in all cases details the author of the rule and other pertinent information. The final column in all cases is labelled Comment; this facilitates the inclusion of information about the tuning rule that may be useful in its application. The remaining columns detail the formulae for the controller parameters. Chapter 2 explores the range of PI and PID controller structures proposed in the literature. It is often forgotten that different manufacturers implement different versions of the PID controller algorithm (in particular); therefore, controller tuning rules that work well in one PID architecture may work poorly in another. This chapter also details the process models used to define the controller tuning rules. Chapters 3 and 4 detail, in tabular form, PI and PID controller tuning rules (and their variations), as applied to a wide variety of self-regulating process models and non-self-regulating process models, respectively. One-hundred-andsixteen such tables are provided altogether. To allow the reader to access data readily, the author has arranged that each table starts on its own page; each table is preceded by the controller used, together with a block diagram showing the unity feedback closed loop arrangement of the controller and process model. In Chapter 5, analytical calculations of the gain and phase margins of a large sample of PI and PID controller tuning rules are determined, when the process is modelled in first order lag plus time delay (FOLPD) form, at a range of ratios

Chapter 1: Introduction

of time delay to time constant of the process model. Results are given in graphical form. An important feature of the book is the unified notation used for the tuning rules; a glossary of the symbols used is provided in Appendix 1. Appendix 2 outlines the range of methods used to determine process model parameters; this information is presented in summary form, as this topic could provide data for a book in itself. However, sufficient information, together with references, is provided for the interested reader. Finally, a comprehensive reference list is provided. In particular, the author would like to recommend the contributions by McMillan (1994), strm and Hgglund (1995), (2006), Shinskey (1994), (1996), Tan et al. (1999a), Yu (1999), Lelic and Gajic (2000) and Ang et al. (2005) to the interested reader, which treat comprehensively the wider perspective of PID controller design and application.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- SANS 347 - 2012 - Ed 2 - OPENDocument51 pagesSANS 347 - 2012 - Ed 2 - OPENLincs lincolnNo ratings yet

- Material Selection and Corrosion Resistant AlloysDocument4 pagesMaterial Selection and Corrosion Resistant Alloysعزت عبد المنعمNo ratings yet

- Machinery's Handbook Guide to All Engineering TopicsDocument3 pagesMachinery's Handbook Guide to All Engineering Topicssenthil031277100% (1)

- Pipe and Tubing FormulaeDocument1 pagePipe and Tubing FormulaeLincs lincolnNo ratings yet

- Pipe and Tubing FormulaeDocument1 pagePipe and Tubing FormulaeLincs lincolnNo ratings yet

- A Study of Three-Node Triangular Plate Bending ElementsDocument42 pagesA Study of Three-Node Triangular Plate Bending ElementsGirish Dev Chaurasiya100% (1)

- Roark's Formulas For Stress and Strain 10.1Document1 pageRoark's Formulas For Stress and Strain 10.1Lincs lincolnNo ratings yet

- Solution Methods For Nonlinear Finite Element Analysis (NFEA)Document39 pagesSolution Methods For Nonlinear Finite Element Analysis (NFEA)janaaidaas1996No ratings yet

- ANSI Y14 - 5-1994 Geometric Tolerancing CheatsheetDocument2 pagesANSI Y14 - 5-1994 Geometric Tolerancing Cheatsheetjlel12100% (1)

- 20090727143031273Document8 pages20090727143031273Lincs lincolnNo ratings yet

- Materials Selection Guide Final VersionDocument77 pagesMaterials Selection Guide Final VersionRahul ManeNo ratings yet

- Rules of Thumb For Steel StructuresDocument5 pagesRules of Thumb For Steel StructuresLincs lincoln100% (1)

- Heat Exchanger NomenclatureDocument1 pageHeat Exchanger NomenclatureSikandar HayatNo ratings yet

- A Geometric Constraint SolverDocument30 pagesA Geometric Constraint SolverLincs lincolnNo ratings yet

- Numerical Methods For Scientific and Engineering Computation - M. K. Jain, S. R. K. Iyengar and R. K. JainDocument152 pagesNumerical Methods For Scientific and Engineering Computation - M. K. Jain, S. R. K. Iyengar and R. K. JainRishabh Singhal50% (10)

- 02Document42 pages02Lincs lincolnNo ratings yet

- 01 - Fatigue Theory (Part 1)Document42 pages01 - Fatigue Theory (Part 1)Lincs lincolnNo ratings yet

- Transmission Characteristics of IR Signals in The AtmosphereDocument54 pagesTransmission Characteristics of IR Signals in The AtmosphereLincs lincolnNo ratings yet

- 01Document8 pages01Katai MwanzaNo ratings yet

- 20090727143031273Document8 pages20090727143031273Lincs lincolnNo ratings yet

- CMA Fill Heights Over Precast CulvertsDocument6 pagesCMA Fill Heights Over Precast CulvertsLincs lincolnNo ratings yet

- 20090727143031273Document8 pages20090727143031273Lincs lincolnNo ratings yet

- 01Document29 pages01Lincs lincolnNo ratings yet

- Units: 3. U.S. Units of Measurement 4. Tables of EquivalentsDocument8 pagesUnits: 3. U.S. Units of Measurement 4. Tables of EquivalentsLincs lincolnNo ratings yet

