Professional Documents

Culture Documents

Intelligent Photoelectric Smoke Sensors

Uploaded by

mubs73Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Intelligent Photoelectric Smoke Sensors

Uploaded by

mubs73Copyright:

Available Formats

INSTALLATION AND MAINTENANCE INSTRUCTIONS

CONVOY ©

SECURITY

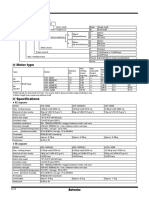

YT202, YT202T

Intelligent Photoelectric Smoke Sensors

Used instead of Honeywell, System Sensor, Notifier, Johnson Controls

Convoy Security Honeywell System Sensor Notifier Johnson Controls

YT202 TC806A1037,TC906 ZM992, 2251B, 2551 ND682,SDX-751 2251J,2551J

YT202T 2251TB,2551T

SPECIFICATIONS

Operating Voltage Range: 15 to 32 VDC

Standby Current: 300µA @ 24 VDC (one communication every 5 seconds with LED blink enabled)

Maximum Alarm Current (LED on: ) 2.5 mA @ 24 VDC

Operating Humidity Range: 10% to 93% Relative Humidity, Non-condensing

Operating Temperature Range: 32°F to 120°F (0°C to 49°C)

Heat Sensor: 135°F Fixed Temperature Electronic Thermistor (only YT202T)

Height: 2.3˝ (59 mm) installed in Base

Diameter: 4.1˝ (105 mm)

Weight: 4.6 oz. (130 g)

BEFORE INSTALLING 3. Install the sensor into the sensor base. Push the sensor

This sensor must be installed in compliance with the into the base while turning it clockwise to secure it in

control panel system installation manual. The installation place.

must meet the requirements of the Authority Having 4. After all sensors have been installed, apply power to

Jurisdiction (AHJ). Sensors offer maximum performance the control unit and activate the communication line.

when installed in compliance with the National Fire 5. Test the sensor(s) as described in the TESTING section

Protection Association (NFPA); see NFPA 72. of this manual.

GENERAL DESCRIPTION Figure 1. Wiring diagram:

Models YT202, YT202T are plug-in type photoelectronic

smoke and heat sensors with addressable analog

Fire Alarm Control Panel

communications. The sensors transmit an analog Loop(+)

Honeywell Intelligent

representation of smoke density or temperature over a

communication line to a control panel. Inside MCU’s

EEPROM keep the sensor’s address that can be set by a

portable Address setting device.

Two LEDs on the sensor are controlled by the panel to

S S

indicate sensor status. AB AB

Models YT202T combine a photoelectronic sensing Loop(-)

chamber and 135°F (57.2°C) fixed temperature heat Loop(-)

Loop(+) OPTIONAL RETUREN LOOP

detector.

The YT202, YT202T require compatible addressable

communications to function properly. Connect these

sensors to listed-compatible control panels only. CAUTION

WIRING GUIDE Dust covers provide limited protection against

All wiring must be installed in compliance with the airborne dust particles during shipping. Dust covers

National Electrical Code, applicable local codes, and any must be removed before the sensors can sense smoke.

special requirements of the Authority Having Jurisdiction. Remove sensors prior to heavy remodeling or

Proper wire gauges should be used. The installation wires construction.

should be color-coded to limit wiring mistakes and ease

system troubleshooting. Improper connections will TAMPER-RESISTANCE

prevent a system from responding properly in the event of Models YT202, YT202T include a tamper-resistant

a fire. capability that prevents their removal from the bracket

Remove power from the communication line before without the use of a tool.

installing sensors. TESTING

1. Wire the sensor base per the wiring diagram, Figure 1. Before testing, notify the proper authorities that the

2. Set the desired address by portable address setting system is undergoing maintenance, and will temporarily

device. be out of service. Disable the system to prevent unwanted

YT202Manual Page 1 of 2 ©2008 Convoy Security

alarms. plastic housing. The detector will reset only after it has

All sensors must be tested after installation and had sufficient time to cool. Make sure both thermistors

periodically thereafter. Testing methods must satisfy the are tested individually.

Authority Having Jurisdiction (AHJ). Sensors offer A sensor that fails any of these tests should be cleaned as

maximum performance when tested and maintained in described under CLEANING, and retested. If the sensor

compliance with NFPA 72. fails after cleaning, it must be replaced.

