Professional Documents

Culture Documents

Special Report On Injectables PDF

Uploaded by

herfuentesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Special Report On Injectables PDF

Uploaded by

herfuentesCopyright:

Available Formats

SPECIAL REPORT ON INJECTABLES

ARE YOU READY TO OUTSOURCE INJECTABLES? Key things you need to know

RAPID GROWTH IN THE DEMAND

Most biotechnology drugs and many pharmaceuticals are inactivated in the gastrointestinal tract when taken orally and must be developed as injectable drugs.

OVERCOME TECHNICAL HURDLES

The manufacturing of injectables is a complex process. Common technical challenges to overcome are stability, solubility and sterility.

OUTSOURCE TO THE RIGHT PARTNER

Partnering with the right outsourcing partner can help overcome signicant hurdles and ensure a quick and seamless product development.

SPECIAL REPORT ON INJECTABLES

ARE YOU READY TO OUTSOURCE INJECTABLES? Key things you need to know

Product development for injectable drugs requires a rigorous strategy and process consisting of four steps: (1) characterization, (2) formulation and process development, (4) lyophilization and (3) assurance of sterility. The process can be lengthy, expensive and risky, so its important to outsource to an experienced partner who can address the challenges involved. This white paper provides a roadmap for understanding how injectables are developed and offers suggestions on how to nd the right outsourcing partner to manage the process. This report is sponsored by CARBOGEN AMCIS AG, a leading service provider, offering a portfolio of drug-development and commercialization services to the pharmaceutical and biopharmaceutical industry at all stages of drug development.

The global injectable drug delivery market is expected to reach roughly $30 billion in 2015

Most biotechnology drug ingredients, including peptides, proteins and chemotherapeutic agents, are inactivated in the gastrointestinal tract when taken orally, hence the need for an injectable drug form

Since 1982, the year human insulin became the rst biotechnology product approved by the Food and Drug Administration, there has been enormous growth in the pharmaceutical biotechnology market segment. In fact, the global injectable drug delivery market is expected to reach roughly $30 billion in 2015 - more than double the amount reached in 2009. This trend has spurred the rapid development of drugs that can only be administered through injection, due to the bioavailability and stability of biomolecules. Most biotechnology drug ingredients, including peptides, proteins and chemotherapeutic agents, are inactivated in the gastrointestinal tract when taken orally, hence the need for an injectable drug form. Moreover, for metabolic disorders treated by small molecules with an immediate therapeutic action, the parenteral route is considered as a must. Despite rapid growth in the demand for injectables, also known as parenterals, the formulation and manufacturing process of these drugs continues to face complex technical challenges.

The market for injectables is expected to reach $30 billion in 2015 - more than double the amount reached in 2009

2 | Special Report on Injectables

www.carbogen-amcis.com

SPECIAL REPORT ON INJECTABLES

CHALLENGES & TECHNICAL HURDLES Stability

One of the most common problems manufacturers face when developing injectables is ensuring the stability of the product. While additives are often used to stabilize drugs, the choice of safe additives is limited and some additives may also undergo degradation. Drugs that are sufciently stable in ready-to-use solutions may require special storage conditions to preserve their stability, such as light-protected packaging systems or refrigeration. Some drugs interact with the surfaces of storage containers or of administration devices, presenting issues that must be addressed through adequate packaging. Many injectables become unstable over extended periods of time, so shelf-life must be taken into account. Moreover, a majority of injectable drug products are too unstable to be marketed as readyto-use solutions. Instead, they are available as sterile solids produced by lyophilization (freeze drying), sterile crystallization or other powder lling technologies. Additionally, manufacturers need to be aware of physical and chemical incompatibilities that can occur when certain injectables are combined with other drugs, which can compromise their stability and cause adverse reactions in patients.

Striking the right balance between safety and costeffectiveness is a delicate process that requires a knowledgeable partner who can mitigate the risks involved

Solubility

Solubility is another major challenge formulation scientists must overcome. Ideally, an injectable drug formulation contains an active ingredient and water. However, most of the common active ingredients are poorly soluble in water. As a result, additives are often required to improve the solubility of an injectable drug product. Finding the right additive to conserve the bioavailability of the molecule, while improving solubility may lead to manufacturing difculties and/or increased cost of production. Striking the right balance between safety and cost-effectiveness is a delicate process that requires a knowledgeable partner who can mitigate the risks involved.

