Professional Documents

Culture Documents

Fault Tolerant Modular Linear Transverse Flux Reluctance Machines

Uploaded by

arnika33Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fault Tolerant Modular Linear Transverse Flux Reluctance Machines

Uploaded by

arnika33Copyright:

Available Formats

FAULT TOLERANT MODULAR LINEAR TRANSVERSE

FLUX RELUCTANCE MACHINES

Vasile IANCU, Dan-Cristian POPA, Loránd SZABÓ

Electrical Machines Department

Technical University of Cluj-Napoca

400750 Cluj-Napoca, P.O. Box 358, Romania

e-mail: Vasile.Iancu@mae.utcluj.ro

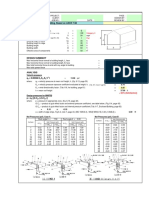

Abstract – This paper deals with two types of variable magnets on it and a hybrid linear stepper motor [2]. The

reluctance machines, both having linear movement. machine is shown in Fig. 1. The minimum number of

There are in fact modular structures that can operate modules for a continuous functioning is three. Here, the

even if different kinds of faults occur. One of the variant with such number of modules was chosen to be

presented machines will be a linear transverse flux presented considering the possibilities of an easier control

reluctance machine, the other a tubular transverse flux using the existing converters on the market:

reluctance machine. Both of them have the same

operating principle, and, as it will be proved, many of the

considerations done here are valid for both machines.

Keywords: linear, tubular, transverse flux, reluctance

machine.

I. INTRODUCTION

The number of the transverse flux machines with linear

movement studied so far is relatively small comparing to

the rotary structures [1]. The goal of the authors is to make

a presentation of two new topologies of such machines that

can be used in various applications requiring precise

positioning. The machines to be presented belong to the

class of the variable reluctance machines, without Fig. 1. The three-phase linear transverse flux reluctance

permanent magnets. It is the case of a linear and a tubular machine with permanent magnets.

transverse flux reluctance machine. Both of them are By removing the permanent magnets and the upper U-

machines built of modules. shaped iron core a simpler variant is obtained [3]. This

In the paper will be presented the working principle of machine, having only electromagnetic excitation, is shown

these machines and the conditions they can operate if a in Fig. 2:

fault should occur.

II. TRANSVERSE FLUX RELUCTANCE MACHINES

WITH LINEAR MOVEMENT

As a general consideration, it can be said that any linear

machine has two correspondents: a rotary structure and a

tubular one. So, considering for a linear machine its plane

of the movement, it can be noticed the above mentioned

aspect. If one folds a linear structure on the perpendicular

direction on the movement one a rotary variant of the

machine is obtained. On the other hand, if the same linear

structure is folded on the direction of the movement a

tubular variant results, having however a linear movement.

In this case, the initial linear transverse flux machine was

obtained as a combination between a rotary transverse flux Fig. 2. The three-phase linear transverse flux reluctance

machine with passive rotor and a stator with permanent machine without permanent magnets.

The second structure was obtained followind some Starting from the linear transverse flux reluctance

analyzes concerning the initial one presented above. These machine without permanent magnets, a tubular variant can

showed that the contribution of the permanent magnets to be obtained [6] structure after the direction of movement.

the developed tangential force are very small, aspect that The iron core of the resulted machine is shown in Fig. 4.

lead to their removal from the circuit. Besides that, a As in the previous case, the variant with three modules is

significant improvement of the first variant is achieved by presented here. The elements that form the machine are

enlarging the teeth surface of the module [4], as shown in shown bellow [7].

Fig. 3.

Fig. 3. The iron core of a module of the machine without

permanent magnets. Fig. 5. The stator and its components

1 – stator iron piece; 2 – stator non-magnetic piece

To work properly the teeth of the modules have to be

shifted from the stator ones by

kτ + τ N , k ∈ ℵ (1)

where τ is the tooth pitch and N is the number of the

modules. The step of the machine is given by the number

of modules at a certain τ [5].

shaft

1

mobile armature

iron core

stator iron core 2

Fig. 6. The moving armature and its components

1 – stator iron piece; 2 – stator non-magnetic piece

Both the stator and the rotor of this machine are realized

using magnetic (iron) pieces and non-magnetic ones. This

construction is possible because the machine is operating

based on the variable reluctance principle. Two advantages

are obtained in this way: a lower mass of the structure and

Fig. 4. The tubular transverse flux reluctance machine a cheaper machine.

The tubular machine has the same modular structure as the

linear variant [7]. As the linear variant, the tubular machine

has two major parts: the active and the passive armature.

