Professional Documents

Culture Documents

Technical Specification Scooptram ST7 9851 2681 01 Tcm835-1532854

Uploaded by

Emanuel Andrés Rosas SaldivarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Specification Scooptram ST7 9851 2681 01 Tcm835-1532854

Uploaded by

Emanuel Andrés Rosas SaldivarCopyright:

Available Formats

Atlas Copco Underground loaders

Scooptram ST7

Technical specication

The Scooptram ST7 is a robust LHD that is built for demanding underground applications where small size combined with high performance is the key to superior productivity. Features

Safe Working Environment

Spring applied, hydraulic released (SAHR) brakes Automatic brake-test with diagnostics and logging ISO ROPS/FOPS approved cabin, oil-free operators compartment and door interlock (applies brakes, blocks steering and bucket/boom movement when door opens) The best operator visibility in its class due to the low back end Increased leg-room with AC Footbox Rubber mounted cabin or canopy for reduced vibration level Ergonomic multifunction control joysticks Comfortable air suspended seat (optional) Simple and clear, multifunction display with intuitive operator interface Steering and boom soft stop reduces vibration for the operator (optional) Fuel efficient, clean burning EPA Tier 3/EU Stage IIIA engine Rock tough catalytic purifier Proven powertrain components On board diagnostics give the operator a clear indication of the machine status L&M V-tube Core radiator Machine status indication lights, displays the machine status for personnel working around the machine Load weighing system (optional)

Peak Performance

Superior Operators Comfort

Load sensing variable displacement hydraulic pump for increased tractive effort and reduced fuel consumption Integrated de-clutch function, saves fuel and improves life of drivetrain components Traction control improves loading performance, reduces tyre slip, improves tyre life Easy access to service points, filters and valve blocks Atlas Copco Rig Control System (RCS) provides service information in clear text on the monitor Filter sensors with data collection for air, hydraulic and transmission filters Daily lube points quick and easy to service All daily maintenance from ground level Patented automatic lubrication system with low level warning and lube fault detection for all daily lube points.

Serviceability

Environmental

Reliability for Enhanced Productivity

Scooptram ST7

Scooptram ST7

Specications

CAPACITIES

kg Tramming capacity* Breakout force, hydraulic Breakout force, mechanical 6 800 13 350 11 750 sec

Grade Performance

MOTION TIMES

sec Boom raising Boom lowering Dumping 5.3 3.5 2.1

WEIGHTS

Standard equipped vehicle (EVW) kg Approximate weight Axle load, front end Axle load, rear end 19 300 8 600 10 700

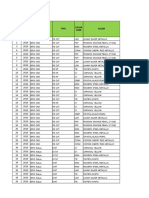

GRADE PERFORMANCE - EMPTY BUCKET

% Ratio km/h Grade Grade 1st gear 2nd gear 3rd gear 4.5 7.4 14.3 23.1 0.0 4,4 7.3 13.7 21.4 2.0 4.3 7.1 13.1 19.1 4.0 4.3 7.0 12.4 16.5 6.0 4.2 6.8 11.6 12.7 8.0 10.0 1:10 4.2 6.7 10,8 12.5 1:8 4.1 6.5 9.6 14.3 1:7 4.1 6.3 8.3 4.0 6.1 7.1 16.0 4.0 5.4 18.0 20.0 1:5 3.9 5.7 25.0 1:4 3.8 5.2

*Tramming capacity with EOD bucket 5 800 kg.

Engine

Brand/model:.... Cummins QSB6.7 EPA Tier 3/EU Stage IIIA Power rating at 2 200 rpm. ............................. 144 kW/193 hp Maximum torque at 1 400 rpm.................................. 931 Nm MSHA Part 7 ventilation: Ventilation rate..................................................... 241 m3/min Particulate index.................................................. 269 m3/min Dry type air cleaner Catalytic exhaust purifier and silencer Exhaust heat protection L&M V-tube core radiator and charge air cooler

Electrical system

24/12 V converter Isolation switch lockout System voltage................................Start & accessories 24 V Mine duty high output alternator...........................140 Amps Driving lights LED.................................................13 x 40W

