Professional Documents

Culture Documents

1 Servo Working Principle

Uploaded by

gminayasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Servo Working Principle

Uploaded by

gminayasCopyright:

Available Formats

Tank Gauging

Historical overview Enraf instruments

Servo

PV70 800/801

802

811

854 990 Flexline

Radar

872 873 MIT

MTT

970 973/971 VITO

MTT MRT/MPT

Ni191/Cu90

Temperature

Spot Pt100 MRT

MESC

MIR

MRT/MPT

MRT-MTT-MPT Microlect, Analog

Density 1950

Honeywell Enraf Training

Hydrostatic (HIMS/HTG) Dip & Profile (Servo)

60

70

80

90

Honeywell Proprietary

00

10

20

Honeywellenraf.com

Servo level gauging

Introduction

apparent weight S

Archimedes law

[DW] = Displacer Weight [DV] = Displacer Volume = product density

apparent weight (grams)

S = [DW] - [DV]

max. [DW]

weight

min. [DW] - [DV]

weight buoyancy

Honeywell Enraf Training

Honeywellenraf.com

Honeywell Proprietary

Servo level gauging

Setpoint [S1]

For level measurement a certain apparent weight (setpoint) is required

apparent weight apparent weight

Setpoint closer to displacer weight less immersion Advantages:

less influence of product density (variations) less contamination of displacer less influence of turbulence

apparent weight (grams)

max. [DW]

apparent weight (grams)

max. [DW]

[S1]

min. [DW] - [DV]

[S1] = [DW] - 15

[S1]

min. [DW] - [DV]

Honeywell Enraf Training

Honeywellenraf.com

Honeywell Proprietary

Servo level gauging

Influence of Product Density Changes

Immersion i = Example

[DW] = 223 gr. [DA] = 64 cm = 800 kg/m (0.8 gr/cm) i=

[DW] - [S1] [DA]

223 - 208= 0.29 cm (2.9 mm) 64 0.8

0.9

= 0.9 i=

Influence of density variations 0.7

= 0.7

i=

223 - 208 = 0.26 (2.6 mm) 64 0.9 223 - 208 = 0.33 (3.3 mm) 64 0.7

0.5 mm

Density change of 100 kg/m causes level change of

Honeywell Enraf Training

Honeywellenraf.com

Honeywell Proprietary

Servo level gauging

Influence of contamination

Immersion i=

[DW] - [S1] [DA] 223 - 208 = 0.29 cm (2.9 mm) 64 0.8

S1=208 Displacement 15 gr.

Displacer clean: i =

Displacer contaminated: i= i=

[DW] = 223 gr.

([DW] + contamination) - [S1] [DA] (223 + 10) - 208 64 0.8

S1=208 Displacement 25 gr.

i = 0.49 cm (4.9 mm) Level error Conclusion: = 2.9 - 4.9 = -2 mm contamination of 1 gr. causes level error of -0.2 mm

Weight = [DW] + 10 gr. Contamination = 233 gr.

Honeywell Enraf Training

Honeywellenraf.com

Honeywell Proprietary

Servo level gauging

Influence of turbulence

Horizontal (error is significant)

[S1] = [DW] - 15: automatic correction 854: positioning actions (up/down) use of stilling well

Vertical (S

[S1], integration action)

adjustable integration time [T1] stable read-out accurate average A<B A L average t A B B A>B A A=B B

Honeywell Enraf Training

Honeywellenraf.com

Honeywell Proprietary

Servo level gauging Servo sensitivity

Minimum required level change for level measurement

instrument sensitivity S 854 0.3 gr. level change i 0.1 mm (displacer size [DA] = 64 cm)

Sensitivity depends on

instrument sensitivity S (manufacturer) displacer diameter (application)

811: standard 140 mm support pipe (if any) 8" 854: standard 90 mm support pipe (if any) 6"

Servo on 2" stilling well

use displacer diameter 45 mm level sensitivity i 0.2...0.4 mm ( = 0.8 gr/cm)

i i=

([DW] - [S1]) S [DA]

