Professional Documents

Culture Documents

Test Facilities Iit Madras

Uploaded by

M.Saravana Kumar..M.EOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Facilities Iit Madras

Uploaded by

M.Saravana Kumar..M.ECopyright:

Available Formats

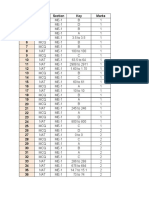

COMPOSITES TECHNOLORY CENTER IIT MADRAS, CHENNAI-600036 TESTING FACULTY INCHARGE : Dr.R.Velmurugan, Professor, Email id : ramanv@iitm.ac.

in Fax : 044-22570545 Tel : 044-22574017,22575915

TEST METHODS AND TESTING CHARGES UNDER COMPOSITES TEST FACILITY TEST OF REINFORCEMENT FIBERS :

SL. NO Names of test ISO Method ASTM Method BS Method

: [ FOR INDUSTRY ]

IS and Others standards DIN53854 53830 10119

No.of Specimens to Be tested

Preparation Charges Per Specimen Nil

Testing Charges Per Specimen 1000*

1.

Specific Gravity of fiber/yarn / rovings

3801 1889

D3317 D1505

2.

Diameter (average)of glass fiber/yarn Linear Density (tex,end,denier) Of Roving/Strands/Yarns Moisture Content of Textile glass/ rovings/filaments/ yarns Mass per unit area of chopped Strand Mat/Woven fabrics Fabrics count (Number of

1888-85

D578-85

50

Nil

1000*

3.

1889-75

D578-89 D861-89

3691-69

11320-85

10

Nil

1000*

4.

3344-77

D2654-89

3691-69 3496-73

11320-85 11551-86

Nil

1000

5.

3374-80

D579-89

3496-73

11551-86

Nil

1000

6.

4603-78

D4029-89

3749-74

DIN53853

Nil

1000

yarns/Unit length) in warp and weft direction of woven fabrics/Woven roving mats * - per test 7. 8. 9. 10. 11. 12.

7211/2/6

D3775-85 D1910

Thickness of Woven Roving Fabrics/Chopped strand Mat Wet out time of Glass fibre Chopped Strand Mat Binder solubility (Time of Dissolution ) of CSM Mat Resin Pick-up CSM Mat (Maximum and minimum) Effect of CSM Mat on Resin Gel Time Thermal Conductivity of Fibre materials Co-efficient of Thermal Expansion of Fibre Materials Tensile Properties of Rovings / Strands / Yarns Tensile Strength / Modulus of High Modulus Single Filament Apparent Tensile Strength of ring by split Disk Methods Breaking Strength of CSM Mat Cross Breaking Strength of Chopped strand mat Laminate Flexural (Cross Breaking ) Strength of composites in the Form of Laminate/Rods Made from Textile Glass Rovings

4603-78 3616-77 3374-80 2558-74 2559 -

D1777-75 D579-89 D579-89 C177-85

3496-73 3496-73 3496-73 3496-73 3496-73 -

11551-86 DIN53855 11551-86 11551-86 -

3 2 3 12 2 -

Nil * * * * X

1000 1000 1000 1000 1000 -

13. 14.

3341-77

D2343-85

3496-73

DIN 53834TI -

X *

1000 5 * 1000

15.

D3379-89

16. 17. 18.

D2290-87 D790-86

3496-63 3496-73 3749-74 3749-74

5 5 5

500 500 500

1000 1000 1000

19.

3597-77

10

500

1000

TESTING FACILITY FOR THERMOSETTING RESINS / RESIN CASTINGS : 20. 21. 22. 23. 24. Specific Gravity of Liquid resin (Density) (Brook Field -RVT Model ) Viscosity of Liquid Resin Viscosity of Liquid resin using Flow-cup Sag flow of high Viscous Resins Total volume shrinkage of polyester and Epoxy Casting Resins Linear shrinkage of Thermosetting plastics at elevated Temp. Shrinkage of moulded and Laminated Thermosetting Plastics at Elevated Temp. Water vapour absorption at 23 C for 7 days Boiling water Absorption 1675-75 2555-74 3214 3521-76 2577 D1475-85 D2393-86 D2730-80 D2566-86 3532Apx 3900-76 3900-76 2782 Part-6 644A DIN51757 6746-72 6746-72 DIN16945 DIN16946 1 1 1 1 * * * X * 1000` 1000 1000 1000 1000

25.

D2566-86

1000

26.

3521

D1299-85

6746-72

1000

27.

R62-80

D1570-81

28.

R117

D1570-81

29.

acid number of unsaturated Polyester Resin Hydroxyl Number of unsaturated polyester resins Epoxy content of the Epoxy resins

2114-74

D1630 D1634 E222-73

30.