4th gear

3% rolling resistance assumed. Actual performance may vary depending on the application. GRADE PERFORMANCE - LOADED BUCKET

% Ratio km/h Grade Grade 1st gear 2nd gear 3rd gear 4th gear 4.4 7.3 14.0 22.2 0.0 4,4 7.1 13.2 19.3 2.0 4.3 6.9 12.2 15.5 4.0 4.2 6.7 11.1 6.0 4.1 6.5 9.8 8.0 10.0 1:10 4.1 6.3 8.1 12.5 1:8 4.0 5.9 14.3 1:7 3.9 5.6 3.8 5.4 16.0 3.8 5.1 18.0 20.0 1:5 3.7 4.7 25.0 1:4 3.4 3.5

Hydraulic system

Heavy duty load sensing pump...............1 x Rexroth A10VO Hydraulic leakage detection system Steering and system pressure..................................24.0 MPa Hydraulic tank capacity........................................... 111 litres Filtration, return line.....................................................12 m Cylinders; chrome plated stems, diameter: Steer cylinders (2).............................................. 80 mm Hoist cylinders (2)............................................125 mm Stabilizer cylinder.............................................150 mm

Transmission and Torque coverter

Automatic power shift with integral converter, fully modulated 4 speed shifting, forward/reverse with de-clutch function Funk .............................................................................DF150

3% rolling resistance assumed. Actual performance may vary depending on the application.

Optional Equipment

System

Manually actuated fire suppression with engine shut-down Ansul checkfire, automatic actuation of fire suppression system Lincoln auto lube Wiggins fast fuel fill Atlas Copco Scooptram RRC (Line of sight - Radio Remote Control) Premium package including: - Auto lube with Lincoln pump - Load weighing (logging of production data, weight per bucket, number of buckets and accumulated payload) CD/MP3 player

Axles

Spiral bevel differential, full floating, planetary wheel enddrive Rock Tough.......................................................................406 Degree of rear axle oscillation..............14 (7 on each side) Differentials: Front.................................................................. No spin Rear...................................................................... Open

Control system

Logging of production data, number of buckets, fuel consumption and tramming distance etc Joystick controls for dump/hoist and steering Automatic ride control (boom suspension) Automatic and semi automatic transmission control Bucket float Operator display Brake test function with diagnostics and logging Engine and transmission diagnostics Radio Remote Control interface Emergency stop buttons

Tyres

17.5R25 X-Mine D2 (lugged) Cold weather package 120V or 240V: - Block heater - Battery warmer - Fuel heater - Hydraulic oil heater - Transmission oil heater - Arctic oil Optional bucket sizes EOD buckets Wheel chocks and brackets Knockdown construction LinkOne parts catalogue, CD LinkOne reader Operator and maintenance manual - plasticized Preventive maintenance kits Repair and rebuild kits Upgrade kits Face mechanics tool set Shop mechanics tool set Service tool box for RCS

Power unit

Brakes

Fully enclosed, force cooled, multiple wet discs at each wheel end Service/parking/emergency brakes...............................SAHR

Fuel

Fuel tank capacity.................................................... 190 litres Fuel filtration: Primary, including water trap.................................2m Secondary................................................................3m Fuel consumptuin @ full load............................... 37 litres/hr Estimated engine load factor............................................ 40% Anti-siphon fuel supply

Main Frame

Tyres*

Tubeless, smooth, tread design for underground mine service Tyre size, front and rear...........................17.5x25 20 ply L5S

* As applications and conditions vary, Atlas Copco recommends that the user consults with tyre suppliers to obtain the optimum tyre selection.