The sensor can be tested in the following ways: When testing is complete, restore the system to normal

A. Smoke Entry test: Aerosol Generator (Gemini 501) operation and notify the proper authorities that the system

The GEMINI model 501 aerosol generator can be used is back in operation.

for smoke entry testing. Set the generator to represent

4%/ft to 5%/ft obscuration as described in the GEMINI CLEANING

501 manual. Using the bowl shaped applicator, apply Before removing the detector, notify the proper

aerosol until the panel alarms. Additionally, canned authorities that the smoke detector system is undergoing

aerosol simulated smoke (canned smoke agent) may be maintenance and will be temporarily out of service.

used for smoke entry testing of the smoke detector. Tested Disable the zone or system undergoing maintenance to

and approved aerosol smoke products are the Smoke prevent unwanted alarms.

Detector Tester model 25S available from Home 1. Remove the sensor to be cleaned from the system.

Safeguard Industries and Chekkit Smoke Detector Tester 2. Remove the sensor cover by pressing firmly on each

models CHEK02 and CHEK06 available from SDi. of the four removal tabs that hold the cover in place.

When used properly, the canned smoke agent will cause 3. Vacuum the screen carefully without removing it. If

the smoke detector to go into alarm. Refer to the further cleaning is required continue with Step 4,

manufacturer’s published instructions for proper use of otherwise skip to Step 7.

the canned smoke agent. 4. Remove the chamber cover/screen assembly by

pulling it straight out.

5. Use a vacuum cleaner or compressed air to remove

CAUTION dust and debris from the sensing chamber.

Canned aerosol simulated smoke (canned smoke agent) 6. Reinstall the chamber cover/screen assembly by

formulas will vary by manufacturer. Misuse or overuse of sliding the edge over the sensing chamber. Turn until

these products may have long term adverse effects on the it is firmly in place.

smoke detector. Consult the canned smoke agent 7. Replace the cover using the LEDs to align the cover

manufacturer’s published instructions for any further and then gently pushing it until it locks into place.

warnings or caution statements. Make sure that the thermistors do not become bent

under the cover on YT202T models.

B. Direct Heat Method (Hair Dryer of 1000-1500 watts) 8. Reinstall the detector.

YT202T only 9. Test the detector as described in TESTING.

A hair dryer of 1000-1500 watts should be used to test the 10. Reconnect disabled circuits.

thermistors. Direct the heat toward either of the two 11. Notify the proper authorities that the system is back

thermistors, holding the heat source approximately 12 on line.

inches from the detector in order to avoid damaging the

Please refer to insert for the Limitations of Fire Alarm Systems

THREE-YEAR LIMITED WARRANTY

Convoy Security warrants its enclosed smoke detector to be free from defects in materials and workmanship under normal use and service for a period of three years

from date of manufacture. Convoy Security makes no other express warranty for this smoke detector. No agent, representative, dealer, or employee of the Company has

the authority to increase or alter the obligations or limitations of this Warranty. The Company’s obligation of this Warranty shall be limited to the repair or replacement of

any part of the smoke detector which is found to be defective in materials or workmanship under normal use and service during the three year period commencing with

the date of manufacture. After phoning Convoy Security’s technical support number for a Return Authorization number, send defective units postage prepaid to Convoy

Security local representative office. Please include a note describing the malfunction and suspected cause of failure. The Company shall not be obligated to repair or

replace units which are found to be defective because of damage, unreasonable use, modifications, or alterations occurring after the date of manufacture. In no case shall

the Company be liable for any consequential or incidental damages for breach of this or any other Warranty, expressed or implied whatsoever, even if the loss or damage

is caused by the Company’s negligence or fault. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or

exclusion may not apply to you. This Warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

FCC STATEMENT

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and,

if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause Harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

YT202Manual Page 2 of 2 ©2008 Convoy Security

You might also like

- MB 101 - InSTRUCTION MANUAL - Temperature Control Device - EnglezaDocument20 pagesMB 101 - InSTRUCTION MANUAL - Temperature Control Device - EnglezaGelu Bordea100% (2)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Wiring Circuit for a Lamp, Fan and SocketDocument3 pagesWiring Circuit for a Lamp, Fan and SocketamanNo ratings yet

- CCTV Pole EarthingDocument2 pagesCCTV Pole EarthingJoselin Leo100% (2)

- (Kurzweil) LCD Repair Guide PDFDocument20 pages(Kurzweil) LCD Repair Guide PDFOwen KalauNo ratings yet

