Professional Documents

Culture Documents

Instruction Manual PLC Line Traps

Uploaded by

shabbireee84@gmail.comCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instruction Manual PLC Line Traps

Uploaded by

shabbireee84@gmail.comCopyright:

Available Formats

INSTRUCTION MANUAL

DLTC PLC Line Traps Installation, Commissioning Maintenance and Operation, Transportation and Storage

HENF 91021

Instruction Manual DLTC

HENF 91021

Revisionstatus: Edition Edition D Prepared 2002-08-12 Doser Checked 2002-08-12 Doser Approved 2002-08-12 Mayer

Authors address: ABB Switzerland Utility Automation Department UTAK CH-5300 Turgi / Switzerland Call Center: E-mail: Internet: ABB +41 844 845 845 utilitycommunication@ch.abb.com www.abb.ch

File name: 91021_020812

Edition D

Language: EN

Page: II

Instruction Manual DLTC

About this Document

This instruction manual applies to the PLC Line Traps Type DLTC.

We reserve all rights to this document, even in the event that a patent is issued and a different commercial proprietary right is registered. Improper use, in particular reproduction and dissemination to third parties, is not permitted. This document has been carefully checked. If the user nevertheless detects any errors, he is asked to notify us as soon as possible. The data contained in this manual is intended solely for the product description and is not to be deemed to be a statement of guaranteed properties. In the interests of our customers, we constantly seek to ensure that our products are developed to the latest technological standards. As a result, it is possible that some differences between the product and the product description or the instruction manual may occur.

Edition D

Language: EN

Page: III

Instruction Manual DLTC

Contents

0

0 1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 2 3 3.1 3.2 3.3 3.4 3.5 4 4.1 4.2 4.3 4.4 5 5.1 5.2 5.3 5.4 5.5 5.6 6 6.1 6.2 7 7.1 7.2 7.3 7.4 7.5 8

CONTENTS

Contents .......................................................................................................................................... 0-1 Introduction ...................................................................................................................................... 1-1 Using the manual............................................................................................................................. 1-1 Application of line trap type DLTC ................................................................................................... 1-1 Requirements to be met by the service personnel .......................................................................... 1-1 Guarantee provisions....................................................................................................................... 1-1 General information about PLC Coupling........................................................................................ 1-1 Purpose of PLC line traps................................................................................................................ 1-2 PLC Coupling principles .................................................................................................................. 1-3 Safety Instruction and Warnings...................................................................................................... 2-1 System description .......................................................................................................................... 3-1 General ............................................................................................................................................ 3-1 Design of PLC line trap.................................................................................................................... 3-1 Main coil........................................................................................................................................... 3-2 Surge arrester.................................................................................................................................. 3-2 Tuning device .................................................................................................................................. 3-2 Transportation and Storage............................................................................................................. 4-1 Transportation ................................................................................................................................. 4-1 Transportation damage ................................................................................................................... 4-1 Unpacking........................................................................................................................................ 4-1 Storage ............................................................................................................................................ 4-1 Installation and mounting instructions ............................................................................................. 5-1 Safety information............................................................................................................................ 5-1 Mounting modes .............................................................................................................................. 5-1 Mounting of optional accessories .................................................................................................... 5-1 Assembly of support insulators, CC or CVT and mounting of line trap ........................................... 5-6 Connections to the line droppers from overhead line and switchyard ............................................. 5-6 General mounting information ......................................................................................................... 5-7 Commissioning ................................................................................................................................ 6-1 Safety information............................................................................................................................ 6-1 Checks during commissioning of equipment................................................................................... 6-1 Maintenance .................................................................................................................................... 7-1 Safety information............................................................................................................................ 7-1 General procedure........................................................................................................................... 7-1 Inspection of HF Characteristic of line trap on site .......................................................................... 7-1 Replacement of tuning device ......................................................................................................... 7-3 Replacement of surge arrester ........................................................................................................ 7-4 Appendix.......................................................................................................................................... 8-5

Edition D

Language: EN

Page: 0-1

Instruction Manual DLTC

HENF 91021

1

1.1

INTRODUCTION

Using the manual

The manual is written for service personnel in the high voltage (HV) power line environment. All existing safety instructions in the client's environment have to be observed and only trained and instructed personnel should work with the equipment. The manual provides the necessary instructions for all the steps in the life-cycle of the equipment, e.g. from transport, storage, commissioning to maintenance. Please refer to the appropriate section for the particular step or function.

1.2

Application of line trap type DLTC

Power Line Carrier (PLC) systems are used for communication on power lines between power system control centres, power stations & sub-stations. The PLC signal has to be coupled to the HVline by means of PLC coupling equipment. The coupling equipment comprises of coupling device, coupling capacitor or capacitive voltage transformer and PLC line trap type DLTC.

1.3

Requirements to be met by the service personnel

Service personnel must read and understand the instruction manual before working with the DLTC equipment. This product may only be installed by individuals who have received training in procedures for installing equipment on high voltage power lines and on PLC coupling equipment. The service personnel must strictly follow all precautions and warnings which could cause personnel injury or damage to the equipment.

1.4

Guarantee provisions

The manufacturer disclaims any responsibility for hazards and material damage, if the equipment is operated other than for its intended use as described in this manual or if the equipment is serviced by non qualified personnel.

1.5

General information about PLC Coupling

Power line carrier (PLC) links supplied by ABB form the backbone of power utility communication systems in all parts of the world. As an economical means of transmitting information and data, PLC has made an important contribution to power system control for many years. PLC is mainly used to reliably transmit speech, energy management data and power system protection signals. In order to meet the varying requirements of power utilities when constructing a new power system or extending an existing one, PLC equipment must be compatible and of modular design.

Edition D

Language: EN

Page: 1-1

Instruction Manual DLTC

HENF 91021

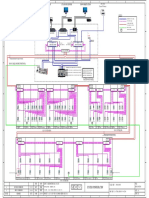

Transport of electrical energy Substation A

Line Trap DLTC

Substation B

HV-line impedance ZI

Line Trap DLTC

CC/CVT

CC/CVT

Coupling Device MCD 80

Coupling Device MCD80

PLCTerminal

PLCTerminal

Transmission of data, speech and protection signal

For injection and extraction of PLC signals on high voltage overhead lines and cables a PLC coupling system is being used at both ends of the PLC transmission path. A complete set of coupling system comprises the PLC line trap, the coupling capacitor (CC) or capacitive voltage transformer (CVT) and the PLC coupling device. Its purpose is to permit the PLC signal to pass, but reject the power system frequency and protect the communications equipment from the power system voltage and transient overvoltages caused by switching operations and atmospheric discharges.

