Professional Documents

Culture Documents

Parking Radar: Parking Aid, or As Eye S' For Robo T Projec Ts

Uploaded by

Balvendra SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Parking Radar: Parking Aid, or As Eye S' For Robo T Projec Ts

Uploaded by

Balvendra SinghCopyright:

Available Formats

Parking Radar

K3502

ILLUSTRATED ASSEMBLY MANUAL H3502IP-2

Total solder points: 185

Difficulty level: beginner 1 2 3 4 5 advanced

U

s

e

a

s

p

a

rk

in

g

a

id

, o

r a

s

e

y

e

s

fo

r ro

b

o

t p

ro

je

c

ts

.

2

Specifications:

Detection range : 5cm - 1,5m (adjustable)

Detection angle : 5

Transmitter frequency : 40KHz.

Sample frequency : 26Hz.

Power supply : 10 - 15VDC / 16mA max.

Dimensions :

Sensor PCB : 28 x 95mm / 1,1 x 3,8

Base PCB : 48 x 125mm / 1,9 x 5

Features & Specifications

If you have problems parking then this kit is for you. Using (ultrasonic) sound waves, whose frequency is

beyond our range of hearing, we can "measure" a distance. Consequently, a sensor mounted at the back of

the car can give an indication of the distance between your car and the car parked behind you or other

obstacles (only at the same height as the sensor). When the preset minimum distance is crossed, an audible

signal is generated.

3

Assembly hints

1. Assembl y (Skipping this can lead to troubles ! )

Ok, so we have your attention. These hints will help you to make this project successful. Read them carefully.

1.1 Make sure you have the right tools:

A good quality soldering iron (25-40W) with a small tip.

Wipe it often on a wet sponge or cloth, to keep it clean; then apply solder to the tip, to give it a wet look. This is called thinning and will

protect the tip, and enables you to make good connections. When solder rolls off the tip, it needs cleaning.

Thin raisin-core solder. Do not use any flux or grease.

A diagonal cutter to trim excess wires. To avoid injury when cutting excess leads, hold the lead so they

cannot fly towards the eyes.

Needle nose pliers, for bending leads, or to hold components in place.

Small blade and Phillips screwdrivers. A basic range is fine.

For some proj ects, a basic multi-meter is required, or might be handy

1.2 Assembl y Hints :

Make sure the skill level matches your experience, to avoid disappointments.

Follow the instructions carefully. Read and understand the entire step before you perform each operation.

Perform the assembly in the correct order as stated in this manual

Position all parts on the PCB (Printed Circuit Board) as shown on the drawings.

Values on the circuit diagram are subject to changes.

Values in this assembly guide are correct*

Use the check-boxes to mark your progress.

Please read the included information on safety and customer service

* Typographical inaccuracies excluded. Always look for possible last minute manual updates, indicated as NOTE on a separate leaflet.

0

.0

0

0

4

Assembly hints

1.3 Soldering Hints :

1- Mount the component against the PCB surface and carefully solder the leads

2- Make sure the solder joints are cone-shaped and shiny

3- Trim excess leads as close as possible to the solder joint

REMOVE THEM FROM THE TAPE ONE AT A TIME !

AXIAL COMPONENTS ARE TAPED IN THE COR-

RECT MOUNTING SEQUENCE !

You will find the colour code for the resistances and the LEDs in the HALG

(general manual) and on our website: http://www.velleman.be/common/service.aspx

5

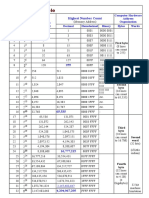

R1 : 10M (1 - 0 - 6 - B)

R2 : 22K (2 - 2 - 3 - B)

R3 : 27K (2 - 7 - 3 - B)

R4 : 27K (2 - 7 - 3 - B)

R5 : 47 (4 - 7 - 0 - B)

R6 : 10K (1 - 0 - 3 - B)

3. Resistors

R...

Construction

(A) Assembl y of the base PCB : P3502B

D1 : 1N4148

D2 : 1N4148

D3 : 1N4148

D4 : 1N4148

D5 : 1N4007

2. Diodes. Watch the polarity!

D...