Sterility

The third major challenge for manufacturers in the parenteral drug industry is sterility. Sterility means that the drug product is free from microbial contaminants and, by extension, essentially free from endotoxins. However, sterility testing requires a signicant amount of time, money and resources. Sterility tests only use a small sample of a much larger product population. In other words, sterility cannot be proven, only assured. Pyrogens are metabolic or/and constituting products of microorganisms, which are known to induce fever in humans. Some of the most common forms of sterilization, such as aseptic ltration and heat terminal sterilization cannot destroy pyrogens. Therefore, preventing pyrogenic contamination from the beginning of the product development process is crucial. Prevention requires using solutes prepared under clean conditions, pyrogen-free constituents including pyrogen-free water and pyrogen-free packaging materials. For complex process that considers heat treatments, the implementation of ion-exchange resins is advised to reduce the endotoxins charge. Additionally, manufacturers must ensure injectables are free from all particulate matter contamination. The heat sterilization and the gamma radiations represent the most efcient ways to sterilize a drug product when a compound that resists to heat and radiations. But in any case these techniques are leading to pyrogens generation if the preliminary preparation steps and are not ensuring a low level of contamination. When the drug substance is heat sensitive, such as biomolecules, the 0.2 m ltration represents the preferred method to sterilize a drug product. The lter membrane and the parameters must be determined carefully.

Finding the right additive to conserve the bioavailability of the molecule, while improving solubility may lead to manufacturing difculties and/or increased cost of production

Sterility means that the drug product is free from microbial contaminants and, by extension, essentially free from endotoxins

3 | Special Report on Injectables

www.carbogen-amcis.com

SPECIAL REPORT ON INJECTABLES

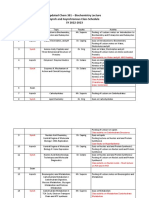

PRODUCT DEVELOPMENT

Product development for injectable drugs can be lengthy, expensive and risky, so its important to outsource to an experienced partner who can address the challenges involved. Development requires a rigorous strategy and process consisting of four steps: (1) characterization, (2) formulation and process development, (4) lyophilization and (3) assurance of sterility.

Product development for injectable drugs can be lengthy, expensive and risky, so its important to outsource to an experienced partner who can address the challenges involved

Characterization Studies

At the beginning of development, it is important to analyze the structural characteristics of the proposed active ingredient and clearly dene the clinical specications of the parenteral drug product. This process, referred to as characterization, involves assessing the physicalchemical properties of the bulk active ingredient and of the biomolecule. Nowadays, the characterization of most chemical compounds is relatively easy thanks to the wide availability of technology, including infrared (IR), differential scanning calorimetry (DSC), X-ray diffraction, and mass spectrometry. For biomolecules such as peptides and proteins, it is also often necessary to assess the primary structure and the amino acid sequence of the active ingredient to conrm principal properties. Characterization also involves impurity proling and tracking, determination of degradation pathways, as well as stress tests to determine the sensitivity of the molecule to heat, humidity, oxygen and light.

Formulation and Process Development

Initial formulation is performed to dene the most appropriate conditions for the solubilization, stabilization and administration of the biomolecule or active pharmaceutical ingredient. Parenteral drugs are formulated as solutions, suspensions, emulsions and powders to be reconstituted as solutions and at this step, it is critical to ensure that the additives dont trigger unintended chemical degradation processes. First, the needs and specications of the parenteral drug product are dened according to its clinical purpose, including therapeutic indication, patient typology, administration route, therapeutic dose and required posology. Next, the molecule is tested under different temperatures, time, and atmospheric conditions, in combination with a wide range of additives, such as stabilizing agents, buffers, solubilizers, surfacants, tonicity modiers, cryoand lyoprotectants and bulking agents, in order to identify the most appropriate candidate for the drug product formulation. Compatibility testing with the packaging components is also performed to identify the most suitable packaging of the nal drug product. It is important to select the type of packaging (container size and composition, type of closure, light protection) early in the process so the formulation developers can ensure that the product is compatible with the chosen packaging system. Then the solution is assessed to determine how well it is able to withstand storage conditions. Stability studies are used to determine the container size, formulation components and type of container, as well as the product expiration date. Depending on the product prole, a variety of stability studies can be conducted, such as: ICH stability, stress stability, drug substance stability, drug product stability and degradation proling. Prior to production, the manufacturer should also test the compatibility of the equipment (vessels, sterilization lters and tubing) used during the manufacturing process with the active ingredient to ensure that there will be no degradation, adsorption or undesired leaching and contamination.

