Professional Documents

Culture Documents

3.01.operating Procedures - Construction Requirements PDF

Uploaded by

carlosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3.01.operating Procedures - Construction Requirements PDF

Uploaded by

carlosCopyright:

Available Formats

SECTION

3.01

PROPANE PIPELINE STANDARDS MANUAL

Page 1 of 2

OPERATING PROCEDURES

CONSTRUCTION REQUIREMENTS

07/15/11

HIS SECTION DESCRIBES MINIMUM CONSTRUCTION REQUIREMENTS for steel pipelines in the Companys Liquid Propane (L.P.) systems.

GENERAL

The requirements in this section apply to new pipeline systems constructed with steel pipe, and for relocating, replacing or otherwise changing existing steel pipe systems. They do not apply to movement of pipeline covered by CFR 49, Part 195.424 (Pipe Movement.).

CONSTRUCTION REQUIREMENTS

Propane pipeline construction must comply with the Companys written specifications or standards, which comply with CFR 49, Part 195.202 (Compliance with specifications or standards.). These requirements include: All propane system piping and components must be visually inspected before installation to ensure there is no damage that could reduce the systems serviceability or strength Supports and braces should not be welded directly to pipeline systems transporting propane A propane pipeline must not have a wrinkle bend. Any field bend(s) should have a smooth contour, free of buckling, cracks or other mechanical damage. Field bends should be made with a bending shoe or bending machine. Pipeline system components must be protected against external corrosion. Buried pipelines or components must have an external protective coating which is inspected just before burying to ensure it is not damaged. Any coating damage must be repaired before backfilling. The coating material should meet the criteria of CFR 49, Part 195.599, see Section 3.03 (Normal Operating & Maintenance Requirements-Pipeline Coatings) for criteria information. Underground propane piping should: Be installed in a manner to minimize any stress Have at least 36 inches of cover Have at least 12 inches clearance from any other underground structure Have (preferred) at least 48 inches of cover in cultivated, agricultural areas where plowing or subsurface ripping is common Have (preferred) at least 48 inches of cover in drainage ditches at roadways and railroads Backfilling must be performed in a manner to protect the pipeline coating Pipelines at railroad and highway crossings must be installed to withstand traffic loads continued

Formatted: Bullets and Numbering

SECTION

3.01

PROPANE PIPELINE STANDARDS MANUAL

Page 2 of 2

OPERATING PROCEDURES

CONSTRUCTION REQUIREMENTS

07/15/11

Valves installed in propane pipelines must be protected from damage or tampering, and installed: Where accessible to authorized employees At the suction and discharge ends of pump stations At locations along the pipeline to minimize damage or pollution from accidental liquid discharge A record must be maintained for the life of the pipeline showing the: Number of welds (including the number nondestructively tested, the number rejected and the disposition of the rejected weld[s]) Amount, location and cover of the pipe size installed Locations of: Foreign pipeline crossings Valves Corrosion test stations In accordance with the Companys Welding Procedures Manual: Welding on a propane pipeline system will be performed by qualified welders using qualified procedures, with test weld quality determined by destructive testing Each weld should be visually inspected, with 10% of each welders daily welds supplemented with non-destructive testing performed by personnel trained in the established procedures. The weld acceptance standards is based on API Standard 1104 (Welding of Pipelines and Related Facilities) Unacceptable welds must be removed or repaired A propane pipeline should not be located within 50 feet of a private dwelling, industrial building or place of public assembly unless it has at least 12 inches of cover in excess of that described in Table 3.01.1:

TABLE 1: PROPANE PIPELINE COVER REQUIREMENTS (FROM CFR 49, Part 195.248) LOCATION NORMAL SOIL INCHES (MILLIMETERS) 36 (914) 36 (914) 30 (762) CONSOLIDATED ROCK INCHES (MILLIMETERS) * 30 (762) 36 (914) 18 (457)

Industrial, commercial, and residential areas Drainage ditches at public roads and railroads Any other area

EXCEPTION: Where an underground structure prevents installing a steel propane line with the minimum cover, the line may be installed with less cover if additional protection, equivalent to the required minimum cover, is provided to withstand anticipated external loads.

*

Rock excavation is any excavation that requires blasting or removal by equivalent means.