CATHODE

IC1 : 16p

IC2 : 16p

IC3 : 14p

IC4 : 14p

IC5 : 16p

5. IC sockets, Watch the

position of the notch!

C1 : 12pF (12)

C2 : 12pF (12)

C3 : 22nF (223)

C4 : 10nF (103)

C5 : 100nF (104)

6. Capacitors

J

1. Jumpers

X1 : 5MHz

Fix the quartz crystal by means of

a jumpwire.

X...

4. Quartz crystal

6

Construction

C6 : 470F

7. Electrol ytic capacitor.

Watch the polarity !

C...

RV1 : 470K

RV1

8. Trim Potentiometer

J 1 : 2p +2p

J 2 : 2p +2p

9. Screw connectors

BUZ1

Be sure to put the longest

connection into the bore

marked +

10. Buzzer

IC1 : CD4060 or eq.

IC2 : CD4020 or eq.

IC3 : CD4068 or eq.

IC4 : CD4093 or eq.

IC5 : CD4049 or eq.

Pay attention to the position

of the notch!

11. ICs mounting

PIN 1

1

7

T1 : BC547B

3. Transistor

R7 : 15K (1 - 5 - 3)

R8 : 15K (1 - 5 - 3)

R9 : 15K (1 - 5 - 3)

R10 : 15K (1 - 5 - 3)

R11 : 1K (1 - 0 - 2)

R12 : 1K (1 - 0 - 2)

R13 : 10K (1 - 0 - 3)

R14 : 270K (2 - 7 - 4)

1. Resistors

R...

Construction

(B) Assembl y of the receiver PCB : P3502S

IC6 : 14p

Pay attention to the position

of the notch!

2. IC socket.

C7 : 10nF (103)

C8 : 10nF (103)

C9 : 100nF (104)

4. Capacitors

C10 : 10F

C11 : 100F

5. Electrol ytic capacitors.

Watch the polarity !

C...

J 1 : 3 x 2p

6. Screw connectors

8

Construction

SENS 1 : MA40A5S or eq.(marked with T).

SENS 2 : MA40A5R or eq. (marked with CTD)

Either on the print or connect them to the soldering terminals,

see chapter concerning the installation in the car.

7. Sensors

IC6 : TL074

Pay attention to the position

of the notch!

8. IC mounting

PIN 1

1

9

Connect the points GND, +V, RW, DIS, S1 and S2 of the main PCB to the corresponding points on the

receiver PCB.

Make sure that the distance between the receiver print and the base print is approx. 50cm.

Adjust the trimmer RV1 at the middle position RV1.

Connect a 12VDC power supply (or a battery) between the points GND (-) and +.

If you hold your hand or a sheet of paper in front of the sensors, you should hear the sound of the buzzer

when the distance from the object to the sensors decreases to about 70cm.

3. TEST

Test

Mount the receiver print in a synthetic housing, which can be done in two different ways (depending on

where it is built in on the car):

A) With the sensors in upright position (fig. 1):

Mount the four terminals for SENS1 and SENS2

Solder the sensors to the terminals so that they are in a traverse-position regarding the print.

Realise the bores in the housing as shown on the drawing (fig. 4).

4. INSTALLATION IN THE CAR

10

Install the print behind the bores using spacing sleeves,

so that the sensors are facing the bores properly without

touching the housing.

B) With the sensors in horizontal position (fig. 2):

In this case the sensors are simply mounted on the print.

Now realise the gaps in the housing as shown on the drawing 4.0

Install the print behind the bores using spacing sleeves, so that the sensors are

facing the bores properly without touching the housing.

REMARK: Cover the bores at the inside of the housing with a piece of very fine wire gauze (see fig.3). (if

the meshes of the wire gauze are to wide to prevent penetration of splash-water, the gauze should be

doubled up two or four times before fixing it to the bores). The sensors should be positioned properly

AGAINST the wire gauze which has been placed behind the bores.

Make a small hole in the bottom of the housing in order to enable the evacuation of the water that

eventually has infiltrated.

Installation

Fig. 1

Fig. 2

11

Installation

Close the housing as watertight as possible f.i. by using silicone.

