Professional Documents

Culture Documents

Chapter 17 - NT PWC SDM Substation Layouts and Facilities - Outdoor Section Rev 2 - 17-1-2012

Uploaded by

Punit RatnaniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 17 - NT PWC SDM Substation Layouts and Facilities - Outdoor Section Rev 2 - 17-1-2012

Uploaded by

Punit RatnaniCopyright:

Available Formats

SUBSTATION DESIGN MANUAL CHAPTER 17 Substation Layouts and Facilities - Outdoor Power & Water Corporation Power Networks

Revision: 2 Page 2 of 12

Substation Design Manual Chapter 17 Substation Layouts and Facilities Outdoor

Document Number D2010/287838

Document Control Revision History Title Section Document ID Prepared Reviewed Substation Design Manual Substation Layouts and Facilities Outdoor D2010/287838 Hydro Tasmania Consulting Hydro Tasmania Consulting 09/10/2009 09/10/2009

Revision

Revision Date 09/10/2009 4/12/2009

Details

Authorised Name / Position Signature

Draft Final Draft

For client review and input Revised following client comments Brendon Gannon Specialist Engineer Doc No & Doc Id Inserted SLD Initial & Ultimate Drawing Nos inserted Reference Docs [38] to [41] Doc Nos added 17.2 second last paragraph switchyard added, last paragraph of the 11kV Switchboard added 17.7 changed to aggregate shall be installed 17.8 last paragraph added Revised to suit client comments

Rev 1

2/11/2010

Greg Brand Manager Contracts & Projects

Rev 2

17/01/2012

Luke Whitehouse/ Entura

Changes made to this manual since the last revision are highlighted in yellow.

Disclaimer The information contained in this document has been carefully compiled but Power & Water Corporation takes no responsibility for any loss or liability of any kind suffered by any party, not being the intended recipient of this document, in reliance upon its contents whether arising from any error or inaccuracy in the information or any default, negligence or lack of care in relation to the preparation of the information in this document.

Revision: 2 Page 3 of 12

Substation Design Manual Chapter 17 Substation Layouts and Facilities Outdoor

Document Number D2010/287838

Reference documents Documents listed below are relevant to this chapter of the Power & Water Corporation (PWC) Substation Design Manual. Each reference shall be followed by its list number E.g.: [1]. Any listed reference which has a later edition will take precedence unless indicated otherwise.

[1] [2]

AS 2067 ESAA ENA EG1 ESAA AS 1940 ESAA (series) IEEE 980 AS 1379 AS 1478.1 AS 3600 AS 3610 AS 3799 AS 3972 AS/NZS 4671 AS 1726 AS/NZS 3725 AS 1597.2

Substations and high voltage installations exceeding 1 kV a.c. National Guidelines for Prevention of Unauthorised Access to Electricity Networks Substation Earthing Guide Substation Earthing Guide The storage and handling of flammable and combustible liquids Guidelines for Oil Containment in the Electrical Supply Industry IEEE Guide for Containment and Control of Oil Spills in Substations Specification and supply of concrete Chemical admixture for concrete, mortar and grout - Admixtures for concrete Concrete structures Formwork for concrete Liquid membrane - forming curing compounds for concrete Portland and blended cements Steel reinforcing materials Geotechnical site investigations Design for installation of buried concrete pipes Precast reinforced concrete box culverts - Large culverts (from 1500 mm span and up to and including 4200 mm span and 4200 mm height) Precast concrete access chambers for sewerage applications Aggregates and rock for engineering purposes (Series) Degrees of protection provided by enclosures for electrical equipment (IP Code) Control of the obtrusive effects of outdoor lighting

[3] [4] [5] [6] [7] [8] [9]

[10] [11] [12] [13] [14] [15] [16] [17]

[18] [19] [20]

AS 4198 AS 2758 AS 1939 AS 4282

[21]

Revision: 2 Page 4 of 12

Substation Design Manual Chapter 17 Substation Layouts and Facilities Outdoor

Document Number D2010/287838

[22] [23] [24]

AS/NZS 3000 IEC 61936-1 AS/NZS 2312 AS/NZS 2373 AS 2650 AS 2870

Electrical Installations - Wiring Rules Power Installations exceeding 1 kV a.c. Part 1: Common rules Guide to the protection of structural steel against atmospheric corrosion by the use of protective coatings Electric cables - Twisted pair for control and protection circuits Common specifications for high-voltage switchgear and controlgear standards (IEC 60694) Residential slabs and footings

