Professional Documents

Culture Documents

Proposal 2

Uploaded by

viswakshaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Proposal 2

Uploaded by

viswakshaCopyright:

Available Formats

PURPOSE Going green is a new concept as public and individuals begin to switch to a more energy efficient, natural lifestyle

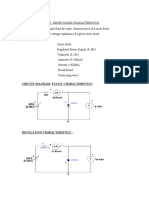

. o achieve the goal of being more energy efficient, we put our eyes on the lighting system of the !!!.. University campus. Replacing ordinary bulbs with more efficient "E# tubes will save a significant amount of energy. $s one of the largest multifunctional buildings on campus, the !!!.. has more than %&',''' gross s(uare feet lit by fluorescent tubes. Our pro)ect aims to reduce the lighting power consumption by replacing the e*isting bulbs with new "E# energy saving bulbs. +omparing with the incandescent light bulbs and +," bulbs, "E# light bulbs have two shining characteristics that ma-e them more suitable. low driven current and low energy consumption. /n other words, "E# bulbs consume much less energy than ordinary bulbs and have 0 times longer lifetime. +onsidering the concept of Going Green, it is high time to promote a new lighting system with "E# technology on campus, which could have remar-able economic and environmental benefits. 1ecause we are targeting a younger generation of energy users, we hope to inspire a new concept incorporated with Going Green. Energy ,itness. Using the ma-eover of /ndia2s largest collegiate recreational facility, Energy ,itness breeds pride is physical and mental health, and we hope this idea of healthiness starts with our lighting #esign 3 "ayout "E#, light4emitting diode is a semiconductor device that emits light completely different from the incumbent fluorescent bulb. $n "E# has several uni(ue characteristics that set it apart from its competition. "ow #+ driven current "ow supply voltage "ow energy consumption o ma-e the installment process as simple as possible, there are )ust two parts in this "E# lighting system.

E*ternal driver

"E# tube

/t is -nown that the common supply voltage is 55' volts $+6 however, an "E# needs a low #+ voltage. hus, a driver for reducing the voltage and changing $+ voltage to #+ voltage is needed. Some "E# tube manufacturers prefer to use an internal driver assembled in the fi*ture. $lthough it ma-es whole system more compact, it would create higher maintenance fees because the entire fi*ture needs to be changed if it brea-s down. herefore, this system prefers to use an e*ternal driver. he ballast is an essential part for a fluorescent tube6 so previous fi*ture already has a space for it. o ma-e the replacement process simple and reduce labor hours, the e*ternal driver is well designed to fit in the same space. #ue to its low driven current, one "E# does not produce as much light compared to the fluorescent tube. he "E# array is needed and is made into a "E# tube. he soc-et and the length of the "E# tube are designed to fit the previous fi*ture, so it is pertinent for the facility management team members to properly install them. Replacing the tube and switching the ballast with the e*ternal driver will allow for optimal efficiency.

You might also like

- DocumentationDocument70 pagesDocumentationviswakshaNo ratings yet

- DocumentationDocument76 pagesDocumentationviswakshaNo ratings yet

- A Novel Voice Verification System Using WaveletsDocument14 pagesA Novel Voice Verification System Using WaveletsviswakshaNo ratings yet

- 11 Performance AnalysisDocument6 pages11 Performance AnalysisviswakshaNo ratings yet

- Building Automated Robots: Sensors, Motors, and ControlDocument34 pagesBuilding Automated Robots: Sensors, Motors, and ControlviswakshaNo ratings yet

- Summary of Accounts Held Under Cust ID: 511365502 As On May 31, 2014Document2 pagesSummary of Accounts Held Under Cust ID: 511365502 As On May 31, 2014viswakshaNo ratings yet

- Frequency Domain Packet Scheduling With MIMO For 3GPP LTE DownlinkDocument10 pagesFrequency Domain Packet Scheduling With MIMO For 3GPP LTE DownlinkviswakshaNo ratings yet

- C Programming: by Deepak Majeti M-Tech CSE Mdeepak@iitk - Ac.inDocument19 pagesC Programming: by Deepak Majeti M-Tech CSE Mdeepak@iitk - Ac.inviswakshaNo ratings yet

- 06 - Reversible Data Embedding Using Reflective BlocksDocument4 pages06 - Reversible Data Embedding Using Reflective BlocksviswakshaNo ratings yet

- Pick and Place RoboDocument44 pagesPick and Place RoboviswakshaNo ratings yet

- Gabor FilterDocument23 pagesGabor Filtervitcon1909No ratings yet

- AodvDocument67 pagesAodvSushain SharmaNo ratings yet

- Analysis of Mobile IP For NS-2: Toni Janevski, Senior Member, IEEE, and Ivan PetrovDocument4 pagesAnalysis of Mobile IP For NS-2: Toni Janevski, Senior Member, IEEE, and Ivan PetrovviswakshaNo ratings yet