Surch for a suitable place somewhere in the trunk, to built in the base print (by preference as close as possible to

the sensor, see below)

Find a suitable place, approximately in the middle of the backside of the car, for installing the sensors f.i. : underneath

or above the bumper. The sensors can be mounted directly behind the bumper as well, but then you will have to

perforate the bumper with holes of a corresponding diameter (or wider) there where the sensors are situated.

REMARK : The sensors should be in a 90 angle position to the soil.

Before fixing the receiver, first of all you have to connect a piece of

cable with 6 conductors (or shielded 5 cable with 5 conductors, the

shielding having to be connected to the terminal GND) to its terminals

(to the terminals GND, +V, RW, DIS, S1 and S2), so that it can be

connected afterwards to the base print (use by preference a color

coding cable).

SENSOR

CASE

FINE WIRE GAUZE

FINE WIRE

GAUZE

SENSOR

CASE

Fig. 3

POSITION OF SENSOR HOLES

Fig. 4

12

Connect the receiver to the base print.

Connect the terminal GND of the base print to the - of the car (chassis)

Connect the terminal + of the base print to the + of the reverse light.

5. DEFINITIVE CONNECTION

Connection & use

The circuit is activated as soon as the gear is shifted in reverse (this is marked by a 'bip' tone) and will detect

any obstacle within the range of the sensors, the detection distance (i.e. the sensitivity) being adjusted by

means of the trimmer RV1. A distance of approx. 25 to 30cm from the backside of the car seems to be a

value of practical use. First of all make some tests with the help of a second person who can survey the

distance from the outside (in order to avoid damaging the coach-work).

In case the buzzer cannot be heard clear enough, you can bring it closer to the driver by means of a 2

conductor extension cord.

REMARK : Be carefully when washing the car that no water is getting into the receiver (eventually you

should cover the sensors by means of adhesive tape).

6. USE

13

P

3

5

0

2

B

G

N

D

+

V

R

W

S

1

S

2

P3502B

P3502S

G

N

D

+

V

R

W

D

IS

+

G

N

D

G

N

D

+

V

R

W

D

IS

S

1

S

2

S

1

S

2

+

-

Connection

14

7. Schematic diagram (Control section)

Schematic diagram

15

PCB

PCB layout P3502S

PCB layout P3502B

8. PCBs

16

Modifications and typographical errors reserved

Velleman Components nv.

H3502IP - 2004 - ED2

VELLEMAN Components NV

Legen Heirweg 33

9890 Gavere

Belgium Europe

www.velleman.be

www.velleman-kit.com

5 410329 291594

You might also like

- TTC 1000Document2 pagesTTC 1000svismaelNo ratings yet

- Parking SonarDocument20 pagesParking SonarBerkin Yaşar DilsizNo ratings yet

- Injetor Seguidor de SinalDocument12 pagesInjetor Seguidor de SinalLuiz Henrique SantosNo ratings yet

- Audio Video Transmitter KitDocument0 pagesAudio Video Transmitter KitKiTrojan Hadikusumo Jr.No ratings yet

- Led Theo NhacDocument16 pagesLed Theo NhacNguyễn Thắng LợiNo ratings yet

- Manual K8048 PicDocument0 pagesManual K8048 PicRed WarrantNo ratings yet

- 4 Channel Running Light: Creating Disco Ligh T Effects, Light Speed Ad Justable. Suited Fo R Inductiv e LoadsDocument12 pages4 Channel Running Light: Creating Disco Ligh T Effects, Light Speed Ad Justable. Suited Fo R Inductiv e LoadsNikola TesanovicNo ratings yet

- Illustrated Assembly Manual - Velleman K8042 Symmetric 1A Power SupplyDocument12 pagesIllustrated Assembly Manual - Velleman K8042 Symmetric 1A Power Supplymr_sharkNo ratings yet

- Welleman Illustrated Assembly Manual k8081 Rev2Document36 pagesWelleman Illustrated Assembly Manual k8081 Rev2adibzzNo ratings yet

- Temporizator Start StopDocument12 pagesTemporizator Start StopeliboyzzNo ratings yet

- Mini FM Transmitter Kit: Hear Sounds Up to a Mile AwayDocument6 pagesMini FM Transmitter Kit: Hear Sounds Up to a Mile AwayGoncalo EscusaNo ratings yet