2554-74

31.

3001-78

D1652-88

2782 Method 503F/G 2782 method 5013A/C 2782 Method 647B 2782 Method 407A 2782 Method 407A

DIN53472 53475 DIN53471

1000

1000

6746-72DIN

53183 53402 2

1000

1000

6746-72 DIN16945

1000

32.

Gelation time (Peak Exothermic temp. of reacting Thermosetting Resins) Effects of liquid Chemicals (Chemicals Resistance) on solid Plastics Volatile Content (Residual styrene Monomer ) of Unsaturated Polyester Resins Gel and Peak Exotherm Temperature of Reacting Thermosetting Resins Deflection Temp of Plastics under Flexural loads Martin's Heat Deflection Temperature of Cast Resins Coefficient of cubical Thermal Expansion of Plastics Rate of Burning (Flammability) of Flexible Plastics in a Vertical position Plastic Yield Tensile strength of cast Resin Tensile modulus, Elongation @Break of cast Resin / Plastics Compressive Strength / Modulus of Cast Resin /Rigid Plastics Flexural Strength / Modulus of Unreinforced plastics Shear strength and Mechanical Damping (with Torsion Pendulum)

2535-74

D2471-88

2782 Method 111ND 2782 Method 505A 2782 Method 107B-D -

6746-72 DIN16945

1000

33.

175-81

34.

2561-74

C543-67 C581-74 C582-68 -

6746-72 1146-81 6746-72

500

1000

1000

35.

584-82

D2471-88

1000

36.

75-74

D648-88

37. 38. 39.

1210-82

D864 D568-85 D635-88 D638-89

2782 Method 102G/H 2782 Method50 8A 2782 Method 320C 2782 Method 303B 2782 Method 304A 2782 Method 305A

6746-72 DIN53461 DIN53462 53456 6746-72 DIN53459 1146-81 DIN53455

500

1000

X X 500

1000

40. 41.

R527-66

2 5

500 500

1000 1000

42.

604-73

D695-89

DIN53454

500

1000

43.

178-75

D790-86

DIN53452

500

1000

44.

537-80

D73

500

1000

45.

Shear Modulus of cast Resin

537-80

46.

Charpy Impact Resistance of Plastics Izod Impact Resistance of Plastics Tensile Impact Energy to break plastics Indentation Hardness of Rigid Plastics by means of Barcol Impressor GYSJ.9341 Volume resistivity of cast Resin

179-82

D256-88

47.

180-82

D256-88

48.

D1822-84

49.

2039

D2583-87

50.

D257-76

51.

High voltage, Low current, DryArc Resistance of solid Electrical Insulation

D495-84

2782 Method 305A 2782 Method 305B 2782 Method 305A 2782 Method 305C 2782 Method 1001 2782 Method 202A -

500

1000

500

1000

500

1000

500

1000

1000

DIN53482

IEC93

500

1000

TEST FACILITY FOR THERMOPLASTICS :

52.

53.

54.

55.

Measuring the flow properties of thermoplastic moulding materials Flow rates of thermoplastics by Extrusion Plastometer. ( Melt Flow Index) Specific Gravity (Relative Density) and Density of plastics by Displacement Water absorption of plastics at Room temperature for 24hrs/7days/28days

D569-82

1000

R292-67

D1238-88

1000

D792-86

62-80 Method 1

D570-88

2782 Method 509A 2782 Method 502F/G

6746-72

1000

53472 53475

500

1000

56.

57.

Gas permeability Characteristics of Plastic Film and sheet Permeability of Gases

D1434-88

DIN53471

58. 59. 60

Thermal Conductivity of Plastics Coefficient of cubical Thermal Expansion of Plastics Deformation of Plastics under Compression (Parallel Plate Method) Mar Resistance of plastics Compressive Properties of Rigid Plastics Rockwell Hardness of Plastics & Electrical Insulating Materials Bond or Cohesive Strength of Sheet Plastics Bearing Strength of Plastics Recommended Practice for Determining Permanent Effect of heat on Plastics

2582 -

2782 Method 504A -

DIN53471

X X X

61. 62. 63. 64. 65. 66.

604-73 -

D673-88 D695-89 D785-89 D952-84 D953-87 D794-82

5 5 5 -

X 500 X 500 500 X

1000 1000 1000 -

TEST FACILITY FOR COMPOSITE MATERIALS : 67. Specific Gravity (Relative density) & Density of Plastics by Displacement Fibre content of Resin Matrix Composites by Matrix Digestion Void content of Reinforced Plastics Water absorption of Reinforced Plastics 24hrs/7days/28days R1183-70 D792-86 DIN53479 2 * 1000

68.

1172-75

D3171-82

2782 Method 1002-77 -

DIN53395

500

1000

69.