For this machine the stator represents the active armature.

Only the iron core of the machine is presented, considering

that the excitation coils are placed in the slots of the stator.

The term “slot” has in this case a different signification

than at the linear machine where it meant the distance

between two succesive teeth.

At the tubular transverse flux machine, the teeth of the two

armatures are obtained by alternating the magnetic

elements with the non-magnetic ones. The modules of the

stator are distanced one from another by non-magnetic

materials like the ones used for the modules of the stator

and for the mobile armature. The condition they have to

meet is the same as in the case of the linear machine, which Fig. 8. Coils placed in the slots of the stator, wound around

is expressed in relation (1). the yoke, at the tubular transverse flux reluctance machine

One of the great advantages of the tubular machine is that

its stator is the same as the one of the induction machine. III. FAULT TOLERANT LINEAR TRANSVERSE FLUX

The magnetic pieces of the modules of the stator can be MACHINES

represented by steel sheets exacly like the ones used in the

asynchronous machine. The solution of using non-magnetic In the previous paragraphs two variants of transverse flux

materials has come following the technological difficulties reluctance machine with linear movement were presented.

of obtaining magnetic pieces of different diameters. Their operating principle is the same, consequently the

Regarding the materials used for the mobile armature’s aspects regarding the functioning of the linear variant,

components, these are cylinders made of magnetic and which is in fact the basic one, can be applied as well to the

non-magnetic materials. tubular machine [7].

Concerning the windings of the tubular machine, here two The operating principle of these machine determines their

possibilities will be presented [7]. As it can be noticed in modular character. As mentioned above, in order to obtain

the above figures, the stator has slots where the coils can be a continuous movement the minimum number of the

placed. The first solution is similar with a variant used at modules must be three, but theoretically a limit cannot be

the rotary machines. This implies the use of a homopolar set. Still, one must consider a few aspects. First of all, the

winding of Gramme type, without endings. The proposed developed forces at the linear reluctance machines are not

solution is given in Fig. 7. It should be underlined that, in constant. If the tooth length is the same with the slot one,

order to obtain a more clear representation of the winding the tangential force versus the armatures teeth displacement

only a steel sheet on which the coil is wound was has a sinusoidal variation. Hence, one of the goals when

considered. designing such a machine will be to realize an initial

shifting corresponding to the maximum tangential force.

Besides that, a big number of modules would increase the

length of the machine.

For a given tooth pitch of the armatures, the positioning

step of the machine is obtained by imposing the number of

modules. At each particular structure, considering the

chosen tooth pitch, one must take into consideration the

above mentioned aspects. It must be underlined that in

order to obtain a certain maximum tangential force the

geometrical dimensions of a module are the same,

regardless of their number. The mean force developed by

the machine depends however upon the number of

modules.

A natural conclusion that arises from what was presented

Fig. 7. Homopolar winding without endings, Gramme type, so far is that the machine can operate even if one of the

at the tubular transverse flux reluctance machine modules is out of order, regardless of the cause of this fault

[7]. The only condition that should be met is that the

The second possible variant to build the winding is to place number of the operating modules is minimum three.

in the slots coils that are wound around the yoke as shown Obviously, the shifting between the teeth of the two

in Fig. 8. The coils can be connected either series or armatures must be modified comparing to the initial

paralel. position (when all the modules were working properly).

This modification of the initial shifting can be done by IV. CONCLUSIONS

construction.

The above mentioned considerations are valid if the teeth This paper deals with two variants of transverse flux

of each module are shifted differently from the stator ones reluctance machines with linear movement. After

comparing to those of the other modules. However, a presenting the structure of the linear transverse flux

“composed” machine can be imagined. The term reluctance machine that is obtained from a rotary transverse

“composed” signifies that the initial structure is multiplied flux machine, a new machine that derives from the linear

in such way that the obtained machine will have more structure is proposed. The tubular transverse flux

modules with the teeth shifted identically from the stator reluctance machine is shown here with all its components

ones. One can say that the machine has r groups of and possibilities of construction.

modules. The advantage brought by such a structure is, that The fault character of these types of linear machine is given

compared to its basic variant, the developed tangential by their modular construction. The aspects related to the

force is multiplied by r times, while the normal one functioning in fault conditions are presented here.

remains the same. Its shortcomings are related mainly to Advantages offered by such structures are detailed in the

the length of the machine and the resulted price [7]. paper.

