Professional Documents

Culture Documents

Designing Ground Level Water Storage Tanks

Uploaded by

camagnacOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Designing Ground Level Water Storage Tanks

Uploaded by

camagnacCopyright:

Available Formats

Designing a Ground

Technical Note

level Storage Tank

No. RWS. 5.D.2

Under suitable circumstances, ground level storage tanks may be used to deliver water to users by gravity flow. Storage tanks are a very important part of a water system because they ensure that adequate quantities of water are available to meet demand. Storage tanks also help in preserving water quality. This technical note discusses the design of ground level storage tanks and offers suggestions for locating a suitable site, determining adequate capacity and selecting appropriate construction materials. Read the technical note carefully and attempt to adapt the suggestions to the local environment to ensure successful design of the storage tank. The design process should result in the following three items which should be given to the construction supervisor. 1. A map of the area showing the location of the storage tank in relation to the water source and the community. Include important landmarks, elevations, if known, and distances on the map. Figure 1 gives an example of the type of map which should be provided. 2. A list of all labor, materials and tools needed similar to Table 1. The list will help make sure that adequate quantities of materials are available to prevent construction delays. 3. A plan of the storage tank with dimensions shown as in Figure 2. The plan shows a side, top and end view.

Useful Definitions ALGAE - Tiny green floating in surface part of pond scum. HEAD - Difference tween the inflow water system. plants water; usually found may form

in water level beand outflow ends of a

Distribution System Elev: 620 1 -_-.-.i.-.-

Flgure 1. Location Map

Site Selection and Tank location The most Important consideration in the choice of a site for a storage tank The height of water is the elevation. stored, measured from the bottom of the tank, must produce sufficient head or pressure to enable water to flow The through a pipeline to the users. height needed is determined by the height of the taps in the system and the amount of pressure desired for the distribution system.

I Table 1. Sample Materials List

Item Labor Foreman Laborers Portland cement Clean sand and gravel Clean water Reinforcing rod Pipe for inlets, overflow and drain (PVC or steel) Screening and wire mesh for pipes Tar forms Boards and lumber Lubricating oil

Rocks, if masonry tank

Description

Quantity

Estimated

Coat

Supplies

Float valve (if needed) Cut-off valves Lock for manhole cover Iron for steps In tank Lumber and rafters, If wooden Cover Str"Ct"Pe Shingles Plywood Rope or string Nails, t1e wire Tools Shovels, picks and other tools Measuring tape Plumb line Hammer Saw Buckets Carpenters square Level bln or machine Mixing Pipe wrench Adjustable wrench Trowel Hoe Wheelbarrow Sieve dlgglng

tank

Total

Estimated

Cost

= ~ /

Manhole and cover

Side View --- - ----------___

L r E .cn I

Manhole and cover

Overflow

Width --~-

End View

--mm---Figure 2. Storage Tank Design

--_-

-----Top View

._____.

I-

\L

A general rule to follow is that small water systems should have at least 14m of pressure. This means that the bottom of the storage tank must be at least 14m higher than the highest A general rule is that the minitap. mum water level in the storage tank should be 20-4Om above the area served. Figure 3 shows a profile of a system. Note that the elevation of the highest tap is 210m and that the system is built for a minimum of 14m pressure. The ground storage is on a hill at an elevation of 230m which provides sufficient pressure to reach the highest tap in the community. If no location of suitable height is available, an elevated storage tank may be needed. For information of the design of elevated storage tanks see "Designing an Elevated Storage Tank," RWS.5.D.3. In order to save money, try to locate the storage tank as close as possible to the water source and the population being served. If possible, put it between the source and the population to limit the need for long lines of pipe. The location of storage shown in Figure 3 is distant from the of pump. This has the advantage drawing water from the pump and tank drum peak demand periods. For complete information about the design of water transmission lines, the choice of pipe, and head losses due to friction, see "Designing a Transmission Main, RWS.4.D.3 and "Designing Community Distribution Systems," RWS.4.D.4. Tank Capacity The capacity of the storage tank is important for the efficient operation of a water supply system. The tank should be large enough to store sufficient water to meet both average and peak daily demands. When designing a storage tank keep in mind that demand for water varies during the year. In the hotter months, people use more water than in cooler months and on certain religious or cultural occasions water use may increase. The first step in determining storage capacity is calculating the demand for water in the community. Follow the steps below in estimating demand.

