Professional Documents

Culture Documents

Rotametros FVA 250

Uploaded by

ampowersidOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rotametros FVA 250

Uploaded by

ampowersidCopyright:

Available Formats

Variable area flowmeter F VA 250

Fig. 2 Flow tube/scale angle ___________________________________________________________ Fig. 1 F VA 250 variable area flow meter ___________________________________________________________

___ Note of application

The operator of these measuring instruments is responsible for suitability, proper use and corrosion resistance of the used materials with regard to the measuring material. It must be ensured that the materials selected for the flowmeter parts in contact with the medium are suitable for the used process media. No external loads may act on the meter. Provide a touch guard for surface temperatures of > 70C. This touch guard must be designed in a way that the max. allowable ambient temperature on the unit is not exceeded. The flowmeter may only be used within the pressure and voltage limits specified on the identification plate. Before replacing the measuring tubes, check that the unit is free of hazardous media and pressures. The measuring instruments are primarily designed for static loads.

___________________________________________________________

___ Application

The VA 250 variable area flowmeters with a standard length of 250 mm (9.84 inch) and a completely metal design can be used to measure many different types of liquids and gases passing through closed piping. The robust design means that they can also be used in rough conditions. Different types of flanges, liners and float materials satisfy the requirements of the pharmaceutical and chemical industries. The measured value is displayed directly on the scale, and output via a switch contact or as a current output. The main applications for the VA 250 can be found in the following fields: Chemical industry Water Power generation and distribution.

___________________________________________________________

___

Classification according to PED 97/23/EG Order No. 7ME58207ME5821xAxxx-xxxx xBxxx-xxxx xCxxx-xxxx xDxxx-xxxx xExxx-xxxx Permissible media Category

___ Special features

Standard design available at short notice Robust all-metal fitting with impact-resistant housing cover Can also be used for corrosive and flammable media Use possible at high pressures and temperatures Product and percentage scales Can be optionally fitted with heating and cooling sheaths Contamination-insensitive guiding of float. DN 15 DN 25 DN 50 DN 80 DN 100

___________________________________________________________

___ Design and mode of operation

The VA 250 operates like the other units in the VA range according to the variable-area flow tube principle: the flowing medium lifts the conical float in the flow tube. The annular gap is then increased until equilibrium exists between the buoyant force of the medium and the force due to the weight of the float. The height of the float is directly proportional to the flow quantity. The movement of the float is transmitted by a magnet to a slave magnet in the display unit outside the flow tube. The contacts or the electric remote sensor are controlled by a contact lug or a cam which is mounted on the pointer shaft.

Gases and group 1 Gases and group 1 Gases and group 1 Gases and group 1 Gases and group 1

liquids of fluid liquids of fluid liquids of fluid liquids of fluid liquids of fluid

Art. 3.3 Art. 3.3 III III III

Mecon GmbH Zieglerstrae 10 16 D-52078 Aachen

Phone +49(0)241 41369 0 www.mecon.de

Fax +49(0)241 41369 40 info@mecon.de

Page 1 to 7 Mecon 04/2005

Variable area flowmeter F VA 250

___________________________________________________________ ___________________________________________________________

___ Technical specification

Application Design and mode of operation Measuring principle Input Measuring range Pressure rating see page 1 see page 1 variable-area flowmeter see tables on page 3 PN10 (MWP 145 psi) to PN40 (MWP 580 psi) depending on version (see Tables on page 3 and 4) vertically upwards l/h, from 4.000 l/h (17,6 USgpm) in m/h vertical <80C (176F) <70C (158F) with contact display 2% of full-scale value ( 1,6% as option, but not for PTFE liner) max. 125C (257F) (300C (572F) as option)

___ Technical specification

F VA 251 (magnet spring contact) Switching principle Connection Max. switching frequency Max. rating Magnet spring contact, twin contact Appliance plug to DIN 43650 5/min AC 250V / 1A / 50VA DC 250V / 1A / 30W Rating data apply to resistive loads; a suppressor circuit is required for inductive loads 3% of full-scale value -20 to +70C (-4 to 158F)

Flow Dimension for measured variables Rated operating conditions Mounting Ambient temperature

Hysteresis Ambient temperature F VA251 (inductive contact) Switching principle Connection Rated voltage Self-inductance Self-capacitance

Medium conditions Accuracy Temperature of medium Viscosity limits Qmax [m3/h] ! 0,1 > 0,1 to 0,5 > 0,5 to 3 > 3 to 10 > 10 to 25 > 25 to 50 > 50 to 100 > 100 Design Flanges Material Fitting Float Wetted parts materials Degree of protection (display unit) Qmax [USgpm] ! 0,44 > 0,44 to 2,2 > 2,2 to 13 > 13 to 44 > 44 to 110 > 110 to 220 > 220 to 440 > 440