1.6

Purpose of PLC line traps

Provision of defined high-voltage line impedances regardless of configuration of the primary system switchgear. Prevention of signal losses due to propagation into other lines Attenuation of RF signal from other parts of the power systems, thus permitting multiple use of the same frequency bands.

PLC line traps are connected in series with the high-voltage lines and must therefore be rated for the maximum continuous load current and be able to withstand the maximum fault current at the place of installation. DLTC line traps are designed according to the latest IEC recommendations. The main advantages and features of PLC line traps type DLTC are: Low weight and low volume due to multi-layer techniques. Easier to suspend, less wind resistance Open construction for better cooling and excellent RF characteristics with high Q and low stray capacitance No danger of local hot-spots or cracking of insulating material Higher resonant frequencies than those used for PLC transmission Solid construction permits high mechanical loads on terminals. High voltage withstand of tuning units ensures high reliability Transient overvoltage protection by metal oxide arresters with better protection characteristics than arc-gap arresters. Only arresters with a rating of 10kA are used.

Edition D

Language: EN

Page: 1-2

Instruction Manual DLTC

HENF 91021

1.7

1.7.1

PLC Coupling principles

Single-phase coupling (phase-to-ground coupling) This type of coupling is the simpliest type of coupling of PLC signal to the high-voltage line. Since a ground fault close to the substation on the phase used for the PLC link can short-circuit the signal, single-phase coupling should only be used for power systems where transmission reliability in the event of a power system fault is of secondary importance.

1.7.2

Two-phase coupling (phase-to-phase coupling) Coupling to two phases of the power system is much more reliable than coupling to just one phase. A ground fault in this case will normally only cause an additional attenuation of the PLC signal by about 6 dB. A two-phase coupling scheme consists of two coupling units, one of which includes a hybrid module. Schemes are sometimes also used which couplings to all three phases (three-phase coupling) or two phases of one three-phase system and two phases of another three-phase system (intersystem coupling). All of these types of coupling can be handled by moduls of the MCD80 system. Details will be given with project specific documentation. In practice, PLC coupling is a more complex problem since the units at both ends of the HV line have to be optimised for the conditions prevailing there. In the case of long lines with high attenuation, an analysis of the line is necessary to determine the arrangement with the most preferable transmission characteristics. ABB has years of experience in conducting such analyses. Analysis is generally not necessary for short or non-transposed lines. For a horizontal conductor configuration, the centre phase is chosen for single-phase coupling and two adjacent phases for two-phase coupling. In the case of configurations with a vertical distribution, phases as high and as close as possible should be chosen. How many phases are used is largely a question of the reliability requested for the PLC link.

1.7.3

HV line impedance Impedances of HV lines lie typically in the range 350 to 450 per phase for single conductors and 250 to 350 per phase for bundle conductors. In order to terminate the coupling filter correctly for average operating conditions, the shunting effect of the line trap and the station impedance has to be taken into account. The line traps which are inserted to compensate as far as possible the shunt impedance of the substation are designed such that the minimum shunt impedance is 1.41 times the line impedance. Accordingly, the impedance of PLC line traps shall be about 570 for single conductor lines and about 400 for bundle conductor lines. The corresponding impedance for HV cables is much lower and has to be calculated in each individual case. In these cases coupling arrangement and line trap impedance has to be designed individually.

Edition D

Language: EN

Page: 1-3

Instruction Manual DLTC

HENF 91021

SAFETY INSTRUCTION AND WARNINGS

Protect your life while making any modifications!

DANGER

Before handling any part of the electrical circuits: Be sure that the transmission lines are not energized. Apply grounding clamps to high voltage line for earthing. Follow your companys and local safety regulations

DANGER

Do not attempt to handle, install, use or service this product until thoroughly familiar with the informations given in this instruction book.

DANGER

Hazardous voltage can shock, burn or cause death. This product may only be installed by individuals who have received training in procedures for installing equipment on high voltage power lines and on PLC coupling equipment.

Always consider following warnings:

DANGER

A power line can carry dangerous voltages even when switched off.

Edition D

Language: EN

Page: 2-1

Instruction Manual DLTC

HENF 91021

3

3.1

SYSTEM DESCRIPTION

General

The PLC line trap is in general formed by the main coil, a surge arrester and a tuning device

3.2

Design of PLC line trap

Edition D

Language: EN

Page: 3-1

Instruction Manual DLTC

HENF 91021

3.3

Main coil

The coil conductor is of square section aluminium and the turns are spaced by impregnated fibre glass tape or spacer rods depending on rating. The entire main coil is impregnated with a twocomponent epoxy resin of known good outdoor performance. Depending on the rated current and rated inductance, the main coil is wound with either one or several layers. Especially shaped fibre glass spacers or spacer rods keep the layers of multiple layer line traps apart. The multiple layer winding technique enables compact and robust line traps having a small diameter and low height. The spider supports in the ends of the coils are held together by tie bars of fibre glass reinforced epoxy or spacer rods. To achieve a reliable corrosion-proof connection, the HV terminals are welded directly to the ends of the winding. Generally, vertical flat terminals with 4 or 9 holes are fitted, but round or horizontal flat terminals can be welded to the spiders on request. Because of their low weight, most DLTC coils can be mounted on coupling capacitors or capacitive voltage transformers. They can also be mounted on insulator posts or simply suspended. All coils are equipped with lifting eyes on both sides. Optionally, a pedestal, bird barriers and the corona shield can also be attached to the spiders. The corona protection consists of either corona caps at the edges or corona rings, needed at the higher power system voltages. The tuning unit and the surge arrester are secured inside the main coil. The electrical characteristics of the main coils are indicated on the rating plate which is placed on the top spider.

3.4

Surge arrester

The surge arrester protects the main coil and tuning device against overvoltages. All line traps are equipped with MO-surge arresters based on extremely non-linear metal oxide varistors. The components of the surge arresters are completely sealed in one housing and therefore protected against environmental conditions. The electrical characteristics of the surge arresters are indicated on the rating plate which is placed at the top of the unit. The surge arrester is fixed with screws at the upper spider.

3.5

Tuning device

The tuning device is connected in parallel with the main coil and the surge arrester. It provides a defined impedance or blocking resistance in the frequency band. The tuned circuit is usually of the dual-circuit broadband type. This solution has proved to produce the best results in the majority of cases. Alternatively, the line trap can be tuned as a damped single frequency filter. The main characteristic of this type of tuning is its excellent withstand to transient overvoltages. The tuning device may consist of up to 3 packs all of which are electrically connected in parallel. The components of the tuning device are completely sealed in one or more housings and therefore protected from environmental conditions. Only the resistors are partly placed outside the housing and surrounded by air for better cooling. The tuning device is fixed with screws at the upper spider. In certain cases no tuning devices are being used. The electrical characteristics of the tuning devices are indicated on the rating plate which is placed at the top of the unit.