Sensitivity:

i=

S [DA]

Honeywell Enraf Training

Honeywellenraf.com

Honeywell Proprietary

Servo level gauging

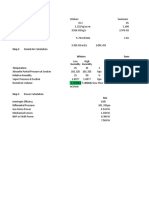

Summary

Setpoint [S1] = [DW] - 15 [g]

Immersion

[DW] - [S1] [DA]

i=

[mm]

Sensitivity

S [DA]

[mm]

Honeywell Enraf Training

Honeywellenraf.com

Honeywell Proprietary

You might also like

- Control Valves and SensorsDocument86 pagesControl Valves and SensorsWilmar Antonio Zuluaga ArangoNo ratings yet

- Control Chapter 5 - RemoteDocument87 pagesControl Chapter 5 - RemoteJhonny PerezNo ratings yet

- ms-03-19 HoseDocument8 pagesms-03-19 HoseBowo Edhi WibowoNo ratings yet

- ET ValveDocument48 pagesET ValveDaniel SantillanNo ratings yet

- Ciu Plus & Ciu PrimeDocument8 pagesCiu Plus & Ciu Prime91665111No ratings yet

- Density Measurement - System OverviewDocument20 pagesDensity Measurement - System OverviewLuis MayorgaNo ratings yet

- 100 Remote View 505 PDFDocument3 pages100 Remote View 505 PDFWilliam Will Controle WoodwardNo ratings yet

- Fisher ET and EAT Easy-E Valves CL125 Through CL600 PDFDocument48 pagesFisher ET and EAT Easy-E Valves CL125 Through CL600 PDFARMANDONo ratings yet

- Hydraulic Valves AnalyticsDocument8 pagesHydraulic Valves Analyticspartha6789No ratings yet

- d200318x012 PDFDocument12 pagesd200318x012 PDFLimuel EspirituNo ratings yet

- Product Bulletin Fisher 3582 3582i Positioners 582i Electro Pneumatic Converter en 124122Document12 pagesProduct Bulletin Fisher 3582 3582i Positioners 582i Electro Pneumatic Converter en 124122Sakthi Sekar CbiNo ratings yet

- Liquid Level Switches Asme B31.1 ConstructionDocument36 pagesLiquid Level Switches Asme B31.1 Constructionsamer8saifNo ratings yet

- Woodward Governor: Presented By: Saraswati Je/Dsl/GocDocument42 pagesWoodward Governor: Presented By: Saraswati Je/Dsl/GocTirthankar DasNo ratings yet

- Mesin Cuci RepDocument11 pagesMesin Cuci RepRefli MaulanaNo ratings yet

- Speed (%) Vs Time (Min) : Gas Turbine Starting CurveDocument2 pagesSpeed (%) Vs Time (Min) : Gas Turbine Starting CurveAdy FardyNo ratings yet

- MincoTs103A 3Document18 pagesMincoTs103A 3Jeff AyersmanNo ratings yet

- 02 Yokogawa Vigilant-Catalogue PDFDocument4 pages02 Yokogawa Vigilant-Catalogue PDFm33mNo ratings yet

- Application Letter HSE Manager Chairunnas M.oshDocument2 pagesApplication Letter HSE Manager Chairunnas M.oshOka WansyahNo ratings yet

- Masoneilan+ +124000+Spec+DataDocument20 pagesMasoneilan+ +124000+Spec+DataEphraem KalisNo ratings yet

- Ceritarakyatbahasajawa 141220215106 Conversion Gate01Document10 pagesCeritarakyatbahasajawa 141220215106 Conversion Gate01istiqomahNo ratings yet

- MK6e Control System ChecksDocument4 pagesMK6e Control System ChecksAugustine Owo Ukpong100% (1)

- GT - GTG - STG Cooling Air SystemDocument17 pagesGT - GTG - STG Cooling Air SystemLeelanandaNo ratings yet

- System DescriptionDocument28 pagesSystem DescriptionGloria HamiltonNo ratings yet

