Professional Documents

Culture Documents

Civil Design Criteria

Uploaded by

Harish Kumar MahavarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Civil Design Criteria

Uploaded by

Harish Kumar MahavarCopyright:

Available Formats

CHAPTER 8: CIVIL DESIGN AND COST ESTIMATES

8.1 PROPOSED DHOBIGHAT IN ARA The geo-technical survey of the site revealed that load bearing structure may require extra precaution or strengthening of the structure, otherwise for normal load the civil work involves utilization of concrete frame. The proposed Dhobighat is a single storied structure of 253 feet span with Ceiling height of 13 feet. Therefore, as per requirement civil structure shall be constructed to cater the need. For proper designing following steps has been followed: 1. Layout plan of existing site of proposed Dhobighat 2. The conceptual and layout plan of proposed Dhobighat 3. Architectural drawings of the proposed Dhobighat 4. Structural drawing & design of proposed Dhobighat 5. Drawing and Design for Treatment plant based on expected effluent 6. Drawing and Design of Electrical fittings based on calculated design load 7. Provision of water distribution system including supply to various washing units, toilets, bathrooms, to and from overhead tanks. 8. Proper illumination 9. Non-conventional energy system

Arrangement of module in linear system has been planned for better water supply and power system. The non corrosive and non-skating flooring arrangement has been provided. The water retaining structure is considered leak-proof and of non-corrosive material. The power supply will be provided for the designed load of 15 KW. The power backup is given by providing the Gen set of 5 KVA. The RCC structure is provided with following standard; RCC structures Steel structures Shallow foundations Soil exploration and testing Water retaining structures Reinforcement IS 456 IS 800 IS 6403 IS 2720 IS 3370 IS 1786 for HYSD bars; IS 432 for mild steel bars

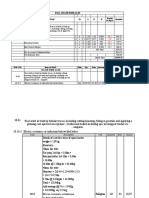

The estimation of proposed Dhobighat is based on the Bihar Schedule of Rates (BSR) 2013. For those items which are not covered in the DSR, current market rates are considered. The standards for the proposed facilities are based on the items being used in similar nature of works in Bihar or elsewhere in India. However structural design, type of material and specification to be used is based on the requirements of situation as well as the suitability of the product for effective and long term usages. In general, existing Indian standards will be followed for the designs and detailed calculations. The detail of calculation and load bear structures is also given in this Chapter, however the specification of material to be used in construction are summarized as under. The use of water at all the stages is obvious because clothes washing shall be done in the water, thus tiles and concrete structures where ever used shall be of high grade/quality to sustain in wet conditions. The use of soap and detergents will also affect the material, thus corrosion resistant material is considered predominantly.

DESIGN BASIS REPORT ON STRUCTURE SYSTEM ABASIC DESIGN CONSIDERATIONS

PROJECT DESCRIPTIONS LOCATION: The site of building is located at Lodhi Road near Meharchand Market Type of Building: R.C.C. FRAMED STRUCTURE

This is a (G+1) floor building. It is planned to provide grids of 3.4mx7.0m. The whole building has been divided into three parts by providing two expansion joints adjacent to the stair case.

The width of expansion joints is 40mm. The clear height of all floors is 3.75m. Two overhead water tank of 80000 litre capacity has been designed at a height of 1.20m above mumty slab. The depth of foundation from the original ground level is 1.25m as advised in soil test report. This building is designed for RCC framed structure having slab beam system throughout. STRUCTURAL DESIGN: The main considerations followed for the design of structure are: (a) (b) Structural safety and stability To meet the demands of aesthetics conceived by the architect

(c) (d) (e) (f)

Availability of material , equipment and expertise Constructability and ease of maintenance Durability Economy