- System Sensor 2151 & 2151T - Installation ManualDocument2 pagesSystem Sensor 2151 & 2151T - Installation ManualAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- 5151 - Manual - I56-5151 DHCDocument2 pages5151 - Manual - I56-5151 DHCmeribout adelNo ratings yet

- ND22051E (I) : EnglishDocument4 pagesND22051E (I) : EnglishAzita NaimiNo ratings yet

- Notifier SD 651 SD 651A Low Profie Plug in Smoke DetectorsDocument2 pagesNotifier SD 651 SD 651A Low Profie Plug in Smoke Detectorsด้วกส์ เอเชีย ไม่เคยเสียท่าใครNo ratings yet

- Sistema Contra IncendiosDocument4 pagesSistema Contra IncendiosMIGUEL ÁNGEL TOMÉNo ratings yet

- SECTION 16721 Fire Alarm SystemDocument8 pagesSECTION 16721 Fire Alarm Systemahmed fouadNo ratings yet

- Heat Detector Maintenance Testing ProcedureDocument2 pagesHeat Detector Maintenance Testing ProcedureAlvin MiraNo ratings yet

- SD365 and SD365-IV Intelligent Photoelectric Smoke Sensors: Installation and Maintenance InstructionsDocument2 pagesSD365 and SD365-IV Intelligent Photoelectric Smoke Sensors: Installation and Maintenance Instructionsjosue ivan Herrera de La LuzNo ratings yet

- VAR TEC FDR Series User ManualDocument2 pagesVAR TEC FDR Series User ManualmicrajacutNo ratings yet

- 7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsDocument2 pages7351 Intelligent High-Sensitivity Photoelectric Smoke SensorsAakash JunejaNo ratings yet

- FSP951 I56-6519Document2 pagesFSP951 I56-6519Marcelo Fabián OrtizNo ratings yet

- Manual 2WBDocument4 pagesManual 2WBAlfredo Zambra Alarcón Alias MorroNo ratings yet

- FSP-951T ManualDocument2 pagesFSP-951T Manualjohn hidalgoNo ratings yet

- H365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsDocument2 pagesH365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsAngel Jorge LLopiz IbarraNo ratings yet

- H365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsDocument2 pagesH365, H365-IV, H365R, H365R-IV, H365HT, and H365HT-IV Intelligent Programmable Temperature SensorsAlexamder CalleNo ratings yet

- 3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetDocument2 pages3102465-EN R003 KI-PD Intelligent Photoelectric Smoke Detector Installation SheetAlejandro coronelNo ratings yet

- Nfx-Opt / Nfxi-Opt: EnglishDocument4 pagesNfx-Opt / Nfxi-Opt: EnglishYves Sylvère YILINo ratings yet

- GDWP468 - DFC-FL-GA-ETDS-014-Smoke Detector-R1Document4 pagesGDWP468 - DFC-FL-GA-ETDS-014-Smoke Detector-R1Ankita vaghelaNo ratings yet

- Operation & Installation Manual For Alarm Panel M2Ap01Document20 pagesOperation & Installation Manual For Alarm Panel M2Ap01sholeh rozakNo ratings yet

- A) Fire Detection Cum Alarm SystemDocument11 pagesA) Fire Detection Cum Alarm SystemhomesxxxNo ratings yet

- Smoke DetectorDocument2 pagesSmoke DetectoratharvawazurkarNo ratings yet

- Gamewell E3 ManualDocument102 pagesGamewell E3 ManualJhonny López Alcalá0% (1)

- Gamewell 7100 Manual PDFDocument50 pagesGamewell 7100 Manual PDFHenrySiviraNo ratings yet

- PT295 LEL Sensor Rev 6Document31 pagesPT295 LEL Sensor Rev 6Hossam A.MoneimNo ratings yet

- Intelligent Photoelectric Smoke Detector Features Twin LED DetectionDocument2 pagesIntelligent Photoelectric Smoke Detector Features Twin LED DetectionSeagull MarineNo ratings yet

- I-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01Document2 pagesI-9101 Intelligent Combination Heat and Smoke Detector Issue 1.01HiteshgangeleNo ratings yet

- Manual - Panel Board - Tablero de Control RTQ RIELLOtech PrimeDocument20 pagesManual - Panel Board - Tablero de Control RTQ RIELLOtech PrimeLuis Fernando OrtigozaNo ratings yet