Parenteral drugs are formulated as solutions, suspensions, emulsions and powders to be reconstituted as solutions and at this step, it is critical to ensure that the additives dont trigger unintended chemical degradation processes

4 | Special Report on Injectables

www.carbogen-amcis.com

SPECIAL REPORT ON INJECTABLES

Lyophilization

When the main active ingredient is too unstable and the injectable cannot be formulated as a ready-to-use liquid dosage form, the drug may undergo lyophilization, a dehydration method that makes it possible to keep the product stable in a dry state. Many biopharmaceutical drugs, such as proteins and peptides, or even small molecules, are unstable in water and therefore must be freeze-dried for clinical and commercial use.

Many biopharmaceutical drugs, such as proteins and peptides, or even small molecules, are unstable in water and therefore must be freeze-dried for clinical and commercial use

Assurance of Sterility

To address sterility in the production of injectables, manufacturers must follow current good manufacturing practices (cGMPs). Strict adherence to cGMP principles plays a critical role in ensuring the highest quality standards in manufacturing processes as well as in end products. The manufacturer starts with the procurement of the active ingredient, excipients and packaging components (containers, closures, etc.) and ends with the sterile product sealed in its dispensing package. Using FDA approved GRAS (Generally Regarded as Safe) excipients helps to assure sterility as these ingredients have low endotoxin and bioburden levels. During production, there are a variety of methods available to achieve sterility, including autoclave, dry heat, sterile ltration and aseptic processing. Each sterilization procedure must undergo signicant testing to ascertain that the method offers a high degree of assurance. Qualication of sterilizing processes or specic validation of a sterile ltration method should be done throughout the clinical stages and prior commercialization. This validation of an aseptic process, an integral part of cGMP requirements, helps ensure there are no microorganisms present that could contaminate the nal drug product.

Strict adherence to cGMP principles plays a critical role in ensuring the highest quality standards in manufacturing processes as well as in end products

The aseptic process should be by validated by media ll testing, microbiological and analytical controls and 100% visual inspection

5 | Special Report on Injectables

www.carbogen-amcis.com

SPECIAL REPORT ON INJECTABLES

WHAT TO LOOK FOR IN AN OUTSOURCING PARTNER

As illustrated, developing injectables is a complex process. Outsourcing to a knowledgeable contract manufacturing organization (CMO) offers a variety of advantages, such as access to expertise, increased exibility, risk reduction, adequate supply and increased speed to market. When selecting a CMO, there are several characteristics to look for. An experienced CMO should have a complete service offering: from API characterization to sterile manufacturing. This includes a complete supply chain solution for active ingredients, excipients and packaging components. Choosing a CMO with strong project management capabilities and economies of scale in all development phases (preclinical to phase III projects) will expedite the production process and create cost savings. One should also look for a CMO with a awless track record of quality. Aside from passing regulatory inspections and client audits, a well-qualied outsourcing partner will have a successful manufacturing history of sterile batches and a strong culture of safety to minimize the risk of cross contamination. Additionally, the CMO should have a highly qualied team with a broad customer base. This includes having experience with diversied molecules, such as vaccines, monoclonal antibodies, enzymes, hormones, proteins, peptides, prostaglandins, opiates, steroids and cytotoxics. Excellent customer response rates and a strong presence in the industry are also important factors to take into account when selecting a CMO. Last but not least, the human element and t of two companies corporate cultures often determine the success of a partnership. Thus, its critical to choose a partner with a exible and collaborative team to ensure frequent and open communication on both sides of the table. The smoother the communication, the better off both parties will be to navigate any issues that might arise. The manufacturing of chemical and biopharmaceutical injectables is a complex process and partnering with the right CMO can help overcome signicant hurdles and ensure that product development happens in a quick and effective manner.