Inductive contact, single contact; twin contact as option PG 11 10..28V DC 500H 80 nF -20 to +70C (-4 to 158F)

Viscosity [mPa.s] (cp)

1,0 1,0 1,0 1,0 1,0 1,0 1,0 1,0

to to to to to to to

3,0 5,0 8,0 10 15 25 50

Ambient temperature without EX-protection F Va 252 (electric remote sensor, current output) Principle Connection Power supply Self-capacitance Short-circuit current Output 2-wire system 3-and 4-wire systems Load Ambient temperature without EX-protection

Rotation angle transmitter 2-, 3- or 4-wire system DC 12 to 30V <10 nF max. 160mA 4 to 20mA 0 to 20mA max. 900 at 30V

DIN, ANSI Stainless steel 1.4571/ 316Ti Stainless steel 1.4571/ 316Ti, Hastelloy, Titanium, Aluminium Stainless steel 1.4571/316Ti, PTFE, C22.8, Hastelloy depending on version IP65

-20 to +70C (-4 to 158F)

Fig. 3 F VA 252 rotation angle transmitter, connection diagrams

Mecon GmbH Zieglerstrae 10 16 D-52078 Aachen

Phone +49(0)241 41369 0 www.mecon.de

Fax +49(0)241 41369 40 info@mecon.de

Page 2 to 7 Mecon 04/2005

Variable area flowmeter F VA 250

___________________________________________________________

___ Measuring ranges for liquids

Version AF-S CF-S CF-K EF-H FF-P )

Wetted parts mat. Fitting

C22.8 mat.No. mat.No.1.4571/ mat.No.1.4571/ 1.4571/316Ti 316Ti 316Ti mat.No.1.4571/ mat.No.1.4571/ mat.No.1.4571/ 316Ti 316Ti 316Ti C22.8

PTFE/ Hastelloy C mat.No. 1.4571/ 316Ti

PTFE

mat.No.1.4571/316Ti

Flange

mat.No.1.4571/ mat.No.1.4571/ mat.No. 1.4571/ mat.No.1.4571/316Ti with PTFE liner 316Ti 316Ti 316Ti with PTFE liner Hastelloy PTFE

Float/flow mat.No.1.4571/ mat.No.1.4571/ mat.No.1.4571/ tube 316Ti 316Ti 316Ti Max.tem125C (257F) 125C (257F) 125C (257F) perature of optional 300C optional 300C optional 160C medium (572F) (572F) (320F) Nominal pressure DN15 to DN80/ DN15 to DN80/ DN15 to DN25 (1/2 to 3 inch): (1/2 to 3 inch): (1/2 to 1 inch): PN40 (580 psi) PN40 (580 psi) PN40 (580 psi) DN100 (4 inch): DN100 (4 inch): PN16 (232 psi) PN16 (232 psi)

80C (176F) PN16 (232 psi)

50C (122F)

PN16 (232 psi)

Connection DIN2501

DN 15 DN 25 DN 50 DN 80 DN 100

Full-scale value Flow tube l/h 16 25 40 63 100 160 250 400 630 1.000 1.600 2.500 4.000 6.300 10.000 16.000 20.000 25.000 40.000 50.000 63.000 100.000 (USgpm) (0,07) (0,11) (0,18) (0,28) (0,44) (0,7) (1,1) (1,76) (2,77) (4,4) (7,0) (11,0) (17,6) (27,7) (44) (70) (88) (110) (176) (220) (277) (440) A B C D E F G H J K L M N P Q R S T U V W X x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x x DN15-25 (1/2-1 inch) 250 (1,1) DN15-25 (1/2-1 inch) 400 (1,76) DN15-25 (1/2-1 inch) 630 (2,77) DN25 (1 inch) 1.000 (4,4) DN25 (1 inch) 1.600 (7,0) DN25 (1 inch) 2.500 (11,0) DN50 (2 inch) 4.000 (17,6) DN50 (2 inch) 6.300 (27,7) DN50 (2 inch) 10.000 (44)

Nominal diameter

l/h (Usgpm)

DN80-100 (3-4 inch)

25.000 (110)

1)

For the FF-P version, only the measuring ranges of the listed nominal diameters are possible Pressure loss mbar (psi) 60 (0,87) 60 (0,87) 90 (1,3) 160 (2,3) 240 (3,5)

Nominal diameter DN 15 (1/2 inch) DN 25 (1 inch) DN 50 (2 inch) DN 80 (3 inch) DN 100 (4 inch)

Measuring ranges and pressure losses for liquids (density "= 1kg/l (62,43 lb/cu.ft) and viscosity 1mPa.s(cp)) with standard scales. The dynamic range is always 1:10.