[25] [26]

[27] [28]

AS/NZS 3008.1.1 Electrical Installations - Selection of cables - Cables for alternating voltages up to and including 0.6/1 kV - Typical Australian installation conditions AS/NZS 3947.3 AS 4100 AS/NZS 61000 AS 62271.200 Low voltage switchgear and controlgear - Switches, disconnectors, switch-disconnectors and fuse-combination units Steel Structures Electromagnetic compatibility (Series) High-voltage switchgear and controlgear - A.C. metal-enclosed switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV (IEC 62271-200, Ed. 1 (2003) MOD) High-voltage switchgear and controlgear - AC insulation-enclosed switchgear and controlgear for rated voltages above 1 kV and up to and including 52 kV High voltage switchgear and controlgear - Dimensional standardization of terminals HV switchgear and controlgear - use and handling of SF6 in HV switchgear and controlgear Lightning protection Chapter 1 - 11 or 22 kV Metal Clad Switchgear Chapter 6 - HV Cables and Conductors Chapter 15 - Earthing Chapter 19 - AC Supply Chapter 25 - Substation Signage Chapter 28 - Security Chapter 30 - 66 kV Gas Insulated Metal Enclosed Switchgear

[29]

[30] [31] [32]

[33]

AS 62271.201

[34]

AS 62271.301 AS 2791 AS/NZS 1768 D2010/287823 D2010/287831 D2010/287859 D2010/287840 D2010/287847 D2010/287851 XXX

[35]

[36] [37] [38] [39] [40] [41] [42] [43]

Revision: 2 Page 5 of 12

Substation Design Manual Chapter 17 Substation Layouts and Facilities Outdoor

Document Number D2010/287838

Table of Contents 17.1 17.2 17.3 17.4 17.5 17.6 17.7 17.8 17.9 17.10 17.11 17.12 Single Line Diagram - Initial Development ................................................................. 6 Single Line Diagram - Ultimate Development ............................................................. 7 Fencing and Gates ................................................................................................... 7 Switchyard Lighting ................................................................................................. 8 Switchyard Civil Works ............................................................................................. 8 Ducts and Trenches ................................................................................................. 9 Transformer Bunding ............................................................................................. 10 Oil Containment .................................................................................................... 10 Fire Walls ............................................................................................................. 11 Transformer Spacing ............................................................................................. 11 Switchyard AC Supply ............................................................................................ 12 Fire Protection ...................................................................................................... 12

Revision: 2 Page 6 of 12

Substation Design Manual Chapter 17 Substation Layouts and Facilities Outdoor

Document Number D2010/287838

17.1

Single Line Diagram - Initial Development

The typical initial development single line diagram of the substation is shown in the drawing B10-12014. The 66 kV plant shall be an outdoor air insulated switchyard arrangement. The initial development shall comprise: Two (2) 66 kV line circuits A single 66 kV busbar with two (2) 66 kV bus section circuit breakers and disconnectors to form three (3) bus sections, Bus A, Bus B and Bus C Two (2) 66/11 or 66/22 kV power transformers, with provision for a third transformer

For further details on 66 kV indoor Gas Insulated Metal Enclosed Switchgear refer to [43]. The 11 or 22 kV plant shall be an indoor metal clad switchboard arrangement. For further details refer to [37].Initial development shall consist of a single busbar with two (2) sections. Each 11 or 22 kV bus section shall have: o o o o One (1) incoming circuit breaker Five (5) outgoing feeder circuit breakers One (1) capacitor banks circuit breaker One (1) auxiliary transformer/outgoing feeder circuit breaker

One (1) bus section circuit breaker on the right hand side of each bus when viewed from the front

A cable connection chamber shall be installed at the left hand end of Bus 1, when viewed from the front, to facilitate future connection of ring bus cables.

As w ell as the above requirem ents there m ay also be a need to supply facilities to connect a Nom ad substation in the event of a transform er and equipm ent failure. R efer to the scope of w orks for further details.

The designer shall consider all aspects of civil and primary construction and installation of the future equipment in the design as described in section 17.2. The initial substation design shall not impede on the ease of the installation of the future equipment.