- DC To Pulse Width Modulator: Allows Very Eff Icient Control o FDC Motors, Heate Rs or LightsDocument0 pagesDC To Pulse Width Modulator: Allows Very Eff Icient Control o FDC Motors, Heate Rs or Lightsapostol_menNo ratings yet

- 2 X 15 Led Stereo Vu Meter: For High PR Ecision Aud Io Level IndicationDocument16 pages2 X 15 Led Stereo Vu Meter: For High PR Ecision Aud Io Level IndicationCarlos Enrique Falcon ZapataNo ratings yet

- Assembly and User Manual: 500 SeriesDocument37 pagesAssembly and User Manual: 500 SeriesjacomartNo ratings yet

- Masurator de Camp FSI - Manual20170207Document8 pagesMasurator de Camp FSI - Manual20170207fox7878No ratings yet

- Cricket 80 AmanualDocument9 pagesCricket 80 Amanualdanielboiangiu4754No ratings yet

- Illustrated Assembly Manual k2032 Rev2Document12 pagesIllustrated Assembly Manual k2032 Rev2Long Nguyen KimNo ratings yet

- Service Manual: Color MonitorDocument47 pagesService Manual: Color MonitorGuido AmarillaNo ratings yet

- DX 6550Document45 pagesDX 6550victorino2009No ratings yet

- Illustrated Assembly Manual k4003 Rev1 PDFDocument12 pagesIllustrated Assembly Manual k4003 Rev1 PDFMilan MilosavljevićNo ratings yet

- Wiring Manual Nescaf: Switched Capacitor Audio FilterDocument31 pagesWiring Manual Nescaf: Switched Capacitor Audio Filterag1tatorNo ratings yet

- Instruction Manual: Model RSP Sanitary Electronic Pressure TransmitterDocument16 pagesInstruction Manual: Model RSP Sanitary Electronic Pressure Transmittergrincheu70No ratings yet

- QRPGuys Digital RF Probe Assembly GuideDocument8 pagesQRPGuys Digital RF Probe Assembly GuideStevanus ColonneNo ratings yet

- M Series SPEX MonochromatorDocument20 pagesM Series SPEX Monochromatorstre0539100% (1)

- Ss-40ht Assembly Manual v1.1fDocument30 pagesSs-40ht Assembly Manual v1.1fIan McNairNo ratings yet

- 3-30v 3A Power Supply Circuit ManualDocument12 pages3-30v 3A Power Supply Circuit ManualRavindra ParabNo ratings yet

- Clarion Pn2165mDocument12 pagesClarion Pn2165mJorge NovoaNo ratings yet

- DIY Geiger Counter Radiation Detector Kit Ver.2 PDFDocument16 pagesDIY Geiger Counter Radiation Detector Kit Ver.2 PDFLeonardo VelezNo ratings yet

- ServiceManual CTV2131PFDVDDocument44 pagesServiceManual CTV2131PFDVDcroefus9525100% (1)

- ZX81 ServiceManualAndAssemblyInstructions PDFDocument43 pagesZX81 ServiceManualAndAssemblyInstructions PDFViorel AldeaNo ratings yet

- Stereo Coder PDFDocument3 pagesStereo Coder PDFDragonestaNo ratings yet

- Gold PicDocument6 pagesGold PicBalbalaManiukNo ratings yet

- Micro80D Builders Guide-Ver3Document18 pagesMicro80D Builders Guide-Ver3knujdloNo ratings yet

- SW20+ ManualDocument17 pagesSW20+ ManualhackmanNo ratings yet

- Philips Chasis l9Document58 pagesPhilips Chasis l9videosonNo ratings yet

- How To Build The KNQ7 Transceiver IssBDocument24 pagesHow To Build The KNQ7 Transceiver IssBJuanma IceNo ratings yet

- Illustrated Assembly Manual k8018Document16 pagesIllustrated Assembly Manual k8018FitzGritzNo ratings yet

- LCMeterHombrewmanual PDFDocument5 pagesLCMeterHombrewmanual PDFwayan.wandira8122No ratings yet