\ Figure 3. Distribution

System with Ground Storage

Table 2. Population

Growth Factors

1. Determine the population of the Use census data or initiate community. a survey to obtain population figures. Check past records to determine the rate of population growth over the years. If funds permit, the storage tank should be designed to last for twenty-five years. Therefore, use the estimated population for 25 years in the future to determine demand for water. Use the growth factors in Table 2 when estimating future population. If money is short, the storage tank can be sized to serve only the current population and the size Increased later on, if necessary. For example, the present population of a community Is approximately 1300 and it has been growing at a rate of 3 percent per year. To determine the population in 25 years multiply 1300 by the population growth factor 1.81 found in the row marked 20 and the 3 percent column in Table 2. Population Population

2400.

= 1300 x 1.81 = 2350 or approximately for a

The reservoir should be designed population of 2400 people.

2. Once the population is known, the demand for water can be calculated. Demand can be estimated by considering the type of distribution system used. Table 3 shows estimated water consumption rates for different types of distribution arrangements. Another important factor affecting demand is the use of water for purposes other than household drinking and cleaning. If the community has hotels and restaurants or if animals will be watered from the public system consumption figures would reflect these uses. Table 4 shows estimated water use for various institutions and for animals. Use these figures when designing the capacity of the reservoir. The total daily demand for water can be calculated using Worksheet A. The calculations are done for a population of 2400 people in a town that has a small hospital with twenty beds, one hotel for 75 people and two schools. A large chicken farm with 5000 chickens also uses water from the public system. It is estimated that 40 percent of the population will be served by multiple taps, 35 percent by single taps in the yard and 20 percent by standpipe. Five percent will have no service. 3. Once the total daily demand is determined, peak demand should be considered. Peak demand is the highest rate of demand during the day. Usually peak demand occurs during the morning when people get up to begin the day and in the early evening after work is completed. Peak demand is estimated by adding 20-40 percent to average daily demand. Multiply the average daily demand by 1.2 or 1.4. For example, Average day = 120000 liters/day = 144000

Table 3. Estimated Water Consumption

Type of Water Supply Average water COnaumptlon (Liters/Capita/Day)

(Liters/Capita/Day)

Range

Community water point (i.e., well, spring, public standpipe) At distance At distance Village Standpipe well 1000, 500-1000, (250m) or 7 10 12

15 40

;;I:;

IO-15 10-20 20-60

(250m)

Yard connection s1ng1e tap nouse connection (multiple taps) \ /

70

50-120

(or more) /

Table 4. Water Use Requirements

Category Typical Water (Liters/Day) 15-30 per pupil Use

Schools Hospital (with (without Clinics Hotels Restaurants Office Bus Station Livestock* Cattle Horses Sheep Pigs Poultry* Chickens and Mules laundry) laundry)

200-300 120-220 15-30 80-120 60-90 25-40 15-20

per per per per per per per

bed bed patient guest seat person user

25-35 20-25 15-25 lo-15

per per per per

head head head head

Peak day = 1.2 liters/day

x 120000

0.15-0.25 of

per

head a /

A general rule to follow is that the capacity of the storage tank should be 20-40 percent of the peak day water demand. With a peak daily demand of 144000 liters, the capacity of the tank should be at least 30m3: 144000 liters x .2 = 30000 liters. At the 40 percent value, the tank would be 58m3: 144000 liters x .4 = 58000 liters. In this of between 40case, a reservoir

*If at all possible, use public supply for livestock should be avoided. \

water from and poultry

50m3 would be needed to meet peak A possible design size would demand. For this capacity be 5.5m x 4m x 2.3m. the water height in the tank tank, should be at least 2m and some space should be available between the high water level and top of the tank.

Tank Design Ground level storage tanks are generally made from reinforced concrete, masonry or brick depending on the materials available In the area and the skills of the local people. Steel tanks may be purchased. Reinforced concrete is used in many areas. Its advantages are that it provides a very sturdy watertight structure that will last many years, and it uses less concrete than mass concrete structures which reduces construction costs. A disadvantage of using a reinforced structure is that steel, lumber for forms and skilled labor and supervision are needed to build the tank. Neither the materials nor the expertise may be affordable or available; if not, an alternative structure design should be chosen. If large building stone is available, the tank can be built of masonry. When building with masonry, no forms are necessary and construction is generally easier. Masonry tanks are not watertight, however. For best results, make thin masonry walls and fill In between them with concrete as shown in Figure 4.