- CollegepptDocument38 pagesCollegepptneethurj9No ratings yet

- Ex2100e and Ex2100 Comparison Fact Sheet EnglishDocument1 pageEx2100e and Ex2100 Comparison Fact Sheet EnglishOrissa KonsbahalNo ratings yet

- Dresser ValveDocument37 pagesDresser ValvePradeep KumarNo ratings yet

- Cross TrippingDocument2 pagesCross TrippingNimeshNo ratings yet

- Safety and Security Roadshow 2012 Safety Systems PDFDocument26 pagesSafety and Security Roadshow 2012 Safety Systems PDFSameer KapareNo ratings yet

- Fundamentals Orifice Measurement - DanielDocument11 pagesFundamentals Orifice Measurement - DanielKuwat Riyanto0% (1)

- Fundamental Signal Processing ExerciseDocument7 pagesFundamental Signal Processing ExerciseAdang PriantoNo ratings yet

- Masoneilan Transfer ValveDocument4 pagesMasoneilan Transfer Valveiviji81No ratings yet

- Bap - MBP SystemDocument93 pagesBap - MBP SystemGloria HamiltonNo ratings yet

- Control Valve SourcebookDocument218 pagesControl Valve SourcebookJuanita JitomateNo ratings yet

- GTG#2Document6 pagesGTG#2joymotiNo ratings yet

- Api StandartDocument2 pagesApi Standartyg89No ratings yet

- NEW 505view Operator Interface MANUALDocument60 pagesNEW 505view Operator Interface MANUALWilliam Will Controle WoodwardNo ratings yet

- OHSAS18001Document67 pagesOHSAS18001Anand Dubey100% (1)

- Fisher 8580 Rotary Valve PDFDocument24 pagesFisher 8580 Rotary Valve PDFARMANDONo ratings yet

- MOOG2Document1 pageMOOG2BouazzaNo ratings yet

- Fisher Volume BoosterDocument16 pagesFisher Volume Boosterpawank_kswnNo ratings yet

- Speed TronicDocument3 pagesSpeed Tronicscribdkhatn0% (1)

- Steam Stop ValveDocument15 pagesSteam Stop Valveankur raiNo ratings yet

- Sec 4 41000Document51 pagesSec 4 41000iqjoeljoachinNo ratings yet

- 945 Cci 100dpc Drag Production Wellhead Choke New ConstructionDocument4 pages945 Cci 100dpc Drag Production Wellhead Choke New ConstructionAnderson SiqueiraNo ratings yet

- Fisher Vee-Ball v150, v200 and v300 PDFDocument48 pagesFisher Vee-Ball v150, v200 and v300 PDFARMANDONo ratings yet

- Technical Proposal - 181120-114811-8 Rev.04Document41 pagesTechnical Proposal - 181120-114811-8 Rev.04manuelarrano100% (1)

- GE Power Systems Fundamentals of Speedtronic Mark V Control SystemDocument34 pagesGE Power Systems Fundamentals of Speedtronic Mark V Control SystemHung NgoNo ratings yet

- Displacer Type Level SwitchDocument10 pagesDisplacer Type Level SwitchKarthik Chockkalingam100% (1)

- Inlet ValveDocument5 pagesInlet Valveujwol_phaijuNo ratings yet

- 4 - Flow Measurment DevicesDocument50 pages4 - Flow Measurment DevicesAli MoustafaNo ratings yet

- MkvbinDocument25 pagesMkvbinnabil160874No ratings yet

- HAZOPSDocument21 pagesHAZOPSMalak HindiNo ratings yet

- Null BiasDocument33 pagesNull BiasGoh Seng TakNo ratings yet

- Control Valve CharacteristicsDocument3 pagesControl Valve CharacteristicsgifitrianggraeniNo ratings yet

- Diagrama P ID Ammonium Nitrate Fertilizer Production Unit PDFDocument1 pageDiagrama P ID Ammonium Nitrate Fertilizer Production Unit PDFYecid Fabian AlvaradoNo ratings yet

