Professional Documents

Culture Documents

Recycling Material Supply

Uploaded by

Bhagatsingh Harisingh SonayeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Recycling Material Supply

Uploaded by

Bhagatsingh Harisingh SonayeCopyright:

Available Formats

Zinc Recycling

Material Supply

The world is naturally abundant in zinc, which is an essential element for all living organisms. Its unique metallurgical and chemical properties have also made it the material of choice for an extensive range of applications in modern society. At the end of their useful life, the zinc recovered from these products can be recycled without loss of its metallurgical characteristics or value. Further, while the attributes of zinc contribute significantly to sustainability during use, zinc recycling plays an important role in reducing concentrate demand, energy use, emissions, and minimizing waste disposal.

How much zinc is available?

There is an estimated 1.9 billion tonnes of zinc contained in the earths crust and natural waters (Figure 1). Not all of this zinc, however, is available for use. Economics and environmental considerations dictate whether a particular ore body can or should be developed. Zinc reserves are geologically identified ore bodies whose location, grade, quality, and quantity are deemed suitable for recovery. Since exploration and mine development is an ongoing process, the amount of zinc reserves is not a fixed number and sustainability of zinc ore supplies cannot be judged by simply extrapolating the combined mine life of todays zinc mines. This concept is well supported by data from the United States Geological Survey (USGS), which illustrates that although refined zinc production increased 80% between 1990 and 2010, the reserve lifetime for zinc has remained unchanged (Table 1).

Figure 1. Global estimates of zinc resources, reserves, production, and use, 2010.

(Sources: 1. International Lead Zinc Study Group (ILZSG). 2. In-Use Stocks of Metals. M.D. Gerst and T.E. Graedel. American Chemical Society. 2008. 3. U.S. Geological Survey, Mineral Commodities Summary, 2010.)

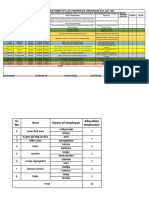

Table 1. Historic estimates of zinc reserve lifetime. Year 1960 1970 1980 1990 2000 2010 Global Production of Refined Zinc (Mt) 3.5 5.6 6.1 7.3 7.6 12.9 Identified Reserves (Mt) 85 117 140 144 190 250 Reserve Lifetime (yrs) 24 21 23 20 25 19

Source: US Geological Survey. Mineral Commodity Summaries - Zinc. http://minerals.usgs.gov/minerals/pubs/commodity/zinc/index. html#mcs (Accessed 18 January 2013). Personal Communication; Amy Tolcin, USGS.

Are reserves the only source of zinc?

While reserves are determined by geology and the interaction of economics, technology, and politics; available zinc resources also include in-use stocks or secondary (recycled) sources of zinc. Due to zincs unique metallurgical properties and long lifetime in product applications, the stock of material currently in use (~280 Mt) is equivalent to that considered as reserves. As zinc-bearing products come to their useful end-of-life (old scrap), they are collected, processed, and recycled into new products. In 2010, nearly 4 Mt of zinc was recovered and returned to use through mature recycling networks.

How are estimates of recycling currently applied?

What is the difference between zinc metal production and use?

Zinc metal production quantifies the amount of refined zinc (zinc which is processed through a smelter or refinery) while use encompasses both refined zinc and that which is available from other sources. To illustrate, there is an estimated 13 Mt of refined zinc metal produced annually. Of this, 12 Mt comes from ores and concentrates (Figure 1) while the remaining million tonne feedstock is supplied from old scrap that requires refinement before reuse. The amount of zinc consumed annually, however, is approximately 16 Mt. This 3 million tonne gap is supplied from secondary or recycled sources that do not require further refinement prior to reuse. This category is made up primarily of alloys (brass and die castings) and zinc sheet, which are simply re-melted. Therefore, refined zinc production is only one source of material available to satisfy overall annual zinc demand.

Many chemicals management policy initiatives, from product efficiency declarations to public procurement legislation, apply estimates of Recycled Content (secondary material in refined metal production) as targets for achieving sustainability and resource efficiency. For example, the U.S. Green Building Council, (the designer of the LEED certification program), prescribes thresholds of recycled content in building materials to satisfy certain certifications. LEED certification is only recognized where >10%-recycled content is achieved for all building materials used in a project. For zinc, as with many other metals, restricting such estimates to refined metal alone introduces significant limitations. Instead, recycled content should include all sources of secondary zinc used for fabrication of new products (i.e. about 25% recycled content; Figure 1). Further, by considering End-of-Life Recycling Rates the amount recycled relative to what was used in original fabrication recycling indicators can be as high as 90% for some products (see Zinc Recycling: Closing the Loop).

How does the zinc industry use material supply data?

The International Zinc Association (IZA) generates and monitors information on the effectiveness of zinc recycling to help communicate and promote the many ways zinc contributes to a sustainable society. The industry is also advancing technologies for recovering zinc from products at end of life. In addition, the IZA is working with regulators, producers, fabricators, architects, and builders to communicate the practical aspects of interpreting production and use data to facilitate objective decision-making.