You might also like

- Ultrasonic Inspection of Welds: Section 3.02 ("Non-Destructive Testing Requirements")Document5 pagesUltrasonic Inspection of Welds: Section 3.02 ("Non-Destructive Testing Requirements")carlosNo ratings yet

- Welding Procedure ManualDocument7 pagesWelding Procedure ManualcarlosNo ratings yet

- Weld Identification: Welding Procedures ManualDocument2 pagesWeld Identification: Welding Procedures ManualcarlosNo ratings yet

- Radiography Test Inspection Free NDT Sample ProcedureDocument4 pagesRadiography Test Inspection Free NDT Sample ProcedureAjay KumarNo ratings yet

- Arc-Air Gouging (Air - Carbon Arc Gouging) PDFDocument1 pageArc-Air Gouging (Air - Carbon Arc Gouging) PDFcarlosNo ratings yet

- 3.00.OperatingProcedures - Establishing Qualified Welding Procedure SpecificationsPROCESSPIPING PDFDocument6 pages3.00.OperatingProcedures - Establishing Qualified Welding Procedure SpecificationsPROCESSPIPING PDFcarlosNo ratings yet

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDocument26 pagesNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNo ratings yet

- Non-Destructive Testing Requirements: Welding Procedures ManualDocument4 pagesNon-Destructive Testing Requirements: Welding Procedures ManualcarlosNo ratings yet

- Maintaining welding procedure and welder qualification recordsDocument8 pagesMaintaining welding procedure and welder qualification recordscarlosNo ratings yet

- 3.03.OperatingProcedures - Visual Inspection of WeldsPROCESSPIPING PDFDocument13 pages3.03.OperatingProcedures - Visual Inspection of WeldsPROCESSPIPING PDFcarlosNo ratings yet

- B... (GTA) Welding Practices PDFDocument2 pagesB... (GTA) Welding Practices PDFcarlosNo ratings yet

- Detailed Supply Specification For PipesDocument3 pagesDetailed Supply Specification For PipescarlosNo ratings yet

- 3.04.OperatingProcedures - Radiographic Inspection of WeldsPROCESSPIPING PDFDocument8 pages3.04.OperatingProcedures - Radiographic Inspection of WeldsPROCESSPIPING PDFcarlosNo ratings yet

- B... (GTA) Welding Practices PDFDocument2 pagesB... (GTA) Welding Practices PDFcarlosNo ratings yet

- Welding Procedure ManualDocument7 pagesWelding Procedure ManualcarlosNo ratings yet

- B31.3 Process Piping Course - Supplement BECHTDocument55 pagesB31.3 Process Piping Course - Supplement BECHTJonah TravisNo ratings yet

- Guia de Usuario Sitescan d10 y 20 PDFDocument106 pagesGuia de Usuario Sitescan d10 y 20 PDFcarlosNo ratings yet

- Bond Testing Babbitt-Lined Bearings StandardDocument19 pagesBond Testing Babbitt-Lined Bearings StandardShawn BirdNo ratings yet

- ANCI 315-R-94 Manual of Engineering and Placing Drawings Fo PDFDocument58 pagesANCI 315-R-94 Manual of Engineering and Placing Drawings Fo PDFcarlosNo ratings yet

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDocument26 pagesNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNo ratings yet

- 3.11.OperatingProcedures - Weld DiscontinuitiesPROCESSPIPING PDFDocument12 pages3.11.OperatingProcedures - Weld DiscontinuitiesPROCESSPIPING PDFcarlosNo ratings yet

- Maintaining welding procedure and welder qualification recordsDocument8 pagesMaintaining welding procedure and welder qualification recordscarlosNo ratings yet

- Evaluation of Current Methods For Creep Analysis PDFDocument80 pagesEvaluation of Current Methods For Creep Analysis PDFcarlosNo ratings yet

- Handbook of Casting DefectsDocument90 pagesHandbook of Casting DefectsAnshuman Roy90% (10)

- V5N2W CharacterizationDocument8 pagesV5N2W CharacterizationShahZad AhmedNo ratings yet

- WWC Technical Data BookDocument73 pagesWWC Technical Data BookMario BertoneriNo ratings yet

- 05 Integrated Inspection and Failure Analysis of Boilers PDFDocument15 pages05 Integrated Inspection and Failure Analysis of Boilers PDFcarlosNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Mark Anthony CondittDocument14 pagesMark Anthony CondittCBS Austin WebteamNo ratings yet

- MQSeries Setup UAT - Generali China (CSC Use Only)Document17 pagesMQSeries Setup UAT - Generali China (CSC Use Only)rajsundarsNo ratings yet

- NIH Design Requirements Manual (NIH, 2016 Rev 2019)Document1,219 pagesNIH Design Requirements Manual (NIH, 2016 Rev 2019)Mic MostalesNo ratings yet