Mecon GmbH Zieglerstrae 10 16 D-52078 Aachen

Phone +49(0)241 41369 0 www.mecon.de

Fax +49(0)241 41369 40 info@mecon.de

Page 3 to 7 Mecon 04/2005

Variable area flowmeter F VA 250

___________________________________________________________

___ Measuring ranges for air

Version Wetted parts mat. Fitting CL-A mat.No. 1.4571/316Ti Aluminium mat.No.1.4571/ 316Ti mat.No.1.4571/ 316Ti CL-T mat.No.1.4571/ 316Ti, Titan CL-K mat.No.1.4571/ 316Ti EL-T PTFE/ Hastelloy C, Titanium mat.No. 1.4571/ 316Ti FL-R PTFE

mat.No..1.4571/ mat.No.1.4571/ 316Ti 316Ti mat.No.1.4571/ 316Ti

mat.No.1.4571/316Ti

Flange

mat.No.1.4571/ mat.No.1.4571/ mat.No.1.4571/316Ti with PTFE liner 316Ti 316Ti with PTFE liner mat.No.1.4571/ 316Ti 125C (257F) optional 160C (320F) DN15 to DN25 (1/2 to 1 inch) PN40 (580 psi) Titanium/ Hastelloy 80C (176F) PN16 (232 psi) PTFE

Float/flow tube

Aluminium/ mat.No.1.4571/ 316Ti

Titanium mat.No.1.4571/ 316Ti 125C (257F) optional 300C (572F) DN15 to DN80/ (1/2 to 3 inch): PN40 (580 psi) DN100 (4 inch): PN16 (232 psi)

Max. tempe125C (257F) rature of optional 300C (572F) medium Nominal pressure DN15 to DN80/ (1/2 to 3 inch): PN40 (580 psi) DN100 (4 inch): PN16 (232 psi)

50C (122F)

PN16 (232 psi)

Connection DIN2501

DN 15 DN 25 DN 50 DN 80 DN 100

Full-scale value Flow tube m/h (USgpm) 0,5 1,0 1,6 2,5 4,0 12,0 16,0 25,0 25,0 40,0 63,0 100,0 100,0 160,0 250,0 400,0 400,0 630,0 (0.294) (0.589) (0.942) (1.47) (2.35) (7.06) (9.42) (14.71) (14.71) (23.54) (37.08) (58.86) (58.86) (94.17) (147.1) (235.4) (235.4) (370.8) A B C D E F G H H J K L L M N P P Q X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X X

Nominal diameter DN 15 (1/2 inch) DN 25 (1 inch) DN 50 (2 inch) DN 80 (3 inch) DN 100 (4 inch)

Pressure loss mbar (psi) 40 (0,58) 40 (0,58) 65 (0,94) 80 (1,16) 80 (1,16)

Minimum inlet pressure mbar (psi) 500 (7,25) 100 (1,45) 100 (1,45) 100 (1,45) 100 (1,45)

Measuring ranges and pressure losses for air (pabs= 1,013 bar (14,69 psi) at T=20C (68F)). The dynamic range is 1:10 for each flow tube.