More detailed information is available on the IZA website at www.zinc.org.

Copyright 2011 International Zinc Association. All Rights Reserved.

International Zinc Association - Avenue de Tervueren 168/Box 4, B-1150, Belgium

Tel: +32 2 776 00 70 Fax: +32 2 776 00 89 Email: contact@zinc.org Web: www.zinc.org

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Recycling and ReuseDocument30 pagesRecycling and ReuseAmirah Sufian100% (2)

- Design of Each Process of ETPDocument9 pagesDesign of Each Process of ETPFaisal Sr. ExecutiveNo ratings yet

- Development of Black Soldier Fly Larvae Production Technique As An Alternate Fish FeedDocument7 pagesDevelopment of Black Soldier Fly Larvae Production Technique As An Alternate Fish FeedFitriasyifa AsriningtyasNo ratings yet

- (Edited) Water Supply Chapter 10Document2 pages(Edited) Water Supply Chapter 10Hannah JovannNo ratings yet

- Oasis Water Friendly Solution - Water Drinking FountainsDocument23 pagesOasis Water Friendly Solution - Water Drinking FountainsPankaj SinhaNo ratings yet

- CTET Question BankDocument347 pagesCTET Question BankDMNo ratings yet

- UPC Format - Fresh Air Calculation SheetDocument54 pagesUPC Format - Fresh Air Calculation SheetEng Islam HiNo ratings yet

- Biogas DigestersDocument4 pagesBiogas DigestersAnoop ChauhanNo ratings yet

- Private Housing Project Land Development Rule'2004Document23 pagesPrivate Housing Project Land Development Rule'2004Sheikh Ahnaf HasanNo ratings yet

- Social media study shows benefits for teensDocument7 pagesSocial media study shows benefits for teensTAKERUOONo ratings yet

- Report 4 Waste DisposalDocument302 pagesReport 4 Waste DisposalYooseob JeongNo ratings yet

- Imdifl12H: Product Data SheetDocument3 pagesImdifl12H: Product Data SheetAsanka Niroshan SamaranayakeNo ratings yet

- Community Wastewater Treatment and DisposalDocument18 pagesCommunity Wastewater Treatment and DisposalJestoni FloresNo ratings yet

- CABP February 09 Single LRDocument52 pagesCABP February 09 Single LRRahul ChandrawarNo ratings yet

- 2 The 20 Keys MethodologyDocument14 pages2 The 20 Keys Methodologymilou88No ratings yet

- Green Modernization Practices For Food Businesses in Bacolor PampangaDocument20 pagesGreen Modernization Practices For Food Businesses in Bacolor PampangaReigne CostasNo ratings yet

- Ces 6.0.6Document2 pagesCes 6.0.6tarasevychmaxNo ratings yet

- Quiz 2 PDFDocument4 pagesQuiz 2 PDFFahmy DiaaNo ratings yet

- Housing and Urban Upgrading in Yantai, ChinaDocument70 pagesHousing and Urban Upgrading in Yantai, ChinaUnited Nations Human Settlements Programme (UN-HABITAT)No ratings yet

- Green Consumer DayDocument14 pagesGreen Consumer Dayashish250195No ratings yet

- Y Grit ClassifierDocument2 pagesY Grit ClassifierYousef AlipourNo ratings yet

- Signup: 1) Aptitude TestDocument145 pagesSignup: 1) Aptitude TestVinod KumarNo ratings yet

- 1 - 2 - 8 - Checklist Template - Electric-Arc-Furnace-Iron-&-Steel - 160204 - ENDocument17 pages1 - 2 - 8 - Checklist Template - Electric-Arc-Furnace-Iron-&-Steel - 160204 - ENmozo dingdongNo ratings yet

- Ehs - Parent DivDocument2 pagesEhs - Parent Divkumar kannanNo ratings yet

- Environmental microbiology study of microorganisms in waterDocument9 pagesEnvironmental microbiology study of microorganisms in waterKiel Lee Dawn BurgeyNo ratings yet

- 740 760 Control 255 and Performa Series Valves 268 268FADocument67 pages740 760 Control 255 and Performa Series Valves 268 268FAelizita_hmNo ratings yet

- Electrical Plan: LegendDocument1 pageElectrical Plan: LegendDaryl Jay YubalNo ratings yet

- Designing of Scrap Minimizer MachineDocument8 pagesDesigning of Scrap Minimizer MachineIJRASETPublicationsNo ratings yet

- Submitted By:-Gourav AgarwalDocument28 pagesSubmitted By:-Gourav Agarwaladjat2014No ratings yet

- Indonesia Law On Water and Waster Water Quality No 82-2001Document10 pagesIndonesia Law On Water and Waster Water Quality No 82-2001Anonymous 6cQRWqNo ratings yet