- Honeywell 5808w3 Install GuideDocument4 pagesHoneywell 5808w3 Install GuideAlarm Grid Home Security and Alarm Monitoring100% (1)

- FSP-951 Detector de FumaçaDocument2 pagesFSP-951 Detector de FumaçaRicardo Alves da SilvaNo ratings yet

- Notifier FSP 851 FSP 851t and FaptDocument2 pagesNotifier FSP 851 FSP 851t and FaptYhair Cortes SanchezNo ratings yet

- 1251BPI inDocument2 pages1251BPI inEufemiano Noble JrNo ratings yet

- NP200 Manu Eng 170823Document74 pagesNP200 Manu Eng 170823JRaulk PalomaresNo ratings yet

- KM260_inst_engDocument13 pagesKM260_inst_engFermalux FermaluxNo ratings yet

- Fire Alarm & Smoke Detection SystemsDocument9 pagesFire Alarm & Smoke Detection SystemsJalizco RuedaNo ratings yet

- Honeywell 5800pir Res Install GuideDocument2 pagesHoneywell 5800pir Res Install GuideAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- 10-3514-505-LSHS-02 LaserSense HSSD-2 Detector Installers HandbookDocument86 pages10-3514-505-LSHS-02 LaserSense HSSD-2 Detector Installers HandbookMohamed SayedNo ratings yet

- Hd912 ManualDocument2 pagesHd912 ManualrhomadonaNo ratings yet

- 020 FDO181 A6V10214488 A enDocument4 pages020 FDO181 A6V10214488 A enmaztonny SPVNo ratings yet

- PA25/3L Remote LED Indicator Installation SheetDocument8 pagesPA25/3L Remote LED Indicator Installation SheetArturo GuerreroNo ratings yet

- Scorpio Fire Control PanelDocument16 pagesScorpio Fire Control PanelJORGE ENRIQUE ARANGONo ratings yet

- 780HT - Catalytic Gas Detector PDFDocument48 pages780HT - Catalytic Gas Detector PDFinelecstarNo ratings yet

- NOTIFIER Addressable Multi-Criteria SMART2 Detector SpecificationDocument2 pagesNOTIFIER Addressable Multi-Criteria SMART2 Detector Specificationnambi.kumresan1No ratings yet

- 133 - I56-3388-004 Nfx-OptDocument4 pages133 - I56-3388-004 Nfx-OptYves Sylvère YILINo ratings yet

- 10-3514-505-STHS-03 Stratos HSSD-2 Installers handbookDocument86 pages10-3514-505-STHS-03 Stratos HSSD-2 Installers handbookRizwan IqbalNo ratings yet

- 5809-Detector termico inalambricoDocument2 pages5809-Detector termico inalambricochristian yelpoNo ratings yet

- Manual ChimeneaDocument16 pagesManual ChimeneaAntonio MontemayorNo ratings yet

- 10-3512-505-LS10-02 LaserSense 100 Installers HandbookDocument56 pages10-3512-505-LS10-02 LaserSense 100 Installers HandbookMohamed SayedNo ratings yet

- SA8023 360 Suite Reference ManualDocument129 pagesSA8023 360 Suite Reference ManualpqpnbnrmNo ratings yet

- FHSD82xx-Xx Instrukcja Instalacji enDocument84 pagesFHSD82xx-Xx Instrukcja Instalacji enMohamed SayedNo ratings yet

- Installation and Maintenance Instructions For Model 2351E Low Profile Photoelectronic Smoke DetectorDocument1 pageInstallation and Maintenance Instructions For Model 2351E Low Profile Photoelectronic Smoke Detectorharsha dtNo ratings yet

- Bharat Sanchar Nigam Ltd. Protection Engineering Instructions Fire A/T-001Document6 pagesBharat Sanchar Nigam Ltd. Protection Engineering Instructions Fire A/T-001Rajesh PorwalNo ratings yet

- 01 Tech. Spec Int. Fire Detection System 20230624Document15 pages01 Tech. Spec Int. Fire Detection System 20230624Jaydeep ParmarNo ratings yet

- Addressable Smoke and Heat Detector Installation GuideDocument2 pagesAddressable Smoke and Heat Detector Installation GuideAdrian Oprisan100% (1)

- AMS-220/220T: Addressable Smoke DetectorDocument4 pagesAMS-220/220T: Addressable Smoke DetectorCarlosNo ratings yet