Choosing a CMO with strong project management capabilities and economies of scale in all development phases (preclinical to phase III projects) will expedite the production process and create cost savings

Its critical to choose a partner with a exible and collaborative team to ensure frequent and open communication on both sides of the table

REFERENCES: 1) Development and Manufacture of Protein Pharmaceuticals (Pharmaceutical Biotechnology) by Steve L. Nail (Editor) and Michael J. Akers (Kluwer Academic / Plenum Publishers) 2) Sterile Drug Products - Formulation, Packaging, Manufacturing, and Quality, Michael J. Akers (Informa Healthcare) 3) The Development of Injectable Bioproducts: The Perfect Three-Step Waltz, Maxime Laugier, Life Science Leaders, 2010

6 | Special Report on Injectables

www.carbogen-amcis.com

SPECIAL REPORT ON INJECTABLES

CARBOGEN AMCIS - YOUR PARTNER FOR INJECTABLES

Complex Small Molecules Biologics Highly Potents Liquids Semi Solids Injectables Vials Prelled Syringes Freeze Dried Products

DEVELOPMENT

Formulation Development Characterization Studies GMP Lyophilization Services Analytical Methods

SUPPORT ACTIVITIES

Microbiological controls Analytical controls 100% visual inspection Stability studies (ICH guidelines)

MANUFACTURING

Process Development & Scale Up Pre-clinical & Clinical Batches Media Fill Testing Cross Contamination Management

GMP COMPLIANT

Successfully Inspected by - Health Authorities - Pharmaceutical Companies 340 batches Produced since 2000

Riom Site CARBOGEN AMCIS SAS, 10, rue des Boules, 63200 Riom France Tel (+33) 47-333 72 40 Fax (+33) 47 333 72 55 We are looking forward to helping you go to market faster. If you have any questions or would like to know more about CARBOGEN AMCIS, please feel free to contact us at info@carbogen-amcis.com Or visit our website: www.carbogen-amcis.com/sciSpecialties/aseptic-production.asp

7 | Special Report on Injectables

www.carbogen-amcis.com

SPECIAL REPORT ON INJECTABLES

ABOUT CARBOGEN AMCIS

CARBOGEN AMCIS AG (www.carbogen-amcis.com) is a leading service provider, offering a portfolio of drug-development and commercialization services to the pharmaceutical and biopharmaceutical industry at all stages of drug development. CARBOGEN AMCIS site located in Riom, France is exclusively focused on the development and manufacturing of injectables drugs. With over 10 years of experience in the rapid supply of sterile batches for clinical trials, CARBOGEN AMCIS offers support for the outsourcing of injectables including: formulation dosages, aseptic lling, and lyophilization of injectables, small-molecule APIs, highly-potent APIs and biologics. CARBOGEN AMCIS operates to European Good Manufacturing Practice (GMP) and was successfully inspected by the French Health Agency (Agence Nationale de Scurit du Mdicament et des Produits de Sant ANSM) over the past 10 years.

Bubendorf Site (Headquarters) CARBOGEN AMCIS AG Hauptstrasse 171 CH-4416 Bubendorf Switzerland Tel (+41) 61-935 53 53 Fax (+41) 61-935 53 00

You might also like

- Astm 505M 12Document10 pagesAstm 505M 12Alan Isai Valdez CastrejónNo ratings yet

- Guidance For Industry - ATP - PremisesDocument13 pagesGuidance For Industry - ATP - PremisesFISHNo ratings yet

- A Risk Based Cleaning and Disinfection ProgramDocument83 pagesA Risk Based Cleaning and Disinfection ProgramiSanguinoNo ratings yet

- Curing Agents For Epoxy ResinsDocument10 pagesCuring Agents For Epoxy ResinsmombarreNo ratings yet

- GMP Inspections enDocument56 pagesGMP Inspections ennaokijoe34No ratings yet

- Presentation Cleaning ValidationDocument38 pagesPresentation Cleaning ValidationNishit SuvaNo ratings yet

- Clean Room Training Procedures ISO Class 7 CertificationDocument17 pagesClean Room Training Procedures ISO Class 7 CertificationLoraNo ratings yet