DESIGN APPROACH: A 3-dimensional model of each block of the building is generated using STAAD PRO software. All the beams and columns have been modeled as finite elements (beams). The structure is analyzed for the possible combination of loads i.e. gravity loads (dead loads and live loads) and earthquake load (wherever applicable). Fatigue effects of persistent cyclic loads are not anticipated and may be negligible, if, any. STRUCTURAL SYSTEM The building has been designed as RCC framed structure with RCC slab, beams and Columns. The building has been designed as slab column arrangement from plinth to terrace level. The building has been designed with the relevant Indian code of practice for civil work. i.e. I.S.456, I.S. 875, I.S.1893-2002, I.S.4326-1976 and I.S. 13920-1993. The foundations are designed for a safe bearing capacity of 11.5t/sqm at a depth of 1.25m from general ground level. Isolated and combined footings are provided as foundation arrangement for this building DEAD LOADS: The dead load on the structure includes all the permanent loads attached with structure.The dead load in a building shall comprise of the weight of all walls,partitions, floors,roofs and all other permanent components of structure and shall conform to the unit weight of the materials asper IS 875. Unit weight of various structural members considered is as below: 1 Unit weight of water 1.0t/cum 2 Unit weight of RCC 2.5 t/cum 3 Unit weight of plaster 2.0t/cum 4 Unit weight of Brick work 2.0t/cum 5 Unit weight of soil 1.8t/cum 6 Unit weight of cinder 1.0t/cum Following are the permanent loads which have been considered in analysis. Self weight of structure i.e. slabs, beams and columns Floor finish Wall loads

LIVE LOAD Live loads on all the floors shall comprise all the loads other than dead loads. The minimum live loads on different occupancies have been considered as per IS 875 (part-II) -1987. The live loads adopted are as follows: Toilets and bath rooms Corridors, passage, stair case, lobby Area except bath rooms & s/case 2.0 kn/sqm 4.0 KN/sqm 4.0 Kn/sqm

SIESMIC LOAD: Siesmic coefficient method has been used as per IS 1893 Design Horizontal seismic coefficient Ah Zone factor Z Importance factor, I Reduction factor, R = Sa/2Rg =0.24 (Zone-IV) =1.0 =5.0

DUCTILITY & DURABILITY Besides the strength to ensure durability of the structure, concrete mix of M20 is used for all components of the structure the provisions in IS 13920 have been adopted to ensure adequate ductility of the structure.

SIESMIC ANALYSIS & DESIGN: 3-D analysis has been carried out using STAAD PRO software. In plane rigidity of slab is simulated in the model by providing moment of inertia of the slab and beams in the hor. Plane in both the direction. For seismic load evaluation for static approach using seismic coefficient method are used. Minimum base shear and mass participation approach factor asper IS 1893 is considered in the design. LOAD COMBINATIONS 1. 1.5*(DL+LL) 2. 3. 4. 5. 1.5*(DL+/- EQX) 1.5*(DL+/-EQZ) 1.2(DL+LL+/-EQX) 1.2*(DL+LL+/-EQZ)

Legends: DL DEAD LOAD

LL EQX EQZ

LIVE LOAD EARTHQUAKE LOAD IN X DIRECTION EARTHQUAKE LOAD IN Z DIRECTION

WHERE X & Z ARE TO PRINCIPAL AXIS

MATERIALS 1 Concrete: Concrete of mix M20 shall be used 2 Steel reinforcement: Steel reinforcement of grade Fe: 415 shall be used

DESIGN STANDARDS: All the relevant codes and specifications are followed. Some main codes are mentioned below: 1234567IS-456 2000 code of practice for plain and reinforced concrete structure IS 875 (PART-I,II,II) , code of practice for loads other than earthquake loads IS 1893 (Criteria for earthquake resistant design for structure) IS 4326 1993, code of practice for earthquake resistant design IS 13920 -1993, Ductile detailing of reinforced concrete structure SP 16 (design aid to IS 456) SP-34 (reinforcement detailing)