The storage tanks can be built either above or partially or completely below ground. Underground structures provide added support for the walls. If soil conditions permit and elevation is sufficient, a storage tank partially or totally underground is recommended. Where such a tank cannot be Installed, at least build the form work In the ground for support. If a steel tank is purchased, the tank will be placed directly on a concrete slab on the surface of the ground. Steel tanks provide good storage but may not be feasib-le in many places due to their cost. All tanks must have covers. In some cases, reinforced concrete is used but forms are expensive and construction difficult. Cast-in-place roofing may not be possible. A concrete cover can be built by casting several sections ;;z fY&ing them together on the top of See Figure 5. The advantage of casting in sections is that the smaller sections can be cast at ground level and lifted into place.

CROSS-SECTION

Cover sections Supporting wall for - cover of large tank

Cover \

END VIEW

/cover

section

Concrete mortar on

oncrete foundation and floor

Forms full 01 concrete, troweled smooth

Form half full of concrete, reinforcing bars in place Wooden forms

Figure 4. Example of Mass Concrete Wall Construction

Figure 5. Casting Cover Sections

A wooden roof structure can be made with shingles, slate, or roofing tar placed on it to make it watertight. Roofing structures follow the general design pattern for house roofs and should extend well beyond the ends of the tank so that rain runs away from the structure. All ground level storage should be designed with the features. See Figure 6. tanks following

Overflow and vent :

Manhole

Manholes and Tightly Fitting Manhole Manholes with raised covers Covers. They should be installed in each tank. prevent the entrance of dust, debris and sunlight which is a major factor in the growth of algae. The manholes should have a diameter of 0.8-lm, sufficient to allow a person access to the tank for cleaning. A screened ventilation Ventilation. pipe should be installed to allow air to escape from the tank when water enters. The pipe should be screened so bats or debris can that no insects, enter the storage tank. Inlet, Outlet, Overflow and Drain. The inlet pine should be located near the bottom-of the tank. In many cases, the same pipe acts as both intake and outlet. The end of the pipe should be screened and should be at least 150mm above the floor of the tank. Below the intake-outlet pipe, water is not able Instead, this to leave the reservoir. area acts as a settling zone for parPVC, or steel pipe ticles. Plastic, The choice can be used for the outlet. depends on availability and cost. The overflow pipe should be located above the expected high water level in the tank. The overflow pipe should be screened. Water that overflows from the tank should be moved away from it to prevent contamination and the accumulation of standing water in which Lay rock around mosquitoes can breed. the tank or line a small diversion ditch to move all water away from the The overflow pipe can also serve area. as an air vent.

Figure 6. Ground Level Storage Tank

A drain pipe should be installed at To ensure adethe bottom of the tank. quate drainage, slope the floor toward Install a drain pipe with a the drain. diameter large enough, perhaps 200mm, so that sediment can be flushed without clogging the pipe. To control Other Design Features. the level of water in the tank, the installation of a float valve is recommended. If a float valve is not used, the operator must be well trained to ensure that water is pumped to storage when needed and not wasted through the overflow. Small tanks can either be built as a 6 or single unit as shown in Figure divided into two sections as shown in the two Figure 7. A wall divides storage compartments and pipes and valves are arranged so that each can be This arrangement used separately. allows for continuous service when one One alternative side is being cleaned. is to build a single storage tank as in Figure 6 and make a wall strong enough to act as a partition if expansion is Another comdesired in the future. partment can be added when and if it is needed, and the cost can be postponed to a later date.

Where suitable conditions exist. ground level storage tanks are a good choice. They require a great deal of material for construction. Worksheet B shows the general calculations for a one compartment storage tank made of reinforced concrete. Using these calculations, determine the specific amounts needed and cost of all materials. The concrete mixture should be 1 part cement to 2 parts sand to 3 parts gravel (1:2:3) and 1Omm reinforcing bars laid in a grid pattern should be All bars used for the walls and cover. should be separated by 150mm. For all storage facilities, experienced builders are needed to do the work properly whether masonry tanks or reinforced tanks are built, construction expertise is essential. Never attempt construction without the expert advice of an engineer or builder.