Revision: 2 Page 7 of 12

Substation Design Manual Chapter 17 Substation Layouts and Facilities Outdoor

Document Number D2010/287838

17.2

Single Line Diagram - Ultimate Development

The typical single line diagram of the ultimate substation is shown in drawings B10-12015 and B10-12016. Provision for installation of a third incoming transmission line and a third 66 kV transformer shall be made as indicated on the SLD. This will enable PWC to increase the capacity of its substation with minimal disruptions to the operation of the existing equipment. The designer shall consider the construction of transformer foundations, bund walls and all the other components of the transformer circuit. The space allowed on site for the future equipment shall be sufficient to install equipment of the same type as the equipment being installed.

Foundations for future sw itchyard equipm ent form ing part of the ultim ate developm ent shall not be installed unless called for in the scope of w orks for the specific project.

Ultimate development of the 11 or 22 kV Switchboard will include the installation of a third bus section (No. 3) and connection of cable from this section to No. 1 section to form a ring bus.

17.3

Fencing and Gates

Due to the high voltages within the PWC substations, any access by unauthorised personnel can result in loss of life or serious injury and damage to plant items. To prevent unauthorised access PWC substations shall have adequate fencing and locked gates. Refer to AS2067 [1] Section 5.2. An emergency door/gate shall be provided adjacent to the main gate for the use in emergency evacuation. This door shall have a quick release button that can only be activated from the inside and shall not allow personal to enter into the site. All security fences and gates shall be designed in accordance with [1] and [2]. To reduce the risk associated with step and touch potentials during a fault, fences and gates shall be earthed to the main earth grid in accordance with [1], [3], and [4]. The type of fence shall be TG/CE anti climb, 4 barbed cyclone fence.

Other security m easures shall be selected in accordance w ith the criteria set out in the scope of w orks for the particular site , also refer to [42] for further details on

substation security.

Revision: 2 Page 8 of 12

Substation Design Manual Chapter 17 Substation Layouts and Facilities Outdoor

Document Number D2010/287838

17.4

Switchyard Lighting

Switchyards and substations shall have sufficient lighting to allow personnel to move around the switchyard and operate equipment safely at night. The designer shall perform lux level calculations to ensure that 20 lux is maintained throughout the switchyard at ground level. Additional lighting shall be provided at places where particular hazard existed such as stairs or step changes in ground level. The outdoor lights shall be of industrial type, and illumination shall cover the entire switchyard area and the property boundary fence. The lighting shall be designed such that the light spill does not disturb neighbouring areas. Substation yard lights shall have High Pressure Sodium bulbs and a minimum of IP56 rating and comply with [20] and [21]. If hinged mast lights are used, the designer shall ensure that the light does not impinge on the clearances around any of the equipment while in motion. The outdoor lighting shall not be on a single circuit. Lighting shall also be on a separate circuit to the outdoor GPOs. Switchyard lighting shall not be mounted on lightning protection masts.

17.5

Switchyard Civil Works

For full description of site civil requirem ents refer to project specific technical docum entation and scope of w ork.

The civil works that shall be undertaken for construction of new substations or switchyards shall cover, but not be limited to: Full geotechnical investigation shall be performed at all new sites in accordance with [15] Permanent datum points shall be installed on the site based on geotechnical investigations The site shall be cleared of any vegetation and other materials Earth works Slopes, crowns and ditches shall be excavated and filled to ensure satisfactory storm water drainage of the site. The installation and design of pipes, culverts and pits shall be in accordance with [16], [17] and [18]. PWC has a preference for a near level site where possible. Where a gradient is required for drainage a fall of 1:50 shall be used.

Revision: 2 Page 9 of 12

Substation Design Manual Chapter 17 Substation Layouts and Facilities Outdoor

Document Number D2010/287838

The site shall be compacted to achieve appropriate soil strength. Consideration shall be given to operation and maintenance equipment that shall be driven onto the site when designing the switchyard civil works. Substation base layer and finishing - installation of loose crushed granite or other form of rock to a nominal depth of 100 mm, using a maximum of 20 mm aggregate size on the switchyard surface to provide acceptable step and touch voltages. The layer shall be designed in accordance with [19]. Refer to [39] for earthing design details. Road works to ensure that access roads and substation roads are suitable for transport of power transformers and crane as the largest onsite equipment and suit the turning radius of low loader for road used to transport transformers Power transformer foundations and bunds - The power transformer foundations and bund walls shall be connected to the oil containment system. Refer to 17.7 and 17.9 Control building and its foundations Cable ducts/trenches - The main cable duct shall be installed from the substation control building to the outdoor yard equipment. Refer to 17.6. Below ground basement cable ducts shall use, as a minimum, water tight rubber membranes to maintain a seal from external water ingress. Additional concrete admixtures to increase the concrete waterproofing may also be applied if the designer considers the benefits advantageous and economical, however, this does not preclude the use of the rubber membrane.