- FinTech Company India IT Contact - 5Document2 pagesFinTech Company India IT Contact - 5vijay.raval7268No ratings yet

- Pulmon Ficha Técnica PDFDocument2 pagesPulmon Ficha Técnica PDFderlingNo ratings yet

- NRL Autonomous Systems Research Timeline: 1923 - 2012Document12 pagesNRL Autonomous Systems Research Timeline: 1923 - 2012U.S. Naval Research Laboratory0% (1)

- MIS 102 Chapter 1Document2 pagesMIS 102 Chapter 1Boyet Dela CruzNo ratings yet

- Panasonic CS-W7DKR CS-W9DKR CS-W7DKR Series Service Manual Repair GuideDocument92 pagesPanasonic CS-W7DKR CS-W9DKR CS-W7DKR Series Service Manual Repair Guideevangalos100% (1)

- Fingerprints Comparison GuideDocument2 pagesFingerprints Comparison GuideRokr125No ratings yet

- Box PushingDocument4 pagesBox PushingNArendra REddy100% (3)

- 1296 MHZ TransverterDocument8 pages1296 MHZ TransverterNestor Alberto EscalaNo ratings yet

- Injection Molding - Fundamentals and Applications - Kamal Et AlDocument39 pagesInjection Molding - Fundamentals and Applications - Kamal Et AlmohammadNo ratings yet

- AP EAMCET - 2018 Engineering Mock Counselling - AP EAMCET 2017 Last Ranks - SAKSHI Education, Expected Engineering CollegesDocument7 pagesAP EAMCET - 2018 Engineering Mock Counselling - AP EAMCET 2017 Last Ranks - SAKSHI Education, Expected Engineering CollegesAnantha KrishnaNo ratings yet

- 7025-f40 Manual PDFDocument245 pages7025-f40 Manual PDFVivian AspdinNo ratings yet

- ACSLS Admin TasksDocument11 pagesACSLS Admin Tasksjeetmajumdar007No ratings yet

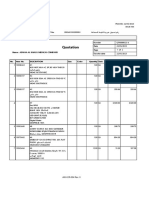

- QuotationDocument2 pagesQuotationMahmoud Sadaka SafiaNo ratings yet

- Unit 3 Slides PSK - QAMDocument87 pagesUnit 3 Slides PSK - QAMSam JonesNo ratings yet

- Training AdvancedDocument2 pagesTraining AdvancedDana BumatayNo ratings yet

- How To Write A Clear Problem StatementDocument4 pagesHow To Write A Clear Problem Statementthyeoh3383No ratings yet

- Manage Information SystemsDocument13 pagesManage Information SystemsNayra DizonNo ratings yet

- List Scs SadcDocument4 pagesList Scs SadcDhananjayan GopinathanNo ratings yet

- Clam Antivirus 0.90: User ManualDocument42 pagesClam Antivirus 0.90: User ManualAlfonsito SadeNo ratings yet

- Oracle SQL PL SQL A Brief IntroductionDocument112 pagesOracle SQL PL SQL A Brief IntroductionSadat Mohammad Akash100% (2)

- Aerofoil Climafan Brochure 50Hz (ENG) For RefDocument58 pagesAerofoil Climafan Brochure 50Hz (ENG) For RefAnonymous BbZceWkVnNo ratings yet

- Documentary StoryboardDocument13 pagesDocumentary StoryboardMegan RutterNo ratings yet

- Invoice Matching V2 PDFDocument15 pagesInvoice Matching V2 PDFRx DentviewNo ratings yet

- Rotor-Gene 6000 ManualDocument143 pagesRotor-Gene 6000 ManualamineNo ratings yet

- ETSI TS 101 052: Rules For The Management of The TETRA Standard Authentication and Key Management Algorithm Set TAA1Document16 pagesETSI TS 101 052: Rules For The Management of The TETRA Standard Authentication and Key Management Algorithm Set TAA1trsghstrhsNo ratings yet

- Hidden Village Apartments For Sale in Atlanta - 235,900 SF, 280 Units, 11% CAP RateDocument7 pagesHidden Village Apartments For Sale in Atlanta - 235,900 SF, 280 Units, 11% CAP RateHenry LaraNo ratings yet

- Floor Response Spectrum Analysis in STAAD.ProDocument7 pagesFloor Response Spectrum Analysis in STAAD.Pro폴로 쥰 차No ratings yet