Edition D

Language: EN

Page: 3-2

Instruction Manual DLTC

HENF 91021

4

4.1

TRANSPORTATION AND STORAGE

Transportation

Line traps are fitted with top lifting eyes which shall be used for lifting during transportation. All line traps must be fixed on the load floor of the truck or ship by appropriate tows to prevent any movement or lateral tilting during transportation.

4.2

Transportation damage

The transported goods are to be checked immediately for transport damages. In case of damage please proceed as follows: notify insurance company immediately contact the carrier and declare him liable by indicating the damage on the receipt. substantiate the carriers liability for the damage by sending him a registered letter. contact your contractual partner immediately, especially if transported goods were shipped at the risk of the contractual partner.

4.3

Unpacking

The line trap with fitted surge arrester and tuning device is packed in wooden frame crates or supplied on a wooden pallet with a wooden cover. The line trap is easily removed from the pallet by cutting the plastic tension bands or removing the wooden planks of the crate respectively. The optional pedestals are either mounted on the wooden pallets under the line trap or packed separately. Mounting bolts and occasionally other mounting hardware as well as optionally used corona caps and bird barriers may be attached to the line trap in small bags fixed to the spider arms. During unpacking care should be taken that all packing material, such as wooden braces etc. which may have been attached to the tuning device or protective device are removed. Please consider that wooden braces may be used between the housings of tuning device(s) and arrester.

4.4

Storage

The PLC line traps are shipped in a vertical position. Optionally available support insulators are shipped in a horizontal position. They have to be stored in these positions. DLTC line traps packed in wooden crates or open on palletts are suitable for outdoor storage for reasonable periods of time. The packing serves mainly as protection for mechanical damage.

Edition D

Language: EN

Page: 4-1

Instruction Manual DLTC

HENF 91021

5

5.1

INSTALLATION AND MOUNTING INSTRUCTIONS

Safety information

DANGER

Follow safety instructions according to chapter 2.

5.2

Mounting modes

PLC line traps type DLTC may be suspended or mounted on top of support insulators, coupling capacitors (CC) or capacitive voltage transformers (CVT). Samples of typical arrangement drawings are enclosed. Suspension Mounting All standard line traps type DLTC are fitted with lifting eyes at the top and the bottom. These lifting eyes can be used for suspension mounting. Special versions for suspension from 2, 3 or 4 suspension insulators are available. The maximum force of suspension system of line trap indicated on rating plate of line trap may not be exceeded. Mounting on post insulator, CC or CVT Various different pedestals are available for mounting of the line trap on top of support insulators, coupling capacitors (CC) or capacitive voltage transformers (CVT). If the line trap is mounted on top of CC or CVT, the electrical connection between the bottom terminal of line trap and top of CC/CVT will be carried out by the metallic pedestal itself. The cylindrical pedestal from fiberglass material is fitted with a potential connection between the top terminal and the bottom terminals of this pedestal. In all cases where PLC line trap is mounted on top of CC or CVT line dropper of overhead line must be connected with bottom terminal of the line trap. Line traps type DLTC may only be mounted in the vertical position.

5.3

5.3.1

Mounting of optional accessories

Pedestals Different types of pedestals may be supplied. Pedestals with 2 and 4 legs are being used depending on the type of line trap. Cylindrical pedestals from glassfiber material are being used for mounting of line traps on top of 3 or 4 columns of support insulators or coupling capacitors. The holes in the bottom plate of the pedestal should correspond with the holes of the top flange of the support insulator, CC or CVT. Fixing blocks may be used for mounting of pedestal on the lower spider of line trap in some cases. For mounting of pedestal please refer to project specific drawings or if these are not available to the enclosed standard drawings. Bird barriers Bird barriers can optionally be attached to the PLC line traps Type DLTC. Their function is to prevent birds from penetration into the main coil and build their nests. They have to be mounted on the top and bottom side of the PLC line trap. These bird barriers are placed inside of the line trap in a bag together with optional corona caps and other optional mounting material during transportation.

5.3.2

Edition D

Language: EN

Page: 5-1

Instruction Manual DLTC 5.3.2.1 Mounting of bird barrier on top of PLC line trap

HENF 91021

Take out one bird barrier from the bag, which is placed inside of the PLC line trap. There are two holes cut into the net. One in the centre for the lifting eye and the second for the terminal at the edge close to the knot of the cord. Push the latter over the terminal as given in picture 1. Push the centre hole of the net over the lifting eye as shown in picture 2 Distribute the net constantly among the top of the coil and pull the edges down around the perimeter of the coil as shown in picture 3. Pull the cord and adjust it round the perimeter so that cord is preferably fixed between second and third or third and fourth turn of coil as shown in picture 4. At last, when bird barrier net is adjusted equally round the perimeter, tie the cord and cut the remaining cord as shown in picture 5.

5.3.2.2

Mounting of bird barrier on bottom side of suspended PLC line traps Lift the line trap and proceed with mounting of the bird barrier on the bottom side in the same sequence as described above for the top side of the line trap. The second bird barrier is placed in the same bag as the first.

5.3.2.3

Mounting of bottom side bird barrier and pedestal of PLC line traps The legs of the pedestals can either be directly mounted to the bottom bar of the PLC line trap or by means of fixing blocks, depending on the required pitch circle diameter on the mounting plate. The mounting procedure is slightly different. Bird barrier mounting procedure for pedestals with fixing blocks Take out the second bird barrier from the bag, which is placed inside of the PLC line trap during transportation. Lift the line trap and mount the fixing blocks provisionally at the lower spider arm as shown in picture 6. The contact surfaces between fixing blocks and bottom bar of line trap shall be cleaned carefully (with wire brush or similar) and subsequently treated with acidless grease appropriate for electrical connections. There are two holes cut into the net. One in the centre for the lifting eye and the second for the terminal at the edge close to the knot of the cord. Push this latter one over the terminal as shown in picture 7. Push the centre hole of the net over the lifting eye as given in the section above and distribute the net constantly among the bottom of the coil and push the edges up around the perimeter of the coil, pull the cord and adjust the net provisionally round the perimeter. Cut small holes in the net where the fixing blocks are located as shown in picture 8. The holes should only be as big as the fixing blocks to pass through. Loose the cord and take down the bottom net partly, place the fixing blocks in the correct position, push the net over the fixing blocks and mount the pedestal on the fixing blocks as shown in picture 9 by means of the enclosed mounting material. Clean carefully the contact surface between fixing blocks and legs of pedestal (with wire brush or similar) and treat it with acidless grease appropriate for electrical connections. All screws shall be tightened with the appropriate torque moment. For mounting details please refer to appropriate mounting drawings in Appendix. Distribute the net constantly among the bottom of the coil and push the edges up around the perimeter of the coil, pull the cord and adjust it round the perimeter so that cord is preferably fixed between second and third turn or third and fourth turn of coil as shown in picture 10. At last, when bird barrier is adjusted equally round the perimeter, tie the cord and cut the remaining cord.

