Professional Documents

Culture Documents

Approved Welding Electrodes for Refinery Equipment

Uploaded by

Kailas Anande0 ratings0% found this document useful (0 votes)

523 views3 pagesselection of welding electrode

Original Title

Welding Electrode Selection

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentselection of welding electrode

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

523 views3 pagesApproved Welding Electrodes for Refinery Equipment

Uploaded by

Kailas Anandeselection of welding electrode

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

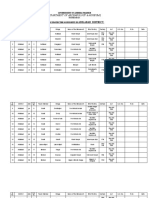

VISAKH REFINERY

INSPECTION ADVISORY ON APPROVED WELDING ELECTRODES TO

BE USED FOR VARIOUS WELDING JOBS OF THE REFINERY

EQUIPMENTS

INSPECTION DIVISION

Advisory no. : TSD/INSP/GEN/24

Rev. 1

Date of issue: 26.04.2013

Date of first issue: 04.12.2011

TECHNICAL SERVICES

DEPARTMENT

Page 1 of 3

1.0 OBJECTIVE

To advise the approved welding electrodes/Iiller wires to be used Ior various welding jobs.

2.0 SCOPE

a) To list out the approved welding electrodes/Iiller wires oI various manuIacturers.

b) Maintenance/Projects Depts. shall ensure to speciIy the approved welding electrodes to be

used in various Maintenance/Projects jobs.

3.0 INTRODUCTION

There are diIIerent welding electrodes/Iiller wires used Ior welding/repair jobs on various

existing/new ReIinery equipments.

Various welding electrodes oI certain manuIactures have been approved earlier by HPCL

based on their testing/perIormance/credentials Irom other ReIineries.

This advisory is issued to provide a consolidated list oI approved manuIacturers Ior the

speciIied welding electrodes.

4.0 APPROVED WELDING ELECTRODES

The Iollowing electrodes are approved by HPCL:

AWS Specification Electrode specification Electrode brand

SFA 5.1

Carbon Steel electrodes)

E6010 ESAB, L&T, Ador Fontech,

D&H Secheron, D&H

Welding Electrodes (India)

Ltd., Honavar, Maruti

Superon

E6013

E7018-1/ER70S2-1

E7018/ ER70S2

SFA 5.4

Stainless Steel electrodes

SFA 5.4

E308/ER308 ESAB, L&T, Ador Fontech,

D&H Secheron, D&H

Welding Electrodes (India)

Ltd., Honavar, Maruti

ESAB, L&T, Ador Fontech,

E308L/ER308L

E316L/ER316L

E309/ER309 Mo

E309L/ER309L

E310/ER310

E347/ER347

E383/ER383

E385/ER385

VISAKH REFINERY

INSPECTION ADVISORY ON APPROVED WELDING ELECTRODES TO

BE USED FOR VARIOUS WELDING JOBS OF THE REFINERY

EQUIPMENTS

INSPECTION DIVISION

Advisory no. : TSD/INSP/GEN/24

Rev. 1

Date of issue: 26.04.2013

Date of first issue: 04.12.2011

TECHNICAL SERVICES

DEPARTMENT

Page 2 of 3

Stainless Steel electrodes

( Duplex Stainless Steel )

ER-2209 D&H Secheron, Sandvik

E 2594-16 / ER2594

SFA 5.5

Low Alloy Steel electrodes

E8018-B2/ER80S-B2 ESAB, L&T, Ador Fontech,

D&H Secheron E8018-B3/ER80S-B3

E8018-B6/ER80S-B6

E8018-B8/ER80S-B8

SFA 5.6

SpeciIication For Copper

And Copper Alloy Arc

Welding Electrodes

ECuAl- A1 ESAB, L&T, Ador Fontech,

D&H Secheron

ECuAl- A2

ECuAl- A3

ECuAl- B

SFA 5.7

SpeciIication For Copper

And Copper Alloy Bare

Welding Rods And

Electrodes

E CuNi / E CuNi-2 /

E CuNi-7

ESAB, L&T, Ador Fontech,

D&H Secheron

SFA 5.11/5.14

SpeciIication For Nickel

and Nickel Alloy Ior

SMAW & Bare Welding

Rods And Electrodes

E CuNi-2 / E NiCu-7

ESAB, L&T, Ador Fontech,

D&H Secheron

E NiCrFe2,E NiCrFe3

ER NiCr-2/ ERNiCr-3

SFA 5.13

Solid SurIacing Welding

Rods And Electrodes

(Sterilite -6)