- Sony KDL 42W800A42W801A42W807A47W800A47W801A47W807A55W800A55W801A55W807A L3Document34 pagesSony KDL 42W800A42W801A42W807A47W800A47W801A47W807A55W800A55W801A55W807A L3pasantito100% (1)

- Led Circuit Diagram 3WDocument12 pagesLed Circuit Diagram 3WVinod Kumar Guravareddigari100% (1)

- Service Manual Highlights for Sony LCD TVDocument34 pagesService Manual Highlights for Sony LCD TVHamza AbbasiNo ratings yet

- Colour Television Chassis: Electrical Diagram's en PWB's Diagram PWBDocument30 pagesColour Television Chassis: Electrical Diagram's en PWB's Diagram PWBSotiris IoannouNo ratings yet

- Kit Manual IN14Document19 pagesKit Manual IN14Caio VilarNo ratings yet

- DIY Geiger Counter Radiation Detector Kit Ver.2Document16 pagesDIY Geiger Counter Radiation Detector Kit Ver.2Adrian PaleacuNo ratings yet

- Panasonic Th-37pv8p Th-37px8b Th-42pv8p Th-42px8b Th-42px8e Chassis Gph11deDocument173 pagesPanasonic Th-37pv8p Th-37px8b Th-42pv8p Th-42px8b Th-42px8e Chassis Gph11deYoly Rio RamosNo ratings yet

- Linear Power Supply: Model 9771-15 Assembly and Using ManualDocument20 pagesLinear Power Supply: Model 9771-15 Assembly and Using ManualCharles AustinNo ratings yet

- Dds 2016vmanualDocument11 pagesDds 2016vmanualalirisad aliNo ratings yet

- Electronic Transistor Ignition For Cars Kit Manual PDFDocument12 pagesElectronic Transistor Ignition For Cars Kit Manual PDFRaúl MartínNo ratings yet

- Panasonic Tc-42px14 Chassis Gph12du SMDocument108 pagesPanasonic Tc-42px14 Chassis Gph12du SMraulrosiqueNo ratings yet

- Modifications For The Kenwood TS-940Document10 pagesModifications For The Kenwood TS-940ursindNo ratings yet

- NorCal S9 Assy V1Document15 pagesNorCal S9 Assy V1Rudik WidNo ratings yet

- Dvpnc675p Sony DVDDocument98 pagesDvpnc675p Sony DVDLuis M L HerreraNo ratings yet

- Simple Diy Aoa Sensor v1Document14 pagesSimple Diy Aoa Sensor v1clanonNo ratings yet

- Instruction Manual: Model RSP Sanitary Electronic Pressure TransmitterDocument16 pagesInstruction Manual: Model RSP Sanitary Electronic Pressure TransmitterHectorNo ratings yet

- DX5000 Manual - NewDocument17 pagesDX5000 Manual - NewIonCristinelNo ratings yet

- DLP Panasonic Pt50dl54 Pt60dl54Document93 pagesDLP Panasonic Pt50dl54 Pt60dl54SonnyandDawn BerryNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- Reactive Power Compensation of Transmission Lines: (By: Yongan Deng, Masc Student at Concordia University)Document14 pagesReactive Power Compensation of Transmission Lines: (By: Yongan Deng, Masc Student at Concordia University)Meen DhamiNo ratings yet

- Project Thesis FinalDocument64 pagesProject Thesis FinalMohamed AlkamalyNo ratings yet

- Ram PDFDocument3 pagesRam PDFAngela SosaNo ratings yet

- SibasishDocument6 pagesSibasishSatya Ranjan PanigrahiNo ratings yet

- SibasishDocument6 pagesSibasishSatya Ranjan PanigrahiNo ratings yet

- 10 - Home Appliances ControllingDocument10 pages10 - Home Appliances ControllingBalvendra SinghNo ratings yet

- Zaragoza Factory - Accessories and Options - enDocument45 pagesZaragoza Factory - Accessories and Options - enBalvendra SinghNo ratings yet

- Controlling Home Appliances Using Cell PhoneDocument2 pagesControlling Home Appliances Using Cell PhoneBalvendra SinghNo ratings yet

- 405 Method Not AllowedDocument40 pages405 Method Not AllowedBalvendra SinghNo ratings yet