Edition D

Language: EN

Page: 5-2

Instruction Manual DLTC

HENF 91021

Bird barrier mounting procedure for pedestals without fixing blocks Take out the second bird barrier from bag, which is placed inside of the PLC line trap. There are two holes cut into the net. One in the centre for the lifting eye and the second for the terminal at the edge close to the knot of the cord. Push the latter one over the terminal as shown in picture 7. Push the centre hole of the net over the lifting eye as given in the section above and distribute the net constantly among the bottom of the coil and push the edges up around the perimeter of the coil, pull the cord and adjust the net provisionally round the perimeter. Take the pedestal and place it below the bottom of the line trap exactly where it should be placed. Cut small holes in the net where the legs of the pedestal should pass through. Loose the cord and take down the bottom net partly, pull the legs of the pedestal through the holes of the net and fix the pedestal at the bottom bar of the line trap by means of the enclosed mounting material. Clean carefully the contact surface between bottom bar of line trap and the legs of pedestal (with wire brush or similar) and treat it with acidless grease appropriate for electrical connections. All screws shall be tightened with the appropriate torque moment. For mounting details please refer to appropriate mounting drawings in Appendix. Distribute the net constantly among the bottom of the coil and push the edges up around the perimeter of the coil, pull the cord and adjust it round the perimeter so that cord is preferably fixed between second and third turn or third and fourth turn of coil as shown in picture 10. At last, when bird barrier is adjusted equally round the perimeter tie the cord and cut the remaining cord.

Set of pictures Picture 1 Picture 2

Picture 3

Picture 4

Edition D

Language: EN

Page: 5-3

Instruction Manual DLTC

HENF 91021

Picture 5

Picture 6

Picture 7

Picture 8

Picture 9

Picture 10

5.3.2.4

Mounting of pedestal for PLC line traps which are not equipped with optional bird barrier The legs of the pedestals can either be directly mounted to the bottom bar of the PLC line trap or by means of fixing blocks, depending on the required pitch circle diameter on the mounting plate. The mounting procedure is slightly different. Mounting procedure for pedestals with fixing blocks Clean carefully the contact surface between bottom bar of line trap, fixing blocks and legs of pedestal (with wire brush or similar) and treat it with acidless grease appropriate for electrical connections. Place the fixing blocks in the correct position and fix provisionally by means of the enclosed mounting material. Mount the legs of the pedestal on the fixing blocks by means of the enclosed mounting material. All screws shall be tightened with the appropriate torque moment. For mounting details please refer to appropriate mounting drawing in Appendix. Mounting procedure for pedestals without fixing blocks Clean carefully the contact surface between bottom bar of line trap and the legs of pedestal (with wire brush or similar) and treat it with acidless grease appropriate for electrical connections. Fix the pedestal at the bottom bar of the line trap by means of the enclosed mounting material. All screws shall be tightened with the appropriate torque moment. For mounting details please refer to appropriate mounting drawing in Appendix.

Edition D

Language: EN

Page: 5-4

Instruction Manual DLTC 5.3.3

HENF 91021

Corona caps For corona shielding purposes corona caps are being used depending on the system voltage range. These caps are fixed at all edges of the upper and lower spider arms with the exception of the terminals. Corona caps or corona rings have to be mounted after mounting of bird barriers. For mounting proceed as follows: Fix the corona caps by means of the mounting hardware as given in specific project drawing or if these are not available as given in enclosed standard drawing. Secure the screw, which is welded into the caps by glue (Loctite or similar). Tighten all screws with the indicated torque moment. See drawings 1KHJ 035459 for mounting illustration. Picture 11 shows a PLC line trap with mounted bird barrier and pedestal and corona caps as reference.

Picture 11

5.3.4

Corona rings For corona shielding purposes in the ultra high voltage range corona rings are being used. These rings are fixed on the upper and lower spider arm. For mounting proceed as follows: Corona rings of different diameters are being used. Each corona ring is electrically connected to the line trap at only one fixing point. Insulating spacers are being used on the other fixing points. The reason for this is to prevent current loops causes by the electro-magnetic field of the PLC line trap. Fix the appropriate corona rings with the mounting hardware as given in project specific drawings or if these are not available in the enclosed standard drawing 1KHJ 035697. Tighten all screws with the indicated torque moment.

Edition D

Language: EN

Page: 5-5

Instruction Manual DLTC

HENF 91021

5.4

Assembly of support insulators, CC or CVT and mounting of line trap

Assembly of CVT / CC For mounting of CC or CVT please refer to the product specific manual. For complete assembly please refer to the specific project drawings. Some standard drawings of typical arrangements are enclosed. Assembly of support insulator. For complete assembly of support insulators please refer to the specific drawing of this equipment. The elements of the support insulators can clearly be identified by the markings on the uppermost sheds. The marking is referred to in the relevant drawings. Nuts and bolts for assembling of all sections of support insulators are enclosed in the packing of the support insulators. The contact surfaces on top and bottom of each support insulator element should be cleaned carefully (with wire brush or similar) and subsequently treated with acidless grease appropriate for electrical connections. Put the column of the bottom section onto the base plate in such a way that the position for the fixing screws are correct. Fix the column to the base plate with corresponding screws. Tighten them only slightly so that the column still may be moved a little bit during the consequential work. Put the column of the next section, if applicable, onto the bottom section in such a way that the position for the fixing screws are correct. Fix this column on the lower column with corresponding bolts, nuts and washers. Tighten them only slightly so that the columns still may be moved a little bit during the consequential work. Proceed with the next sections, if applicable, in the same way as descibed above. In case of three or four columns in parallel please proceed with the other columns in the same way as with the first column. Mounting of line trap The contact surfaces of pedestal and support insulator or CC/CVT should be cleaned carefully (with wire brush or similar) and subsequently treated with acidless grease appropriate for electrical connections. Place the line trap with mounted pedestal in the correct position onto the top flange of the CC, CVT or support insulator respectively. Please observe the correct direction of the terminals of the line trap. In all cases where PLC line trap is mounted on top of CC or CVT line dropper of overhead line shall be connected to bottom terminal of the line trap. Fix the line trap with screws, washers and nuts as given in the project specific drawing or if this is not available according to the enclosed standard drawing. Tighten all screws of support insulator, CC or CVT and line trap with the indicated torque moment.