- Data Sheet ROTAVISC Me-Vi CompleteDocument4 pagesData Sheet ROTAVISC Me-Vi CompleteAmbiental ItaxNo ratings yet

- ROTAVISC Lo-Vi Complete: /// Data SheetDocument4 pagesROTAVISC Lo-Vi Complete: /// Data SheetFernanda ContursiNo ratings yet

- Workshop Manual: GB GBDocument110 pagesWorkshop Manual: GB GBSelwinNo ratings yet

- CalculationReport PDFDocument10 pagesCalculationReport PDFFikret DavudovNo ratings yet

- Data Sheet Model VD 115Document5 pagesData Sheet Model VD 115Bősze GáborNo ratings yet

- PN Series ManualDocument23 pagesPN Series ManualgminayasNo ratings yet

- Datasheet Processgauge 1279Document2 pagesDatasheet Processgauge 1279gminayasNo ratings yet

- 1784 U2dnDocument1 page1784 U2dngminayasNo ratings yet

- Aps0e2b TPGDocument8 pagesAps0e2b TPGmcserNo ratings yet

- Installation Instructions For 2102141Document1 pageInstallation Instructions For 2102141gminayasNo ratings yet

- Adjust radial vibration probe gapDocument3 pagesAdjust radial vibration probe gapgminayasNo ratings yet

- Start-Up and Operation of GE Frame 9EDocument23 pagesStart-Up and Operation of GE Frame 9Efazzlie100% (2)

- Aps0e2b TPGDocument8 pagesAps0e2b TPGmcserNo ratings yet

- Datasheet C&D Ups (Bateria) High Rate Max InglesDocument6 pagesDatasheet C&D Ups (Bateria) High Rate Max InglesPedroNo ratings yet

- Position Paper SIL Platform Jun2013 FinalsDocument18 pagesPosition Paper SIL Platform Jun2013 FinalsgminayasNo ratings yet

- Human FactorsDocument24 pagesHuman FactorsgminayasNo ratings yet

- Technical White Paper: Fieldbus Testing With Online Physical Layer DiagnosticsDocument11 pagesTechnical White Paper: Fieldbus Testing With Online Physical Layer DiagnosticsgminayasNo ratings yet

- ACU AnnunciatorDocument93 pagesACU AnnunciatorgminayasNo ratings yet

- PST-WVD218 User ManualDocument10 pagesPST-WVD218 User ManualgminayasNo ratings yet

- Buckling Pin Pressure Relief TechnologyDocument8 pagesBuckling Pin Pressure Relief Technologynature75No ratings yet

- Burn PilotsignitersDocument6 pagesBurn PilotsignitersM Ahmed LatifNo ratings yet

- Model 6290 OperationDocument20 pagesModel 6290 Operationgminayas100% (1)

- Oil Gas Salary Guide 2012 - WebDocument32 pagesOil Gas Salary Guide 2012 - WebAdam BartonNo ratings yet

- 2165 CCST Brochure WebDocument5 pages2165 CCST Brochure WebgminayasNo ratings yet

- Model 6290 OperationDocument20 pagesModel 6290 Operationgminayas100% (1)

- Production of LNG Using Dual Independent Expander Refrigeration Cycles - Jorge H Foglietta (ABB Lumnus)Document19 pagesProduction of LNG Using Dual Independent Expander Refrigeration Cycles - Jorge H Foglietta (ABB Lumnus)Joe Wong100% (1)

- MCHEtestDocument8 pagesMCHEtesth1ari1sh1771No ratings yet

- Oil Gas Salary Guide 2012 - WebDocument32 pagesOil Gas Salary Guide 2012 - WebAdam BartonNo ratings yet

- FMEA RCM Course - Foundations of Effective FMEA - RS 470 CourseNotes - Rev9.1Document358 pagesFMEA RCM Course - Foundations of Effective FMEA - RS 470 CourseNotes - Rev9.1gminayas100% (1)

- Start-Up and Operation of GE Frame 9EDocument23 pagesStart-Up and Operation of GE Frame 9Efazzlie100% (2)