Mecon GmbH Zieglerstrae 10 16 D-52078 Aachen

Phone +49(0)241 41369 0 www.mecon.de

Fax +49(0)241 41369 40 info@mecon.de

Page 4 to 7 Mecon 04/2005

Variable area flowmeter F VA 250

___________________________________________________________

___ Installation and operating instructions

The main information for installation and startup is listed below. Further information can be obtained from VDI/VDE 3513, sheet 3, installation recommendations for variable area meters. Installation instructions The variable area meter is delivered protected in a PVC sleeve, and is ready for operation. It has been checked for correct functioning prior to delivery. Before installing, check that the float moves freely: the float must slide smoothly in the flow tube without sticking or tilting. The pointer must smoothly follow the movement of the float. In the rest position (zero flow), the pointer must point to the marked reference point (first scale line). In the end position of the float, the pointer must be positioned above the full-scale value. The variable area meter must be fitted into the piping vertically and without tension. Magnetic fields from other equipment may influence the result. If several variable area meters are installed next to one another, the following minimum distances must be observed between the main axes of the variable area meters: DN 15 to 50 ( to 2 inch): 250 mm (9.84 inch) DN 80 to 100 (3 to 4 inch): 400 mm (15.74 inch). The flange screws of the PTFE-lined fittings must only be tightened with the following maximum torques: DN 15 to 25 ( to 2 inch): 14 Nm DN 50 (2 inch): 25 Nm DN 80 (3 inch): 35 Nm DN 100 (4 inch): 42 Nm Interference-free inlet and outlet pipe sections are not usually required. However, additional measures (inlet pipe sections, flow stabilizers) may be meaningful to retain the measuring accuracy in the case of highly asymmetric flow profiles. To prevent pulsations resulting from compression when measuring gases, a throttle should be positioned directly downstream of the variable area meter. To avoid faulty measurements, the arrangement should be selected such that the pressure in the variable area meter corresponds to the reference pressure for the calibration. The flowmeter may only be used within the pressure and voltage limits specified on the identification plate. Startup 1. When starting up new plants, material residues (e.g. welding spatter) are carried over in the medium and could be deposited on the variable area meter. In such cases it is recommendable to clean the variable area meter after a short period of operation. 2. The float must not be exposed to sudden pressures. It is therefore recommendable to start with a closed valve which is then slowly regulated to the operating pressure. Liquids should be vented carefully to prevent pressure surges resulting from gas bubbles. 3. The variable area meter outputs values in all scale ranges according to its accuracy class. Each time a flow is started, permit the variable area meter to settle. When measuring in the lowest range, initially set a higher flow for a short time. Maintenance and repair Depending on the medium, contamination, abrasion or chemical reactions may attack the orifice and the float, thus influencing the accuracy of the measurement. In such cases it is recommendable to dismount the variable area meter and to clean it, including the float, with appropriate agents. The orifice and float must not be damaged mechanically or by aggressive cleaning agents. If erosion is noticed on the orifice or float, recalibration or replacement is necessary. Following all maintenance and cleaning operations, carry out a function test of the variable area meter before using it again. DNconnection 15 (1/2inch) 25 (1 inch) 50 (2 inch) 80 (3 inch) 100 (4 inch) Dimensions A in mm (inch) Versions AF-S, CF-S,CF-K EF-H, FF-P, CL-A, CL-T, CL-K EL-T, FL-R 86 (3,4) 89 (3,5) 92 (3,6) 96 (3,8) 92 (3,6) 111 (4,4) 125 (4,9) 132 (5,2) 138 (5,4) 138 (5,4) Weight kg (lb) 4 (8,8) 5 (11) 9 (19,8) 13 (28,7) 15 (33)

Fig. 4 F VA 250, dimensions in mm (inch)

Mecon GmbH Zieglerstrae 10 16 D-52078 Aachen

Phone +49(0)241 41369 0 www.mecon.de

Fax +49(0)241 41369 40 info@mecon.de

Page 5 to 7 Mecon 04/2005

Variable area flowmeter F VA 250

___________________________________________________________ ___________________________________________________________

___ Selection and ordering data

F VA 250 variable area meter, made completely of metal for measurement of liquids Version Type AF-S (standard) Fitting: stainless steel 1.4571/316Ti Flange: steel C22.8 Float: stainless steel 1.4571/316Ti Type CF-S (standard) Fitting: stainless steel 1.4571/316Ti Flange: stainless steel 1.4571/316Ti Float: stainless steel 1.4571/316Ti Type CF-K Fitting: stainless steel 1.4571/316Ti Flange: stainless steel 1.4571/316Ti Float: stainless steel 1.4571/316Ti Type EF-H Fitting: stainless steel 1.4571/316Ti Flange: 1.4571/316Ti with PTFE liner Float: Hastelloy Type FF-P Fitting: stainless steel 1.4571/316Ti Flange: 1.4571/316Ti with PTFE liner Float: PTFE Norm.diam./flange connection DN15 (1/2" ANSI) DN25 (1" ANSI) DN50 (2" ANSI) DN80 (3" ANSI) DN100 (4" ANSI) Flow tube Size Full-scale value l/h (Usgpm) A 16 (0,07) B 25 (0,11) C 40 (0,18) D 63 (0,28) E 100 (0,44) F 160 (0,7) G 250 (1,1) H 400 (1,76) J 630 (2,77) K 1000 (4,4) L 1600 (7,0) M 2500 (11) N 4000 (17,61) P 6300 (27,7) Q 10000 (44) R 16000 (70,4) S 20000 (88) T 25000 (110) U 40000 (176) V 50000 (220) W 63000 (277) X 100000 (440) Flange connection standard EN1092-1 (standard) ANSI B 16.5 Special connections (thread or other pressure stages) Temperature shield Without (standard) With temperature shield 125 to 200C (257 to 392F) With displaced display 200 to 300C (392 to 572F) 1 Order No. 7ME5820see right