But besides the possibility to increase the tangential force Considering the principles exposed here one can conclude

by using a greater number of modules, they have another that these variable reluctance machines represent possible

important advantage which is given by their fault tolerant solutions for systems that require precise positioning and a

character. In order to keep this advantage of the machine, safe operating regime [8].

one has to supply each phase independently. Concerning

the operation mode of this machine, this is very similar to REFERENCES

the one of the SRM. Consequently one must take into

account that most of the characteristics of the variable [1] I.A. Viorel, G. Henneberger, R. Blissenbach, L. Lowenstein,

reluctance machine are valid for these machines too. In Transverse Flux Machines; Their behavior, design, control

both cases, for the linear and tubular transverse flux and applications, Cluj-Napoca (Romania), 2003.

reluctance machine, any faults during operation cannot [2] D.C. Popa, V. Iancu, L. Szabó, Linear Transverse Flux Motor

appear at the passive armature – the rotor. The possible for Conveyors, 6th International Symposium on Linear Drives

faults are related to the windings. These are of two types: for Industrial Application (LDIA '2007), Lille, France, paper

- open circuit of maximum N different channels that supply 188.

a group of N modules having teeth differently shifted [3] D.C. Popa, V. Iancu, L. Szabó, Improved Design of a Linear

from the stator ones; Transverse Flux Reluctance Motor, Proceedings of 11th

International Conference on Optimization of Electrical and

- shortcircuit of maximum N different channels Electronic Equipment, Braşov, Romania, 2008, pp. 137 - 142.

(shortcircuit of maximum N windings of a group of [4] D.C. Popa, V. Iancu, Method of Measuring the Forces

modules). Developed by a Linear Variable Reluctance Machine,

Exactly as in the case of SRM, in order to supply the Proceedings of the International Scientific Conference

phases of these machines a power converter is needed. This MicroCAD '2009, Miskolc (Hungary), Section J

would supply the windings with the required voltage (Electrotechnics and Electronics), Miskolc, pp. 63 – 69.

function of the mobile armature position and of the desired [5] D.C. Popa, V. Iancu, L. Szabó, Linear Transverse Flux

tangential force. In this way, the power electronic part can Reluctance Machine With Permanent Magnets, Proceedings

represent as well a source of faults, affecting the whole of the International Conference on Transversal Flux

Machines (ICTFM '2006), Changwon (South Korea), pp.

electrical driving system of these machines. A mention 85 - 90.

about the protection to fault appears for the tubular [6] I.A. Viorel, Larisa Strete, K. Hammeyer, Transverse Flux

machine with the winding consisting of coils placed in the Tubular Switched Reluctance Motor, Proceedings of 11th

slots and connected in parallel. In this way, even if one or International Conference on Optimization of Electrical and

more coils are out of order, that module still operates. Electronic Equipment, Braşov, România, 2008, pp. 131-136.

If the machines operates in falut conditions, the developed [7] D.C. Popa, Theoretic and Experimental Study of the Linear

forces on each phase will be different. This is due to the Transverse Flux Reluctance Motor, Ph.D. thesis, Technical

fact that the phase which is out of order cannot contribute University of Cluj-Napoca, 2008.

[8] L. Szabó, D.C. Popa, V. Iancu, Compact Double Sided

at all to the developed tangential and normal forces. From

Modular Linear Motor for Narrow Industrial Applications,

this reason, this is an important aspect that must be taken Proceedings of the 12th International Power Electronics and

into account when using this type of machines in various Motion Control Conference (EPE-PEMC '2006), Portoroz

applications requiring precise positioning. (Slovenia), pp. 1064-1069.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Literal Equations Name ProjectDocument4 pagesLiteral Equations Name Projectapi-297789948No ratings yet

- Margarine 12Document74 pagesMargarine 12the_gunners2004No ratings yet

- Cylinders of The PharaohDocument18 pagesCylinders of The PharaohiguandiánNo ratings yet

- Optimization of New Geometries of Switched Reluctances Motors Using FEM and Multi Objective Genetic AlgorithmDocument16 pagesOptimization of New Geometries of Switched Reluctances Motors Using FEM and Multi Objective Genetic Algorithmarnika33No ratings yet

- Design of A 43kW Switched Reluctance Machine For A High-Performance Hybrid Electric VehicleDocument6 pagesDesign of A 43kW Switched Reluctance Machine For A High-Performance Hybrid Electric Vehiclearnika33No ratings yet

- Cannizzaro 2016 JEDocument7 pagesCannizzaro 2016 JEarnika33No ratings yet

- Cannizzaro 2016 JEDocument7 pagesCannizzaro 2016 JEarnika33No ratings yet

- A Survey On Rotary-Linear Motors Used in Emerging ApplicationsDocument6 pagesA Survey On Rotary-Linear Motors Used in Emerging Applicationsarnika33No ratings yet