D2734-85

1000

70.

R62-80 Method 1 -

D570-88

2782 Method 502F4 -

DIN53472 53475

500

1000

71.

Volatile Matter (Including Water ) of Vinyl Chloride Resin Outgasing of Composites

D3030-84

1000

72.

73.

Linear Shrinkage of cured Thermosetting Casting Resins during cure Shrinkage of Moulded & Laminated Thermosetting Plastics at elevated temp. Acetone Extraction and Ignition of Glass fibre strands, yarns and rovings for Reinforced plastics

3521-76

D2566-86

1000

74.

D1299-79

75.

D2587-85 D494-79

1000

76.

Loss of Ignition of glass reinforced Plastics

1172-75

D2584-85

2782 Method 1002-77 -

500

1000

77.

Resistance Of Plastics To Chemical Reagent (Effect On Liquid Chemicals Of Plastics) Coefficient of Linear Thermal Expansion of Plastics Heats of fusion and Crystallization of polymers by Thermal Analysis Flammability,Extent & Time of Burning of self supporting Reinforced plastics in a horizontal position Oxygen Index Test Ignition Properties of plastics

175-81

D543-87

IS1146

Per hour

500

1000

78.

D696-88

79.

2582

D3417-88

80.

1210-82

D635-88 D229-77 D757-77 D2863-88 D1929-85

2782 Method 508A -

DIN53454

500

1000

81. 82.

X X

83.

Density of smoke from the burning or Decomposition of plastics Tensile properties of Plastics/Reinforced plastics

D2843-88

84.

3268-78

D638-89 D3039

2782 Method 1003

DIN53455 53451

500

1000

85.

Tensile properties of Glass fibre strands, yarns, Rovings used in Reinforced Plastics Poisson's Ratio

3268-78

D2343-85 D695-89

2782 Method100 3 2782 Method 1003 2782 Method 303B 2782 Method 303B 2782 Method 304B/D -

500

1000

86.

3268-78

D638-89 D3039

DIN53455 53451

500

1000

87.

Compressive Properties of Unidirectional Cross-Ply fibre resin Composites Compressive Properties of Rigid Plastics

D3410-B7

DIN53463 53463

500

1000

88.

604-73

D695-89

DIN53463

500

1000

89.

Flexural properties of Unreinforced /Reinforced Plastics Inplane shear strength of Plastics / Reinforced plastics by Punch Tool In planed Shear Strength Inter laminar (Lab)Shear strength of composites (Short beam method) Inter Laminar Shear strength of composites (Short Beam Method)

178-85

D790-86

DIN5352

500

1000

90.

D3846-58 D732-85 D3914-84 D2344 D2345

500

1000

91.

4585

4994-87 App-B10

500

1000

92.

500

1000

93.

Inplane shear, stress-strain response of unidirectional Reinforced Plastics (Picture Frame Method ) Charpy Impact /Izod impact resistance of Plastics Tensile Impact energy to break plastics Ball impact strength of composites Tensile properties of reinforced plastics at high speeds

D3518-82

2782 Method 306A/E Method 306B

500

1000

94.

180-82 179-75

D256-88 D1822-84

DIN53453

500

1000

95.

96.

D2289-84

2782 Method 1001 -

97.

Indentation hardness of rigid/Reinforced plastics by means of a Barcol Impressor / Durometer Bearing Strength of Plastics Projection penetration into Composites impact resistance by freeing . Dynamic Ball burst (Pendulum) Impact resistance of plastic film Effect of Exposure to Damp Heat, Water spray & Salt Mist

2039

D2583-87 D1706 D2240 D953-87 D1709-85 D3029-84

DIN53505 53456

1000

98. 99.

5 -

500 X

1000 -

100.

D3420-85

101.

4611-87

G23

102.

Weathering of Composites under Xenon-Arc lamp Accelerated - Outdoor weathering of plastics using Natural Sun Light Index of Refraction of Transparent Oraganic Plastics (Can be done at optic lab ) Mar resistance of plastics

D2565-84

103.

D4364-84

53387 53389 To be Mutually Agreed between Clients

104.

R489-83

D542-88

53491

1000

105.

D673-88

106.

Creep & creep rupture of plastics Fatigue Resistance of Composites Bond strength of Joints / Sandwich composites (Peel of Strength ) Dynamic Mechanical Properties of Plastics Dielectric breakdown voltage & Dielectric strength of Insulating Materials A.C. Loss Characteristics & Permittivity of solid Electrical insulation

D2990-82

107.

D671-87

108.

D1781-86 D2918 D2919 D3167 D4065-82

4994-87 AppB11/B12 -

500

1000

109.

110.

D149-81

2782 Method 201A-g 2782 Method 206E

IEC243 DIN53481

111.