- SGLS Guide to Oxo-biodegradable PlasticsDocument12 pagesSGLS Guide to Oxo-biodegradable PlasticsherfuentesNo ratings yet

- Disinfectants in Pharmaceutical Industry Tim SandleDocument8 pagesDisinfectants in Pharmaceutical Industry Tim SandleshwampaNo ratings yet

- Bioburden USP PDFDocument4 pagesBioburden USP PDFKatyaSNNo ratings yet

- Leachables and Extractables Handbook: Safety Evaluation, Qualification, and Best Practices Applied to Inhalation Drug ProductsFrom EverandLeachables and Extractables Handbook: Safety Evaluation, Qualification, and Best Practices Applied to Inhalation Drug ProductsDouglas J. BallNo ratings yet

- Guidelines Packaging Pharmaceutical Products TRS902 Annex 9Document38 pagesGuidelines Packaging Pharmaceutical Products TRS902 Annex 9Shuhash100% (1)

- White Paper 10 Problems With Pharma Plant MaintenanceDocument9 pagesWhite Paper 10 Problems With Pharma Plant MaintenanceAlok Kumar SharmaNo ratings yet

- Comparison of Aseptic Process Simulation Media fill Guidance’sDocument17 pagesComparison of Aseptic Process Simulation Media fill Guidance’smaheedhar231gmailcom100% (1)

- Risk Assessment Single-Use White Paper en MRK March 2017 LowDocument4 pagesRisk Assessment Single-Use White Paper en MRK March 2017 LowRui PiresNo ratings yet

- BIS CreamsDocument13 pagesBIS CreamsNAVNEET BAGGA100% (2)

- The Media Fill Approach An UpdateDocument3 pagesThe Media Fill Approach An UpdateajmalnasirNo ratings yet

- A Review Article On Visual Inspection Program For Sterile Injectable Product 2018Document38 pagesA Review Article On Visual Inspection Program For Sterile Injectable Product 2018Marcelo Sousa SilvaNo ratings yet

- Media Fills and Environment Atl Monitoring 26 July 2011 Presentation OneDocument18 pagesMedia Fills and Environment Atl Monitoring 26 July 2011 Presentation OneRiccardo TorelliNo ratings yet

- Development and Manufacturing of Injectable (Parenteral) Drug Products UnitDocument10 pagesDevelopment and Manufacturing of Injectable (Parenteral) Drug Products UnitParul SrivastavaNo ratings yet

- All About Fatty AlcoholDocument43 pagesAll About Fatty Alcoholrpyjcth100% (1)

- Evaluation of BFS Extrusions Through Processing Polymer Co.Document25 pagesEvaluation of BFS Extrusions Through Processing Polymer Co.alejandro carmona henaoNo ratings yet

- Validation of Aseptic ProcessDocument21 pagesValidation of Aseptic ProcessAdarsh KumarNo ratings yet

- Evaluation Study For Determination of Quantities of Disinfectant Solution Used For Fogging of Clean Rooms With Respect To Area VolumeDocument6 pagesEvaluation Study For Determination of Quantities of Disinfectant Solution Used For Fogging of Clean Rooms With Respect To Area VolumeSurjeet SamantaNo ratings yet

- Designing Aseptic Process Simulations: The Time and Container Number ConundrumDocument13 pagesDesigning Aseptic Process Simulations: The Time and Container Number ConundrumAmi AfiyatiNo ratings yet

- ObjectionableDocument9 pagesObjectionabledmtalbhogeNo ratings yet

- Ipa Best Practices Media FillDocument96 pagesIpa Best Practices Media FillValfar Robles100% (1)

- Tim Sandle White Paper EU - GMP - Annex - 1 - The - New - Draft - and - Implications 2020Document15 pagesTim Sandle White Paper EU - GMP - Annex - 1 - The - New - Draft - and - Implications 2020Supriya KapasNo ratings yet

- Lyophilization Competence06!11!2014 Tcm11 17173Document16 pagesLyophilization Competence06!11!2014 Tcm11 17173JPensacolaNo ratings yet

- Nonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsFrom EverandNonclinical Safety Assessment: A Guide to International Pharmaceutical RegulationsWilliam J. BrockNo ratings yet