E CoCr-A ESAB, L&T, Ador Fontech,

D&H Secheron E CoCr B

E CoCr-C

SFA 5.16

SpeciIication For Titanium

and Titanium Alloy Bare

Welding Rods And

Electrodes

ER Ti 1/ Ti2 ESAB, L&T, Ador Fontech,

D&H Secheron

SFA 5.15

Welding electrodes and

rods Ior Cast Iron

E Ni-CI

ESAB, L&T, Ador Fontech,

D&H Secheron

VISAKH REFINERY

INSPECTION ADVISORY ON APPROVED WELDING ELECTRODES TO

BE USED FOR VARIOUS WELDING JOBS OF THE REFINERY

EQUIPMENTS

INSPECTION DIVISION

Advisory no. : TSD/INSP/GEN/24

Rev. 1

Date of issue: 26.04.2013

Date of first issue: 04.12.2011

TECHNICAL SERVICES

DEPARTMENT

Page 3 of 3

Special Electrodes Magna 303 Permaweld Pvt. Ltd.

Magna 405

Magna 720

Magna 770

Magna 8N12

Magna 28 TIG

Magna 39 TIG

Note: Other reputed international brands oI electrodes may be considered Ior usage on case to

case basis. Such electrodes shall be reIerred to HPCL Inspection Ior approval prior to usage.

5.0 RESPONSIBILITIES

5.1 Executing Department (Maintenance/Minor Projects/Projects)

a) Shall ensure to usage oI welding electrodes oI approved manuIacturers only,

speciIied in the advisory Ior all types oI welding jobs in the ReIinery.

b) Shall ensure to prevent the usage oI any spurious electrodes Ior the welding jobs.

Accordingly the Executing Dept. shall advise the electrode manuIacturers to

prevent the usage oI spurious electrodes by designating the authorized dealers.

c) For usage oI welding electrodes other than the approved electrodes, the

Executing Dept. shall report to Inspection Division and obtain their approval.

Inspection Division will review the perIormance oI the new electrodes based on

their testing/history/perIormance.

6.0 OTHERS

a) Review oI perIormance oI the welding electrodes will be carried out by HPCL-Inspection

on periodical basis. In case, the quality oI the approved electrodes is not Iound satisIactory,

HPCL-Inspection reserves the right to cancel the manuIacturer Irom the approved list.

b) HPCL I nspection Division will review/approve new welding electrodes based on

testing/history/perIormance on periodical basis.

c) This Advisory will be valid till the Head Inspection Division issues the next revision as

and when required.

You might also like

- Effective Leadership Skills in The 21ST CenturyDocument67 pagesEffective Leadership Skills in The 21ST CenturySam ONi100% (1)

- Charater Letter To JudgeDocument9 pagesCharater Letter To Judgechong seng fooNo ratings yet

- Electrode IDentificationDocument3 pagesElectrode IDentificationAmit AgarwalNo ratings yet

- Cooperative by LawsDocument24 pagesCooperative by LawsMambuay G. MaruhomNo ratings yet

- SAMPLE Information On RapeDocument2 pagesSAMPLE Information On RapeMay May100% (2)

- 17.06 Planned Task ObservationsDocument1 page17.06 Planned Task Observationsgrant100% (1)

- Submerged Arc WeldingDocument21 pagesSubmerged Arc WeldingSACHIN A. MORENo ratings yet

- Contemplation of The Mind - Bhikkhu KhemavamsaDocument106 pagesContemplation of The Mind - Bhikkhu KhemavamsaGeorge PuscasuNo ratings yet

- BGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&AFrom EverandBGAS-CSWIP Welding and Coating Inspection: Certification, Process, Exam Preparation and Q&ANo ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Roadmap To Prayer Lesson 16Document18 pagesRoadmap To Prayer Lesson 16Krisztian KelemenNo ratings yet

- Fabricating Techniques: Welding Aluminum: Different But Not DifficultDocument5 pagesFabricating Techniques: Welding Aluminum: Different But Not DifficultDee Dee0% (1)

- The Marcos DynastyDocument19 pagesThe Marcos DynastyRyan AntipordaNo ratings yet

- Welding Joint Design and Welding SymbolsDocument43 pagesWelding Joint Design and Welding Symbolsnavas hassanNo ratings yet