D150-87

DIN53483

112.

Comparative Tracking Index of electrical insulating Materials High voltage Low Current, DryArc resistance of solid Electrical Insulation Surface resistance of Composites

D3638-85

11221

IEC243 IS2824 DIN53480 -

500

1000

113.

D495-84

500

1000

114.

Dis continued

2782 Method 203A 2782 Method 203A 2782 Method 204A -

DIN53482 IEC93

115.

Volume Resistivity of Composites

D257-76

IEC93 DIN53482

116.

Insulation Resistance

IEC 167

117.

Method of Exposure to 4607-78 (Outdoor) Natural weathering of 877-76 Plastics

D1435-85

IS 53386 IS 53388 To be Mutually Agreed Between Clients

118.

Damping Factor

D162 D662

TEST FACILITY FOR COMPOSITE PRODUCTS : 119. Longitudinal Tensile properties of Reinforced Thermosetting Resin pipe and tube Axial compressive strength of filament wound tubes / Pipes Determination of External loading characteristics of Plastic pipe by Parallel plate loading Bolt shear test, water absorption, Glass content Testing of Roofing sheets/ panels (Load deflection) Loading test on Panels upto 2m2m plan size D2105-85 X -

120.

121.

D2412-87

122.

--

4154

IS12866-1989

500

1000

123.

4154

IS12866-1989

5000

124.

XX

125.

Hydraulic Test for Battery containers

IS11464

1000

126.

Testing of FRP Doors (Performance) test Materials test for doors Testing of Squating Pan

IS11246 IS4020

10000

127.

IS11286

500

6000

TEST FACILITY FOR GEO GRID : 128 Tensile Strength Of Geogrid D6637-0 5 500 1000

129.

Elongation at break

R527-66

D6637-01

130.

Melting Point

D276

1000

131.

Mass per unit Area

D5261-92

500

1000

TEST FACILITY FOR FIBRE ROVINGS : 132. Roving Tex 11320-97 3 500 1000

133.

Moisture Content

3344-77

D2584-85 D2654-89

2782 Method 1002 2782 Method 1002 -

11320-97

500

1000

134.

Loss on ignition

1172-75

D2584-85

11320-97

500

1000

135.

Glass Content

11320-97

500

1000

136.

Tensile Breaking Load

11320-97

500

1000

137.

Cross Breaking Strength

D2343-85

2782 Method 1003 3496-73

3268-78

500

1000

138.

Tensile Properties

3341-77

D1557-03 D2343-85

11551-86

500

1000

TEST FACILITY FOR STEEL METALS : 139. Tensile Strength Modulus 2062-99 5 500 1000

140. 141.

Yield Strength Bending Strength (Bend at 180 )

2062-99 1599-85

5 5

500 500

1000 1000

MATERIALS CHARACTERISATION FACILITIES : 142. 143. 144. 145. Barb Length Diameter of wire Width of Barb Pitch of Barb F1379-95 F1379-95 F1379-95 F1379-95 3 3 3 3 1000 1000 1000 1000

146.

Tensile Strength

F1379-95

500

1000

MATERIALS CHARACTERISATION FACILITIES :

S.No Name of the Test Equipment No. of specimens to be tested 1 Nil 148. Structural determination of Thermoplastics FT-IR 1 Nil 149. Structural determination of Elastomers FT-IR 1 Nil 150. Structural determination of Ceramics FT-IR Ultrasonic 151. Determination of sample / Coating thickness Nil 152. Identification of interior defects Ultrasonic 1 300 1 1 Nil 500 300 500 500 Preparation charges per Specimen Nil Testing Charges per Specimen 500

147.

Structural determination of Thermoset Resins

FT-IR

153.

Determination of the degree of cure

DMA

500

3000

154.

Estimation of Crystatallinity

DMA

500

3000

155.

Determination of the degree of the compatibility of Copolymers

DMA

500

3000

156.

Determination of glass transition temperature of Thermosets(RT HT )

DSC

500

2000

157.

Determination of glass transition temperature of Thermosets(LT HT )

DSC

500

2000

158.

Determination of Curing Temperature

DSC

500

2000

159.

Determination of heat of reaction in thermosets

DSC

500

2000

160.

Determination of melting temperature

DSC

500

2000

161.

Determination of glass transition temperature of Thermoplastics(RT HT )

DSC

500

2000

162.

Determination of glass transition temperature of Thermoplastics(LT HT )

DSC

500

2000

162.

Determination of heat of reaction in Thermoplastics

DSC

500

2000

164.

Quantitative estimation of decomposition products in thermosets Determination of glass transition temperature of Thermosets Quantitative estimation of decomposition products in thermoplastics

STA

Nil

2000

165.