8.2 PROPOSED CTCs CONSTRUCTION in ARA The detailed study of the sites identified revealed that load bearing structure may require extra precaution or strengthening of the structure, otherwise for normal load the civil work involves utilization of concrete frame. The proposed site for CTCs is a single storied structure of different span with Ceiling height of 12 feet. Therefore, as per requirement civil structure shall be constructed to cater the need. For proper designing following steps has been followed: 1. Layout plan of existing site of proposed CTCs 2. The conceptual and layout plan of proposed CTCs 3. Architectural drawings of the proposed CTCs 4. Structural drawing & design of proposed CTCs 5. Drawing and Design of Electrical fittings based on calculated design load 6. Provision of water distribution system including supply to various washing units, toilets, bathrooms, to and from overhead tanks. 7. Proper illumination

Arrangement of module in linear system has been planned for better water supply and power system. The non corrosive and non-skating flooring arrangement has been provided. The water retaining structure is considered leak-proof and of non-corrosive material. The power supply will be provided for the designed load of 5 KW. The power backup is given by providing the Gen set of 3 KVA. The RCC structure is provided with following standard; RCC structures Steel structures Shallow foundations Soil exploration and testing Water retaining structures Reinforcement IS 456 IS 800 IS 6403 IS 2720 IS 3370 IS 1786 for HYSD bars; IS 432 for mild steel bars

The estimation of proposed CTCs construction is based on the Bihar Schedule of Rates (BSR) 2013. For those items which are not covered in the DSR, current market rates are considered. The standards for the proposed facilities are based on the items being used in similar nature of works in Bihar or elsewhere in India. However structural design, type of material and specification to be used is based on the requirements of situation as well as the suitability of the product for effective and long term usages. In general, existing Indian standards will be followed for the designs and detailed calculations. The detail of calculation and load bear structures is also given in this Chapter, however the specification of material to be used in construction are summarized as under. The use of water at all the stages is obvious because clothes washing shall be done in the water, thus tiles and concrete structures where ever used shall be of high grade/quality to sustain in wet conditions.

You might also like

- Shahdara Drain Site Visit On 06.10.2023Document8 pagesShahdara Drain Site Visit On 06.10.2023Harish Kumar MahavarNo ratings yet

- Stability of Ogee Shaped Weir & EstimateDocument18 pagesStability of Ogee Shaped Weir & EstimateHarish Kumar MahavarNo ratings yet

- Brest Wall Stability DesignDocument3 pagesBrest Wall Stability DesignHarish Kumar MahavarNo ratings yet

- Analysis of Random Rubble Stone Masonary Breast WallDocument3 pagesAnalysis of Random Rubble Stone Masonary Breast WallHarish Kumar MahavarNo ratings yet

- Methods of Discharge CalculationDocument3 pagesMethods of Discharge CalculationHarish Kumar MahavarNo ratings yet

- GS2011 QP BiologyDocument16 pagesGS2011 QP BiologyRahulLeoNo ratings yet

- Williamnagar 5 Min. Rainfall Data of August 2017Document408 pagesWilliamnagar 5 Min. Rainfall Data of August 2017Harish Kumar MahavarNo ratings yet

- Waste Weir Gate EstimateDocument2 pagesWaste Weir Gate EstimateHarish Kumar MahavarNo ratings yet

- Kodaikanal Weir GateDocument32 pagesKodaikanal Weir GateHarish Kumar MahavarNo ratings yet

- Methods of Discharge CalculationDocument3 pagesMethods of Discharge CalculationHarish Kumar MahavarNo ratings yet

- Methods of Discharge CalculationDocument3 pagesMethods of Discharge CalculationHarish Kumar MahavarNo ratings yet

- S. No. Chainage Structure Number Type SizeDocument46 pagesS. No. Chainage Structure Number Type SizeHarish Kumar MahavarNo ratings yet