5.5

Connections to the line droppers from overhead line and switchyard

The line trap is connected to the overhead line and substation equipment by means of aluminium terminals placed at the spiders of the line traps in radial direction. Unless otherwise specified, terminals of line traps of type DLTC having inner diameters of 700mm may not be stressed for pull in excess of 1500N in any direction. Terminals of line traps of type DLTC with inner diameter above 700mm may not be stressed for pull in excess of 3000 in any direction unless otherwise specified.

Edition D

Language: EN

Page: 5-6

Instruction Manual DLTC

HENF 91021

To ensure minimum contact resistance and to avoid corrosion the following practice is recommended: For direct connection only clamps from aluminium are suitable. Clamps from other materials such as copper or bronze etc. shall be connected via approved bi-metal adapters. The contact surfaces must be cleaned carefully (with wire brush or similar) and subsequently treated with acidless grease, approved for electrical connections in HV-substations. Antimagnetic and non-corroding screws and nuts shall be used. Minimum contact resistance can be obtained by using spring washers. All screws shall be tightened with the appropriate torque moment. The line-side terminal of the line trap must electrically be connected to the CC or the CVT. If line trap is mounted on top of CC or CVT, lower terminal of line trap has to be connected with line droppers from overhead line.

5.6

General mounting information

Antimagnetic screws and nuts should be used for connecting clamps to the terminals of line traps. This is for to eliminate the heating effect of eddy currents caused by the electromagnetic field of PLC line traps. No magnetic materials shall be used in a distance of half coil diameter around the PLC line trap. Recommended torque moments for screw connections from stainless steel A2: Screw connection with bolts and nuts of stainless steel type A2 M6 M8 M10 M12 M14 M16 Recommended torque moment 8.8 Nm 21.4 Nm 44 Nm 74 Nm 119 Nm 183 Nm

These values are applicable unless other values are given in the relevant drawings. All bolt and nut connections have to be greased.

Edition D

Language: EN

Page: 5-7

Instruction Manual DLTC

HENF 91021

6

6.1

COMMISSIONING

Safety information

DANGER

Follow safety instructions according to chapter 2.

6.2

Checks during commissioning of equipment

All packing material removed? All material mounted as described in installation instruction and in drawings of equipment of this project? Follow the path of the PLC-signal from overhead line which shall have direct connection to the top of CC/CVT. Make sure that line trap is electrically connected between top of CC or CVT and switchgear of substation. All bolts of tuning device, surge arrester, main coil, pedestal, support insulators, line droppers securely fastened with appropriate torque moment? Make sure that tuning device of required tuning range is connected in cases where PLC line trap is fitted with several tuning devices of different tuning ranges for frequency change. If cylindrical pedestals from glassfiber materials are used: Check inner potential connection of cylindrical pedestal. Measure contact resistance between lower terminal of line trap and uppermost flanges of support insulator or CC columns. Resistance measured shall be below 100m.

Edition D

Language: EN

Page: 6-1

Instruction Manual DLTC

HENF 91021

7

7.1

MAINTENANCE

Safety information

DANGER

Follow safety instructions according to chapter 2.

7.2

General procedure

The line traps do not contain any parts subject to wear and they are therefore considered to be maintenance-free in this respect. However, it is recommended that the following inspections or operations are carried out during normal circuit maintenance intervals: Check whether all bolts of tuning device, surge arrester, main coil, pedestal, support insulators, CC, CVT respectively and line droppers are securely fastened with correct torque moment. In case of heavy pollution by conducting particles cleaning is recommended. Check of painting. If paint touch up is necessary, line trap should be cleaned and exposed parts should be painted with polyurethane laquer. Specifications obtainable from manufacturer.

7.3

Inspection of HF Characteristic of line trap on site

The PLC line trap provides a defined impedance or blocking resistance in the frequency band prescribed for the PLC channel. For tuning purpose a tuning device is connected in parallel with the main coil and the surge arrester. The tuned circuit is usually of the dual-circuit broadband type. The insulation level of the tuning device has been selected with respect to the expected voltage stress. If there are doubts regarding the HF-performance of the the line trap the blocking impedance can be measured. The most common method of carrying out this measurement is the bridge circuit method which is normally only available in the workshop of the line trap manufacturer. The following measuring circuit is therefore recommended for the measurement of blocking impedance on site.

Principle diagram for blocking impedance measurement

overhead line

Main switch Disconnector Line Trap

Disconnector must be in open position

Measuring instruments

Overhead line must be switched off and earthed by auxiliary earth connection

Edition D

Language: EN

Page: 7-1

Instruction Manual DLTC

HENF 91021

Measuring circuit for blocking impedance measurement

To disconnector

Disconnector must be in open position

PLC Line Trap

Line dropper to overhead line

U1

G RH

U2

Overhead line must be switched off and earthed by auxiliary earth connection

This is the only earth point of measuring circuit

G RH

HF-Generator, 24-500kHz, low source impedance, battery powered Resistor, low inductive, about 10 Ohm (value must be low compared with impedance of line trap)

Formula for calculation of Impedance |Z| based on measured voltage levels U1 and U2:

| Z | = ( U1 / U2 - 1 ) * R H

The proposed measuring instruments are common for commissioning of PLC transmission systems. The use of selective voltmeters for measuring of U1 and U2 is recommended. The blocking impedance of the PLC line trap according to IEC 60353 can be measured with this circuit. Please consider that the resistive component of blocking impedance can not be measured with this circuit. When comparing the measured impedance curve with the impedance curve supplied with the new equipment by the manufacturer some deviations are normal due to a measuring error from stray capacitance of the long leads to the terminals of the line trap on site. Nevertheless a decision whether tuning device has been damaged or not can be derived clearly from impedance measurement as impedance characteristic of line trap will be completely different if elements of the tuning device have been damaged by transients during operation.