- DDDocument1 pageDDBalvendra SinghNo ratings yet

- Ultrahigh-Power Subwoofer: DatasheetDocument2 pagesUltrahigh-Power Subwoofer: DatasheetOmarNo ratings yet

- 17color TFT Monitor Dsc1703dcvDocument100 pages17color TFT Monitor Dsc1703dcvFrancisco DiazNo ratings yet

- MWQBDocument8 pagesMWQBArvNo ratings yet

- LAN TopologiesDocument31 pagesLAN TopologiesDinku Minda100% (1)

- Series and Parallel CircuitDocument30 pagesSeries and Parallel CircuitAmirul Syazwan100% (1)

- Bipolar Transistor BiasingDocument29 pagesBipolar Transistor Biasingmoin_mohdNo ratings yet

- Microwave Communications MCQs Answers Part IXDocument3 pagesMicrowave Communications MCQs Answers Part IXRaghu Veer KNo ratings yet

- E-INK Display TechnologyDocument23 pagesE-INK Display Technologydurga454No ratings yet

- C Programe1Document7 pagesC Programe1njpatel9No ratings yet

- PC Wor X LaptopsDocument16 pagesPC Wor X LaptopsEva HubadNo ratings yet

- Si PMDocument10 pagesSi PMKremi TakovaNo ratings yet

- Programador AVR PDFDocument7 pagesProgramador AVR PDFGustavoFloresNo ratings yet

- NAd C425-UM Tuner - Multi-Language ManualDocument68 pagesNAd C425-UM Tuner - Multi-Language ManualPietertje58No ratings yet

- ECE 342: Understanding Transmission LinesDocument44 pagesECE 342: Understanding Transmission Lineskipkorir bettNo ratings yet

- Dynamic Microphone Order # 406.910: Eatures Echnical PecificationsDocument2 pagesDynamic Microphone Order # 406.910: Eatures Echnical PecificationsgbNo ratings yet

- SSP2N60B/SSS2N60B: 600V N-Channel MOSFETDocument11 pagesSSP2N60B/SSS2N60B: 600V N-Channel MOSFETCuenta ParaNo ratings yet

- Abia Polytechnic Electrical Engineering Group Project on 5V Regulated DC Power SupplyDocument7 pagesAbia Polytechnic Electrical Engineering Group Project on 5V Regulated DC Power SupplyKalu SamuelNo ratings yet

- Characteristics of Crystal-Video Receivers PDFDocument24 pagesCharacteristics of Crystal-Video Receivers PDFlazarosNo ratings yet

- ELECTRICAL Sample QuestionDocument17 pagesELECTRICAL Sample QuestionSambit MohapatraNo ratings yet

- ST10F280 JT3Document186 pagesST10F280 JT3Carlos Geeket' El HalabiNo ratings yet

- LG Oled65g6p T-Con Board Layout Voltages 2017Document10 pagesLG Oled65g6p T-Con Board Layout Voltages 2017Fernando AguiarNo ratings yet

- Lesson12 Using DB and DBMVDocument20 pagesLesson12 Using DB and DBMVEdgar NavarroNo ratings yet

- Convergence Problems - LTwiki-Wiki For LTspiceDocument4 pagesConvergence Problems - LTwiki-Wiki For LTspiceCarlos Iván RuedaNo ratings yet

- Analog Circuits Versus Digital CircuitsDocument2 pagesAnalog Circuits Versus Digital CircuitsTalha MaqsoodNo ratings yet

- Folheto s7300 eDocument16 pagesFolheto s7300 eHector GANo ratings yet

- 1155dBTE 504Document13 pages1155dBTE 504Shubham AgrawalNo ratings yet

- Powers of 2 Table - Vaughn's SummariesDocument2 pagesPowers of 2 Table - Vaughn's SummariesAnonymous NEqv0Uy7KNo ratings yet

- Intelligent Power MOSFETDocument6 pagesIntelligent Power MOSFETfreddys merchanNo ratings yet

- Lumped-Element System Dynamics: Joel Voldman Massachusetts Institute of Technology (With Thanks To SDS)Document69 pagesLumped-Element System Dynamics: Joel Voldman Massachusetts Institute of Technology (With Thanks To SDS)Nguyen Thanh KhuongNo ratings yet