STA

Nil

2000

166.

STA

Nil

2000

167.

Determination of glass transition temperature of Thermoplastics

STA

1 Nil

2000

168.

Quantitative estimation of decomposition products in Elastomers

STA

Nil

2000

169.

Determination of Oxidation temperature of Metals

STA

Nil

2000

170.

Estimation of phase changes in metals

STA

Nil

2000

171.

Estimation of oxide products

STA

Nil

2000

172.

Determination of phase changes in Ceramics

STA

Nil

2000

173.

Quantitative estimation of decomposition products in Ceramics

STA

Nil

2000

* X

Indicates that the charges shown are for the total test and not for each specimen Indicates Facility not available

You might also like

- Mechanical Properties and Performance of Engineering Ceramics and Composites XIFrom EverandMechanical Properties and Performance of Engineering Ceramics and Composites XIJonathan SalemNo ratings yet

- COMPOSITES TECHNOLOGY CENTER TESTING FACILITIESDocument18 pagesCOMPOSITES TECHNOLOGY CENTER TESTING FACILITIESNikesh ThammishettiNo ratings yet

- Revised Charges:: Aerospace Engineering Department, Composites Testing Facility, Iit Madras, Chennai-36Document10 pagesRevised Charges:: Aerospace Engineering Department, Composites Testing Facility, Iit Madras, Chennai-36Deepak SharmaNo ratings yet

- Aerospace Engineering Department Composites Testing Facility ChargesDocument13 pagesAerospace Engineering Department Composites Testing Facility ChargespaduNo ratings yet

- PET 9130-104 NewestDocument2 pagesPET 9130-104 NewestwlssagitaNo ratings yet

- Section 18 Design of Plastic Gears PDFDocument15 pagesSection 18 Design of Plastic Gears PDFSergio CandiottiNo ratings yet

- C 582 - 95 - Qzu4mi1sruqDocument8 pagesC 582 - 95 - Qzu4mi1sruqGovinda RajNo ratings yet

- C 864 - 99 Qzg2naDocument3 pagesC 864 - 99 Qzg2naRufo CascoNo ratings yet

- D 4000 - 01 - RdqwmdatmdfbrteDocument18 pagesD 4000 - 01 - Rdqwmdatmdfbrtevongoctu2016No ratings yet

- Astm D4000, 2004Document19 pagesAstm D4000, 2004aletapia100% (1)

- Wrekin Woven Fastrack SG RangeDocument2 pagesWrekin Woven Fastrack SG Rangeryleeha07No ratings yet

- Maeol Test CentreDocument5 pagesMaeol Test CentreSHYAM SUNDARNo ratings yet

- SMC Data Sheet for 40774 Gray/Black CompoundDocument1 pageSMC Data Sheet for 40774 Gray/Black CompoundMarioni Antonio HerreraNo ratings yet

- Plastic Products Guide to Nylon 6/6 and Nylon 6/6 GF-30Document3 pagesPlastic Products Guide to Nylon 6/6 and Nylon 6/6 GF-30S.Mohana sundaramNo ratings yet

- 6-Standard List PDFDocument5 pages6-Standard List PDFAndres FacuNo ratings yet

- CT TDS Rev0 15-12-2011Document1 pageCT TDS Rev0 15-12-2011Mydays31No ratings yet

- Graphite Vademecum E-HDocument27 pagesGraphite Vademecum E-Hdroessaert_stijnNo ratings yet

- D 3771 - 00 - Rdm3nzetukveDocument5 pagesD 3771 - 00 - Rdm3nzetukvePrakash MakadiaNo ratings yet

- Evaluating High-Density Rigid Cellular Thermoplastics PlasticsDocument4 pagesEvaluating High-Density Rigid Cellular Thermoplastics PlasticsdanoninoNo ratings yet

- D3350Document7 pagesD3350Luis Fernando Morales100% (1)

- Finished Woven Glass Fabrics: Standard Specification ForDocument14 pagesFinished Woven Glass Fabrics: Standard Specification ForMuhammad HugoNo ratings yet

- Cycom 823 RTM 031912Document6 pagesCycom 823 RTM 031912juanpalomo74No ratings yet

- 3M Cold Shrink Pre-Stretched Tubes Silicone RubberDocument4 pages3M Cold Shrink Pre-Stretched Tubes Silicone RubberJovelino SimãoNo ratings yet

- Van Hy917 H TDDocument8 pagesVan Hy917 H TDAditi RojatkarNo ratings yet

- AS 312 SealentDocument2 pagesAS 312 SealentbhavinNo ratings yet

- RT-Duroid 5880 PropertiesDocument2 pagesRT-Duroid 5880 PropertiesJesus GarciaNo ratings yet