Modular buildings may be used as long as they are designed to a similar standard.

17.6

Ducts and Trenches

A main cable duct shall be installed from the outside of the control room to the switchyard outdoor equipment. Subsidiary cable ducts shall be installed along each bay of equipment. The ducts shall be constructed from inverted precast concrete box culverts with appropriate checker plate covers and be adequate to support all types of cables including control. LV cables shall be supported on the walls of the duct by means of a cable tray assembly. Buried PVC conduit shall connect the concrete duct to individual items of equipment. Ducting shall be designed to allow stormwater to be drained away from the switchroom via gravity. In situations where gravity draining is not possible, such as a basement, a sump and sump pump may be provided. The duct shall have a sufficient width to allow for a person to stand inside the duct as well as room for mounting two sets of cable trays. Refer to drawings XXX for an example of a typical installation. Also refer to [38] for cabling segregation details. Transformer 11 or 22 kV cabling shall also be installed in concrete ducts or conduits, using separate ducts or conduits for each transformer. The duct covers shall have sufficient strength to withstand the load of heavy vehicles when the trench crosses a substation road or accessway.

Revision: 2 Page 10 of 12

Substation Design Manual Chapter 17 Substation Layouts and Facilities Outdoor

Document Number D2010/287838

17.7

Transformer Bunding

The transformer bund shall be designed to suit the power transformer requirements. The bund shall capture any transformer oil spill and prevent migration to adjacent transformers and other site equipment, external from the substation, and the environment. Transformer bunds shall be designed to comply with [5], [6], [7] and the minimum requirements shall be as follows: Bunds shall be proven to be free of leaks by testing and commissioning procedures Oil flow shall be directed towards drainage pits Bund size shall be estimated such that minimum distance between transformer perimeter and the top of the bund boundary must be at least half of the height difference between bound boundary and the highest oil containing element of transformer Bund size shall be 110% of the oil volume for a single transformer The bund shall be of the open drain type and allow ease of inspection and maintenance The bund construction material shall be concrete 75-100 mm aggregate shall only be installed within the bund for outdoor unenclosed transformers. The thickness of the aggregate layer shall be determined by the designer in consultation with PWC. Signage shall be placed adjacent to the bund on two sides of the transformer identifying the surface within the bunded area as unstable. Refer to [41] for more details The Bund walls shall be designed to allow for future provision of fire walls and noise walls

17.8

Oil Containment

Oil containment will be carried out in accordance with [5], [6] and [7]. An oil containment facility shall be available at every site to catch and contain any oil spilt within the substation. The oil containment facility shall be located to enable easy access by a truck to pump out the oil. The oil containment facility shall be sized for 110% oil capacity of one transformer. To minimise the environmental impact and the spread of fire throughout the substation the oil containment system shall consist of: Bunding

Revision: 2 Page 11 of 12

Substation Design Manual Chapter 17 Substation Layouts and Facilities Outdoor

Document Number D2010/287838

Bund drainage system Oil/water separator

An environmental risk/impact assessment shall be undertaken for every new oil/water separator at a zone substation site to assess the risk of off-site impacts arising from discharge of water from the oil/water separator and must be designed to trap oil on site. PWC has a preference for passive oil/water separators. The units shall: be suitable for a 1 in 50 year storm allow a maximum of 30 ppm suspended solids at its outlet allow a maximum of 10 mg/L of oil at its outlet