- Using Maximum Correlated Kurtosis Deconvolution Method in The Bearing Fault Detection of Wind Turbine GeneratorsDocument4 pagesUsing Maximum Correlated Kurtosis Deconvolution Method in The Bearing Fault Detection of Wind Turbine Generatorsarnika33No ratings yet

- On The Use of Rotary-Linear Generators in Floating Hybrid Wind and Wave Energy Conversion SystemsDocument6 pagesOn The Use of Rotary-Linear Generators in Floating Hybrid Wind and Wave Energy Conversion Systemsarnika33No ratings yet

- Control of Switched Reluctance Motor by Current Profiling Under Normal and Open Phase Operating ConditionDocument9 pagesControl of Switched Reluctance Motor by Current Profiling Under Normal and Open Phase Operating Conditionarnika33No ratings yet

- Novel Permanent Magnet Tubular Linear Generator For Wave Energy ConvertersDocument5 pagesNovel Permanent Magnet Tubular Linear Generator For Wave Energy Convertersarnika33No ratings yet

- Design and Fabrication of Magnetic Engine: Ganesh Bairavan.P, Anojan.TDocument5 pagesDesign and Fabrication of Magnetic Engine: Ganesh Bairavan.P, Anojan.Tarnika33No ratings yet

- Preliminary Comparative Study of Several Structures of Permanent-Magnet Synchronous Generator Used in Wind Energy System OptimizationDocument9 pagesPreliminary Comparative Study of Several Structures of Permanent-Magnet Synchronous Generator Used in Wind Energy System Optimizationarnika33No ratings yet

- FEM Based Prototype of Moving-Coil Coreless Linear-Generator (MCCLG) For Wave Energy ExtractionDocument6 pagesFEM Based Prototype of Moving-Coil Coreless Linear-Generator (MCCLG) For Wave Energy Extractionarnika33No ratings yet

- The History of Using Solar EnergyDocument8 pagesThe History of Using Solar Energyarnika33No ratings yet

- Design and Fabrication of Magnetic Engine: Ganesh Bairavan.P, Anojan.TDocument5 pagesDesign and Fabrication of Magnetic Engine: Ganesh Bairavan.P, Anojan.Tarnika33No ratings yet

- The Determination of Effects of Primary and Secondary Geometry of Tubular Linear GeneratorDocument6 pagesThe Determination of Effects of Primary and Secondary Geometry of Tubular Linear Generatorarnika33No ratings yet

- Ferkova 2017 EDPEDocument4 pagesFerkova 2017 EDPEarnika33No ratings yet

- Using Maximum Correlated Kurtosis Deconvolution Method in The Bearing Fault Detection of Wind Turbine GeneratorsDocument4 pagesUsing Maximum Correlated Kurtosis Deconvolution Method in The Bearing Fault Detection of Wind Turbine Generatorsarnika33No ratings yet

- 03 Paper 1010 CepoiDocument6 pages03 Paper 1010 Cepoiarnika33No ratings yet

- The History of Using Solar EnergyDocument8 pagesThe History of Using Solar Energyarnika33No ratings yet

- Computer Aided Modeling and Simulation of Bio-Inspired Hardware SystemsDocument6 pagesComputer Aided Modeling and Simulation of Bio-Inspired Hardware Systemsarnika33No ratings yet

- Wavelet Transform Approach To Rotor Faults Detection in Induction MotorsDocument6 pagesWavelet Transform Approach To Rotor Faults Detection in Induction Motorsarnika33No ratings yet

- Developing Control Techniques For Two-Coordinate Planar Positioning Systems by Means of Coupled Advanced Simulation ToolsDocument6 pagesDeveloping Control Techniques For Two-Coordinate Planar Positioning Systems by Means of Coupled Advanced Simulation Toolsarnika33No ratings yet

- Theoretical and Experimental Study of A Modular Tubular Transverse Flux Reluctance MachineDocument15 pagesTheoretical and Experimental Study of A Modular Tubular Transverse Flux Reluctance Machinearnika33No ratings yet

- Direct Drive System With Two Phase Transverse Flux Disc-Type MotorDocument6 pagesDirect Drive System With Two Phase Transverse Flux Disc-Type Motorarnika33No ratings yet

- The Evolution of CapacitorsDocument5 pagesThe Evolution of Capacitorsarnika33No ratings yet