- Selection of Welding Electrodes PDFDocument1 pageSelection of Welding Electrodes PDFAnonymous VohpMtUSNNo ratings yet

- Welding Solutions For Oil & Gas Downstream (EN)Document32 pagesWelding Solutions For Oil & Gas Downstream (EN)Kara WhiteNo ratings yet

- Selected Welding Application in Offshore IndustryDocument38 pagesSelected Welding Application in Offshore IndustryzuudeeNo ratings yet

- Advacc 2 Chapter 1 ProblemsDocument5 pagesAdvacc 2 Chapter 1 ProblemsClint-Daniel Abenoja100% (1)

- 13 Analysis of TIG Welding Process Parameters For Stainless Steel (SS202)Document5 pages13 Analysis of TIG Welding Process Parameters For Stainless Steel (SS202)IJAERS JOURNAL100% (1)

- Welding Consumables For Pipeline ConstructionDocument32 pagesWelding Consumables For Pipeline ConstructionElias KapaNo ratings yet

- Welding Electrode Classifications WallchartDocument1 pageWelding Electrode Classifications Wallchartask101100% (1)

- Welding Martensitic Stainless SteelsDocument4 pagesWelding Martensitic Stainless SteelsBabar Manzoor GhauriNo ratings yet

- Welding Terms & Definitions GuideDocument42 pagesWelding Terms & Definitions GuidepchakkrapaniNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- St. Stephen's Association V CIRDocument3 pagesSt. Stephen's Association V CIRPatricia GonzagaNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- WPQDocument3 pagesWPQmoonstar_dmeNo ratings yet

- Project Management ProcedureDocument16 pagesProject Management ProcedureKailas Anande100% (2)

- Welding Engineer Interview Questions GuideDocument7 pagesWelding Engineer Interview Questions GuideVirgil Sorcaru100% (2)

- Office Space Planning - Designing Buildings WikiDocument3 pagesOffice Space Planning - Designing Buildings WikiKailas AnandeNo ratings yet

- Corrosion Quiz AnswersDocument5 pagesCorrosion Quiz AnswersErik Alfiandy100% (1)

- Welding ElectrodeDocument6 pagesWelding ElectrodeKapil PudasainiNo ratings yet

- Tig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsFrom EverandTig and Plasma Welding: Process Techniques, Recommended Practices and ApplicationsRating: 5 out of 5 stars5/5 (1)

- WC-482 - Parts of A Weld PDFDocument1 pageWC-482 - Parts of A Weld PDFNathanLaertePiaiNo ratings yet

- What To Consider When Welding Dissimilar MaterialsDocument8 pagesWhat To Consider When Welding Dissimilar MaterialsWeldPulse100% (2)

- PTA Requests Funds for School ImprovementsDocument6 pagesPTA Requests Funds for School ImprovementsJoan DalilisNo ratings yet

- 304 SsDocument54 pages304 Ssshakir ramzanNo ratings yet

- IIW World OverrviewDocument4 pagesIIW World OverrviewAnonymous hBBam1nNo ratings yet

- Handbook - Weld DefectsDocument1 pageHandbook - Weld Defectskaveh-bahiraeeNo ratings yet

- Asset Management Council 1005 Maintenance Execution and Shutdowns Best PracticeDocument39 pagesAsset Management Council 1005 Maintenance Execution and Shutdowns Best PracticemansourNo ratings yet

- Underwater WeldingDocument16 pagesUnderwater WeldingDinesh ChahalNo ratings yet

- Metrode Dissimilar Consumable SelectorDocument7 pagesMetrode Dissimilar Consumable SelectorClaudia MmsNo ratings yet

- Welding Process and ConsumableDocument64 pagesWelding Process and Consumablenizar_ikmps100% (1)

- PDF Engineering) Esab Welding Handbook - 5 EditionDocument143 pagesPDF Engineering) Esab Welding Handbook - 5 Editionmarshall, of course100% (3)

- Class 150# Flange Dimensions: ANSI B16.5 1/16" Raised Faced - Also Mate With ANSI B16.1 125# Flat Faced FlangesDocument1 pageClass 150# Flange Dimensions: ANSI B16.5 1/16" Raised Faced - Also Mate With ANSI B16.1 125# Flat Faced Flanges║║ Joe Beca ║║No ratings yet

- Design, Fabrication and Economy of Welded Structures: International Conference Proceedings, 2008From EverandDesign, Fabrication and Economy of Welded Structures: International Conference Proceedings, 2008No ratings yet