17.9

Fire Walls

[1] suggests that designers use ENA 18-2008 as a guideline for fire protection of HV substations. This standard establishes that the Building code of Australia (BCA) class 8 requirements can be used as a guide for buildings used for HV installations. Table 6.1 of [1] provides a guide for outdoor transformer segregation. Where a fire hazard exists, HV substation enclosures within or adjacent to buildings must be designed with a minimum FRL 120/120/120 fire rating. Fire barriers providing FRL 120/120/120 are to be used where this minimum cannot be met. Where a transformer fire is part of the risk assessment, then a fire rating greater than 120 minutes needs to be considered. Sufficient space shall be provided around the transformer to the walls of the enclosure or fire wall for the purpose of operation and maintenance access. The structural adequacy, integrity of barrier material and insulative materials must be maintained in the event of a fire for the FRL period. The FRL applies in the same way for the enclosure and any penetrations or opening in the enclosure. Flame traps shall be provided inside the bund of the transformer through the use of a nonflammable pipe within a pit in the bund.

17.10 Transformer Spacing There shall be sufficient spacing between the power transformer bunds to provide safety clearances and service access to equipment in the HV busbar areas, the lines circuits and transformer circuits. Transformers access shall be free from line crossings to allow the transporting and lifting of transformers and buildings without the restrictions presented by overhead lines.

Revision: 2 Page 12 of 12

Substation Design Manual Chapter 17 Substation Layouts and Facilities Outdoor

Document Number D2010/287838

17.11 Switchyard AC Supply A 3 phase 300 A weatherproof junction box shall be installed adjacent to transformers for supplying power to transformer oil filtering equipment. 15 A outlets shall be strategically positioned throughout the yard to provide power for operation and maintenance. Refer to [40] for further details for AC Supply.

17.12 Fire Protection Fire hydrants shall be strategically located around the switchyard and transformer bays. Thermal detectors shall be installed in the transformer area and connected to the substation fire incident panel (FIP).

You might also like

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsFrom EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNo ratings yet

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsFrom EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNo ratings yet

- Design Grounding TransformersDocument9 pagesDesign Grounding TransformerscalecaleNo ratings yet

- Static Compensator Statcom PDFDocument37 pagesStatic Compensator Statcom PDFLeibniz Miranda100% (1)

- HVDC Transmission by Ankur DasDocument24 pagesHVDC Transmission by Ankur DasJuwel J100% (1)

- Modeling of WPP For Short Circuit AnalysisDocument7 pagesModeling of WPP For Short Circuit AnalysisbalajisugunaNo ratings yet

- CBIP-Future AC DC TransmissionDocument74 pagesCBIP-Future AC DC TransmissionkrcdewanewNo ratings yet

- Calculation of Induced Sheath Voltage For Transposed and Untransposed Cable ConductorsDocument6 pagesCalculation of Induced Sheath Voltage For Transposed and Untransposed Cable ConductorsPradeep PooNoorNo ratings yet

- Resistance Grounded Systems: PurposeDocument6 pagesResistance Grounded Systems: Purposerenjithas2005No ratings yet

- Neutral Reactors On Shunt Compensated Ehv LinesDocument8 pagesNeutral Reactors On Shunt Compensated Ehv Linessubbu2051No ratings yet

- Power Evacuation 300 MW - ChettikuruchiDocument8 pagesPower Evacuation 300 MW - ChettikuruchiAbhishek KukrejaNo ratings yet

- An Example of Calculating Transformer Size and Voltage Drop Due To Starting of Large MotorDocument3 pagesAn Example of Calculating Transformer Size and Voltage Drop Due To Starting of Large MotorSujith SukumaranNo ratings yet

- OH2UGDocument17 pagesOH2UGasawinrajaNo ratings yet

- Insulation Coordination Studies for a 132 kV Submarine CableDocument4 pagesInsulation Coordination Studies for a 132 kV Submarine CableJjjjpf100% (1)

- Insulation Coordination Studies For 400 KV Gis in A Hydroelectric Project in IndiaDocument6 pagesInsulation Coordination Studies For 400 KV Gis in A Hydroelectric Project in IndiaAchint KumarNo ratings yet

- Java Power Supply StudyDocument170 pagesJava Power Supply StudyTayachew BerhanNo ratings yet

- Arrestor Energy Calculation PDFDocument6 pagesArrestor Energy Calculation PDFpartha_gang4526No ratings yet

- 1 HVDC Systems in India PDFDocument45 pages1 HVDC Systems in India PDFSrinivas ReddyNo ratings yet

- Short-Circuit Calculation MDocument4 pagesShort-Circuit Calculation MdddscriNo ratings yet