- Environmental Monitoring and Microbiological Manufacture of Sterile DrugsDocument8 pagesEnvironmental Monitoring and Microbiological Manufacture of Sterile DrugsKristian Uriel DelgadoNo ratings yet

- Top Steel Companies in IndiaDocument3 pagesTop Steel Companies in Indiazukmos67% (3)

- Microbial Aspects in Cleaning ValidationDocument15 pagesMicrobial Aspects in Cleaning ValidationPharmacistNo ratings yet

- Cross ContaminationDocument47 pagesCross ContaminationAKKAD PHARMANo ratings yet

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)

- An Inside Look at USP71Document22 pagesAn Inside Look at USP71Dante IulliNo ratings yet

- Oxobiodegradable Plastic: An Article by Professor Gerald ScottDocument3 pagesOxobiodegradable Plastic: An Article by Professor Gerald ScottherfuentesNo ratings yet

- A Final Floor Show For Bugs (Sandle)Document4 pagesA Final Floor Show For Bugs (Sandle)Tim Sandle100% (1)

- Sterile Opthalmic Preparations PDFDocument6 pagesSterile Opthalmic Preparations PDFSundariNo ratings yet

- Design of Aseptic Process SimulationDocument5 pagesDesign of Aseptic Process SimulationFranck BureNo ratings yet

- Clean Room PharmaDocument39 pagesClean Room PharmadurbcomsonoNo ratings yet

- Aseptic Process Validation, SimultationDocument17 pagesAseptic Process Validation, SimultationSean SmithNo ratings yet

- Disinfectants Evaluation GuidelinesDocument44 pagesDisinfectants Evaluation Guidelinesamerican_guy10No ratings yet

- Sampling in Cleaning Validation in Pharmaceutical Industry - Pharmaceutical GuidelinesDocument2 pagesSampling in Cleaning Validation in Pharmaceutical Industry - Pharmaceutical GuidelinesASHOK KUMAR LENKANo ratings yet

- AGALLOCO Aseptic-Processing-Validation PDFDocument13 pagesAGALLOCO Aseptic-Processing-Validation PDFJOHN CARO100% (1)

- Cleanroom MicrobiologyDocument14 pagesCleanroom MicrobiologyKraken UrNo ratings yet

- FDA Issues Concept Paper on Updating Aseptic Processing GuidelinesDocument3 pagesFDA Issues Concept Paper on Updating Aseptic Processing GuidelinesmishannakNo ratings yet

- Production of Plasma Proteins for Therapeutic UseFrom EverandProduction of Plasma Proteins for Therapeutic UseRating: 3 out of 5 stars3/5 (5)

- Portfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesFrom EverandPortfolio, Program, and Project Management in the Pharmaceutical and Biotechnology IndustriesPete HarpumNo ratings yet

- Techniques for Downstream process for Biologic Drugs and VaccinesFrom EverandTechniques for Downstream process for Biologic Drugs and VaccinesNo ratings yet

- Guide For Determining The Confidence Interval Using ExcelDocument2 pagesGuide For Determining The Confidence Interval Using ExcelTim Sandle100% (3)

- 2risk MaPPandContainment PharmaForum2011 1Document35 pages2risk MaPPandContainment PharmaForum2011 1Steven LambertNo ratings yet

- Chem 152 Lab 4Document4 pagesChem 152 Lab 4mifferdk23% (13)

- Current Good Manufacturing Practices (cGMP) for Pharmaceutical ProductsFrom EverandCurrent Good Manufacturing Practices (cGMP) for Pharmaceutical ProductsNo ratings yet

- EU GMP Annex 1 Draft Proposes Expanded Guidance for Sterile Product ManufacturingDocument12 pagesEU GMP Annex 1 Draft Proposes Expanded Guidance for Sterile Product ManufacturingAntónio Ferreira100% (1)

- 320 Other 1210 2 10 20180111Document10 pages320 Other 1210 2 10 20180111Vivek PrasadNo ratings yet

- BFS-FRIEDMAN - Contamination Case Studies Paper PDFDocument9 pagesBFS-FRIEDMAN - Contamination Case Studies Paper PDFipatoffNo ratings yet

- Aseptic ProcessingDocument13 pagesAseptic Processingnsk79in@gmail.comNo ratings yet