- RRRKMDocument20 pagesRRRKMAnonymous HyOfbJ6No ratings yet

- Rainfall Data at The District Agricultural Office, Williamnagar For The Year 2018Document1 pageRainfall Data at The District Agricultural Office, Williamnagar For The Year 2018Harish Kumar MahavarNo ratings yet

- Agr Ins Corp Vac 2013Document8 pagesAgr Ins Corp Vac 2013Naveen Kumar PagadalaNo ratings yet

- Fci Paper1 ResultDocument854 pagesFci Paper1 ResultHarish Kumar MahavarNo ratings yet

- Standard General Condition 060919Document108 pagesStandard General Condition 060919Santosh iyerNo ratings yet

- FCI 2011 Website WriteupDocument3 pagesFCI 2011 Website WriteupHarish Kumar MahavarNo ratings yet

- ScheduleDocument8 pagesScheduleHarish Kumar MahavarNo ratings yet

- Chap. II) (Appendix 2.13Document23 pagesChap. II) (Appendix 2.13Harish Kumar MahavarNo ratings yet

- Cpa CoefficientsDocument1 pageCpa CoefficientsBridgetNo ratings yet

- Abstract For Bill Amount: Materials ConsumptionDocument3 pagesAbstract For Bill Amount: Materials ConsumptionHarish Kumar MahavarNo ratings yet

- Adjusting Your Study Habits During COVID: We'll Get Through This TogetherDocument4 pagesAdjusting Your Study Habits During COVID: We'll Get Through This TogetherHarish Kumar MahavarNo ratings yet

- Details of Price Escalation For Period Oct 2014 To Dec 2014Document5 pagesDetails of Price Escalation For Period Oct 2014 To Dec 2014Harish Kumar MahavarNo ratings yet

- Corrigendum T-273Document4 pagesCorrigendum T-273shivamdubey12No ratings yet

- Williamnagar 5 Min. Rainfall Data of August 2017Document408 pagesWilliamnagar 5 Min. Rainfall Data of August 2017Harish Kumar MahavarNo ratings yet

- Details of Price Escalation For Period Oct 2014 To Dec 2014Document5 pagesDetails of Price Escalation For Period Oct 2014 To Dec 2014Harish Kumar MahavarNo ratings yet

- Estimated Invoice: Invoice Number 130000347427 Invoice Date 12.05.2020Document1 pageEstimated Invoice: Invoice Number 130000347427 Invoice Date 12.05.2020Harish Kumar MahavarNo ratings yet

- Novel Cornavirus - Self Reporting Form For Travelers Arriving From 2019-Ncov Affected CountriesDocument1 pageNovel Cornavirus - Self Reporting Form For Travelers Arriving From 2019-Ncov Affected CountriesManik JainNo ratings yet

- Methods of Discharge CalculationDocument3 pagesMethods of Discharge CalculationHarish Kumar MahavarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bring Natural Light Further Into Your BuildingDocument2 pagesBring Natural Light Further Into Your BuildingEki RizkyandhaniNo ratings yet

- PW 371Document150 pagesPW 371Patrick SilberbauerNo ratings yet

- Title: Construction Technology Ii Course Work Report: Siti Nadiah Binti Mokhtar Noor Safika Faezan Binti AzahariDocument107 pagesTitle: Construction Technology Ii Course Work Report: Siti Nadiah Binti Mokhtar Noor Safika Faezan Binti AzahariSeid HodzicNo ratings yet

- Lennox MinisplitDocument46 pagesLennox MinisplitUbaldo PérezNo ratings yet

- Properties of Concrete With Coconut Shell and Fallen Leaves As Aggregate ReplacementBy Nadine Marie Silva and Noel Calatrava Jr.Document2 pagesProperties of Concrete With Coconut Shell and Fallen Leaves As Aggregate ReplacementBy Nadine Marie Silva and Noel Calatrava Jr.Nadz Silva-Soriano100% (2)