- ATPDraw Simulation of Switching TL500kV-00Document8 pagesATPDraw Simulation of Switching TL500kV-00Ratana KemNo ratings yet

- Short Circuit Current CalculationDocument7 pagesShort Circuit Current CalculationKalyan RanjanNo ratings yet

- Electromagnetic Transient Analysis On 500kV and 230kV Ecuador Transmission ProjectDocument59 pagesElectromagnetic Transient Analysis On 500kV and 230kV Ecuador Transmission ProjectYANDRI PINARGOTE MENENENDEZ100% (2)

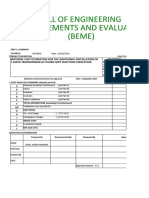

- BILL OF ENGINEERING MEASUREMENTS AND EVALUATIONDocument18 pagesBILL OF ENGINEERING MEASUREMENTS AND EVALUATIONMubarak AleemNo ratings yet

- 001 Grounding PFDocument45 pages001 Grounding PFshawnr7376No ratings yet

- Surge Arrester ModelingDocument3 pagesSurge Arrester ModelingJulián García ZamoraNo ratings yet

- Quick Guide On CDEGS CRDocument28 pagesQuick Guide On CDEGS CRrian0201100% (1)

- Lightning Over Voltage Performance of 132kV GIS Substation in MalaysiaDocument7 pagesLightning Over Voltage Performance of 132kV GIS Substation in MalaysiaboopelectraNo ratings yet

- Back Flashover Phenomenon Analysis in Power Transmission Substation For Insulation CoordinationDocument5 pagesBack Flashover Phenomenon Analysis in Power Transmission Substation For Insulation CoordinationgiovanipifferNo ratings yet

- Technical Standards For Connectivity To The Grid (CEA)Document14 pagesTechnical Standards For Connectivity To The Grid (CEA)Sanjay RoutNo ratings yet

- Insulation Coordination Study of 275kV AIS Substation in Malaysia PDFDocument6 pagesInsulation Coordination Study of 275kV AIS Substation in Malaysia PDFSer 345No ratings yet

- What Is BIL and How Does It Apply To TransformersDocument4 pagesWhat Is BIL and How Does It Apply To TransformersAmitabhaNo ratings yet

- When Surge Arresters FailDocument4 pagesWhen Surge Arresters FailneomindxNo ratings yet

- Lecture Note: Insulation CoordinationDocument8 pagesLecture Note: Insulation CoordinationMehmet Efe OzbekNo ratings yet

- DEBA-EL-CC-3143.B.1 Earthing Transformer Calculation NoteDocument6 pagesDEBA-EL-CC-3143.B.1 Earthing Transformer Calculation Notejie zhangNo ratings yet

- In S Coords Ample CalcDocument36 pagesIn S Coords Ample CalcPankaj ThataiNo ratings yet

- Sag 340Document15 pagesSag 340tanujaayerNo ratings yet

- Fast-Front OvervoltagesDocument49 pagesFast-Front Overvoltagessorry2qazNo ratings yet

- POWERSYS Solutions: POWERSYS Is The Worldwide Commercializer of EMTP-RV Since 2011Document3 pagesPOWERSYS Solutions: POWERSYS Is The Worldwide Commercializer of EMTP-RV Since 2011Joseph MakarNo ratings yet

- HVDC Lecture 2Document18 pagesHVDC Lecture 2MuHammad AbuNaga0% (1)

- As D SW SP 4600 3Document9 pagesAs D SW SP 4600 3Odipiyo Paul100% (2)

- Improved Design and Evaluation of Electrical Earthing Systems For Maryland 13233 KV Transmission StationDocument9 pagesImproved Design and Evaluation of Electrical Earthing Systems For Maryland 13233 KV Transmission StationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Schneider Electric Cahier Technique 151Document24 pagesSchneider Electric Cahier Technique 151Anonymous BwLfvuNo ratings yet

- Electromagnetic Transient Analysis On 500kV and 230kV Ecuador Transmission Project (VER6) - revTE-1Document66 pagesElectromagnetic Transient Analysis On 500kV and 230kV Ecuador Transmission Project (VER6) - revTE-1YANDRI PINARGOTE MENENENDEZ100% (1)