Electrical System Hydraulic System

Brake release retriever tow hook Electric pump for hydraulic tank fill Air suspended Grammer seat with 2-point retractable seat belt Cabin or canopy Block out 3rd and 4th gears Production logging Maintenance logging Brake apply after 3 sec in neutral Load weighing system

Documentation

Operators compartment

Included features

Boom up lock Central manual lubrication system Fire extinguisher Audio-visual reverse alarm Steering soft stop

Parts and Services

Operators Compartment

Canopy ISO ROPS/FOPS Open door retainer Side seated operator for bi-directional operation Spring suspended Grammer seat with 2-point retractable seat belt External sound level according to ISO 6393 LwA 124,5 dB(A) Sound level in canopy according to ISO 6394 LpA 105 dB(A) Sound level in cabin according to ISO 6394 LpA 82 dB(A) Whole body vibration value according to below EN 14253 A(8)w maximum 0.55+/-0.2m/s

Controls and instruments

Scooptram ST7

Measurements

LEFT TURN STD BUCKET

42.5

Dimensions

2 860 3 540

All dimensions are shown in millimetres All dimensions and calculations shown are based on standard vehicle configuration with 27mm tyre deflection, unloaded

2 820

R5

94

2 860 3 540

2 000 x 45

4 270

40

14

310 1 380 2 610 1 650 1 650 1 420 2 240 22,4

T1

2 220 2 800

8 720

2 120

1 160

TOP VIEW

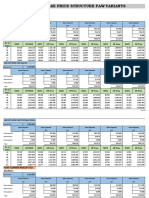

STANDARD BUCKET DATA

Volume, nominal heaped (m3) Maximum material density (t/m3) Width, bucket (mm) Tramming position: Axle centreline to bucket lip (mm) Tramming position: Ground to bucket tip (mm) Reach dimension (mm) Raised position: Back height, max. (mm) Raised position: Bucket tip, height (mm)

W T1 T2 L1 H1 H2

STD

3.8 1.8

2 280 2 970 1 540 2 380 4 760 1 750

3.4 2.0

2 280 2 900 1 450 2 280 4 660 1 850

3.1 2.2

2 280 2 800 1 400 2 220 4 570 1 890

2.8 2.4

2 280 2 770 1 330 2 160 4 540 1 940

W 2 280

1 920

T2 1 400 H2 1 890

2 160

1 390

2.6 2.6

2 280 2 650 1 200 2 010 4 540 2 050

2 900

2.4 2.8

2 280 2 670 1 230 2 050 4 500 2 020

3 200

2.3 3.0

2 280 2 600 1 190 2 000 4 490 2 070

EOD BUCKET DATA

Volume, nominal heaped (m3) Maximum material density (t/m3) Width, bucket (mm) Tramming position: Axle centreline to bucket lip (mm) Tramming position: Ground to bucket tip (mm) Reach dimension (mm) Raised position: Back height, max. (mm) Raised position: Bucket tip, height (mm)

W T1 T2 L1 H1 H2

3.2 1.8

2 280 3 020 1 650 2 500 4 650 1 700

2.9 2.0

2 280 2 970 1 580 2 420 4 600 1 740

2.7 2.2

2 280 2 920 1 530 2 370 4 530 1 800

2.5 2.4

2 280 2 870 1 480 2 310 4 510 1 840

2.4 2.6

2 280 2 830 1 430 2 270 4 490 1 880

2.2

2 280 2 780 1 370 2 200 4 490 1 940

9851 2681 01e 01/2012

2.8

H1

4 570

SIDE VIEW STD BUCKET

Copyright 2012, Atlas Copco Rock Drills AB, rebro, Sweden. All product names in this publication are trademarks of Atlas Copco. Any unauthorized use or copying of the contents or any part thereof is prohibited. Illustrations and photos may show equipment with optional extras. No warranty is made regarding specications or otherwise. Specications and equipment are subject to change without notice. Consult your Atlas Copco Customer Center for specic information.