___ Selection and ordering data

Order code F VA 250 variable area meter made completely of metal for measurement of liquids Order No. 7ME58200 2 3 A B C D E A D E G H Order code

see left Heating/cooling sheath Without (standard) H/K with flange connection H/K without flange connection Display With local display (standard) With magnet spring contact F VA 251 With inductive contact F VA 251 With electric remote sensor F VA 252 (0 bis 20mA) With electric remote sensor F VA 252 (4 bis 20mA)

Contact function No contact (standard) For magnet spring contact (twin contact): Close on upward or downward violation of limit Open on upward or downward violation of limit Close on downward violation, open on upward violation of limit Open on downward violation, close on upward violation of limit For inductive contacts: Open on downward violation of limit Close on downward violation of limit Close on upward or downward violation of limit Open on upward or downward violation of limit Close on downward violation, open on upward violation of limit Open on downward violation, close on upward violation of limit

A B C D E

J K L M N P

A B C D E F G H J K L M N P Q R S T U V W X 1 2 9 0 1 2

L1Y

Calibration Standard calibration Without calibration certificate 0 With calibration certificate 1 Special calibration 9 R1Y (1,6% accuracy) Further designs Order code Please add "-Z" to Order No. and specify Order code(s) Acceptance test B to C12 DIN50049, Section. 3.1 and EN10204 Measured medium, specify in Y01 plain text (always required): Medium, measuring range, dimension, density, density dimension, viscosity, viscosity dimension, operating temperature, operating pressure Silicone-free version Y04 Water as measured medium Y05 Viscosity: 1mPas (cp) Density: 1 kg/l (62,43 lb/cu.ft) Stainless steel tag plate Y17 Special version: Y99 specify in plain text Note:See table on page 3 for possible combinations of nominal diameters and flow tube. Teletransmitters and contacts cannot be ordered simultaneously.

Mecon GmbH Zieglerstrae 10 16 D-52078 Aachen

Phone +49(0)241 41369 0 www.mecon.de

Fax +49(0)241 41369 40 info@mecon.de

Page 6 to 7 Mecon 04/2005

Variable area flowmeter F VA 250

___________________________________________________________ ___________________________________________________________

___ Selection and ordering data

F VA 250 variable area meter, made completely of metal, for measurement of gases Version Type CL-A Fitting: stainless steel 1.4571/316Ti Flange: stainless steel Float: aluminium Type CL-T Fitting: stainless steel 1.4571/316Ti Flange: stainless steel 1.4571/316Ti Float: titanium Type CL-K Fitting: stainless steel 1.4571/316Ti Flange: stainless steel1.4571/316Ti Float: stainless steel 1.4571/316Ti Type EL-T Fitting: stainless steel 1.4571/316Ti Flange: 1.4571/316Ti with PTFE liner Float: titanium Type FL-R Fitting: stainless steel 1.4571/316Ti Flange: 1.4571/316Ti mit PTFE liner Float: PTFE Nom.diam./flange connection DN15 (1/2" ANSI) DN25 (1" ANSI) DN50 (2" ANSI) DN80 (3" ANSI) DN100 (4" ANSI) Flow tube Size Full-scale value m/h (Usgpm) A 0,5 (2,2) B 1,0 (4,4) C 1,6 (7,04) D 2,5 (11,0) E 4,0 (17,6) F 12,0 (53) G 16,0 (70) H 25,0 (110) J 40,0 (176) K 63,0 (277) L 100 (440) M 160 (704) N 250 (1100) P 400 (1761) Q 630 (2774) Flange connection standard EN 1092-1 (standard) ANSI B 16.5 Special connections (thread or other pressure stages) Temperature shield Without (standard) With temperature shield 125 to 200C (257 to 392F) With displaced display 200 to 300C (392 to 572F) 1 Order No. 7ME5821see right

___ Selection and ordering data

F VA 250 Order code variable area meter made completely of metal for measurement of gases Order No. 7ME5821see left

Order code -

Heating/cooling sheath Without (standard) H/C with flange connection H/C without flange connection Display With local display (standard) With magnetic spring contact F VA 251 With inductive contact F VA 251 With electric remote sensor F VA 252 (0 to 20mA) With electric remote sensor F VA 252 (4 to 20mA) Contact function No contact (standard) For magnet spring contacts: Close on upward or downward violation of limit Open on upward or downward violation of limit Close on downward violation, open on upward violation of limit Open on downward violation, close on upward violation of limit For inductive contacts: Open on downward violation of limit Close on downward violation of limit Close on upward or downward violation of limit Open on upward or downward violation of limit Close on downward violation, open on upward violation of Open on downward violation, close on upward violation of limit