I II

Worksheet A. Calculating

2400

1. Multiple

Water Demand

Population

taps in homes of 40% of population 40% x 2400 x 70 lpcd tap in yards or 35% of population 35% x 2400 x 40 lpcd for 20% of population

x 15 lpcd students 20% x 2400

67200 33600

7200

2. Single

3. Standpipe

4. 5.

Two schools Chickens

500 with 1000 x 20

lpcd lpcd laundry

2000 1000

3200 5625

(5000)

5000 x 0.2

6. Hospital

7.

with

20 beds without 20 x 160 lpcd

75 x 75 lwd

Hotel

75 guests Total

119825

iii;;:!,

Separating wall

compantenr

.. 9

Valves for compartment #2

.,.

Inlet

Drain valves

CROSS-SECTION

t

let

TOP VIEW

Figure 7. Storage Tank wlth Two Compartments

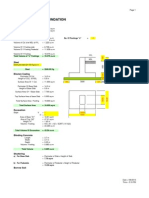

/ Worksheet B. Calculation of Quantity of Materials Needed for a Reinforced Concrete Reservolr (5Sm x 4m x 2.3 with Cover of Concrete Sections)

Total Volume of of of of of of Reservoir walls top two two = 0.2m cover1 front side = 5.7 walls walls including 1, 2, = x = --s.r Lf.0 x

4.2.

= length

x width

x height

Thickness 1. Volume 2. Volume 3. Volume 4. Volume 5. Total 6. Unmixed 7. Volume cement: Sand: Gravel: 8. Number 9. Volume 10. 11. Volume Number Length Sides 2 ends

x x d. 3 A.3

8.2. m = X/m3 x x = &'.7 0.z. ~7.2. x xz=.nJ x 2 = zm3 gt x 8.t = g.8 m3 m3

bottom

foundation 3,

volume volume of

= sum of

4, = am3 volume sand, gravel = - 4.L = Em3 = /3.m3 volume x 1.5 = /&Y-m3 or l/6, x 1.5 l/3, = cm3 1/2j2

of materials material x total x total

= total (cement,

each .167 .33

1:2:3 m3 cement = Lm3 gravel

volume volume volume

.Z'l?rm3 JTsrn3 Em3 =

sand

.5 x total of of 50k bags cement of

cement i

volume of cement per bag (.033mj/bag) = /yo bags bags = 3920 liters

= &m3

0.033m3 x m

of water of i =

= 28 liters/bag bars placed

reinforcing 150mm + height 5.5 + .15

at

150mm apart of bars needed3 /5.33 + 15.33 x 2 = ~ 5tx2=& x 2 = __4% + 18 x 2 = x2=*

f 150mm = number

+a+.

15 x 2 = 36.67+ .15 x 2 = 2L.67 $ .15

= 25.15+2.3: s.7 3 .15 + &

Top and Bottom J&&x2=Total Notes: = 320 bars

x 2 = jB

l~over overhangs 2To save cement, 3Rods are placed the edge; tips forcing rods In outside edge

O.lm on each side use a mixture of 1:2:4 so that last rod parrallel to the edge Is .75mm from of rods are 25mm from the end of walls; place relnforms so that they are one-third the distance from thr

/

Tochnlcal

3

Notea are part of a set of Water for the World materials produced under contract to the U.S. Agency for International Development by National Demonstration Water Project, Institute for Rural Water, and National Environmental Health Association. Artwork was done by Redwing Art Service. Technical Notes are intended to provide assistance to a broad range of people with field responsibility for village water supply and sanitation projects in the developing nations. For more detail on the purpose, organization and suggestions for use of Technical Notes, see the introductory Note in the series, titled Using Water for the World Technical Notes. Other pads of the Water for the World series include a comprehensive Program Manual and several Policy Perspectives. Further information on these materials may be obtained from the Development Information Center, Agency for International Development, Washington, DC., 20523, U.S.A. /

You might also like

- Multi-Level Basement Construction - A Dossier of The Londoner HotelDocument11 pagesMulti-Level Basement Construction - A Dossier of The Londoner HotelVictor OmotoriogunNo ratings yet

- Rules of Thumb For Steel StructuresDocument309 pagesRules of Thumb For Steel Structuresjayaraman3100% (1)

- Design Pile Foundations in ExcelDocument13 pagesDesign Pile Foundations in ExcelHeang LongsengNo ratings yet