- Owner Manual for Trane CFEB Chilled Water Fan Coil SystemsDocument16 pagesOwner Manual for Trane CFEB Chilled Water Fan Coil SystemssoldatechNo ratings yet

- AHU Instruction - BookletDocument12 pagesAHU Instruction - BookletShahNo ratings yet

- I1 PureGUARD 6 Digital Alarm AIBDocument36 pagesI1 PureGUARD 6 Digital Alarm AIBdan singh choudharyNo ratings yet

- Sensepoint XCD TechMan MAN0873 Iss8 0913 EMEAIDocument84 pagesSensepoint XCD TechMan MAN0873 Iss8 0913 EMEAImusajcNo ratings yet

- Toshiba Product Guide: Bringing You The OFDocument4 pagesToshiba Product Guide: Bringing You The OFmubs73No ratings yet

- Current Feedback Op Amp Applications Circuit Guide: Summing AmplifierDocument9 pagesCurrent Feedback Op Amp Applications Circuit Guide: Summing Amplifiermubs73No ratings yet

- Ac DC Coil Codes Ei Coil Upgrade AddersDocument30 pagesAc DC Coil Codes Ei Coil Upgrade Addersmubs73No ratings yet

- Smoke Detector GuardDocument2 pagesSmoke Detector Guardmubs73No ratings yet

- Fencing System: Lesson 3Document13 pagesFencing System: Lesson 3mubs73No ratings yet

- Metasys® Serial CardDocument1 pageMetasys® Serial Cardmubs73No ratings yet

- Chapter-3 Op AmpDocument19 pagesChapter-3 Op Ampmubs73No ratings yet

- 19-0431 Rev 2 8/01Document12 pages19-0431 Rev 2 8/01mubs73No ratings yet

- D I G I T A L T H y R Istor Power Controllers (SCR)Document4 pagesD I G I T A L T H y R Istor Power Controllers (SCR)mubs73No ratings yet

- Op Amp Circuit Collection - National SemiconductorDocument33 pagesOp Amp Circuit Collection - National Semiconductorkok6No ratings yet

- General InformationDocument2 pagesGeneral Informationmubs73No ratings yet

- Two Ics Convert 4-20ma Signal To 0-5v OutputDocument1 pageTwo Ics Convert 4-20ma Signal To 0-5v Outputmubs73No ratings yet

- Intelligent Fire Control PanelsDocument2 pagesIntelligent Fire Control Panelsmubs73No ratings yet

- Metasys® Ifc2-3030Document2 pagesMetasys® Ifc2-3030mubs73No ratings yet

- Nova-5000 Detection & Control SystemDocument2 pagesNova-5000 Detection & Control Systemmubs73No ratings yet

- Intelligent Duct Smoke DetectorsDocument1 pageIntelligent Duct Smoke Detectorsmubs73No ratings yet

- Intelligent Fire Control PanelsDocument2 pagesIntelligent Fire Control Panelsmubs73No ratings yet

- Life Safety SolutionsDocument8 pagesLife Safety Solutionsmubs73No ratings yet

- Metasys® System Ul® 864 Uukl Ninth Edition SmokeDocument262 pagesMetasys® System Ul® 864 Uukl Ninth Edition Smokemubs73No ratings yet

- A Sierra Monitor CompanyDocument50 pagesA Sierra Monitor Companymubs73No ratings yet

- Noti - Fire - NettmDocument8 pagesNoti - Fire - Nettmmubs73No ratings yet

- Dap3 Metasys n2 PointsDocument8 pagesDap3 Metasys n2 Pointsmubs73No ratings yet

- Afp-200 Operators ManualDocument10 pagesAfp-200 Operators Manualmubs73No ratings yet

- Slave Digital Alarm CommunicatorDocument3 pagesSlave Digital Alarm Communicatormubs73No ratings yet

- Ax Series Intelligent I - o Module051208 - 100822Document2 pagesAx Series Intelligent I - o Module051208 - 100822mubs73No ratings yet

- Usdot RegulatedproductsDocument115 pagesUsdot Regulatedproductsmubs73No ratings yet

- Protocol DriverDocument7 pagesProtocol Drivermubs73No ratings yet

- Afp-200 Fire Panel ApplicationDocument20 pagesAfp-200 Fire Panel Applicationmubs73No ratings yet

- TrueAlarm Analog SensingDocument4 pagesTrueAlarm Analog Sensingmubs73No ratings yet