0 2 3 A B C D E

A D E G H

A B C D E

J K L M N P

A B C D E F G H R J K L M N P 1 2 9

L1Y

0 1 2

Calibration Standard calibration Without calibration certificate 0 With calibration certificate 1 Special calibration 9 R1Y (1,6% accuracy) Further designs Order code Please add "-Z" to Order No. and specify Order code(s) Acceptance test B to C12 DIN50049, Section 3.1 and EN10204 Measured medium, specify in Y01 plain text (always required) Medium, measuring range, dimension, density, density dimension, viscosity, viscosity dimension, operating temperature, operating pressure Silicone-free version Y04 Stainless steel tag plate Y17 Special version: Y99 specify in plain text Note: See table on page 4 for possible combinations of nominal diameters and flow tube. Teletransmitter and contacts cannot be ordered simultaneously.

Mecon GmbH Zieglerstrae 10 16 D-52078 Aachen

Phone +49(0)241 41369 0 www.mecon.de

Fax +49(0)241 41369 40 info@mecon.de

Page 7 to 7 Mecon 04/2005

You might also like

- FVA TUBUX M30 Rotameter Flow Meter IcDocument15 pagesFVA TUBUX M30 Rotameter Flow Meter IcSarkodie KwameNo ratings yet

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter Specificationsjimbo2032No ratings yet

- Ue 24013Document8 pagesUe 24013Johnny CormanNo ratings yet

- 19 102be PDFDocument6 pages19 102be PDFSani PoulouNo ratings yet

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosNo ratings yet

- Pressure Sensor ModulesDocument3 pagesPressure Sensor Modulesphani22No ratings yet

- L-Dens 427F Ex Density Sensor SpecificationsDocument6 pagesL-Dens 427F Ex Density Sensor Specificationsd1arsenovskiNo ratings yet

- Druck PT Data SheetDocument7 pagesDruck PT Data Sheethits289No ratings yet

- Transmision de Presion DiferencialDocument12 pagesTransmision de Presion DiferencialRuben Arteaga'No ratings yet

- Turbine Meter NufloDocument8 pagesTurbine Meter NufloJaime SeguraNo ratings yet

- Multipur AP Multipur AP Multipur AP Multipur AP Multipur AP: WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.deDocument2 pagesMultipur AP Multipur AP Multipur AP Multipur AP Multipur AP: WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.de WWW - Bwt.deJoshua PhillipsNo ratings yet

- BW25Document8 pagesBW25msalem73No ratings yet

- General Specifications: Model EJA110A Differential Pressure TransmitterDocument11 pagesGeneral Specifications: Model EJA110A Differential Pressure TransmitterKao SophearakNo ratings yet

- ST 3000 Smart Transmitter Series 100 Remote Diaphragm Seals Models Specifications 34-ST-03-64 March 2013Document44 pagesST 3000 Smart Transmitter Series 100 Remote Diaphragm Seals Models Specifications 34-ST-03-64 March 2013ruzzo2003No ratings yet

- 62 Series Servovalves Technical OverviewDocument8 pages62 Series Servovalves Technical OverviewDevendra BangarNo ratings yet

- D 102310 X 012Document8 pagesD 102310 X 012Peter BqkNo ratings yet

- 2 and 3 Genesis Series PD Meter SpecificationsDocument6 pages2 and 3 Genesis Series PD Meter SpecificationsMechanicalMarwanNo ratings yet

- Axial Piston Pump CatalougeDocument36 pagesAxial Piston Pump Catalougemrkadu_61No ratings yet

- Eja 110a Yokogawa BoilerDocument11 pagesEja 110a Yokogawa BoilerHoang HiepNo ratings yet

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetsarkaftNo ratings yet

- Diaphragm Seals for Food and Pharma IndustriesDocument4 pagesDiaphragm Seals for Food and Pharma IndustriesJhon Erick Izquierdo SoteloNo ratings yet

- Bronkhorst EL-FLOW Dastec SRLDocument4 pagesBronkhorst EL-FLOW Dastec SRLHesser Taboada MichelNo ratings yet

- Vortex flow meter installation guideDocument83 pagesVortex flow meter installation guideltrongluanvn100% (1)

- Compact pressure transmitter for precise fine pressure measurementDocument5 pagesCompact pressure transmitter for precise fine pressure measurementduiechNo ratings yet

- 2020 2e6Document6 pages2020 2e6Jaikishan KumaraswamyNo ratings yet

- Control Ad or Neumatico de Nivel Fisher 2502Document16 pagesControl Ad or Neumatico de Nivel Fisher 2502mizor82No ratings yet

- Data Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 CompressorDocument4 pagesData Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 Compressortutuli1990No ratings yet