- Urban Storm Drainage DesignDocument26 pagesUrban Storm Drainage Designsatria11No ratings yet

- Design of RC Building - ExerciseDocument6 pagesDesign of RC Building - Exercisesajeerala100% (1)

- Volume of Water Required, Distance, Flow Rate and Pressure. Water Reticulation System Should BeDocument2 pagesVolume of Water Required, Distance, Flow Rate and Pressure. Water Reticulation System Should BeMae Gillain Maquilan MilanaNo ratings yet

- Lux Simulation Report 10.8.2018wDocument12 pagesLux Simulation Report 10.8.2018wChi Kit PhoonNo ratings yet

- RC Raft Foundation (Bs8110) : Project Job RefDocument5 pagesRC Raft Foundation (Bs8110) : Project Job RefsitheeqNo ratings yet

- 7424 SBS Mezzanine Brochure 112019 UK EN PDFDocument24 pages7424 SBS Mezzanine Brochure 112019 UK EN PDFMoon SzDarknessNo ratings yet

- Circular Tank Slab DesignDocument3 pagesCircular Tank Slab DesigngwrmsaNo ratings yet

- Design of rectangular footing for column supportDocument5 pagesDesign of rectangular footing for column supportEldho GeorgeNo ratings yet

- Circular Tanks 1000m3Document42 pagesCircular Tanks 1000m3ARSENo ratings yet

- TG1 Scala Dynamic Cone Penetrometer Cone CalibrationDocument4 pagesTG1 Scala Dynamic Cone Penetrometer Cone Calibrationanthony100% (1)

- Raft Foundation (Shallow Foundation) Raft or Mat FoundationsDocument7 pagesRaft Foundation (Shallow Foundation) Raft or Mat FoundationsLiewKianHong100% (1)

- Types of EstimateDocument16 pagesTypes of EstimatesambhaviNo ratings yet

- Nalco Ash Pond CaseDocument10 pagesNalco Ash Pond CaseRocking Heartbroker DebNo ratings yet

- VBA Box Gutter DesignDocument2 pagesVBA Box Gutter DesignbradleyrobinsonNo ratings yet

- 8M-Digest VOL 6 PDFDocument52 pages8M-Digest VOL 6 PDFSamuel AcidriNo ratings yet

- BOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFDocument2 pagesBOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFVeena NageshNo ratings yet

- Pumping Stations Design Lecture 6Document45 pagesPumping Stations Design Lecture 6njvargascNo ratings yet

- Detailing StairsDocument7 pagesDetailing Stairselmerbarreras100% (1)

- Project Output ESTIMATEDocument21 pagesProject Output ESTIMATEedgezy07No ratings yet

- Calculation Summary of Pile FoundationDocument24 pagesCalculation Summary of Pile FoundationdedydarwisNo ratings yet

- Level Flat No.: Cold & Hot Water Services Feed Pipe Calculation ScheduleDocument2 pagesLevel Flat No.: Cold & Hot Water Services Feed Pipe Calculation ScheduleMario B. DaluNo ratings yet

- AAE Architects and Engineers Company ProfileDocument14 pagesAAE Architects and Engineers Company Profileharishram123456No ratings yet

- Paper On Design of Roof TrussDocument5 pagesPaper On Design of Roof TrussAmit Chapagain100% (1)

- TEDDS Engineering Library (AU)Document18 pagesTEDDS Engineering Library (AU)Chesho ChitoboloNo ratings yet

- How To Calculate Staircase Dimensions and Designs - ArchDailyDocument7 pagesHow To Calculate Staircase Dimensions and Designs - ArchDailyjcacho68No ratings yet

- Notes On Design of RCC ElementsDocument3 pagesNotes On Design of RCC ElementsrangarajanNo ratings yet

- Waffle SlabDocument3 pagesWaffle Slabnarotham_medi4108100% (2)

- 11705-Struct-Rev-A 200226 PDFDocument18 pages11705-Struct-Rev-A 200226 PDFcathyNo ratings yet

- Catalog Rainwater Harvesting SYSTEMDocument24 pagesCatalog Rainwater Harvesting SYSTEMSqualo80No ratings yet

- Steel Frame Design for Multi-Storey BuildingDocument76 pagesSteel Frame Design for Multi-Storey BuildingTony RenNo ratings yet