- STATCOMDocument5 pagesSTATCOMVenkateshNo ratings yet

- 400kV SWITCHYARD SHORT CIRCUIT FORCE CALCULATIONDocument11 pages400kV SWITCHYARD SHORT CIRCUIT FORCE CALCULATIONrobinknit2009100% (1)

- 765 KV Gis-1Document6 pages765 KV Gis-1gdkansaraNo ratings yet

- 2240 162 Pve U 004 SHT 3 3 01Document13 pages2240 162 Pve U 004 SHT 3 3 01Anagha DebNo ratings yet

- Distribution System Grounding FundamentalsDocument17 pagesDistribution System Grounding FundamentalsJose Alberto RodriguezNo ratings yet

- EarthingDocument87 pagesEarthingAkhil Gangwar100% (1)

- Energy Audit of A 400-220 KV SubstationDocument8 pagesEnergy Audit of A 400-220 KV Substationabhishekrathi09100% (2)

- Transmission Line Design For 200 MW For 160KmDocument26 pagesTransmission Line Design For 200 MW For 160KmPrince RouniyarNo ratings yet

- Line - Cable-Parameter-Calculation-metric MMDocument59 pagesLine - Cable-Parameter-Calculation-metric MMJoseph PoplingerNo ratings yet

- Trfo Voltage DropDocument74 pagesTrfo Voltage DropshivvaramNo ratings yet

- BSF Earthing System Calculation 1Document29 pagesBSF Earthing System Calculation 1Veerasamy KarikalvalavanNo ratings yet

- New Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringFrom EverandNew Approaches to the Design and Economics of EHV Transmission Plant: International Series of Monographs in Electrical EngineeringNo ratings yet

- Integration of Green and Renewable Energy in Electric Power SystemsFrom EverandIntegration of Green and Renewable Energy in Electric Power SystemsNo ratings yet

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Design and Modelling of Multilevel Power Inverter: Presented byDocument27 pagesDesign and Modelling of Multilevel Power Inverter: Presented byPunit RatnaniNo ratings yet

- Development of Solar PV Charge Controller System For Rural ApplicationDocument5 pagesDevelopment of Solar PV Charge Controller System For Rural ApplicationPunit RatnaniNo ratings yet

- Report On Developmental Impacts of REnergyDocument73 pagesReport On Developmental Impacts of REnergyKumar ArvindNo ratings yet

- Al CuDocument88 pagesAl CuPunit RatnaniNo ratings yet

- Career Objective:: ResumeDocument2 pagesCareer Objective:: ResumePunit RatnaniNo ratings yet

- SpaceVector PWM InverterDocument35 pagesSpaceVector PWM Invertersolomong50% (2)

- (1991) A General Circuit Topology of Multilevel InverterDocument8 pages(1991) A General Circuit Topology of Multilevel InverterPunit RatnaniNo ratings yet

- Elect Paper IIDocument20 pagesElect Paper IIbighnesh_nistNo ratings yet

- Elect Paper II ConvDocument12 pagesElect Paper II ConvFarzul ArafinNo ratings yet

- IES 2011 Electrical Engineering Objective Paper 1Document28 pagesIES 2011 Electrical Engineering Objective Paper 1G Vignesh GvsNo ratings yet

- UPSC: Engineering Services Examination 2013Document7 pagesUPSC: Engineering Services Examination 2013TrcStaffNo ratings yet

- Wind Speed ForecastingDocument7 pagesWind Speed ForecastingPunit RatnaniNo ratings yet

- UNITDocument4 pagesUNITDon ReloNo ratings yet

- © 2017, IRJET - Impact Factor Value: 6.171 - ISO 9001:2008 Certified JournalDocument1 page© 2017, IRJET - Impact Factor Value: 6.171 - ISO 9001:2008 Certified Journalpulkit patelNo ratings yet

- APFC Relays Catalogue 2 1Document12 pagesAPFC Relays Catalogue 2 1Maulik PatelNo ratings yet

- 66kV Substation Technical SpecificationDocument4 pages66kV Substation Technical Specificationunited mixNo ratings yet

- Practical Training Report on Power Plant FamiliarizationDocument67 pagesPractical Training Report on Power Plant FamiliarizationAnaytullah AnsariNo ratings yet

- Efficient Recovery of Braking Energy Through A Reversible DC SubstationDocument9 pagesEfficient Recovery of Braking Energy Through A Reversible DC SubstationnpfhNo ratings yet