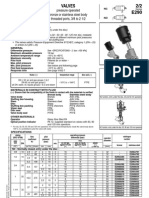

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuNo ratings yet

- High-Quality Pressure Transmitter For General Industrial Applications Model S-10Document8 pagesHigh-Quality Pressure Transmitter For General Industrial Applications Model S-10gliga vasileNo ratings yet

- Blind Pressure & Diff. Pressure Switches GuideDocument38 pagesBlind Pressure & Diff. Pressure Switches GuidearavindNo ratings yet

- Bronkhorst Folder El FlowDocument4 pagesBronkhorst Folder El FlowPankaj GargNo ratings yet

- Relay AP Suat DanfossDocument16 pagesRelay AP Suat DanfossVo Ngoc DucNo ratings yet

- ABB Level Transmiter Ss621emDocument12 pagesABB Level Transmiter Ss621emlorgio_moroNo ratings yet

- Power Factor Correction: Phasecap CompactDocument4 pagesPower Factor Correction: Phasecap CompactvanbaoqnNo ratings yet

- FSM4000 Medidor de Vazão Magnético PDFDocument40 pagesFSM4000 Medidor de Vazão Magnético PDFthiagofilipiniNo ratings yet

- BM 70 ADocument11 pagesBM 70 AmojtabagolestanhaNo ratings yet

- Pressure TransmittersDocument40 pagesPressure TransmittersMilosglNo ratings yet

- MS3770 - EN - DS008REV02 - IS (FT Electromagnetico de Insercion)Document9 pagesMS3770 - EN - DS008REV02 - IS (FT Electromagnetico de Insercion)cacr_72No ratings yet

- Brooks Mass Flow Meters and Controllers: MODEL 5850TRDocument4 pagesBrooks Mass Flow Meters and Controllers: MODEL 5850TRajinkyaNo ratings yet

- Catalogo ASCODocument4 pagesCatalogo ASCOIkaro MatosNo ratings yet

- Apr 2000G Al PDFDocument3 pagesApr 2000G Al PDFvan_dall_2No ratings yet

- D Ape Av1234 - FDocument24 pagesD Ape Av1234 - FAngel FortuneNo ratings yet

- Moog ServovalvesDocument8 pagesMoog Servovalvesdylan_dearing@hotmail.com100% (1)

- Debitmetru ElectromagneticDocument32 pagesDebitmetru ElectromagneticNistor PaulNo ratings yet

- Pss 1-6f2bDocument20 pagesPss 1-6f2bEverton LuizNo ratings yet

- ABB 10D1477 (Magnetic Flow Meter)Document6 pagesABB 10D1477 (Magnetic Flow Meter)1234567890No ratings yet

- fp50 fp100 fp200Document10 pagesfp50 fp100 fp200ducmanh83No ratings yet

- Electromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionDocument4 pagesElectromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionAlphatech1No ratings yet

- Brookfield Process CatalogDocument24 pagesBrookfield Process CatalogenzopandolfiNo ratings yet

- Yokogawa DPIT ModelDocument11 pagesYokogawa DPIT ModelRoopa NaikNo ratings yet

- Rotametro ABBDocument10 pagesRotametro ABBjoticamario123No ratings yet

- Seko Dosing PumpDocument12 pagesSeko Dosing PumptooedNo ratings yet

- Principle of Operation: Target Inline FlowmeterDocument7 pagesPrinciple of Operation: Target Inline Flowmeterابزار دقیقNo ratings yet

- DeaeratorDocument8 pagesDeaeratorfjoesandiNo ratings yet

- Smart Differential Pressure Transmitter APR-2000ALWDocument5 pagesSmart Differential Pressure Transmitter APR-2000ALWDANE80No ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- OverpressureDocument2 pagesOverpressureampowersidNo ratings yet

- ManómetrosDocument2 pagesManómetrosampowersidNo ratings yet

- ManómetrosDocument2 pagesManómetrosampowersidNo ratings yet

- 00 enDocument80 pages00 enampowersidNo ratings yet

- 60Hp - 460vac. Soft StartDocument2 pages60Hp - 460vac. Soft StartampowersidNo ratings yet

- Keigs Nod32Document1 pageKeigs Nod32ampowersidNo ratings yet

- Keigs Nod32Document1 pageKeigs Nod32ampowersidNo ratings yet

- Data Setu 1Document1 pageData Setu 1ampowersidNo ratings yet

- Chem Volume 1Document200 pagesChem Volume 1Marc Laurenze CelisNo ratings yet

- Engineering Metrology and MeasurementsDocument128 pagesEngineering Metrology and MeasurementsArvind Bhosale100% (7)