- Ernst Neufert Neufert Architects Data, Fourth Edition For IpadDocument6 pagesErnst Neufert Neufert Architects Data, Fourth Edition For Ipadahmed sayedNo ratings yet

- Sewer Design Report for Flood Control Structure RepairsDocument17 pagesSewer Design Report for Flood Control Structure RepairsMohd RafiqNo ratings yet

- Designing An Elevated Water Storage Tank For Developing CountriesDocument7 pagesDesigning An Elevated Water Storage Tank For Developing CountriesGreen Action Sustainable Technology Group100% (4)

- All Aluminium Windows and Doors to Match Soffit HeightsDocument12 pagesAll Aluminium Windows and Doors to Match Soffit HeightsVail Lunor100% (1)

- Project PDFDocument36 pagesProject PDFMable MathewNo ratings yet

- Lifts - Planning, Designing, and Installation Guide For Architects - Building and InteriorsDocument29 pagesLifts - Planning, Designing, and Installation Guide For Architects - Building and InteriorsJayathri PasanNo ratings yet

- Passive House Slab For Reactive Soils by Scott StewartDocument10 pagesPassive House Slab For Reactive Soils by Scott StewartScott StewartNo ratings yet

- Storage Tank Design Calculation SheetDocument2 pagesStorage Tank Design Calculation SheetTots HolaresNo ratings yet

- Quick-Connect Moment Connection For Portal Frame Buildings - An Introduction and Case StudiesDocument10 pagesQuick-Connect Moment Connection For Portal Frame Buildings - An Introduction and Case StudiesTuroyNo ratings yet

- Laboratory Manual Subject: Experiment #: Experiment Title: Objectives: Apparatus: ProcedureDocument2 pagesLaboratory Manual Subject: Experiment #: Experiment Title: Objectives: Apparatus: ProcedureJoffer GallamasoNo ratings yet

- Boq For Flarel Foundation: X-Sectional AreasDocument8 pagesBoq For Flarel Foundation: X-Sectional AreasLivian Teddy100% (2)

- Masterseal BC1822: A Non-Toxic Solvent Free High Build, Phenol Novolac Protective Epoxy Resin CoatingDocument3 pagesMasterseal BC1822: A Non-Toxic Solvent Free High Build, Phenol Novolac Protective Epoxy Resin CoatingAlexi ALfred H. Tago100% (1)

- Steel - Roof TrussDocument412 pagesSteel - Roof TrussMuhammad UsmanNo ratings yet

- 01 Boundary Wall - BrochureDocument6 pages01 Boundary Wall - BrochureTantan AñesNo ratings yet

- Cobiax Roof: Lightweight alternative to concrete roofsDocument2 pagesCobiax Roof: Lightweight alternative to concrete roofskomalNo ratings yet

- Training Report Rajasthan Housing BoardDocument13 pagesTraining Report Rajasthan Housing BoardDevendra SharmaNo ratings yet

- Scope of WorkDocument2 pagesScope of WorkRamakrishnaNo ratings yet

- Final Design Flood MitigationDocument44 pagesFinal Design Flood MitigationSiti Rosila Bt BaharinNo ratings yet

- Precast Concrete ConstructionDocument28 pagesPrecast Concrete ConstructionGirl in the CityNo ratings yet

- Engineering Calculation Sheet Consulting EngineersDocument21 pagesEngineering Calculation Sheet Consulting EngineersParthiban Arivazhagan100% (1)

- Mortar Finishes for Brickwork ProjectsDocument1 pageMortar Finishes for Brickwork ProjectsBiju_PottayilNo ratings yet

- Absolute Roughness of Pipe MaterialDocument3 pagesAbsolute Roughness of Pipe MaterialiuiuiooiuNo ratings yet

- Directional Drilling Calculation Example SolvedDocument5 pagesDirectional Drilling Calculation Example SolvedCHAN NYEINNo ratings yet

- "Prying9" - Aisc 9Th Ed. Prying Action Analysis ProgramDocument5 pages"Prying9" - Aisc 9Th Ed. Prying Action Analysis Programmarina10No ratings yet

- Lecture 8 Storage TanksDocument28 pagesLecture 8 Storage Tanksbaruhiye0020No ratings yet

- Reservoirs and Distribution SystemDocument10 pagesReservoirs and Distribution SystemShuvanjan Dahal100% (2)

- 42 Small Scale Irrigation DesignDocument4 pages42 Small Scale Irrigation DesignNiiteSajoNo ratings yet