- UnitsDocument3 pagesUnitsLincs lincolnNo ratings yet

- The Scope of Analytical Chemistry: Ground Rules and FundamentalsDocument10 pagesThe Scope of Analytical Chemistry: Ground Rules and FundamentalsLincs lincolnNo ratings yet

- 01 PDFDocument11 pages01 PDFLincs lincolnNo ratings yet

- 2 Kinematics and Dynamics of A ParticleDocument13 pages2 Kinematics and Dynamics of A ParticleLincs lincolnNo ratings yet

- Cape Grating Load TablesDocument3 pagesCape Grating Load TablesLincs lincolnNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- GSM Modernization Poster2Document1 pageGSM Modernization Poster2leonardomarinNo ratings yet

- Pump Course Material Chapter 2Document16 pagesPump Course Material Chapter 2engr victorNo ratings yet

- Pentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessDocument156 pagesPentecostal Ecclesiology: Simon K.H. Chan - 978-90-04-39714-9 Via Free AccessStanley JohnsonNo ratings yet

- Porta by AmbarrukmoDocument4 pagesPorta by AmbarrukmoRika AyuNo ratings yet

- BS en 12201 5 2011Document20 pagesBS en 12201 5 2011fatjon31100% (4)

- CE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingDocument36 pagesCE 581 Reinforced Concrete Structures: Lecture 4: Axial LoadingCelil OrakNo ratings yet

- Cumulative List of Notices to MarinersDocument2 pagesCumulative List of Notices to MarinersResian Garalde Bisco100% (2)

- PPS120 Rev10 0309 PDFDocument2 pagesPPS120 Rev10 0309 PDFArfanAliNo ratings yet

- Uji Deteksi Biofilm Dari Isolat Klinik Kateter Urin Bakteri Entercoccus Dibandingkan Dengan Tube MethodDocument27 pagesUji Deteksi Biofilm Dari Isolat Klinik Kateter Urin Bakteri Entercoccus Dibandingkan Dengan Tube MethodIyannyanNo ratings yet

- Basic Principles of Local GovernmentDocument72 pagesBasic Principles of Local GovernmentAnne Camille SongNo ratings yet

- Arta Fridei Kahlo A Fost Intotdeauna o ReactieDocument13 pagesArta Fridei Kahlo A Fost Intotdeauna o ReactieAlta DaianNo ratings yet

- AS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDocument31 pagesAS 1418.2 Cranes, Hoists and Winches Part 2 Serial Hoists and WinchesDuy PhướcNo ratings yet

- Ericsson Microwave Outlook 2021Document16 pagesEricsson Microwave Outlook 2021Ahmed HussainNo ratings yet

- 35.2 - ING - El Puente NewsletterDocument13 pages35.2 - ING - El Puente NewsletterIrmali FrancoNo ratings yet

- Computational Kinematics Assignment 2021Document2 pagesComputational Kinematics Assignment 2021Simple FutureNo ratings yet

- SAMMAJIVA - VOLUME 1, NO. 3, September 2023 Hal 235-250Document16 pagesSAMMAJIVA - VOLUME 1, NO. 3, September 2023 Hal 235-250Nur Zein IzdiharNo ratings yet

- Nigeria - S Niger Delta Crisis, Root Causes of Peacelessness (Hassan Tai Ejibunu)Document41 pagesNigeria - S Niger Delta Crisis, Root Causes of Peacelessness (Hassan Tai Ejibunu)Ionescu FloNo ratings yet

- HS-2172 Vs HS-5500 Test ComparisonDocument1 pageHS-2172 Vs HS-5500 Test ComparisonRicardo VillarNo ratings yet

- 841 Specific GravityDocument1 page841 Specific GravityJam SkyNo ratings yet

- IotDocument88 pagesIotLalithyaNo ratings yet

- 3 Variable Cramers Rule PDFDocument4 pages3 Variable Cramers Rule PDFElton DiocsonNo ratings yet

- NarendraVani KallubaluVKV 2010-11Document144 pagesNarendraVani KallubaluVKV 2010-11Vivekananda Kendra100% (1)

- Vrio Analysis Slide Template 16x9 1Document8 pagesVrio Analysis Slide Template 16x9 1Alt HrishiNo ratings yet

- Celiac DiseaseDocument14 pagesCeliac Diseaseapi-355698448100% (1)

- Pemanfaatan Limbah Spanduk Plastik (Flexy Banner) Menjadi Produk Dekorasi RuanganDocument6 pagesPemanfaatan Limbah Spanduk Plastik (Flexy Banner) Menjadi Produk Dekorasi RuanganErvan Maulana IlyasNo ratings yet

- AMYLOIDOSISDocument22 pagesAMYLOIDOSISMohan ChoudharyNo ratings yet

- 1 John 2:15-27 - Bible Commentary For PreachingDocument6 pages1 John 2:15-27 - Bible Commentary For PreachingJacob D. GerberNo ratings yet

- Hairpin tube arrangements and multiple-bend designs for superheatersDocument2 pagesHairpin tube arrangements and multiple-bend designs for superheatersMArifHidayahNo ratings yet

- AOAC 2012.11 Vitamin DDocument3 pagesAOAC 2012.11 Vitamin DPankaj BudhlakotiNo ratings yet

- Jual Sokkia SET 350X Total Station - Harga, Spesifikasi Dan ReviewDocument5 pagesJual Sokkia SET 350X Total Station - Harga, Spesifikasi Dan Reviewbramsalwa2676No ratings yet