- Welding Electrodes ExplainedDocument6 pagesWelding Electrodes ExplainedOwais SialNo ratings yet

- GMAWDocument53 pagesGMAWJithuJohn100% (1)

- Weldability of MaterialsDocument5 pagesWeldability of MaterialsclnNo ratings yet

- WeldingDocument23 pagesWeldingBilal TayyabNo ratings yet

- The Types of Welding Electrodes and Their UsesDocument8 pagesThe Types of Welding Electrodes and Their UsesTIBEBUNo ratings yet

- PreheatDocument2 pagesPreheatZoe ToNo ratings yet

- Electroslag WeldingDocument10 pagesElectroslag WeldingNazmul Ahsan100% (1)

- Gen - Importance of Welding in L & T PDFDocument30 pagesGen - Importance of Welding in L & T PDFSivaNo ratings yet

- Oxy Gas Cutting TechniquesDocument15 pagesOxy Gas Cutting Techniqueskhwanta-bta100% (2)

- Highlights On ASME Essential VariablesDocument8 pagesHighlights On ASME Essential VariableschowhkNo ratings yet

- Gtaw WeldingDocument37 pagesGtaw WeldingSadhasivam VeluNo ratings yet

- Difference between weldolet and sockoletDocument3 pagesDifference between weldolet and sockoletWaqas Waqas100% (3)

- Submerged Arc Welding: by L D PoyyaraDocument29 pagesSubmerged Arc Welding: by L D PoyyararajeshNo ratings yet

- Dissimilar Metal Weldability Concepts Alber SadekDocument45 pagesDissimilar Metal Weldability Concepts Alber SadekMohammad AliNo ratings yet

- MIG-MAG Welding Course OverviewDocument10 pagesMIG-MAG Welding Course OverviewGanesanGovindarjNo ratings yet

- ThesisDocument48 pagesThesismuhammad amir100% (1)

- Dissimilar Stainless Steel Welding ConsumableDocument1 pageDissimilar Stainless Steel Welding ConsumablecraccerNo ratings yet

- Types of Flanges-Definition of FlangesDocument4 pagesTypes of Flanges-Definition of FlangesindikumaNo ratings yet

- ASTM Welding Tips A410 To A643Document20 pagesASTM Welding Tips A410 To A643MARIO HUAMANNo ratings yet

- Welding Metallurgy Part 2Document28 pagesWelding Metallurgy Part 2Anonymous UM7Bt6bNo ratings yet

- Submerged Arc Welding Fluxes BasicityDocument3 pagesSubmerged Arc Welding Fluxes Basicitylram70No ratings yet

- Electrogas WeldingDocument11 pagesElectrogas WeldingDarryl007100% (1)

- Sulzer Chemtech Annual Performance AppraisalDocument6 pagesSulzer Chemtech Annual Performance AppraisalKailas AnandeNo ratings yet

- L&T JobDocument3 pagesL&T JobKailas AnandeNo ratings yet

- Cost EstimatorDocument2 pagesCost EstimatorKailas AnandeNo ratings yet

- Cost Overrun - WikipediaDocument5 pagesCost Overrun - WikipediaKailas AnandeNo ratings yet

- Benefit Shortfall - WikipediaDocument1 pageBenefit Shortfall - WikipediaKailas AnandeNo ratings yet

- L&T Job1Document1 pageL&T Job1Kailas AnandeNo ratings yet

- AmulscoopingpalourDocument17 pagesAmulscoopingpaloursaggy1188No ratings yet

- Estimation - WikipediaDocument3 pagesEstimation - WikipediaKailas AnandeNo ratings yet

- Site Plan - Designing Buildings WikiDocument3 pagesSite Plan - Designing Buildings WikiKailas AnandeNo ratings yet

- Project Planning - WikipediaDocument2 pagesProject Planning - WikipediaKailas AnandeNo ratings yet

- Pre-Construction Information - Designing Buildings WikiDocument4 pagesPre-Construction Information - Designing Buildings WikiKailas AnandeNo ratings yet

- Scaffolding - Designing Buildings WikiDocument3 pagesScaffolding - Designing Buildings WikiKailas AnandeNo ratings yet

- Man Hour WikipediaDocument3 pagesMan Hour WikipediaKailas AnandeNo ratings yet

- Pre-Construction Information - Designing Buildings WikiDocument4 pagesPre-Construction Information - Designing Buildings WikiKailas AnandeNo ratings yet