- 5 PDFDocument8 pages5 PDFsrinilsukumarkhdNo ratings yet

- Engineering Materials Data SheetDocument6 pagesEngineering Materials Data Sheetrajarao1234No ratings yet

- SP-Q-1002.NGR-XXXX-006 - Pipe Coating Repair SystemDocument9 pagesSP-Q-1002.NGR-XXXX-006 - Pipe Coating Repair SystemSaravoot MetahNo ratings yet

- 3 Arkonia Plastisol SpecificationDocument1 page3 Arkonia Plastisol SpecificationOnesany TecnologiasNo ratings yet

- TestingDocument41 pagesTestingJorge Gerardo Riascos QuiñonesNo ratings yet

- Engineering Manual: XXX - XXX.XXXDocument12 pagesEngineering Manual: XXX - XXX.XXXsezio81No ratings yet

- Macgrid Asia BiDocument2 pagesMacgrid Asia Bisundra0No ratings yet

- Silicone Rubber Cold Shrink Connector Insulators 8440 SeriesDocument4 pagesSilicone Rubber Cold Shrink Connector Insulators 8440 SerieshendrabudimanNo ratings yet

- RT Duroid 5870 5880 Data SheetDocument2 pagesRT Duroid 5870 5880 Data SheetAnonymous yz5MQGtNo ratings yet

- Low Outgassing Characteristics PDFDocument2 pagesLow Outgassing Characteristics PDFrahul05singhaNo ratings yet

- PVC SpecDocument2 pagesPVC SpecMuhammad Noor FizuanNo ratings yet

- Astm 4101 PDFDocument18 pagesAstm 4101 PDFRafael GomesNo ratings yet

- Element Warren A2LA 0038 01 MechanicalDocument21 pagesElement Warren A2LA 0038 01 MechanicalBau2NineNo ratings yet

- High Frequency Laminates Product Selector Guide and Standard Thicknesses and Tolerances Low ResolutionDocument12 pagesHigh Frequency Laminates Product Selector Guide and Standard Thicknesses and Tolerances Low ResolutionPriyanka ChoudharyNo ratings yet

- Standard Specification For RIGID PVCDocument5 pagesStandard Specification For RIGID PVCvongoctu2016No ratings yet

- Astm D 3159 - 04Document5 pagesAstm D 3159 - 04phaindikaNo ratings yet

- Fabrication of Large GRP Storage TanksDocument60 pagesFabrication of Large GRP Storage TanksjoekaledaNo ratings yet

- D 3903 - 00 - Rdm5mdmtukveDocument5 pagesD 3903 - 00 - Rdm5mdmtukvePrakash MakadiaNo ratings yet

- Dymax GA-142 UV Curable Gasket Data SheetDocument3 pagesDymax GA-142 UV Curable Gasket Data SheetJoshua WallesNo ratings yet

- HDPE Double Side TextureDocument1 pageHDPE Double Side TextureArun Chandra BabuNo ratings yet

- Mobil DTE 10 Excel SeriesDocument3 pagesMobil DTE 10 Excel SeriesSuprastowo Bin SarinoNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetdrhammoudaNo ratings yet

- Iso-Iec 1116-01 2010Document4 pagesIso-Iec 1116-01 2010Rakhsh KhorvashNo ratings yet

- Tricosal KatalogasDocument32 pagesTricosal KatalogaschaubeyskcNo ratings yet

- WSS M99P32 D1Document6 pagesWSS M99P32 D1jose luisNo ratings yet

- 11149Document4 pages11149SINU0607IITEEENo ratings yet

- Ficha Tecnica Ultramid A4HDocument2 pagesFicha Tecnica Ultramid A4HSandip DesaiNo ratings yet

- Scotch KoteDocument4 pagesScotch KoteJavier Gomez ReyesNo ratings yet

- د عواطفDocument5 pagesد عواطفsambha5No ratings yet

- TxDoT 6210 Vertical Mositure Barrier Specs PDFDocument3 pagesTxDoT 6210 Vertical Mositure Barrier Specs PDFthadikkaranNo ratings yet

- Abs (Basf Terluran Gp22)Document1 pageAbs (Basf Terluran Gp22)hakangokceNo ratings yet

- Arc Insulations BrochureDocument5 pagesArc Insulations BrochureacompositesNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- 2 & 3 - Institutional Vision, Mision, PO, PSO, PEODocument4 pages2 & 3 - Institutional Vision, Mision, PO, PSO, PEOM.Saravana Kumar..M.ENo ratings yet

- Effective Engineering Teaching in PracticeDocument4 pagesEffective Engineering Teaching in PracticeM.Saravana Kumar..M.ENo ratings yet

- Design Subject SyallbusDocument8 pagesDesign Subject SyallbusM.Saravana Kumar..M.ENo ratings yet