- Torque Smoothing of A Fault Tolerant Segmental Stator Switched Reluctance MotorDocument7 pagesTorque Smoothing of A Fault Tolerant Segmental Stator Switched Reluctance Motorarnika33No ratings yet

- Transverse Flux Motor Drive DynamicsDocument4 pagesTransverse Flux Motor Drive Dynamicsarnika33No ratings yet

- Software Environment For Online Simulation of Switched Reluctance MachinesDocument25 pagesSoftware Environment For Online Simulation of Switched Reluctance Machinesarnika33No ratings yet

- Modular Stator Switched Reluctance Motor For Fault Tolerant Drive SystemsDocument11 pagesModular Stator Switched Reluctance Motor For Fault Tolerant Drive Systemsarnika33No ratings yet

- Comparative Study of Switched and Synchronous Reluctance Machines For Electric PropulsionDocument4 pagesComparative Study of Switched and Synchronous Reluctance Machines For Electric Propulsionarnika33No ratings yet

- 2012 - Mak - NatMater - Tightly Bound Trions in Monolayer MoS2Document5 pages2012 - Mak - NatMater - Tightly Bound Trions in Monolayer MoS2Liqin SuNo ratings yet

- 39 Space Air DistributionDocument25 pages39 Space Air DistributionPRASAD326100% (3)

- Wind Analysis For Low-Rise Building, Based On ASCE 7-98Document2 pagesWind Analysis For Low-Rise Building, Based On ASCE 7-98reynoldNo ratings yet

- Flange CouplingDocument16 pagesFlange CouplingARUN VNo ratings yet

- At The Completion of The CourseDocument2 pagesAt The Completion of The Courseoday albuthbahakNo ratings yet

- MRAM: Magnetic Random Access MemoryDocument15 pagesMRAM: Magnetic Random Access MemoryJoyitaNo ratings yet

- Atomic Structure Basic ConceptsDocument39 pagesAtomic Structure Basic ConceptsTithiparna SenguptaNo ratings yet

- Generator DataDocument8 pagesGenerator DataMohammad Ibnul HossainNo ratings yet

- IME Micro ProjectDocument4 pagesIME Micro Projectshubhamghodekar76No ratings yet

- Happens To Be A Uniform Ellipsoid: Chapter 16 Gauss' LawDocument7 pagesHappens To Be A Uniform Ellipsoid: Chapter 16 Gauss' LawSamuel PakianathanNo ratings yet

- Energy Balance CalculationDocument2 pagesEnergy Balance CalculationSzelee KuekNo ratings yet

- Experiment 3 MOMDocument6 pagesExperiment 3 MOMHafiz HamzaNo ratings yet

- ANSYS FLUENT Population Balance Module ManualDocument80 pagesANSYS FLUENT Population Balance Module ManualGokul PrabuNo ratings yet

- Properties of Matter Test ReviewDocument9 pagesProperties of Matter Test ReviewAngel PeayNo ratings yet

- Bunker DesignDocument25 pagesBunker DesignswatkoolNo ratings yet

- Calculable Cross CapacitorDocument43 pagesCalculable Cross Capacitornova1234No ratings yet

- Robot DynamicsDocument52 pagesRobot Dynamicssilviocus88No ratings yet

- DividersDocument7 pagesDividersVenkatesh KarriNo ratings yet

- Physics of Electromagnetic Calorimeters Based On Crystal ScintillatorsDocument49 pagesPhysics of Electromagnetic Calorimeters Based On Crystal ScintillatorsVigneshRamakrishnanNo ratings yet

- Phreatic Line PDFDocument21 pagesPhreatic Line PDFshubhamNo ratings yet

- Str-A6051 52 53 59 61 62 69 79Document13 pagesStr-A6051 52 53 59 61 62 69 79Александр АндриановNo ratings yet

- Experimental study of four-point bending test on CLT deep beamsDocument6 pagesExperimental study of four-point bending test on CLT deep beamsFergus GardnerNo ratings yet

- Lang SethDocument52 pagesLang Sethrrmerlin_2No ratings yet

- 2 Alternating CurrentsDocument20 pages2 Alternating CurrentsJaseela NaufalNo ratings yet

- Quantum Mechanics EssentialsDocument56 pagesQuantum Mechanics EssentialsMuhammad ZeeshanNo ratings yet

- Helium Pycnometry Density TestDocument2 pagesHelium Pycnometry Density TestDapoer OmaOpa100% (1)

- Physics Investigatory ProjectDocument18 pagesPhysics Investigatory ProjectRΛJIBUL ISLΛMNo ratings yet