1 R3 70

You might also like

- Minetruck mt42Document4 pagesMinetruck mt42Miguel Angel Cortes Quintrel100% (1)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Minetruck MT5020Document4 pagesMinetruck MT5020Michael de la BarraNo ratings yet

- Hoja Tecnica Dumper AtlasDocument4 pagesHoja Tecnica Dumper AtlasRoferq Fernandez QuichuaNo ratings yet

- Practical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansFrom EverandPractical Hydraulic Systems: Operation and Troubleshooting for Engineers and TechniciansRating: 4 out of 5 stars4/5 (8)

- MT42 Specification Sheet 9851 2697 01dDocument4 pagesMT42 Specification Sheet 9851 2697 01dJovanyNo ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- Atlas Copco MT6020 PDFDocument4 pagesAtlas Copco MT6020 PDFPaulina Diaz DiazNo ratings yet

- Spec ST2D 9851 2251 01f - tcm795-1539250 PDFDocument4 pagesSpec ST2D 9851 2251 01f - tcm795-1539250 PDFRizky AsharyNo ratings yet

- Spec ST710 - 9851 2256 01Document4 pagesSpec ST710 - 9851 2256 01EVCYNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Atlas Copco - Scooptram ST18 (18t) PDFDocument4 pagesAtlas Copco - Scooptram ST18 (18t) PDFДмитрий АсташонокNo ratings yet

- ST7Document4 pagesST7marcelonieto761No ratings yet

- Minetruck MT436B 9851 2249 01N tcm833-1540890 PDFDocument4 pagesMinetruck MT436B 9851 2249 01N tcm833-1540890 PDFLuis Hernández BarrazaNo ratings yet

- Technical Specification Boomer E1 C - 9851 3137 01 - tcm835-3515820Document4 pagesTechnical Specification Boomer E1 C - 9851 3137 01 - tcm835-3515820VVyldher UghoNo ratings yet

- Atlas Copco Off Highway Dump Trucks Spec 11ece7Document4 pagesAtlas Copco Off Highway Dump Trucks Spec 11ece7Fazal AhmedNo ratings yet

- ScoopDocument3 pagesScoopivantoro76No ratings yet

- 3516 516de4a 50HZ 6300Document6 pages3516 516de4a 50HZ 6300sinliongNo ratings yet

- Especificaciones Tecnicas Dumper Mt2010Document4 pagesEspecificaciones Tecnicas Dumper Mt2010CepiconSacNo ratings yet

- Technical Specification Boomer m2 C With Cop 3038 9851 2774 01 Tcm835-1533267Document4 pagesTechnical Specification Boomer m2 C With Cop 3038 9851 2774 01 Tcm835-1533267death666darkNo ratings yet

- Caterpillar Genset Prime 400 EkW 500kvaDocument6 pagesCaterpillar Genset Prime 400 EkW 500kvaYusuf Isman Wibowo100% (1)

- 1500kva - PrimeDocument6 pages1500kva - PrimeanhutanhoangNo ratings yet

- Genset - 2MVA-5Document6 pagesGenset - 2MVA-5Shawn ZadehNo ratings yet

- Genset - 2MVA-2Document6 pagesGenset - 2MVA-2Shawn ZadehNo ratings yet

- 3516B, 1600 kW-2000 kVA PDFDocument6 pages3516B, 1600 kW-2000 kVA PDFbambangNo ratings yet

- Roc l8 Atlas CopcoDocument4 pagesRoc l8 Atlas Copcojacc009100% (1)

- Cat 3406 Genset Specs enDocument6 pagesCat 3406 Genset Specs enAndrei Bleoju80% (5)

- Caterpillar 3406Document6 pagesCaterpillar 3406api-224431410No ratings yet

- 3406C 275 KW Prime Low BSFC - Larne1Document6 pages3406C 275 KW Prime Low BSFC - Larne1kichiNo ratings yet

- Simba L6 CDocument4 pagesSimba L6 CKoko ElrNo ratings yet

- Minetruck MT436B 9851 2249 01N tcm835-1540890 PDFDocument4 pagesMinetruck MT436B 9851 2249 01N tcm835-1540890 PDFCristian Cabrera0% (1)

- Scooptram ST2GDocument4 pagesScooptram ST2GLUIS ALEJANDRO HURTADO QUIÑONESNo ratings yet

- Spec Est2dDocument4 pagesSpec Est2dJuan David Rondinel BulejeNo ratings yet

- St1520 Serie 60 EngineDocument3 pagesSt1520 Serie 60 EnginemechgNo ratings yet

- Boomer l1 C - DH 9851 2235 01 - tcm835-1533264Document4 pagesBoomer l1 C - DH 9851 2235 01 - tcm835-1533264death666darkNo ratings yet