- Listahang Tubig Info GraphicsDocument2 pagesListahang Tubig Info GraphicsJayjay JuanNo ratings yet

- Small Sewage Treatment Plants: CE Marking and RegulationsDocument12 pagesSmall Sewage Treatment Plants: CE Marking and RegulationsMashaelNo ratings yet

- Siliguri CDP Final Report 29april15Document296 pagesSiliguri CDP Final Report 29april15s_baishyaNo ratings yet

- Experiential Learning - Design 07 - CondominiumDocument23 pagesExperiential Learning - Design 07 - CondominiumLemuel Kim TabinasNo ratings yet

- Lebanon Country Programme Document 2010-2014Document12 pagesLebanon Country Programme Document 2010-2014Anca NedelcuNo ratings yet

- Estimation of SewageDocument14 pagesEstimation of SewageathirarejizachariahNo ratings yet

- PDFDocument304 pagesPDFvarun sNo ratings yet

- Himachal Pradesh Budget 2019-20 For HPAS and Other HP Govt ExamsDocument9 pagesHimachal Pradesh Budget 2019-20 For HPAS and Other HP Govt ExamsAditya ThakurNo ratings yet

- Sitara: Consult Pvt. LTDDocument18 pagesSitara: Consult Pvt. LTDblack webNo ratings yet

- Management of Wastewater Treatment Plants in SudanDocument13 pagesManagement of Wastewater Treatment Plants in SudanHusam AbdalrahmanNo ratings yet

- Ice and Water Sources Used For Commercial Ice Production, Sri LankaDocument1 pageIce and Water Sources Used For Commercial Ice Production, Sri Lankakolita kamalNo ratings yet

- Wabag Bioden: Nitrate Removal Biological Denitrifi Cation of Ground WaterDocument6 pagesWabag Bioden: Nitrate Removal Biological Denitrifi Cation of Ground WaterNguyen AnNo ratings yet

- Internship ReportDocument50 pagesInternship ReportJessy VijayanNo ratings yet

- Charlie Project - Revised Plumbing 20210927Document5 pagesCharlie Project - Revised Plumbing 20210927YesTaratNo ratings yet

- Solutions For Water PollutionDocument9 pagesSolutions For Water Pollutionvisukonidela100% (1)

- Rural Development FrameworkDocument99 pagesRural Development FrameworkSushanto Biswas75% (4)

- Building Utilities Plumbing 1Document4 pagesBuilding Utilities Plumbing 1Christian James TuazonNo ratings yet

- Cen TC 165Document5 pagesCen TC 165ck19654840No ratings yet

- Managing Water Scarcity Through Rainwater HarvestingDocument10 pagesManaging Water Scarcity Through Rainwater HarvestingTrisha Mae TrinidadNo ratings yet

- Rainwater Harvesting Guide for HomesDocument20 pagesRainwater Harvesting Guide for HomesSukesh VNo ratings yet

- Social Aspect TR4 Cidanau Dam Reg 1Document7 pagesSocial Aspect TR4 Cidanau Dam Reg 1Dwi CahyoNo ratings yet

- Status of Water Quality in India 2011Document211 pagesStatus of Water Quality in India 2011Zainy KhanNo ratings yet

- HLURB Guide Sectoral Planning StandardsDocument4 pagesHLURB Guide Sectoral Planning StandardsErnie GultianoNo ratings yet

- One WASH Program - Final PDFDocument206 pagesOne WASH Program - Final PDFDavid TabangNo ratings yet

- Presentation WTP Tce GandhinagarDocument36 pagesPresentation WTP Tce GandhinagarDhaval GadhiaNo ratings yet

- ArticlebsaDocument23 pagesArticlebsaRishi RajNo ratings yet

- Study BG 538 1 Demand PlanDocument22 pagesStudy BG 538 1 Demand Plansofianina05No ratings yet

- 23617950NRCP BackgrpundDocument2 pages23617950NRCP BackgrpundClock 9No ratings yet

- Quiz# 1 Answer Key Part1 - 2 - WatermarkDocument13 pagesQuiz# 1 Answer Key Part1 - 2 - WatermarkReyfel DescaNo ratings yet

- Training Manual-Piping: Piping Study Underground PipingDocument30 pagesTraining Manual-Piping: Piping Study Underground Pipingrazi khan100% (2)