Edition D

Language: EN

Page: 7-2

Instruction Manual DLTC

HENF 91021

7.4

Replacement of tuning device

The rating plate of the tuning device indicates the actual impedance or resistive component of impedance and the specified frequency range as well as the matching type of main coil and surge arrester. In case of new frequency allocations or extensions in the PLC-system changes in the blocking impedance characteristic of line traps may be necessary. New tuning devices with different blocking bands can be manufactured and delivered for each line trap on request. For order of new tuning devices and surge arresters please contact your local ABB sales office and submit following data: Serial number of existing tuning device Type, current rating and inductance of line trap Serial number of main coil. Required blocking impedance Required blocking frequency band Removal: 1. In case line trap is provided with bird barriers, remove the upper bird barrier. Note that corona caps resp. rings must be removed before lifting the upper bird barrier. 2. Loosen the cable connection at the upper terminal of the tuning device. The second nut of the screw connection must be retained with a fork wrench. Some of the tuning devices are already equipped with cables. In this case loosen the cables of the tuning device at the respective terminals. 3. Loosen the two fixing screws of the tuning device in the upper clamping bar and take the tuning device out of the main coil as far as permitted by the cable connected to the lower terminal of tuning device. 4. Loosen the cable connection at the lower terminal of the tuning device. The second nut of the screw connection must be retained with a fork wrench. This is no longer necessary with tuning devices already equipped with cables. 5. Remove the tuning device completely. Installation: 1. Check rating plate whether characteristics of the new tuning device are correct and insulation level is appropriate. 2. Fasten the cable connection at the lower terminal of the tuning device with nut and washers of same type. The second nut of the screw connection must be retained with a fork wrench. If tuning device is already equipped with cables, cut these cables to the same length as cables of replaced tuning device and crimp the appropriate cable terminals at the ends. 3. Place the tuning device inside the main coil and fix it by means of the two screw connections on the upper clamping bar. Please make sure that the Al-side of the bimetallic washers is on the clamping bar side of the screw connection. Use screw connections of same type as former tuning device has been connected. 4. Fasten the upper cable connection at the upper terminal of the tuning device by means of washers and nuts of the same type. The second nut of the screw connection must be retained with a fork wrench. If tuning device is already equipped with cables, fasten both cable terminals at the same terminals where former tuning device has been fastened. 5. Tighten all screws with the recommended torque moments. 6. Install bird barrier, corona caps or corona rings at upper spider, if applicable.

Edition D

Language: EN

Page: 7-3

Instruction Manual DLTC

HENF 91021

7.5

Replacement of surge arrester

The rating plate of the surge arrester indicates its ratings. Use surge arresters with the appropriate rating only! Removal: 1. In case line trap is provided with bird barriers, remove the upper bird barrier. Note that corona caps resp. rings must be removed before lifting the upper bird barrier. 2. Loosen the cable connections at the upper and lower terminal of the surge arrester. The second nut of the screw connection must be retained with a fork wrench. 3. Loosen the two fixing screws of the surge arrester at the upper clamping bar and take surge arrester out of the main coil. Installation: 1. Check rating plate whether characteristics of the new surge arrester are correct. Never use surge arresters with lower ratings! 2. Place the surge arrester inside the main coil and fix it by means of the two screw connections on the upper clamping bar. Please make sure that the Al-side of the bimetallic washer is on the clamping bar side of the screw connection. Use screw connections of same type as former surge arrester has been connected. 3. Fasten the cable connections at the upper and lower terminal of the surge arrester. The second nut of the screw connection must be retained with a fork wrench. Use screw connections of same type as former surge arrester has been fixed. 4. Tighten all screws with the recommended torque moments. 5. Install bird barrier, corona caps or corona rings at upper clamping bar, if applicable. Please consider that blocking band characteristic may change if gapped arrester is replaced by a metal oxide arrester due to the inherent self capacitance of the metal oxide arrester. It is therfore recommended to replace tuning devices and surge arresters together.

Edition D

Language: EN

Page: 7-4

Instruction Manual DLTC

HENF 91021

APPENDIX

Following drawings form an integral part of this instruction: Drawing HENF 471099 Drawing HENF 471103 Drawing HENF 471104 Drawing HENF 333720 Drawing HENF 333825 Drawing HENF 333611 Drawing HENF 329085 Drawing HENF 325993 Drawing HENF 329000 Drawing 1KHJ 035459 Drawing 1KHJ 035697 Drawing HENF 333810 Drawing HENF 333811 Drawing HENF 333812 Drawing HENF 329006 Drawing HENF 329005 Typical arrangement of line trap on CC/CVT Typical arrangement of line trap on support insulator Typical arrangement of suspended line trap Mounting of pedestal H200-1PCD (without fixing blocks) Mounting of pedestal H200-1PCD (with fixing blocks) Mounting of pedestal H350-1PCD (without fixing blocks) Mounting of pedestal H350-1PCD (with fixing blocks) Mounting of pedestal H500-1PCD Mounting of pedestal H500-3PCD and H500-4PCD Mounting of corona caps Mounting of corona rings Mounting of line trap with pedestal H200-1PCD on 1 support insulator Mounting of line trap with pedestal H350-1PCD on 1 support insulator Mounting of line trap with pedestal H500-1PCD on 1 support insulator Mounting of line trap with pedestal H500-3PCD on 3 support insulators Mounting of line trap with pedestal H500-4PCD on 4 support insulators

Edition D

Language: EN

Page: 8-5

You might also like

- 110V Battery SizingDocument13 pages110V Battery Sizingshabbireee84@gmail.com100% (10)

- 4-RCS-9698GH Gateway Instruction Manual PDFDocument83 pages4-RCS-9698GH Gateway Instruction Manual PDFEduard MachadoNo ratings yet

- Singapore Electricity MarketDocument25 pagesSingapore Electricity MarketTonia GlennNo ratings yet

- Colibri - DEMSU P01 PDFDocument15 pagesColibri - DEMSU P01 PDFRahul Solanki100% (4)

- PCS-9611 - X - Instruction Manual - EN - Overseas General - X - R3.01 PDFDocument316 pagesPCS-9611 - X - Instruction Manual - EN - Overseas General - X - R3.01 PDFjayofo8363No ratings yet

- 29.voltage Flicker Compensation Using STATCOMDocument6 pages29.voltage Flicker Compensation Using STATCOMdeepu227No ratings yet

- BGD 2740 Lot 1.1 Volume 3 2019 01 10Document503 pagesBGD 2740 Lot 1.1 Volume 3 2019 01 10vineets058No ratings yet

- Fire and Life Safety Assessment ReportDocument5 pagesFire and Life Safety Assessment ReportJune CostalesNo ratings yet

- Midterm Exam StatconDocument4 pagesMidterm Exam Statconlhemnaval100% (4)

- Starrett 3812Document18 pagesStarrett 3812cdokepNo ratings yet

- Earthing Conductor SizingDocument3 pagesEarthing Conductor Sizingshabbireee84@gmail.comNo ratings yet

- Cab SizingDocument3 pagesCab Sizingshabbireee84@gmail.comNo ratings yet

- Ne02 Sas ArchitectureDocument5 pagesNe02 Sas ArchitectureApoorva BhushanNo ratings yet

- Power Line Carrier: CommunicationDocument66 pagesPower Line Carrier: Communicationmani_2010nairNo ratings yet

- IRTU and IGW User Manual Eng Rev2 0Document190 pagesIRTU and IGW User Manual Eng Rev2 0Bear DguNo ratings yet

- Pet Care in VietnamFull Market ReportDocument51 pagesPet Care in VietnamFull Market ReportTrâm Bảo100% (1)

- FACTS Technologies SVC PDFDocument9 pagesFACTS Technologies SVC PDFKrishnanNo ratings yet