- Engineering Thermodynamics - Unit 4 - Week 3 - Properties of Pure SubstancesDocument4 pagesEngineering Thermodynamics - Unit 4 - Week 3 - Properties of Pure SubstancesM.Saravana Kumar..M.ENo ratings yet

- NDT Syallbus Anna University ScribdDocument2 pagesNDT Syallbus Anna University ScribdM.Saravana Kumar..M.ENo ratings yet

- WEEK 1 SolutionsDocument5 pagesWEEK 1 SolutionsM.Saravana Kumar..M.ENo ratings yet

- IAT2 Key PDFDocument8 pagesIAT2 Key PDFM.Saravana Kumar..M.ENo ratings yet

- M.saravana Kumar Updated Co StatementDocument5 pagesM.saravana Kumar Updated Co StatementM.Saravana Kumar..M.ENo ratings yet

- Details Dr. V KhalkarDocument1 pageDetails Dr. V KhalkarM.Saravana Kumar..M.ENo ratings yet

- Latha MathavanDocument3 pagesLatha MathavanM.Saravana Kumar..M.ENo ratings yet

- Solution - Assignment - Laws of Thermodynamics - 3rd WeekDocument5 pagesSolution - Assignment - Laws of Thermodynamics - 3rd WeekM.Saravana Kumar..M.ENo ratings yet

- Scholar List MechDocument152 pagesScholar List MechM.Saravana Kumar..M.ENo ratings yet

- Mechanics of Solids - Unit 2 - Week 01 - Introduction To Mechanics of SolidsDocument5 pagesMechanics of Solids - Unit 2 - Week 01 - Introduction To Mechanics of SolidsM.Saravana Kumar..M.ENo ratings yet

- Laws of Thermodynamics - Unit 3 - Week 2 PDFDocument3 pagesLaws of Thermodynamics - Unit 3 - Week 2 PDFM.Saravana Kumar..M.ENo ratings yet

- Engineering Thermodynamics - Unit 6 - Week 5 - First Law of Thermodynamics For Non-Flow ProcessesDocument4 pagesEngineering Thermodynamics - Unit 6 - Week 5 - First Law of Thermodynamics For Non-Flow ProcessesM.Saravana Kumar..M.ENo ratings yet

- Engineering Thermodynamics - Unit 2 - Week 1 - SI Unit, Definitions & ConceptsDocument4 pagesEngineering Thermodynamics - Unit 2 - Week 1 - SI Unit, Definitions & ConceptsM.Saravana Kumar..M.ENo ratings yet

- Strength of Materials - Unit 6 - Week 5Document3 pagesStrength of Materials - Unit 6 - Week 5M.Saravana Kumar..M.ENo ratings yet

- Strength of Materials - Unit 2 - Week 1Document3 pagesStrength of Materials - Unit 2 - Week 1M.Saravana Kumar..M.ENo ratings yet

- Engineering Thermodynamics - Unit 3 - Week 2 - SI Unit, Definitions & ConceptsDocument5 pagesEngineering Thermodynamics - Unit 3 - Week 2 - SI Unit, Definitions & ConceptsM.Saravana Kumar..M.ENo ratings yet

- Strength of Materials - Unit 3 - Week 2Document4 pagesStrength of Materials - Unit 3 - Week 2M.Saravana Kumar..M.ENo ratings yet

- DTS 06Document18 pagesDTS 06M.Saravana Kumar..M.ENo ratings yet

- Laws of Thermodynamics - Unit 3 - Week 2Document3 pagesLaws of Thermodynamics - Unit 3 - Week 2M.Saravana Kumar..M.ENo ratings yet

- Anna University Manufacturing Technology1 Previous Year Question Papers CollectionDocument20 pagesAnna University Manufacturing Technology1 Previous Year Question Papers CollectioneurekaNo ratings yet

- Mechanics of Solids - Unit 5 - Week 4 - Force Displacement Relationship and Introduction To Concept of StressDocument4 pagesMechanics of Solids - Unit 5 - Week 4 - Force Displacement Relationship and Introduction To Concept of StressM.Saravana Kumar..M.ENo ratings yet

- Abrasive Jet MachiningDocument12 pagesAbrasive Jet MachiningM.Saravana Kumar..M.ENo ratings yet

- Gate PlanDocument1 pageGate PlanM.Saravana Kumar..M.ENo ratings yet

- Laws of Thermodynamics - Unit 5 - Week 4Document3 pagesLaws of Thermodynamics - Unit 5 - Week 4M.Saravana Kumar..M.ENo ratings yet

- MT-1 Full NotesDocument56 pagesMT-1 Full NotesM.Saravana Kumar..M.ENo ratings yet