- Document Title: Sulfur Dosing System: Project InformationDocument3 pagesDocument Title: Sulfur Dosing System: Project InformationjorgekarlosprNo ratings yet

- ASTM D4253-16e1Document14 pagesASTM D4253-16e1katherine Melo100% (1)

- Physical Chem 1 (Combined)Document35 pagesPhysical Chem 1 (Combined)Yit JuanNo ratings yet

- P 1Document16 pagesP 1Chaos GamingNo ratings yet

- TB Science F1 Chapter 1Document136 pagesTB Science F1 Chapter 1Salmee SallehNo ratings yet

- Dgpys Ans PDFDocument35 pagesDgpys Ans PDFcristinaNo ratings yet

- Density MethodDocument5 pagesDensity MethodMajed DawaNo ratings yet

- Porosity and Permeability LABORATORYDocument5 pagesPorosity and Permeability LABORATORYDavid OrtegonNo ratings yet

- Cement - Mortar - Plaster EstimatorDocument55 pagesCement - Mortar - Plaster EstimatorChristopher UcheNo ratings yet

- Properties of Fluids PDFDocument24 pagesProperties of Fluids PDFAnthony Leire MontealtoNo ratings yet

- Ebooks Chemistry NotesDocument155 pagesEbooks Chemistry Notesb0767212No ratings yet

- Manual Balanza Analitica BELDocument63 pagesManual Balanza Analitica BELPaulina RíosNo ratings yet

- Calibrating Waterjets: An Experiment to Determine Flow RatesDocument5 pagesCalibrating Waterjets: An Experiment to Determine Flow Ratespacoto livingstoneNo ratings yet

- Min-218 Fundamentals of Fluid FlowDocument8 pagesMin-218 Fundamentals of Fluid Flowtri cutNo ratings yet

- MHR bsc7 ch05Document28 pagesMHR bsc7 ch05api-240126372No ratings yet

- 420 The Red Book, Basics of Foundation Design 2022Document540 pages420 The Red Book, Basics of Foundation Design 2022Andrei NardelliNo ratings yet

- Demister Pad Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignDocument22 pagesDemister Pad Selection, Sizing and Troubleshooting, Kolmetz Handbook of Process Equipment DesignMartin Lote Tres0% (1)

- Bulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForDocument7 pagesBulk Density ("Unit Weight") and Voids in Aggregate: Standard Test Method ForshoshaNo ratings yet

- Astm Test MethodDocument37 pagesAstm Test MethodpankajNo ratings yet

- Polyurethane Insulation Coating Specification for STV South West Project PipelinesDocument42 pagesPolyurethane Insulation Coating Specification for STV South West Project Pipelinesnguyenquoc1988100% (1)

- Astm C-91-98Document4 pagesAstm C-91-98Khan ShahzebNo ratings yet

- Dead LoadsDocument1 pageDead LoadsShokry AlkissyNo ratings yet

- Config 600 Software User Manual PDFDocument746 pagesConfig 600 Software User Manual PDFAnonymous LLLK3pqNo ratings yet

- 9 Test To Check Quality of Bitumen For Use in Road WorkDocument6 pages9 Test To Check Quality of Bitumen For Use in Road WorkEulogio Jamero100% (2)

- Chemistry 1 Class 11Document254 pagesChemistry 1 Class 11Aniket Sharma100% (7)

- Matter Test Study Guide KeyDocument26 pagesMatter Test Study Guide Keyapi-278594802No ratings yet

- Thermodynamics Chapter 3 Solution Sta MariaDocument7 pagesThermodynamics Chapter 3 Solution Sta MariaJean PD81% (21)

- Module 16 - Phys 13 Fluid StaticsDocument24 pagesModule 16 - Phys 13 Fluid StaticsRamnuj Orecul SoralcNo ratings yet

- Experiment No. 2 Properties of MatterDocument4 pagesExperiment No. 2 Properties of MatterAprille MartinezNo ratings yet

- Blower Power CalculationsDocument7 pagesBlower Power CalculationsMuzzamilNo ratings yet