- OPU-1R - Installation and Commissioning - R3-IDocument135 pagesOPU-1R - Installation and Commissioning - R3-IАндрюха Луценко100% (1)

- Implementing 802.11 with Microcontrollers: Wireless Networking for Embedded Systems DesignersFrom EverandImplementing 802.11 with Microcontrollers: Wireless Networking for Embedded Systems DesignersNo ratings yet

- PCS-924 PCS-9611 - Setting Calculation - EN - GW1200249 - India Mylapor Substation 230kV Inter Connection Line - R1.00 - SUBQ00383520Document11 pagesPCS-924 PCS-9611 - Setting Calculation - EN - GW1200249 - India Mylapor Substation 230kV Inter Connection Line - R1.00 - SUBQ00383520prabhu_natarajan_nNo ratings yet

- RTU560 Remote Terminal Unit RTUtil560 UsDocument134 pagesRTU560 Remote Terminal Unit RTUtil560 UsAjay SinghNo ratings yet

- SIFANG - CSC-2000 (V2) Substation Automation SCADA System Technical and Application Manual (0SF.492.118E) - V1.00Document88 pagesSIFANG - CSC-2000 (V2) Substation Automation SCADA System Technical and Application Manual (0SF.492.118E) - V1.00MarkusKunNo ratings yet

- RCS-9700C BCUs For 61850 X Instruction Manual en Supplement ECKF100442-100445,100450 R1.01Document63 pagesRCS-9700C BCUs For 61850 X Instruction Manual en Supplement ECKF100442-100445,100450 R1.01Benigno Sayaboc TaradelNo ratings yet

- PCS Explorer Auxiliary Software Instruct PDFDocument190 pagesPCS Explorer Auxiliary Software Instruct PDFTram E29No ratings yet

- Test Guide Current Line Diff Nari Pcs-931Document9 pagesTest Guide Current Line Diff Nari Pcs-931JNo ratings yet

- E560 FD Release 9 0 PDFDocument220 pagesE560 FD Release 9 0 PDFHatem LaadhariNo ratings yet

- Data Sheet: Communication Unit 560CMR01Document5 pagesData Sheet: Communication Unit 560CMR01Mohammed MostefaiNo ratings yet

- Synchroteq® Plus: Installation and WiringDocument38 pagesSynchroteq® Plus: Installation and WiringCô Nàng Song TửNo ratings yet

- Bundle Spacer: Engineering DepartmentDocument4 pagesBundle Spacer: Engineering DepartmentpvenkyNo ratings yet

- Instruction Manual: C650 Bay ControllerDocument284 pagesInstruction Manual: C650 Bay Controllernguyen rinNo ratings yet

- Bang Gia Kacon 3Document16 pagesBang Gia Kacon 3Tùng Mai ThanhNo ratings yet

- Mux General Tech Description PDFDocument212 pagesMux General Tech Description PDFChoirul Huda100% (1)

- ADAM 4541 42 Manual PDFDocument4 pagesADAM 4541 42 Manual PDFDaniel RolonNo ratings yet

- Siemens Switchgear Price ListDocument4 pagesSiemens Switchgear Price ListShiva K RaoNo ratings yet

- 08 RTU560 SCADA-Functions MonitorDir EDocument29 pages08 RTU560 SCADA-Functions MonitorDir EngocanhvyNo ratings yet

- PM2100 RegistersDocument6 pagesPM2100 RegistersMowafq AlkhateebNo ratings yet

- t390 Alsom PLCC PDFDocument84 pagest390 Alsom PLCC PDFchandrakant patelNo ratings yet

- RCS-9798AB - Instruction Manual - EN - General - X - R1.02 - (EN - TXZZ0104.0086.0003)Document77 pagesRCS-9798AB - Instruction Manual - EN - General - X - R1.02 - (EN - TXZZ0104.0086.0003)robert mihayoNo ratings yet

- Elcad731 Manual WorkshopDocument140 pagesElcad731 Manual WorkshopFranco LozanidisNo ratings yet

- Ibraheem Gaffar 124002 PDFDocument65 pagesIbraheem Gaffar 124002 PDFSriram ramsNo ratings yet

- EN RTU500 Modules V206Document77 pagesEN RTU500 Modules V206Srinivasan SriniNo ratings yet

- T Installation Guide (6F2S1910) 1.40Document18 pagesT Installation Guide (6F2S1910) 1.40Bear DguNo ratings yet

- 1) 145kV Disconnecting Switch (DS) and Earthing Switch (ES)Document17 pages1) 145kV Disconnecting Switch (DS) and Earthing Switch (ES)Alaa ZoraNo ratings yet

- Etap - Spel InterfaceDocument9 pagesEtap - Spel Interfacemiguelgg78No ratings yet

- Utility Communications: SDH Multiplexer FOX515Document6 pagesUtility Communications: SDH Multiplexer FOX515alex_feryando42No ratings yet

- NARI - PCS-9611 - X - Instruction Manual - EN - Overseas General PDFDocument290 pagesNARI - PCS-9611 - X - Instruction Manual - EN - Overseas General PDFKAREEM OLAWALE0% (1)

- CSC-1321 Gateway User Guide: Downloaded From Manuals Search EngineDocument48 pagesCSC-1321 Gateway User Guide: Downloaded From Manuals Search EngineKislan MislaNo ratings yet

- Installation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Document22 pagesInstallation Manual Multi-Function PROTECTION RELAY GRE110, GRE120, GRE130Cecep Marfu100% (2)

- PI734EDocument8 pagesPI734E3efooNo ratings yet

- Brosur Voksel Hv-70kvDocument2 pagesBrosur Voksel Hv-70kvSyahrul MakkuassangNo ratings yet

- To HMI Upgrade Site System Questions: Abu Dhabi Company For Onshore Oil OperationsDocument8 pagesTo HMI Upgrade Site System Questions: Abu Dhabi Company For Onshore Oil Operationsmdmaqsoodalikhan2020No ratings yet

- Abb MuxDocument4 pagesAbb MuxkadagysNo ratings yet

- PCS 9705Document3 pagesPCS 9705elkhalfi50% (2)

- DigicontDocument13 pagesDigicontingguedezandresNo ratings yet

- Rtu560 Rtu211Document12 pagesRtu560 Rtu211doquocdangNo ratings yet

- 1MRG014136 B en IET600 Integrated Engineering Tool - IntroductionDocument64 pages1MRG014136 B en IET600 Integrated Engineering Tool - Introductionkass_ecs100% (1)

- 1HYB800001-042A-OM Manual (1-Pole) PDFDocument193 pages1HYB800001-042A-OM Manual (1-Pole) PDFFredy MedranoNo ratings yet