- Advances in Aseptic Blow-Fill-Seal Processing of Pharmaceutical Liquids PDFDocument9 pagesAdvances in Aseptic Blow-Fill-Seal Processing of Pharmaceutical Liquids PDFipatoffNo ratings yet

- PDA 8th Microbiology ConferenceDocument12 pagesPDA 8th Microbiology ConferenceTim SandleNo ratings yet

- Pharmaceutical Regulatory InspectionsDocument2 pagesPharmaceutical Regulatory InspectionsTim SandleNo ratings yet

- S. No. SOP Title Room No. Responsibility StatusDocument1 pageS. No. SOP Title Room No. Responsibility Statusjpmaurya77No ratings yet

- PHSS Annual Members Conference 2014: Book Online Phss - Co.uk/eventsDocument3 pagesPHSS Annual Members Conference 2014: Book Online Phss - Co.uk/eventsTim SandleNo ratings yet

- Basic Principles of GMP: GMP For Sterile Pharmaceutical ProductsDocument19 pagesBasic Principles of GMP: GMP For Sterile Pharmaceutical Productsabhijit_gothoskar6039No ratings yet

- JVT 2012 v18n2 The Contamination Control Plan in Facility ValidationDocument6 pagesJVT 2012 v18n2 The Contamination Control Plan in Facility ValidationPaula Lwiz Isskander100% (1)

- ISO 8573 and Compressed Air TestingDocument2 pagesISO 8573 and Compressed Air TestingPrince MoniNo ratings yet

- Contamination ControlDocument5 pagesContamination ControlPadmanabhan DhanasekaranNo ratings yet

- Data Integrity and Compliance: A Primer for Medical Product ManufacturersFrom EverandData Integrity and Compliance: A Primer for Medical Product ManufacturersNo ratings yet

- Bio SurfactantsDocument15 pagesBio SurfactantsherfuentesNo ratings yet

- Practical ContaminationDocument45 pagesPractical ContaminationRagu RajanNo ratings yet

- ImmunoassaysDocument52 pagesImmunoassaysherfuentesNo ratings yet

- Seminario Spider BiteDocument9 pagesSeminario Spider BiteherfuentesNo ratings yet

- Coat HidrofobicoDocument52 pagesCoat HidrofobicoherfuentesNo ratings yet

- Kefir - A Complex ProbioticDocument33 pagesKefir - A Complex ProbioticherfuentesNo ratings yet

- Hydraulic Fracturing FluidsDocument26 pagesHydraulic Fracturing FluidsherfuentesNo ratings yet

- 5990 8801EN Hi Plex CompendiumDocument98 pages5990 8801EN Hi Plex CompendiumherfuentesNo ratings yet

- Guideline For Stability StudiesDocument44 pagesGuideline For Stability StudiesboddarambabuNo ratings yet

- 5990 8801EN Hi Plex CompendiumDocument98 pages5990 8801EN Hi Plex CompendiumherfuentesNo ratings yet

- Screw Extrusion Pretreatments To Enhance The Hydrolysis ofDocument5 pagesScrew Extrusion Pretreatments To Enhance The Hydrolysis ofherfuentesNo ratings yet

- Antimicrobial Products-Test For Antimicrobial Activity and EfficacyDocument14 pagesAntimicrobial Products-Test For Antimicrobial Activity and EfficacyherfuentesNo ratings yet

- Stem Cells10 PDFDocument17 pagesStem Cells10 PDFherfuentesNo ratings yet

- Test Skin PDFDocument368 pagesTest Skin PDFherfuentesNo ratings yet

- 8-Final Guidance To RPMS - RES 021610Document50 pages8-Final Guidance To RPMS - RES 021610aditya_asvaNo ratings yet

- Guidelines Retail Construction RequirementsDocument25 pagesGuidelines Retail Construction RequirementsherfuentesNo ratings yet

- Antimicrobial Products-Test For Antimicrobial Activity and EfficacyDocument14 pagesAntimicrobial Products-Test For Antimicrobial Activity and EfficacyherfuentesNo ratings yet

- Negative Pressure Wound TherapyDocument2 pagesNegative Pressure Wound TherapyherfuentesNo ratings yet