- V Ec290b D7D Eae2 2124351643 2002-09Document12 pagesV Ec290b D7D Eae2 2124351643 2002-09filipericardodi124780% (5)

- c32 1000 Ekw Standby Low BSFC - Emcp4 - DimDocument6 pagesc32 1000 Ekw Standby Low BSFC - Emcp4 - DimGuillermo HerreraNo ratings yet

- Technical Specification Boomer m2 C - With Cop 3038 - 9851 2774 01 - Web - tcm821-1533267Document4 pagesTechnical Specification Boomer m2 C - With Cop 3038 - 9851 2774 01 - Web - tcm821-1533267David SantiagoNo ratings yet

- Volvo EC210BDocument12 pagesVolvo EC210BStroia Constantin Marius78% (27)

- 3406C 300 KW Standby Low BSFC - GriffinDocument6 pages3406C 300 KW Standby Low BSFC - GriffinkichiNo ratings yet

- GenSet 1825 Kwe PrimeDocument6 pagesGenSet 1825 Kwe PrimeDaniel CicognaNo ratings yet

- Technical Specification Simba w6 C - 9851 2635 01 - tcm835-1537599Document4 pagesTechnical Specification Simba w6 C - 9851 2635 01 - tcm835-1537599Cecitafex2014No ratings yet

- Scooptram ST14Document4 pagesScooptram ST14LEMANo ratings yet

- Komatsu Demag PC4000-6 Shovel - ACF4666Document8 pagesKomatsu Demag PC4000-6 Shovel - ACF4666Miomir Mikić100% (1)

- 350KVA Diesel Generator CATDocument6 pages350KVA Diesel Generator CATAnonymous N0ZIvW100% (1)

- Boltec 235Document4 pagesBoltec 235Jesús Alberto CruzNo ratings yet

- 500 KVA PrimeC15 Lean I6 - EUDocument6 pages500 KVA PrimeC15 Lean I6 - EUanon_46672526No ratings yet

- Boltec 235Document4 pagesBoltec 235Ronald Osorio100% (1)

- DG CatDocument6 pagesDG CatBalis MihaiNo ratings yet

- Specsheet 3516 1825 kVA PrimeDocument6 pagesSpecsheet 3516 1825 kVA PrimeYusman EkaNo ratings yet

- PC4000 6Document8 pagesPC4000 6Sergio Velarde RomayNo ratings yet

- Mp8 Export 400 CDocument2 pagesMp8 Export 400 CLuis M. Valenzuela Arias100% (1)

- Rocket Boomer E3-C18 EspecificacionesDocument4 pagesRocket Boomer E3-C18 EspecificacionesDiego CarrilloNo ratings yet

- Catalogo Generador Olimpian 150-200 KWDocument5 pagesCatalogo Generador Olimpian 150-200 KWlujes99No ratings yet

- CATERPILLAR C9 300kw PDFDocument6 pagesCATERPILLAR C9 300kw PDFanthony7421No ratings yet

- 3512+1250+kVA+Standby+LowBSFC+ EMCP4Document6 pages3512+1250+kVA+Standby+LowBSFC+ EMCP4Hassan FawazNo ratings yet

- NGK Ignition Coils 2017Document220 pagesNGK Ignition Coils 2017sony100% (1)

- Test Vehicle Information/Test Specifications FMVSS 135: FORM 135 05/16/02Document8 pagesTest Vehicle Information/Test Specifications FMVSS 135: FORM 135 05/16/02fghdNo ratings yet

- 770 & 772 PDFDocument235 pages770 & 772 PDFMárioJácome100% (3)

- Drive Shaft For Front Drive Axle, Front Drive Axle To TransmissionDocument2 pagesDrive Shaft For Front Drive Axle, Front Drive Axle To TransmissionSantiago GuayasamínNo ratings yet

- Grove GRT8100: Operator ManualDocument202 pagesGrove GRT8100: Operator ManualAlejandro Zuñiga100% (1)