- Gpd150-A N-Max Abs Electrical 1Document1 pageGpd150-A N-Max Abs Electrical 1apingNo ratings yet

- IEC SYSTEM FOR CONFORMITY TESTING AND CERTIFICATION OF ELECTRICAL EQUIPMENT: TESTING AND MEASURING EQUIPMENT/ALLOWED SUBCONTRACTING FOR TERRESTRIAL PHOTOVOLTAIC (PV) MODULESDocument6 pagesIEC SYSTEM FOR CONFORMITY TESTING AND CERTIFICATION OF ELECTRICAL EQUIPMENT: TESTING AND MEASURING EQUIPMENT/ALLOWED SUBCONTRACTING FOR TERRESTRIAL PHOTOVOLTAIC (PV) MODULESVenkataramanan SNo ratings yet

- Cooling Only (50Hz) : RR SeriesDocument290 pagesCooling Only (50Hz) : RR SeriesstevenloNo ratings yet

- Power Control System: SectionDocument123 pagesPower Control System: Sectionjair Hernandez100% (1)

- History of Computers: From Abacus to AIDocument8 pagesHistory of Computers: From Abacus to AIamihaninternetshop aisNo ratings yet

- AFT-2 Equalizing Check ValvesDocument25 pagesAFT-2 Equalizing Check ValvesHassane AmadouNo ratings yet

- ECP Safe T Pull SSB-DIP (2019)Document2 pagesECP Safe T Pull SSB-DIP (2019)Guang ChenzNo ratings yet

- AK-2 Series 2-Phase Stepper Motors and DriversDocument3 pagesAK-2 Series 2-Phase Stepper Motors and DriversEdson DinizNo ratings yet

- EnerpacDocument1 pageEnerpachenry vegaNo ratings yet

- Instructions For Installation, Operation and Maintenance of Magnum SB Insulated Case Low Voltage Power Circuit BreakersDocument70 pagesInstructions For Installation, Operation and Maintenance of Magnum SB Insulated Case Low Voltage Power Circuit BreakersedgarNo ratings yet

- Forecast Stock 0802Document392 pagesForecast Stock 0802api-3802780No ratings yet

- Prince Prince Prince Prince Prince: Pressure SwitchesDocument2 pagesPrince Prince Prince Prince Prince: Pressure Switchesersanjeeb_456100% (1)

- MAT DS 0055 Spreader FeedersDocument2 pagesMAT DS 0055 Spreader FeedersMoey AhmedNo ratings yet

- 8-1324-7 Pipe Class FC-7Document2 pages8-1324-7 Pipe Class FC-7Fredy Vázquez VelázquezNo ratings yet

- 1235E SheetDocument2 pages1235E Sheetsammsnead100% (1)

- KNX td002 - en PDocument184 pagesKNX td002 - en PNelsonNo ratings yet

- 220KV Line Spare ListDocument30 pages220KV Line Spare ListUmamaheshwarrao VarmaNo ratings yet

- 03 Instruction ManualDocument1 page03 Instruction ManualjNo ratings yet

- Jupiter BT2 ENDocument61 pagesJupiter BT2 ENkędzierzawyNo ratings yet

- KX-TA308, KX-TA616 Manual de InstalareDocument268 pagesKX-TA308, KX-TA616 Manual de InstalareBlue SeekerNo ratings yet

- TM Malaysia MSAN Physical ChecklistDocument13 pagesTM Malaysia MSAN Physical Checklistzamricepu0% (1)

- Aptomat (MCCB, MCB), Contactor LS (LG)Document36 pagesAptomat (MCCB, MCB), Contactor LS (LG)Lê Duy HiệuNo ratings yet

- IR270Document2 pagesIR270JULIETH PAOLA CAMACHO HERNANDEZNo ratings yet

- SERIES 9100A Pumps and Dispensers Installation/Operation ManualDocument68 pagesSERIES 9100A Pumps and Dispensers Installation/Operation ManualEstacion AvenidaNo ratings yet

- Electrical Scope of WorkDocument3 pagesElectrical Scope of Workahmed essaNo ratings yet

- Applied Physics For Scientists and Engineers: Lab Report: Determine The Given High Resistance by Leakage MethodDocument5 pagesApplied Physics For Scientists and Engineers: Lab Report: Determine The Given High Resistance by Leakage MethodHasham AliNo ratings yet

- Install and operate packaged air conditioners safelyDocument10 pagesInstall and operate packaged air conditioners safelyWild AntNo ratings yet