- 4880 AnsiDocument0 pages4880 AnsiabualamalNo ratings yet

- ABM Panel Installation & Trim Guide: A B Martin A B MartinDocument14 pagesABM Panel Installation & Trim Guide: A B Martin A B Martingleber_1No ratings yet

- Buildind Model Estimate With All Data Excel With All Links SSR2017-18 (MPP Building)Document16 pagesBuildind Model Estimate With All Data Excel With All Links SSR2017-18 (MPP Building)Srinivas PNo ratings yet

- Special Concrete & MortarDocument15 pagesSpecial Concrete & MortarKalmesh U PeerannavarNo ratings yet

- Pratik Industrial TranningDocument21 pagesPratik Industrial TranningGopal mutkekarNo ratings yet

- Progress Summary: No Work Package Contractor Progres Percentage (%) Plan Actual DeviationDocument43 pagesProgress Summary: No Work Package Contractor Progres Percentage (%) Plan Actual DeviationfajarbamNo ratings yet

- Adapting Traditional Building ElementsDocument33 pagesAdapting Traditional Building Elementsic3ic3babyNo ratings yet

- Philippine Municipality Approves Drainage Improvement ProjectDocument19 pagesPhilippine Municipality Approves Drainage Improvement ProjectEdison G. CaluzaNo ratings yet

- Solar Heat Gain Calculation MethodsDocument8 pagesSolar Heat Gain Calculation MethodsShravanNo ratings yet

- Spalling of Concrete Prevention & RepairDocument3 pagesSpalling of Concrete Prevention & Repairr_borg100% (1)

- Multideck 60-V2: - Concrete Volume SavingsDocument18 pagesMultideck 60-V2: - Concrete Volume Savingsdexterbox1No ratings yet

- Smoke Control and Day To Day Ventilation For Multi-Storey Residential BuildingsDocument20 pagesSmoke Control and Day To Day Ventilation For Multi-Storey Residential BuildingsThanh Nguyen Ngoc100% (1)

- Me115 2 3T 2022 2023 Air Conditioning System Design Project PDFDocument2 pagesMe115 2 3T 2022 2023 Air Conditioning System Design Project PDFHaze GessoNo ratings yet

- Manar Al Omran Company Branch: Fuj Sales Exeutive: Eng. Muhammad GamalDocument4 pagesManar Al Omran Company Branch: Fuj Sales Exeutive: Eng. Muhammad GamalAbdelrahman ElkhollyNo ratings yet

- Masonry Designer S Guide PDFDocument863 pagesMasonry Designer S Guide PDFdrfkamalodeenNo ratings yet

- Section 4: HVAC Systems & Indoor Air Quality: 4.1 OverviewDocument6 pagesSection 4: HVAC Systems & Indoor Air Quality: 4.1 OverviewMarschall Nuñez GrandisonNo ratings yet

- Rail Over Bridge (ROB)Document36 pagesRail Over Bridge (ROB)sachinNo ratings yet

- National Government Office: Architectural Design Site PlanningDocument8 pagesNational Government Office: Architectural Design Site PlanningAcance EscaNo ratings yet

- FiAM Intumescent Acoustic MasticDocument2 pagesFiAM Intumescent Acoustic MasticPETYTH AIMENo ratings yet

- Cabro Paving BlocksDocument5 pagesCabro Paving BlocksVincent Odhiambo Odhiambo100% (3)

- Moment Frames PDFDocument49 pagesMoment Frames PDFasmitha singhNo ratings yet

- BAMBOO & WIRE-NETTING WORKSDocument4 pagesBAMBOO & WIRE-NETTING WORKSAjithkumarNo ratings yet

- Typical Detail of TrussDocument1 pageTypical Detail of TrussJoshua John Lopez JulioNo ratings yet

- QC Checklist For Block WorksDocument1 pageQC Checklist For Block WorksRsjBugtongNo ratings yet

- Catalogue For OBON ProductsDocument33 pagesCatalogue For OBON ProductsRestoderia CuisineNo ratings yet