- Mercedes Powershift Brochure: Experiences and Tips From Driving Experience For The Service AreaDocument11 pagesMercedes Powershift Brochure: Experiences and Tips From Driving Experience For The Service AreaMohamed AlaaNo ratings yet

- SensorsDocument47 pagesSensorsreinaldo guerra100% (1)

- Torque Specifications: Service Specifications - 2Az-Fxe Engine MechanicalDocument3 pagesTorque Specifications: Service Specifications - 2Az-Fxe Engine MechanicaldiemnganNo ratings yet

- Exile CatalogDocument52 pagesExile Catalogconfused597No ratings yet

- Intro Scania (10 04) PDFDocument1 pageIntro Scania (10 04) PDFForesight MisrNo ratings yet

- 11B2 14 NF Smart Entry and Start System VNDocument41 pages11B2 14 NF Smart Entry and Start System VNMinh Nhat Phan100% (3)

- F4ael 04 W PDFDocument1 pageF4ael 04 W PDFTia0% (1)

- Kioti Daedong EX50CH Tractor Parts Catalogue Manual PDFDocument21 pagesKioti Daedong EX50CH Tractor Parts Catalogue Manual PDFfjjsekfkskemeNo ratings yet

- CLG856H GCICII - 64F0435 494 503 504 532 - Parts Manual 201511002-EN PDFDocument1,212 pagesCLG856H GCICII - 64F0435 494 503 504 532 - Parts Manual 201511002-EN PDFSatria Triana100% (1)

- Condor Body Installation ManualDocument154 pagesCondor Body Installation ManualProfessional TrustNo ratings yet

- Mack Maxitorque T-310Document2 pagesMack Maxitorque T-310fdpc1987100% (1)

- At6604 Vehicle Dynamics R 2013 Learing Material - PM SubramanianDocument51 pagesAt6604 Vehicle Dynamics R 2013 Learing Material - PM SubramanianSubramanian Pm100% (1)

- Chapter25-Equipment FurnishingsDocument134 pagesChapter25-Equipment FurnishingsIman GhNo ratings yet

- Airmatic Check For LeaksDocument3 pagesAirmatic Check For LeaksPaode DaonamaiNo ratings yet

- Diagrama Elétrico - CP274Document13 pagesDiagrama Elétrico - CP274Marcos Aragao75% (4)

- Zodix Cata Exp 2:3 WDocument388 pagesZodix Cata Exp 2:3 WAvi AroraNo ratings yet

- Rg01 D Max Price List 1.9mtl 1.9 3.0 Scab Rs SBHDocument1 pageRg01 D Max Price List 1.9mtl 1.9 3.0 Scab Rs SBHAdren IsrelNo ratings yet

- Rundown Stock SMD 2020-01-17Document48 pagesRundown Stock SMD 2020-01-17TAUFIK HONDA SAMARINDANo ratings yet

- 2020 Can Am Off Road - Apache Track Kits Leaflet - enDocument7 pages2020 Can Am Off Road - Apache Track Kits Leaflet - enNicolas VillamayorNo ratings yet

- State I/M Program Advisory Bulletin: Applicability: Number: Date: SUBJECT: On-Board Diagnostic SystemDocument7 pagesState I/M Program Advisory Bulletin: Applicability: Number: Date: SUBJECT: On-Board Diagnostic Systemcarrasquel0No ratings yet

- Car PricesDocument47 pagesCar PricesMajoo SonsNo ratings yet

- w220 S-Class Encyclopedia - Start HereDocument14 pagesw220 S-Class Encyclopedia - Start HereAziz Al-Qadri Wal Chisti100% (1)

- ZF Astronic Codigos NumeroDocument4 pagesZF Astronic Codigos NumeroJorge100% (4)

- Engine Paccar Mx13 Diesel t800 Kenworth PDFDocument2 pagesEngine Paccar Mx13 Diesel t800 Kenworth PDFThomas Parkinson67% (3)

- VW Phaeton MaintenanceDocument42 pagesVW Phaeton MaintenanceNick P100% (1)