- Reg DA RelayDocument16 pagesReg DA Relayprabhakaran_hdecNo ratings yet

- E560 DNP3 Host R13Document60 pagesE560 DNP3 Host R13mkvaisakhNo ratings yet

- SMART Control Bujagali - DCS System Architecture Rev D PDFDocument1 pageSMART Control Bujagali - DCS System Architecture Rev D PDFBlažević JosipNo ratings yet

- 2ABB FOX515 UserGuide&ucst r8 Re 1KHW002059Document210 pages2ABB FOX515 UserGuide&ucst r8 Re 1KHW002059Juan RuizNo ratings yet

- Modicon Compact PLC ManualDocument222 pagesModicon Compact PLC ManualGuntara Wiguna100% (1)

- LbsDocument44 pagesLbsFarhan Shah100% (1)

- 700 A059 0cgDocument42 pages700 A059 0cgale4107No ratings yet

- 06 - 1 - RTU500 - PLC - Engineering - Quick Steps - EDocument9 pages06 - 1 - RTU500 - PLC - Engineering - Quick Steps - EFikret ŞafakNo ratings yet

- Mifii: Digital Feeder Protection With RecloserDocument187 pagesMifii: Digital Feeder Protection With Reclosersehili ammarNo ratings yet

- DRS o & MDocument16 pagesDRS o & Myuy0607No ratings yet

- 1KHW002582-En Instruction Manual ETL600 Rel.4 (March 2013, Annex Updated June 2013)Document480 pages1KHW002582-En Instruction Manual ETL600 Rel.4 (March 2013, Annex Updated June 2013)fayssal salvadorNo ratings yet

- S.No Total A Insulator For Series ReactorDocument1 pageS.No Total A Insulator For Series Reactorshabbireee84@gmail.comNo ratings yet

- Termination Power CableDocument1 pageTermination Power Cableshabbireee84@gmail.comNo ratings yet

- Conductor Shield Wire Insulator HardwareDocument6 pagesConductor Shield Wire Insulator Hardwareshabbireee84@gmail.comNo ratings yet

- Termination Power CableDocument1 pageTermination Power Cableshabbireee84@gmail.comNo ratings yet

- Power ConnectorDocument3 pagesPower Connectorshabbireee84@gmail.comNo ratings yet

- Wall Mounted ACDB, DCDB-R00Document3 pagesWall Mounted ACDB, DCDB-R00shabbireee84@gmail.comNo ratings yet

- Post and Disc InsulatorDocument1 pagePost and Disc Insulatorshabbireee84@gmail.comNo ratings yet

- Earthing BomDocument1 pageEarthing Bomshabbireee84@gmail.comNo ratings yet

- Design of Al - TubeDocument1 pageDesign of Al - Tubeshabbireee84@gmail.comNo ratings yet

- 11kv Breaker (q02) Closingopening LogicDocument1 page11kv Breaker (q02) Closingopening Logicshabbireee84@gmail.comNo ratings yet

- Corona EffectDocument4 pagesCorona EffectArturo MartinezNo ratings yet

- CT SeismicDocument36 pagesCT Seismicshabbireee84@gmail.comNo ratings yet

- RFL 9550 Line TrapDocument12 pagesRFL 9550 Line TrapSINU0607IITEEENo ratings yet

- Corona and Electrical Breakdown Prevention (Us Department of Defense)Document2 pagesCorona and Electrical Breakdown Prevention (Us Department of Defense)THE NIKOLA TESLA INSTITUTENo ratings yet

- Sem 4 - Minor 2Document6 pagesSem 4 - Minor 2Shashank Mani TripathiNo ratings yet

- Sewing Machins Operations ManualDocument243 pagesSewing Machins Operations ManualjemalNo ratings yet

- Marketing Management - Pgpmi - Class 12Document44 pagesMarketing Management - Pgpmi - Class 12Sivapriya KrishnanNo ratings yet

- Surge Arrester: Technical DataDocument5 pagesSurge Arrester: Technical Datamaruf048No ratings yet

- Incoterms 2010 PresentationDocument47 pagesIncoterms 2010 PresentationBiswajit DuttaNo ratings yet

- Effect of Internet Use To Academic PerformaceDocument4 pagesEffect of Internet Use To Academic PerformaceLeonard R. RodrigoNo ratings yet

- Options Trading For Beginners Aug15 v1Document187 pagesOptions Trading For Beginners Aug15 v1Glo BerriNo ratings yet

- Omae2008 57495Document6 pagesOmae2008 57495Vinicius Cantarino CurcinoNo ratings yet

- Usha Unit 1 GuideDocument2 pagesUsha Unit 1 Guideapi-348847924No ratings yet

- Seminar Report of Automatic Street Light: Presented byDocument14 pagesSeminar Report of Automatic Street Light: Presented byTeri Maa Ki100% (2)

- TRX Documentation20130403 PDFDocument49 pagesTRX Documentation20130403 PDFakasameNo ratings yet

- Fcode 54 en El SytucDocument2 pagesFcode 54 en El SytucAga MenonNo ratings yet

- WPGPipingIndex Form 167 PDFDocument201 pagesWPGPipingIndex Form 167 PDFRaj AryanNo ratings yet

- European Steel and Alloy Grades: 16Mncr5 (1.7131)Document3 pagesEuropean Steel and Alloy Grades: 16Mncr5 (1.7131)farshid KarpasandNo ratings yet

- Irrig in AfricaDocument64 pagesIrrig in Africaer viNo ratings yet

- Saic-M-2012 Rev 7 StructureDocument6 pagesSaic-M-2012 Rev 7 StructuremohamedqcNo ratings yet

- Government of India Act 1858Document3 pagesGovernment of India Act 1858AlexitoNo ratings yet

- CoP - 6.0 - Emergency Management RequirementsDocument25 pagesCoP - 6.0 - Emergency Management RequirementsAnonymous y1pIqcNo ratings yet

- Troubleshooting For Rb750Glr4: Poe Does Not WorkDocument7 pagesTroubleshooting For Rb750Glr4: Poe Does Not Workjocimar1000No ratings yet

- Self-Instructional Manual (SIM) For Self-Directed Learning (SDL)Document28 pagesSelf-Instructional Manual (SIM) For Self-Directed Learning (SDL)Monique Dianne Dela VegaNo ratings yet

- INTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Document7 pagesINTERNATIONAL BUSINESS DYNAMIC (Global Operation MGT)Shashank DurgeNo ratings yet

- For Exam ReviewerDocument5 pagesFor Exam ReviewerGelyn Cruz67% (3)

- BS en 118-2013-11Document22 pagesBS en 118-2013-11Abey VettoorNo ratings yet

- The Website Design Partnership FranchiseDocument5 pagesThe Website Design Partnership FranchiseCheryl MountainclearNo ratings yet