- Star Connection (Y Or Wye) Delta Connection (Δ)Document1 pageStar Connection (Y Or Wye) Delta Connection (Δ)Kinley RabgayNo ratings yet

- Circuit Breaker TestingDocument38 pagesCircuit Breaker Testingm khNo ratings yet

- Bester - OM PV Solar Plants PDFDocument14 pagesBester - OM PV Solar Plants PDFsaeedNo ratings yet

- Numerical Relay Protection of Transformer PDFDocument19 pagesNumerical Relay Protection of Transformer PDFShubham Sharma100% (1)

- Moeller Datasheet ESR4-NV3-30Document4 pagesMoeller Datasheet ESR4-NV3-30Anton SemenyuraNo ratings yet

- Ei6002 Power Plant Instrumentation Question Bank PDFDocument11 pagesEi6002 Power Plant Instrumentation Question Bank PDFLokesh Gopinath100% (1)

- Nuclear Energy Institute: NEI Board of DirectorsDocument7 pagesNuclear Energy Institute: NEI Board of DirectorsJustin ElliottNo ratings yet

- Electrical and Electronics Engineering Question Paper 2012Document10 pagesElectrical and Electronics Engineering Question Paper 2012Thakur Sameer ShettyNo ratings yet

- Enatel's microCOMPACT Power SystemDocument2 pagesEnatel's microCOMPACT Power SystemomarpatNo ratings yet

- Stabilizer PSS2B IEEE Dual-Input Stabilizer ModelDocument1 pageStabilizer PSS2B IEEE Dual-Input Stabilizer ModeldhirendracommonNo ratings yet

- University of The East - Manila College of Engineering Department of Electrical EngineeringDocument25 pagesUniversity of The East - Manila College of Engineering Department of Electrical EngineeringKevin LavinaNo ratings yet

- 13 - Directional Element Application and Evaluation - r7Document51 pages13 - Directional Element Application and Evaluation - r7طه محمدNo ratings yet

- Electrical Standard Products GuidelinesDocument28 pagesElectrical Standard Products GuidelinesNageswar MakalaNo ratings yet

- Growatt 17000TL3-S/20000TL3-S/ 25000TL3-S: Leading - Edge TechnologyDocument2 pagesGrowatt 17000TL3-S/20000TL3-S/ 25000TL3-S: Leading - Edge TechnologyjimmyNo ratings yet

- IEC - Switchgear Collection - IHS, Page 2Document4 pagesIEC - Switchgear Collection - IHS, Page 2anjes10% (1)

- Revised Schematic (C) Copyright 1994-2004 PDFDocument1 pageRevised Schematic (C) Copyright 1994-2004 PDFAlex CardenasNo ratings yet

- MediClinic - Meadows - RoofTop - Solar - PV - Project - VC0-Report (Daily Load Profile Updated)Document13 pagesMediClinic - Meadows - RoofTop - Solar - PV - Project - VC0-Report (Daily Load Profile Updated)Bilal JavaidNo ratings yet

- (PDF) Short Questions and Answers EE1251 Electrical Machines II - Mosybk Getto19 - Academia - EduDocument14 pages(PDF) Short Questions and Answers EE1251 Electrical Machines II - Mosybk Getto19 - Academia - EduSolomon MebrahtuNo ratings yet

- Demand Management Schedule From 08 To 09 October 2022Document2 pagesDemand Management Schedule From 08 To 09 October 2022Ada DeranaNo ratings yet

- Industrial Summer Training: Bhel RudrapurDocument17 pagesIndustrial Summer Training: Bhel RudrapurJITENDRA SINGHNo ratings yet

- 4.circle Diagram of Three Phase Induction Motor From No Load & Blocked Rotor TestsDocument4 pages4.circle Diagram of Three Phase Induction Motor From No Load & Blocked Rotor Testsmandadi_sailesh50% (2)

- Hydro power engineering assignment analysisDocument5 pagesHydro power engineering assignment analysisyasir_mushtaq786100% (3)

- (4-2) Synchronous GeneratorDocument35 pages(4-2) Synchronous Generatorfarah haniNo ratings yet

- 3271005648XX309F1001 As On 110619Document19 pages3271005648XX309F1001 As On 110619kaasroNo ratings yet