- Actividad EnzimaticDocument11 pagesActividad EnzimaticherfuentesNo ratings yet

- Actividad EnzimaticDocument11 pagesActividad EnzimaticherfuentesNo ratings yet

- Insect Repellents ReportDocument46 pagesInsect Repellents ReportherfuentesNo ratings yet

- zx94092538 05Document14 pageszx94092538 05Chenchen HanNo ratings yet

- Ucm 072450Document35 pagesUcm 072450herfuentesNo ratings yet

- Test Report E-Liquid: 1 Sample InformationDocument10 pagesTest Report E-Liquid: 1 Sample InformationVangel PetrovNo ratings yet

- ThermodynamicsDocument12 pagesThermodynamicsWasif RazzaqNo ratings yet

- Unirub Techno India PVT 7Document7 pagesUnirub Techno India PVT 7BalajiYachawadNo ratings yet

- 1 - Pharmacokinetics IDocument20 pages1 - Pharmacokinetics IabdallaNo ratings yet

- Kennicutt Et Al QSAR Adsorption SQER 2016 PDFDocument25 pagesKennicutt Et Al QSAR Adsorption SQER 2016 PDFAlison RoseNo ratings yet

- Psma411-Prelim ReviewerDocument82 pagesPsma411-Prelim ReviewerRebekah EquizNo ratings yet

- Content of The Dossier For Chemical Purity and Microbiological QualityDocument23 pagesContent of The Dossier For Chemical Purity and Microbiological QualityjdemelloNo ratings yet

- 9 Nomenclature of Inorganic CompoundsDocument42 pages9 Nomenclature of Inorganic CompoundsGlen MangaliNo ratings yet

- Year 8 Science End of Term 1 Test: AnswerDocument11 pagesYear 8 Science End of Term 1 Test: Answerchan myaeNo ratings yet

- Orchid Business Group Djibouti Sarl Site Purchase Request Quantity Request in PCS Store Reference Quantity PurchaseDocument2 pagesOrchid Business Group Djibouti Sarl Site Purchase Request Quantity Request in PCS Store Reference Quantity PurchaseSadik BhaiNo ratings yet

- WokaStar - EN1Document8 pagesWokaStar - EN1Huang yen chengNo ratings yet

- SY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchDocument3 pagesSY 2022-2023 Updated Chem 301 Biochem Lec Synch and AsynchLYKA ANTONETTE ABREGANANo ratings yet

- 33021Document32 pages33021elena7yNo ratings yet

- Molecules: Blumea Balsamifera-A Phytochemical andDocument25 pagesMolecules: Blumea Balsamifera-A Phytochemical andAlyssa Leah Veloso EvangelistaNo ratings yet

- Special Fiber Optic PDFDocument18 pagesSpecial Fiber Optic PDFtarluzNo ratings yet

- Alcohol DistillationDocument4 pagesAlcohol DistillationprocesspipingdesignNo ratings yet

- Ceilcote 2000 Flakeline+ds+engDocument4 pagesCeilcote 2000 Flakeline+ds+englivefreakNo ratings yet

- International Maritime Dangerous Goods CodeDocument8 pagesInternational Maritime Dangerous Goods CodeSachin chaudharyNo ratings yet

- TEV Protease Purification Cell StockDocument3 pagesTEV Protease Purification Cell StockGraciela RosasNo ratings yet

- Matriculation Chemistry (Reaction Kinetics) Part 1Document13 pagesMatriculation Chemistry (Reaction Kinetics) Part 1ridwan100% (2)

- Heating Element ArticleDocument10 pagesHeating Element ArticleFrea Kent-Dazze D'DrughiNo ratings yet

- Chemical Operations Safety AuditDocument4 pagesChemical Operations Safety AuditDinda Naiya AzhariNo ratings yet

- Vogel-Johnson Agar, BaseDocument3 pagesVogel-Johnson Agar, BaseshubhrashrotriaNo ratings yet

- Human Respiratory System Based On Law of ThermodynamicsDocument9 pagesHuman Respiratory System Based On Law of ThermodynamicsfatimahNo ratings yet

- ATCO Gas STOPAQ-Vinylester Procedure Rev0Document45 pagesATCO Gas STOPAQ-Vinylester Procedure Rev0mkash028No ratings yet