- ME-1 Section MCQ and NAT Type Exam ResultsDocument2 pagesME-1 Section MCQ and NAT Type Exam ResultsM.Saravana Kumar..M.ENo ratings yet

- Syllabi GATE2017 PDFDocument73 pagesSyllabi GATE2017 PDFAnkit Kumar AJNo ratings yet

- Works Series II II 1 Wq139Document14 pagesWorks Series II II 1 Wq139Simona GastoldiNo ratings yet

- Hr-J480eu SMDocument51 pagesHr-J480eu SMGerman FdrNo ratings yet

- BRKRST-2501 (2018) (QoS)Document291 pagesBRKRST-2501 (2018) (QoS)Paul ZetoNo ratings yet

- Tuning For DummiesDocument45 pagesTuning For Dummiesmanuel1971100% (1)

- Everyone Loves You When Youre Dead SupplementDocument44 pagesEveryone Loves You When Youre Dead SupplementMarin JanušNo ratings yet

- Registetered Companies in ZambiaDocument56 pagesRegistetered Companies in ZambiaNick LunguNo ratings yet

- Seirawan & Silman - Winning Chess Strategies PDFDocument3 pagesSeirawan & Silman - Winning Chess Strategies PDFMihai Jurubita67% (3)

- Falkenbach - Ultima ThuleDocument3 pagesFalkenbach - Ultima ThuleKronos TattooNo ratings yet

- Google CS First Coding Projects PDFDocument4 pagesGoogle CS First Coding Projects PDFMelanie FainNo ratings yet

- 20th Century Latin American Choral MusicDocument10 pages20th Century Latin American Choral MusicJosé A. Clavell AcostaNo ratings yet

- CFPG Meeting Minutes Document TitleDocument58 pagesCFPG Meeting Minutes Document Titleutpal_50No ratings yet

- BIOS Seminar PresentationDocument23 pagesBIOS Seminar PresentationVIKALP KULSHRESTHA67% (3)

- Service Manual for Minarc 150/150 VRD/151 Welding MachinesDocument27 pagesService Manual for Minarc 150/150 VRD/151 Welding MachinesSimpalean NicolaeNo ratings yet

- No Work, No Food: The Lazy Grasshopper and the Hardworking AntsDocument51 pagesNo Work, No Food: The Lazy Grasshopper and the Hardworking AntsSurendharBoobalanNo ratings yet

- Goss Community SSC Press - 22-3/4" Cut-Off: (1) Mobile StepDocument2 pagesGoss Community SSC Press - 22-3/4" Cut-Off: (1) Mobile StepFRANCIS CNo ratings yet

- 2018 Honolulu Star-Advertiser All-State FootballDocument1 page2018 Honolulu Star-Advertiser All-State FootballHonolulu Star-AdvertiserNo ratings yet

- Domestic Cvs Oil Seals Mountings Gear Lever Kits Balance Rod Bush EtcDocument32 pagesDomestic Cvs Oil Seals Mountings Gear Lever Kits Balance Rod Bush Etcdreamz unfulfilledNo ratings yet

- Microfonos DigitalesDocument12 pagesMicrofonos DigitalespabloNo ratings yet

- Annotated Cairn Character SheetDocument1 pageAnnotated Cairn Character SheetLorenzNo ratings yet

- PC Venetica ENG ManualDocument64 pagesPC Venetica ENG Manualandrewh3No ratings yet

- Single Jersey FabricDocument4 pagesSingle Jersey FabricMrcr Kapzap0% (1)

- One in A MillionDocument4 pagesOne in A MillionVasu DevanNo ratings yet

- Pope, G - The House That Love Is BuildingDocument5 pagesPope, G - The House That Love Is BuildingObltSBNo ratings yet

- NIGHTWINGDocument2 pagesNIGHTWINGJitter龍No ratings yet

- Holmes-Poirot DocumentDocument2 pagesHolmes-Poirot Documentapi-242851904No ratings yet

- Sentence TypesssDocument183 pagesSentence TypesssJan Wilbert YusonNo ratings yet

- Proposed Resolution 14-XXX-2016 - Commendation To 2016 Summer Olympics Silver Medalist Hidilyn DiazDocument1 pageProposed Resolution 14-XXX-2016 - Commendation To 2016 Summer Olympics Silver Medalist Hidilyn DiazPhilipBrentMorales-MartirezCariagaNo ratings yet

- Project Simple Universal RPGDocument3 pagesProject Simple Universal RPGdeathbydoughnutNo ratings yet

- Cartilla Preicfes Once 3 Periodo 2021Document3 pagesCartilla Preicfes Once 3 Periodo 2021Elver GalindoNo ratings yet

- OntentsDocument8 pagesOntentsbambi2pyNo ratings yet