- B 244-09 Standard Test Method For Measurement of Thickness of Anodic Coatings On Aluminum and of Other Nonconductive Coatings On Nonmagnetic Basis Metals With Eddy-Current InstrumentsDocument4 pagesB 244-09 Standard Test Method For Measurement of Thickness of Anodic Coatings On Aluminum and of Other Nonconductive Coatings On Nonmagnetic Basis Metals With Eddy-Current InstrumentsTrong Cuong HaNo ratings yet

- List of IEC Standards - Wikipedia, The Free EncyclopediaDocument16 pagesList of IEC Standards - Wikipedia, The Free EncyclopediaAnonymous AvwRPJNo ratings yet

- Indian Standard: Digital Measuring Il'Lstruments ForDocument14 pagesIndian Standard: Digital Measuring Il'Lstruments ForAshish DubeyNo ratings yet

- Scheme of Work and Suggested Activities Formula A pt3 KSSM Science Form 1Document25 pagesScheme of Work and Suggested Activities Formula A pt3 KSSM Science Form 1Thivya RamanNo ratings yet

- Radwag Mass ComparatorsDocument111 pagesRadwag Mass ComparatorsSławomirJanasNo ratings yet

- Questions and AnswersDocument2 pagesQuestions and AnswersDevarakonda KondayyaNo ratings yet

- Oktis - 2: This Translation Was Made by The Chamber of Commerce and Industry of The Vladimir RegionDocument6 pagesOktis - 2: This Translation Was Made by The Chamber of Commerce and Industry of The Vladimir RegionPrasojo Mpj100% (1)

- Sauter - Katalog 2012 ENDocument58 pagesSauter - Katalog 2012 END.T.No ratings yet

- Manual sg2 Mettler Toledo PDFDocument152 pagesManual sg2 Mettler Toledo PDFsauloNo ratings yet

- Specific Heat of Liquids and Solids: Standard Test Method ForDocument6 pagesSpecific Heat of Liquids and Solids: Standard Test Method ForJean-Patrice DeliaNo ratings yet

- Primary Control Surveys For Project Mapping: 3-1. Purpose and ScopeDocument43 pagesPrimary Control Surveys For Project Mapping: 3-1. Purpose and Scopesafdarpk23No ratings yet

- EIGA Doc 07 03 EDocument25 pagesEIGA Doc 07 03 EFrancisco Campos ParadaNo ratings yet

- Section 24 - Geotechnical InstrumentationDocument17 pagesSection 24 - Geotechnical InstrumentationJacky TiongNo ratings yet

- Multi Vision 2020TG/TA: Digital Transmitters With Remote Seals For Gauge / Absolute Pressure and LevelDocument22 pagesMulti Vision 2020TG/TA: Digital Transmitters With Remote Seals For Gauge / Absolute Pressure and LevelMasroor RasoolNo ratings yet

- 0739P300-E Installation Supercal 739 en 14-11-2013Document10 pages0739P300-E Installation Supercal 739 en 14-11-2013pedroNo ratings yet

- Rubric For Pipe BendingDocument4 pagesRubric For Pipe BendingleogarybonNo ratings yet

- Is 12554 1 1988Document10 pagesIs 12554 1 1988rajpd28No ratings yet

- ME5000 MekometerDocument80 pagesME5000 MekometerDjordje NikolicNo ratings yet

- (NEW) U6MEA30 Engineering Metrology & Measurements Question BankDocument227 pages(NEW) U6MEA30 Engineering Metrology & Measurements Question BankSundar RajNo ratings yet

- Enthalpimetric TitulationDocument3 pagesEnthalpimetric TitulationAlessandra Stangherlin OliveiraNo ratings yet

- OKM Catalog enDocument53 pagesOKM Catalog enLiliana LesuNo ratings yet

- Astm D 4052-11Document8 pagesAstm D 4052-11UmarFidaNo ratings yet

- Is 1391 2 1992 PDFDocument36 pagesIs 1391 2 1992 PDFsusmitamandali100% (1)

- Calibration of InstrumentsDocument32 pagesCalibration of InstrumentsEsha Naveed100% (2)

- Calibration and Validation of Welding EquipmentDocument9 pagesCalibration and Validation of Welding EquipmentAliNo ratings yet

- 782 Assignment 1Document18 pages782 Assignment 1Гарпия Сова100% (4)

- (IQC) LG (67) - G3-1213 - Decor Assembly - Detailed Inspection ProcedureDocument10 pages(IQC) LG (67) - G3-1213 - Decor Assembly - Detailed Inspection ProcedureAnonymous Lta32Ta9No ratings yet

- S 7720 PDFDocument44 pagesS 7720 PDFJeremiah CayondongNo ratings yet