- Granolithic Flooring - Durable Concrete Floor FinishDocument2 pagesGranolithic Flooring - Durable Concrete Floor FinishKailas AnandeNo ratings yet

- Piles DesignDocument22 pagesPiles DesignKailas AnandeNo ratings yet

- Materials On Site - Designing Buildings WikiDocument2 pagesMaterials On Site - Designing Buildings WikiKailas AnandeNo ratings yet

- APP20140001 - 014 0001 Method StatementsDocument10 pagesAPP20140001 - 014 0001 Method StatementsSeifeldinNo ratings yet

- Lighting of Construction Sites - Designing Buildings WikiDocument3 pagesLighting of Construction Sites - Designing Buildings WikiKailas AnandeNo ratings yet

- Formwork - Designing Buildings WikiDocument3 pagesFormwork - Designing Buildings WikiKailas AnandeNo ratings yet

- Temporary FacDocument12 pagesTemporary FacKailas AnandeNo ratings yet

- Concrete Work StementDocument9 pagesConcrete Work StementKailas AnandeNo ratings yet

- Formwork - Designing Buildings WikiDocument3 pagesFormwork - Designing Buildings WikiKailas AnandeNo ratings yet

- New - Estimator - Mech ConstDocument1 pageNew - Estimator - Mech ConstKailas AnandeNo ratings yet

- Temp Control PlanDocument12 pagesTemp Control PlanKailas AnandeNo ratings yet

- Temporary FacDocument12 pagesTemporary FacKailas AnandeNo ratings yet

- Facilities Siting PolicyDocument4 pagesFacilities Siting PolicyKailas AnandeNo ratings yet

- Application For Treaty Purposes: (Relief From Philippine Income Tax On Dividends)Document2 pagesApplication For Treaty Purposes: (Relief From Philippine Income Tax On Dividends)Nepean Philippines IncNo ratings yet

- Silent Night (2015) ProgramDocument88 pagesSilent Night (2015) ProgramLyric Opera of Kansas CityNo ratings yet

- Lokesh ResumeDocument2 pagesLokesh ResumeRaj AcharyaNo ratings yet

- Marketing MetricsDocument29 pagesMarketing Metricscameron.king1202No ratings yet

- Tourism and Hospitality LawDocument4 pagesTourism and Hospitality LawSarah Mae AlcazarenNo ratings yet

- Project On-Law of Torts Topic - Judicial and Quasi Judicial AuthoritiesDocument9 pagesProject On-Law of Torts Topic - Judicial and Quasi Judicial AuthoritiesSoumya Shefali ChandrakarNo ratings yet

- Classical Dances of India Everything You Need To Know AboutDocument18 pagesClassical Dances of India Everything You Need To Know AboutmohammadjakeerpashaNo ratings yet

- Ethics in Social Science ResearchDocument33 pagesEthics in Social Science ResearchRV DuenasNo ratings yet

- Protected Monument ListDocument65 pagesProtected Monument ListJose PerezNo ratings yet

- Financial Management Introduction Lecture#1Document12 pagesFinancial Management Introduction Lecture#1Rameez Ramzan AliNo ratings yet

- InvoiceDocument1 pageInvoiceDp PandeyNo ratings yet

- 1Document3 pages1Ashok KumarNo ratings yet

- 2005-06 Annual ReportDocument100 pages2005-06 Annual ReportSiddharth AnandNo ratings yet

- InterContinental Global Etiquette Compendium FO backTVDocument12 pagesInterContinental Global Etiquette Compendium FO backTVGian SyailendraNo ratings yet

- 19 Preposition of PersonalityDocument47 pages19 Preposition of Personalityshoaibmirza1No ratings yet

- The Impact of E-Commerce in BangladeshDocument12 pagesThe Impact of E-Commerce in BangladeshMd Ruhul AminNo ratings yet

- Annotated Bibliography Wet Nurse SlaveryDocument7 pagesAnnotated Bibliography Wet Nurse SlaveryNicholas MusauNo ratings yet

- PATHFINDER On Aquaculture and FisheriesDocument114 pagesPATHFINDER On Aquaculture and FisheriesLIRMD-Information Service DevelopmentNo ratings yet

- Project Muse 205457Document30 pagesProject Muse 205457Andrew KendallNo ratings yet