- C48 - Efficient Localization in Mobile Wireless Sensor NetworksDocument5 pagesC48 - Efficient Localization in Mobile Wireless Sensor NetworksviswakshaNo ratings yet

- 8 Bit Risc McuDocument6 pages8 Bit Risc McuviswakshaNo ratings yet

- Rep07 17Document70 pagesRep07 17viswakshaNo ratings yet

- Chapter 12Document72 pagesChapter 12viswakshaNo ratings yet

- Rectangular Wave GuidesDocument44 pagesRectangular Wave GuidesArshadahcNo ratings yet

- Lecture1 of RtsDocument29 pagesLecture1 of RtsEsha BindraNo ratings yet

- Architecture of FPGAs and CPLDS: A TutorialDocument41 pagesArchitecture of FPGAs and CPLDS: A Tutorialgongster100% (5)

- VerilogDocument61 pagesVeriloganukopoNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- DS LEADER-Volt Catalog USAR ZCL08.264.US .4Document2 pagesDS LEADER-Volt Catalog USAR ZCL08.264.US .4Zouhir kéniNo ratings yet

- JW2SN DC12VDocument5 pagesJW2SN DC12VRvic RaduNo ratings yet

- Kishanganga Hydroelectric PlantDocument3 pagesKishanganga Hydroelectric PlantAbirami BaskaranNo ratings yet

- 637255517710082425Document3 pages637255517710082425Chris PresleyNo ratings yet

- BeeDocument201 pagesBeegopaltry100% (2)

- L & T Catalogue 8Document3 pagesL & T Catalogue 8amulya00428No ratings yet

- Simulation of Phase Controlled Rectifiers UsingDocument10 pagesSimulation of Phase Controlled Rectifiers UsinggubiliNo ratings yet

- DC Generators Unit 1Document96 pagesDC Generators Unit 1a s prakash rao100% (1)

- Catalog Appleton N2led Series Emergency Luminaires en Us 185148Document7 pagesCatalog Appleton N2led Series Emergency Luminaires en Us 185148Devin Yhojan Viafara MancillaNo ratings yet

- FTC Catalogue - 2022Document71 pagesFTC Catalogue - 2022claudioNo ratings yet

- Easylogic Power Metering: CatalogueDocument11 pagesEasylogic Power Metering: Cataloguedeva suryaNo ratings yet

- 93 Tercel EwdDocument17 pages93 Tercel EwdSilvana Herrera100% (2)

- AIM: - A) To Observe and Draw The Static Characteristics of A Zener DiodeDocument3 pagesAIM: - A) To Observe and Draw The Static Characteristics of A Zener DiodeAnonymous eWMnRr70qNo ratings yet

- Aegis Multifunction RelayDocument4 pagesAegis Multifunction RelaySuranjana DasNo ratings yet

- 防災インフラセミナー(2014年10月31日)配布資料9Document9 pages防災インフラセミナー(2014年10月31日)配布資料9ADBJRONo ratings yet

- 10, 37, 38. Hot Sale 220 KV Capacitive Voltage Transformer 230 KV - Buy 220 KV Capacitive Voltage Transformer, 220 KV Voltage Transformer, Voltage Transformer 230 KV Product OnDocument11 pages10, 37, 38. Hot Sale 220 KV Capacitive Voltage Transformer 230 KV - Buy 220 KV Capacitive Voltage Transformer, 220 KV Voltage Transformer, Voltage Transformer 230 KV Product OnSaifudin ZuhriNo ratings yet

- Certyfikat NC RFG EN PLDocument4 pagesCertyfikat NC RFG EN PLgrzybolNo ratings yet

- Over Current Relay Calculation and Settings ExplainedDocument3 pagesOver Current Relay Calculation and Settings Explaineddskymaximus100% (1)

- BessDocument39 pagesBessVishram BairwaNo ratings yet

- MRC I/O: 50 Cables For Indoor/outdoor ApplicationsDocument3 pagesMRC I/O: 50 Cables For Indoor/outdoor ApplicationsBokiNo ratings yet

- Manual Miller Big Blue 400 Puesta A TierraDocument2 pagesManual Miller Big Blue 400 Puesta A Tierragerman gualavisiNo ratings yet

- Fast Recovery Rectifier Diodes DatasheetDocument3 pagesFast Recovery Rectifier Diodes DatasheetLeandro GarciaNo ratings yet

- RTD ConverterDocument1 pageRTD Converterbagja wigunaNo ratings yet

- Pre Commissioning Tests ChecklistDocument9 pagesPre Commissioning Tests ChecklistFeroz Hakkim80% (5)

- Three Phase System ExamplesDocument28 pagesThree Phase System ExamplesahdabmkNo ratings yet

- Standardul Ieee 519Document6 pagesStandardul Ieee 519ovitecNo ratings yet

- CS 3 Phase Inverters Commissioning Checklist FINALDocument5 pagesCS 3 Phase Inverters Commissioning Checklist FINALarunghandwalNo ratings yet

- VVBDocument8 pagesVVBMostafa MohmmedNo ratings yet